tow DODGE DURANGO SRT 2018 Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2018, Model line: DURANGO SRT, Model: DODGE DURANGO SRT 2018Pages: 568, PDF Size: 6.54 MB

Page 369 of 568

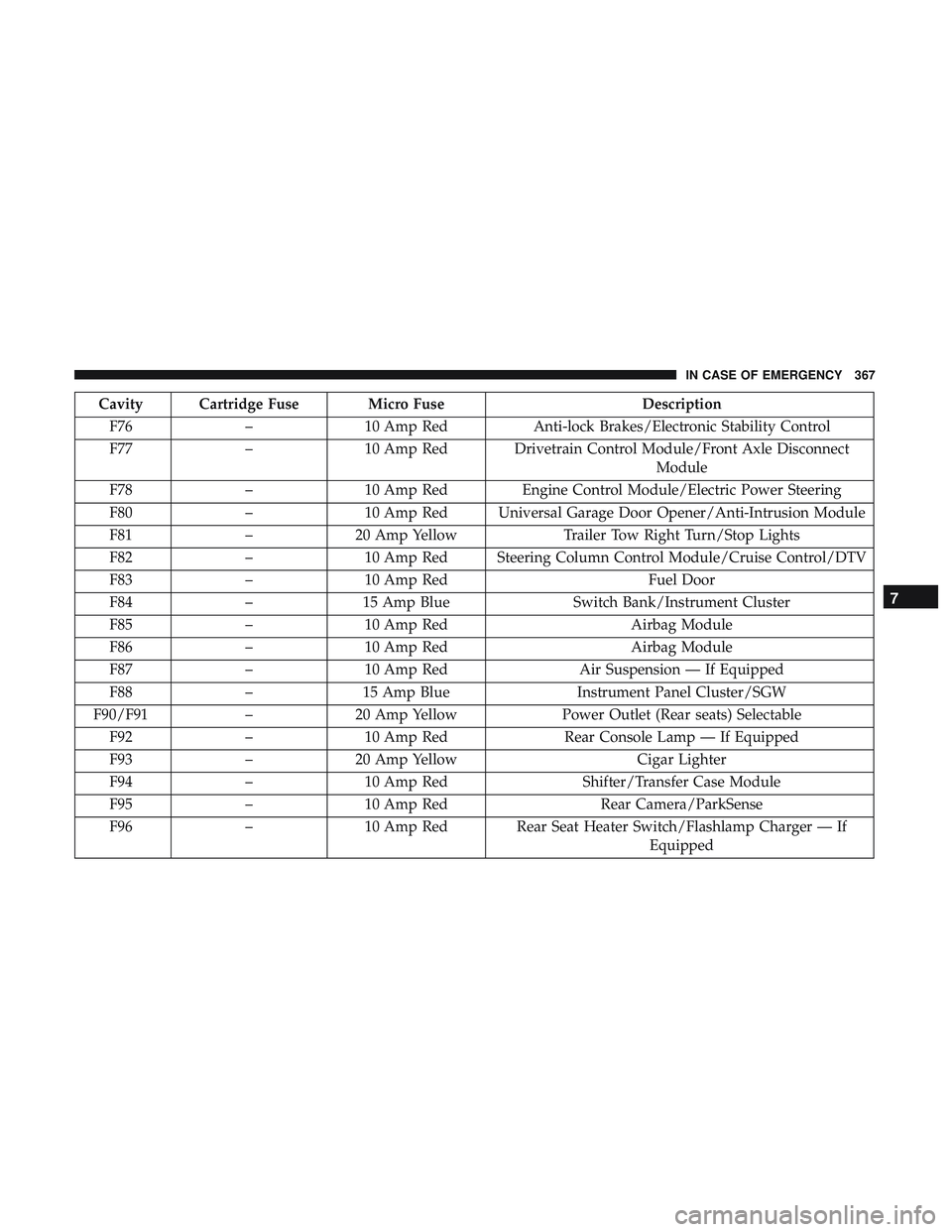

Cavity Cartridge Fuse Micro FuseDescription

F76 –10 Amp Red Anti-lock Brakes/Electronic Stability Control

F77 –10 Amp Red Drivetrain Control Module/Front Axle Disconnect

Module

F78 –10 Amp Red Engine Control Module/Electric Power Steering

F80 –10 Amp Red Universal Garage Door Opener/Anti-Intrusion Module

F81 –20 Amp Yellow Trailer Tow Right Turn/Stop Lights

F82 –10 Amp Red Steering Column Control Module/Cruise Control/DTV

F83 –10 Amp Red Fuel Door

F84 –15 Amp Blue Switch Bank/Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp Red Air Suspension — If Equipped

F88 –15 Amp Blue Instrument Panel Cluster/SGW

F90/F91 –20 Amp Yellow Power Outlet (Rear seats) Selectable

F92 –10 Amp Red Rear Console Lamp — If Equipped

F93 –20 Amp Yellow Cigar Lighter

F94 –10 Amp Red Shifter/Transfer Case Module

F95 –10 Amp Red Rear Camera/ParkSense

F96 –10 Amp Red Rear Seat Heater Switch/Flashlamp Charger — If

Equipped

7

IN CASE OF EMERGENCY 367

Page 372 of 568

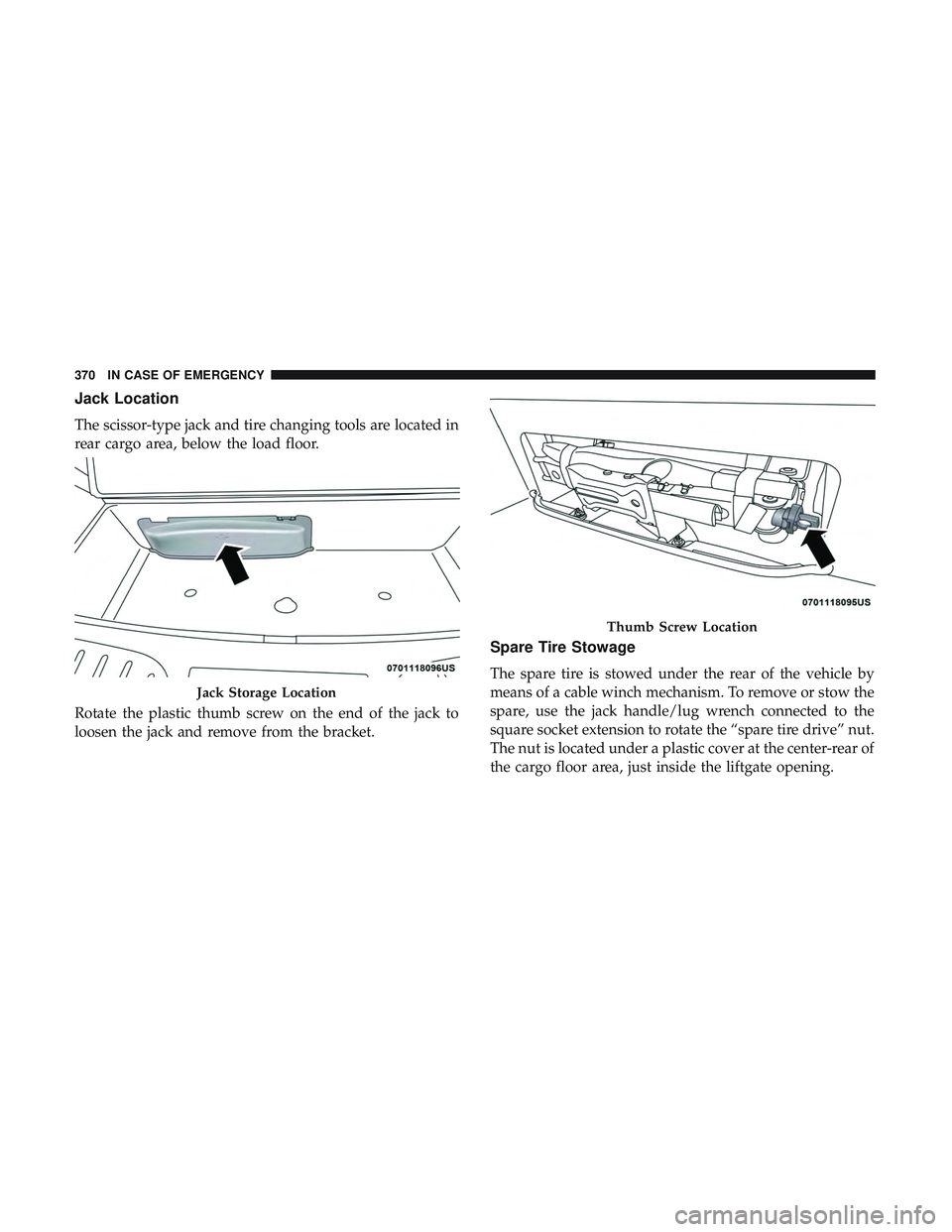

Jack Location

The scissor-type jack and tire changing tools are located in

rear cargo area, below the load floor.

Rotate the plastic thumb screw on the end of the jack to

loosen the jack and remove from the bracket.

Spare Tire Stowage

The spare tire is stowed under the rear of the vehicle by

means of a cable winch mechanism. To remove or stow the

spare, use the jack handle/lug wrench connected to the

square socket extension to rotate the “spare tire drive” nut.

The nut is located under a plastic cover at the center-rear of

the cargo floor area, just inside the liftgate opening.

Jack Storage Location

Thumb Screw Location

370 IN CASE OF EMERGENCY

Page 374 of 568

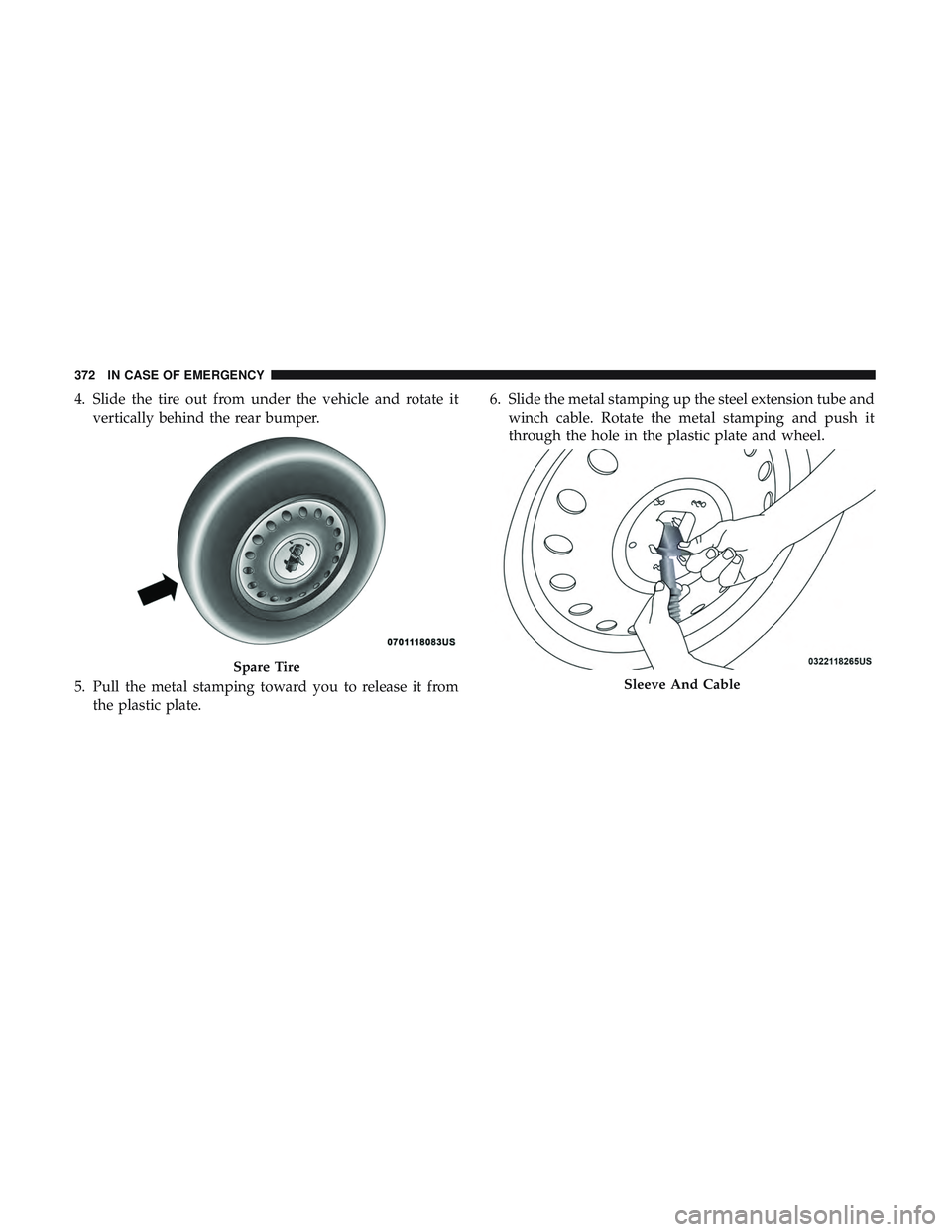

4. Slide the tire out from under the vehicle and rotate itvertically behind the rear bumper.

5. Pull the metal stamping toward you to release it from the plastic plate. 6. Slide the metal stamping up the steel extension tube and

winch cable. Rotate the metal stamping and push it

through the hole in the plastic plate and wheel.

Spare Tire

Sleeve And Cable

372 IN CASE OF EMERGENCY

Page 376 of 568

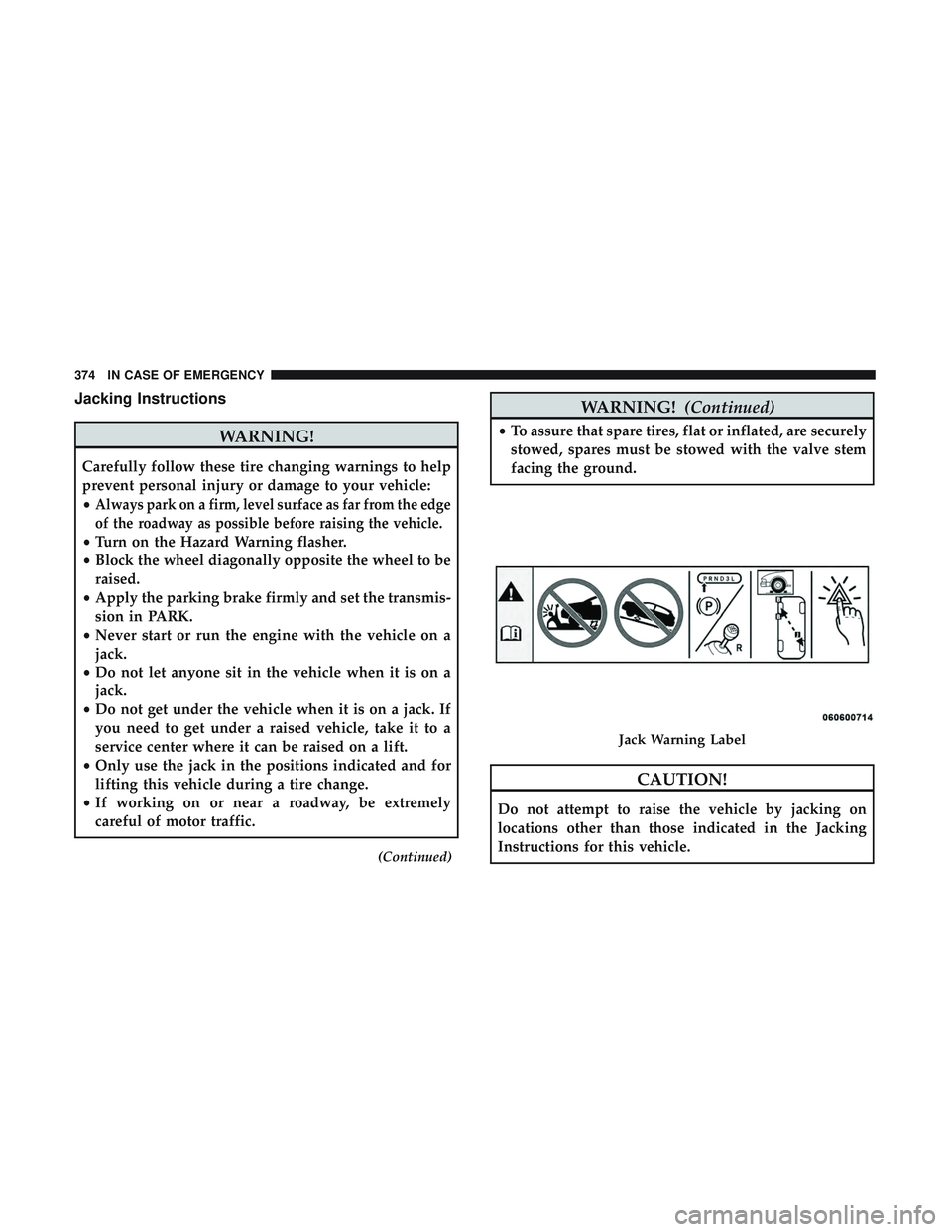

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

•

Always park on a firm, level surface as far from the edge

of the roadway as possible before raising the vehicle.

•Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be

raised.

• Apply the parking brake firmly and set the transmis-

sion in PARK.

• Never start or run the engine with the vehicle on a

jack.

• Do not let anyone sit in the vehicle when it is on a

jack.

• Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

• If working on or near a roadway, be extremely

careful of motor traffic.

(Continued)

WARNING! (Continued)

•To assure that spare tires, flat or inflated, are securely

stowed, spares must be stowed with the valve stem

facing the ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

Jack Warning Label

374 IN CASE OF EMERGENCY

Page 378 of 568

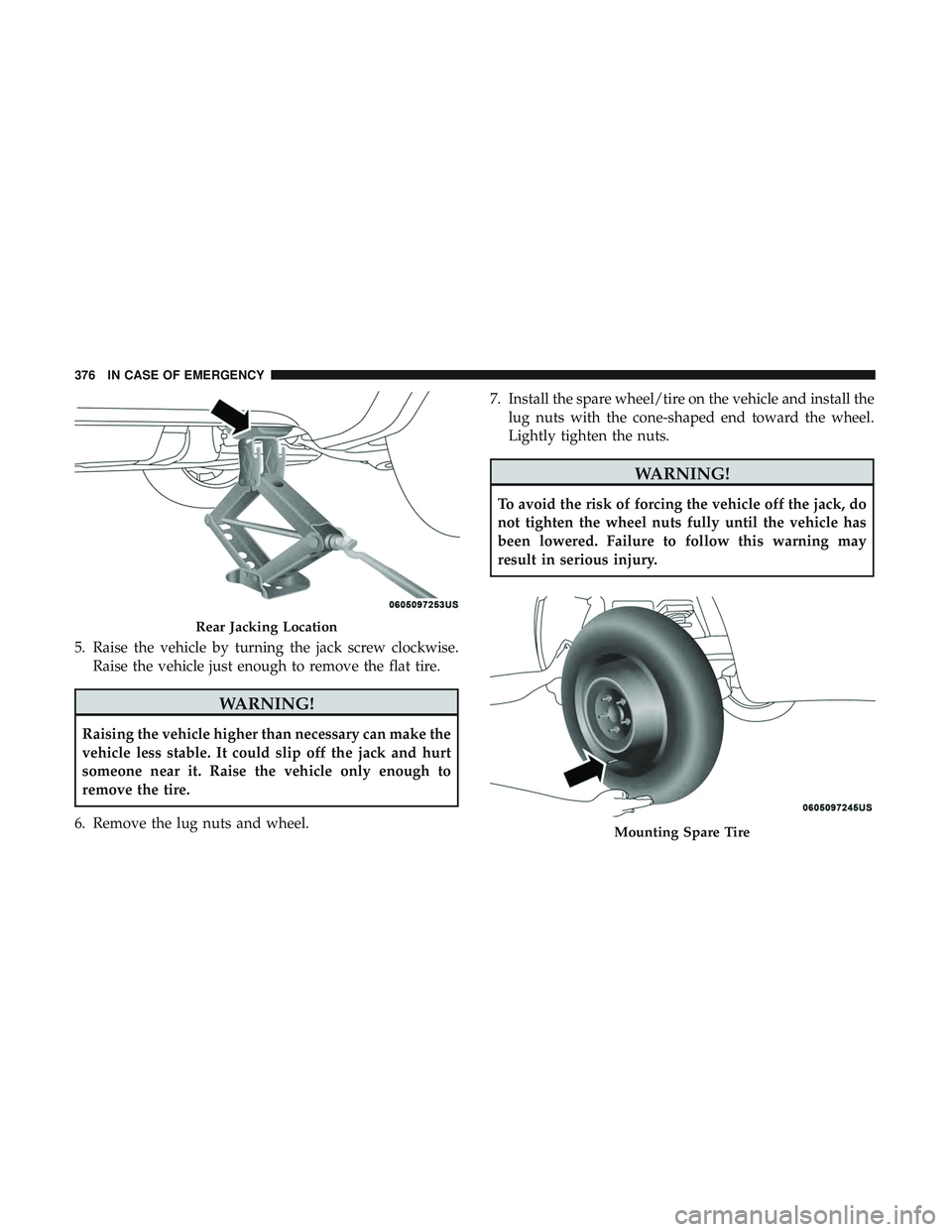

5. Raise the vehicle by turning the jack screw clockwise.Raise the vehicle just enough to remove the flat tire.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

6. Remove the lug nuts and wheel. 7. Install the spare wheel/tire on the vehicle and install the

lug nuts with the cone-shaped end toward the wheel.

Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

Rear Jacking Location

Mounting Spare Tire

376 IN CASE OF EMERGENCY

Page 381 of 568

13. Lower the jack to the fully closed position. Return thetools to the proper positions in the tool bag. Fold the

flap on the tool bag under the tools and roll the tools in

the bag underneath the others. Use the hook and loop

fasteners to secure the tool bag to the jack with the lug

wrench on the forward side of the jack. Expand the jack

on the bracket by turning the thumb screw clockwise

until it is tight to prevent rattles.

14. Reinstall the plastic plug into the floor of the cargo area. Roll up and store the Jack, Tool Kit and Tire

Changing Instructions. Reinstall the cover for the jack

in the rear storage bin.

15. Have the aluminum road wheel and tire repaired as soon as possible and properly secure the spare tire, jack

and tool kit.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop, could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped endof the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Refer to “Torque Specifications” in “Technical Specifica- tions” for proper lug nut torque.

5. After 25 miles (40 km), check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

7

IN CASE OF EMERGENCY 379

Page 386 of 568

CAUTION!

Driving with a hot cooling system could damage your

vehicle. If the temperature gauge reads HOT (H), pull

over and stop the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops back

into the normal range. If the pointer remains on HOT

(H), and you hear continuous chimes, turn the engine

off immediately and call for service.

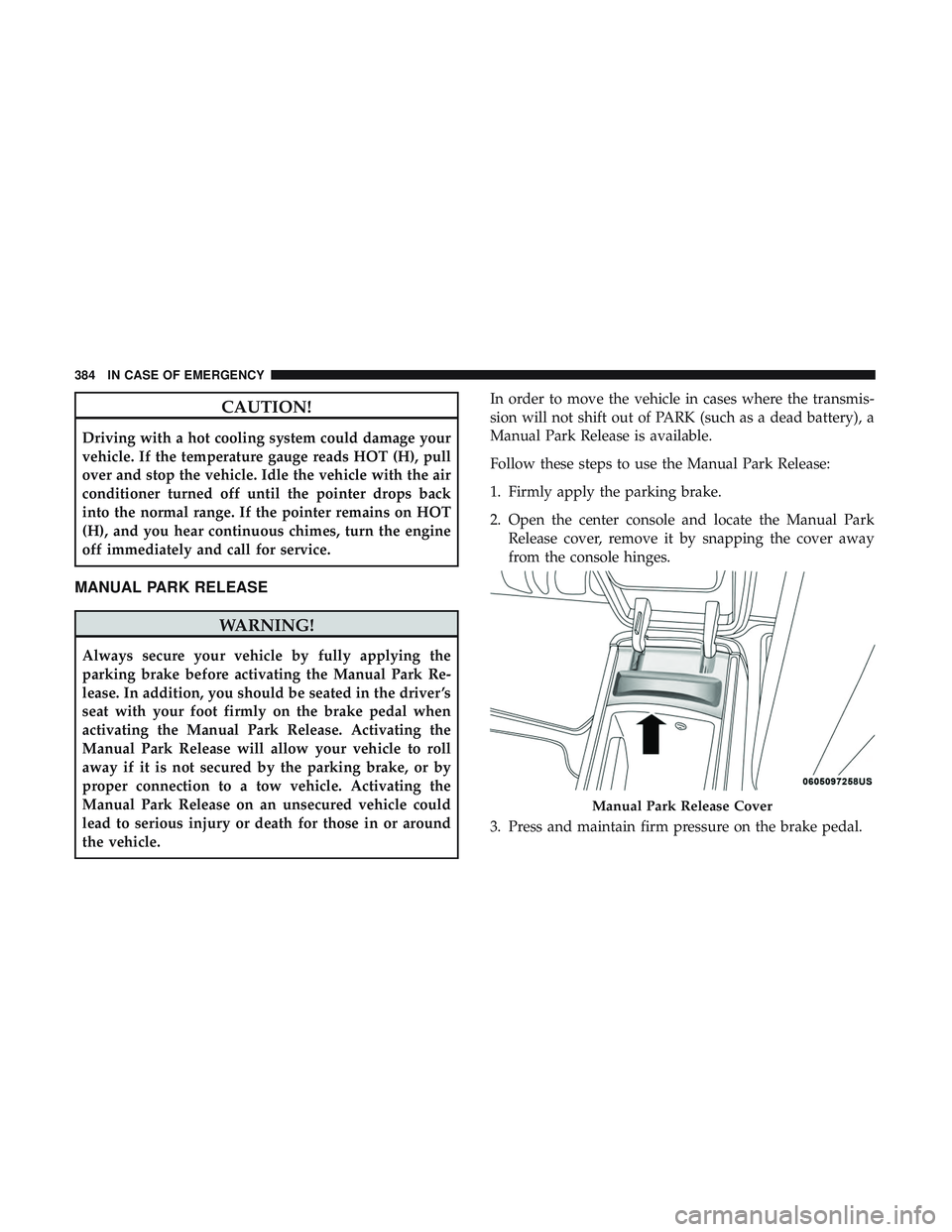

MANUAL PARK RELEASE

WARNING!

Always secure your vehicle by fully applying the

parking brake before activating the Manual Park Re-

lease. In addition, you should be seated in the driver ’s

seat with your foot firmly on the brake pedal when

activating the Manual Park Release. Activating the

Manual Park Release will allow your vehicle to roll

away if it is not secured by the parking brake, or by

proper connection to a tow vehicle. Activating the

Manual Park Release on an unsecured vehicle could

lead to serious injury or death for those in or around

the vehicle.In order to move the vehicle in cases where the transmis-

sion will not shift out of PARK (such as a dead battery), a

Manual Park Release is available.

Follow these steps to use the Manual Park Release:

1. Firmly apply the parking brake.

2. Open the center console and locate the Manual Park

Release cover, remove it by snapping the cover away

from the console hinges.

3. Press and maintain firm pressure on the brake pedal.

Manual Park Release Cover

384 IN CASE OF EMERGENCY

Page 387 of 568

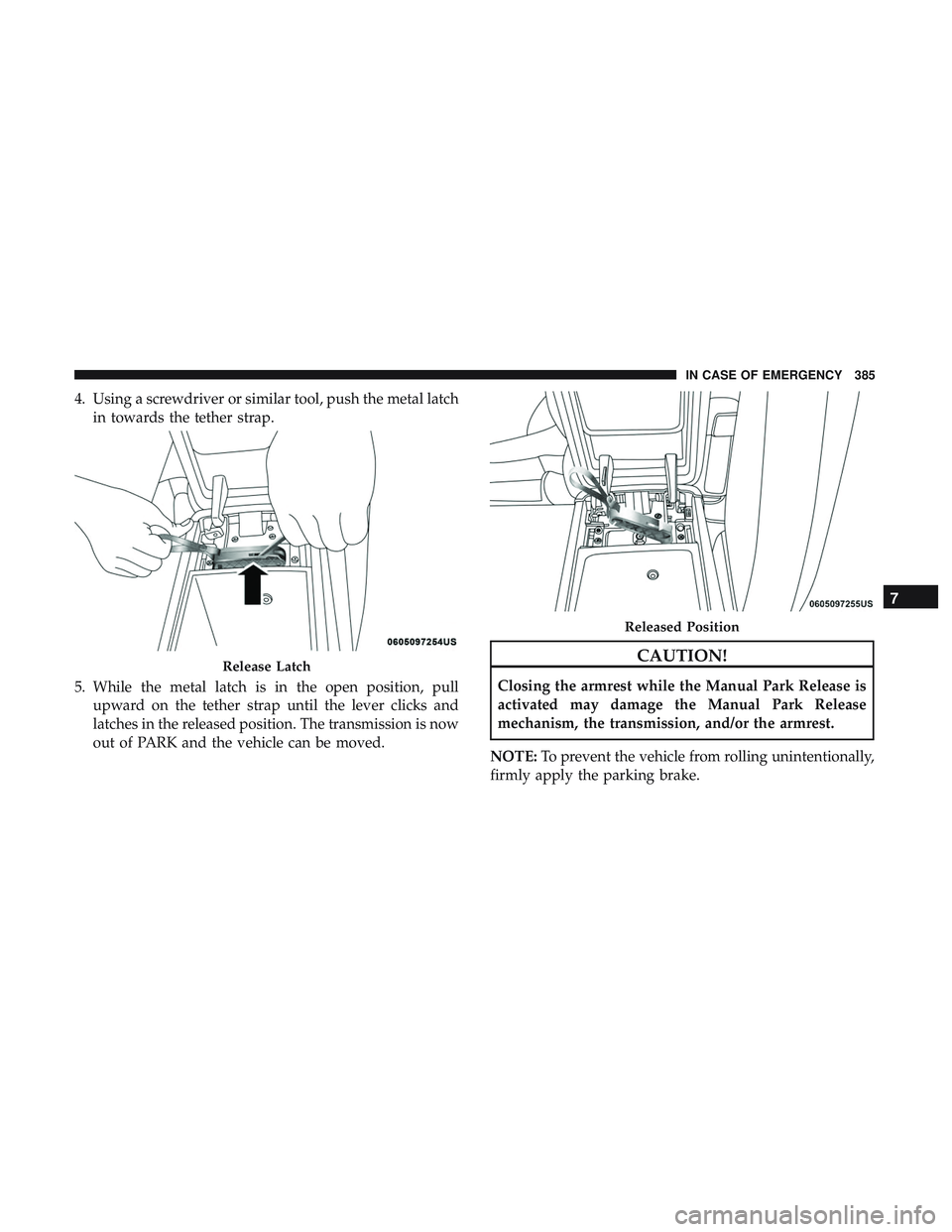

4. Using a screwdriver or similar tool, push the metal latchin towards the tether strap.

5. While the metal latch is in the open position, pull upward on the tether strap until the lever clicks and

latches in the released position. The transmission is now

out of PARK and the vehicle can be moved.

CAUTION!

Closing the armrest while the Manual Park Release is

activated may damage the Manual Park Release

mechanism, the transmission, and/or the armrest.

NOTE: To prevent the vehicle from rolling unintentionally,

firmly apply the parking brake.

Release Latch

Released Position

7

IN CASE OF EMERGENCY 385

Page 388 of 568

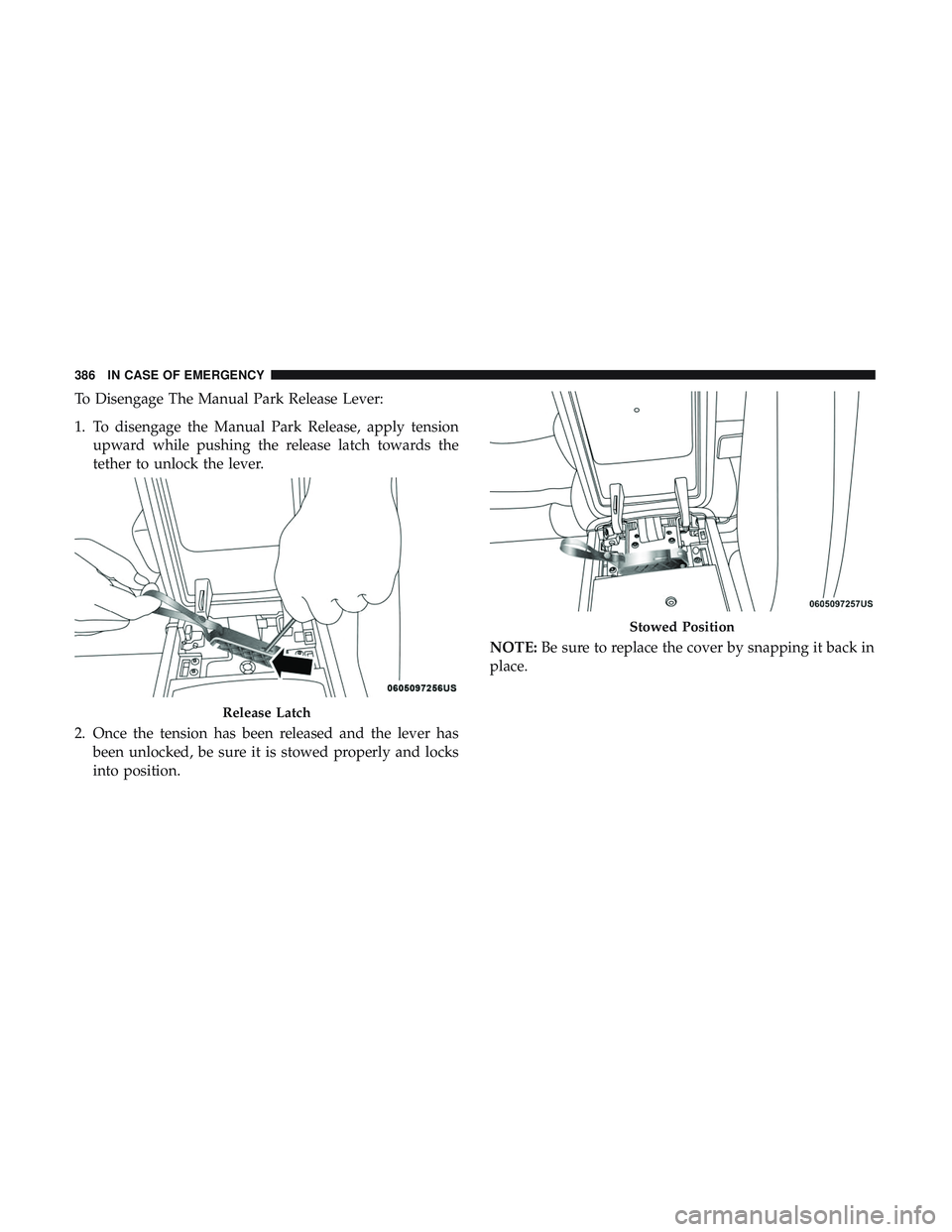

To Disengage The Manual Park Release Lever:

1. To disengage the Manual Park Release, apply tensionupward while pushing the release latch towards the

tether to unlock the lever.

2. Once the tension has been released and the lever has been unlocked, be sure it is stowed properly and locks

into position. NOTE:

Be sure to replace the cover by snapping it back in

place.

Release Latch

Stowed Position

386 IN CASE OF EMERGENCY

Page 390 of 568

CAUTION!(Continued)

•Revving the engine or spinning the wheels too fast

may lead to transmission overheating and failure. It

can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmis-

sion shifting occurring).

TOWING A DISABLED VEHICLE

The manufacturer requires towing your vehicle with all

four wheels OFFthe ground using a flatbed.

If the key fob is unavailable, or the vehicle’s battery is

discharged, refer to “Manual Park Release” in this section

for instructions on shifting the transmission out of PARK

for loading onto a flatbed truck.

CAUTION!

• Towing this vehicle using any other method can

cause severe transmission and/or transfer case dam-

age.

• Damage from improper towing is not covered under

the New Vehicle Limited Warranty.

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS)

This vehicle is equipped with an Enhanced Accident

Response System.

Please refer to “Occupant Restraint Systems” in “Safety”

for further information on the Enhanced Accident Re-

sponse System (EARS) function.

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an Event Data Recorder

(EDR). The main purpose of an EDR is to record data that

will assist in understanding how a vehicle’s systems per-

formed under certain crash or near crash-like situations,

such as an air bag deployment or hitting a road obstacle.

Please refer to “Occupant Restraint Systems” in “Safety”

for further information on the Event Data Recorder (EDR).

388 IN CASE OF EMERGENCY