tire pressure DODGE GRAND CARAVAN 2015 5.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2015, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2015 5.GPages: 703, PDF Size: 19.83 MB

Page 568 of 703

from the vehicle or tire and wheel components. Once

the sealant dries, it can easily be peeled off and

properly discarded.

•For optimum performance, make sure the valve stem

on the wheel is free of debris before connecting the Tire

Service Kit.

•You can use the Tire Service Kit air pump to inflate

bicycle tires. The kit also comes with two needles,

located in the Accessory Storage Compartment (on the

bottom of the air pump) for inflating sport balls, rafts,

or similar inflatable items. However, use only the Air

Pump Hose (7) and make sure the Mode Select Knob

(5) is in the Air Mode when inflating such items to

avoid injecting sealant into them. The Tire Service Kit

Sealant is only intended to seal punctures less than¼”

(6 mm) diameter in the tread of your vehicle.

•Do not lift or carry the Tire Service Kit by the hoses.

WARNING!

•Do not attempt to seal a tire on the side of the

vehicle closest to traffic. Pull far enough off the

road to avoid the danger of being hit when using

the Tire Service Kit.

•Do not use Tire Service Kit or drive the vehicle

under the following circumstances:

– If the puncture in the tire tread is approximately

1/4” (6 mm) or larger.

– If the tire has any sidewall damage.

– If the tire has any damage from driving with

extremely low tire pressure.

– If the tire has any damage from driving on a flat

tire.

– If the wheel has any damage.

– If you are unsure of the condition of the tire or

the wheel.

(Continued)

566 WHAT TO DO IN EMERGENCIES

Page 571 of 703

NOTE:Sealant may leak out through the puncture in the

tire.

If the sealant (white fluid) does not flow within0–10

seconds through the Sealant Hose (6):

1. Press the Power Button (4) to turn Off the Tire Service

Kit. Disconnect the Sealant Hose (6) from the valve

stem. Make sure the valve stem is free of debris.

Reconnect the Sealant Hose (6) to the valve stem.

Check that the Mode Select Knob (5) is in the Sealant

Mode position and not Air Mode. Press the Power

Button (4) to turn On the Tire Service Kit.

2. Connect the Power Plug (8) to a different 12 Volt

power outlet in your vehicle or another vehicle, if

available. Make sure the engine is running before

turning ON the Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous

use. Call for assistance.

NOTE:If the Mode Select Knob (5) is on Air Mode and

the pump is operating, air will dispense from the Air

Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the

Sealant Hose (6):

1. Continue to operate the pump until sealant is no

longer flowing through hose (typically takes 30 - 70

seconds). As the sealant flows through the Sealant

Hose (6), the Pressure Gauge (3) can read as high as 70

psi (4.8 Bar). The Pressure Gauge (3) will decrease

quickly from approximately 70 psi (4.8 Bar) to the

actual tire pressure when the Sealant Bottle (1) is

empty.

2. The pump will start to inject air into the tire immedi-

ately after the Sealant Bottle (1) is empty. Continue to

operate the pump and inflate the tire to the pressure

indicated on the tire pressure label on the driver-side

6

WHAT TO DO IN EMERGENCIES 569

Page 572 of 703

latch pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (3).

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

•The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

NOTE:If the tire becomes over-inflated, press the Defla-

tion Button to reduce the tire pressure to the recom-

mended inflation pressure before continuing.

If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 Bar) pressure within 15 minutes:

1. Press the Power Button (4) to turn off the Tire Service

Kit.

2. Remove the Speed Limit sticker from the top of the

Sealant Bottle (1) and place the sticker on the instru-

ment panel.

3. Immediately disconnect the Sealant Hose (6) from the

valve stem, reinstall the cap on the fitting at the end of

the hose, and place the Tire Service Kit in the vehicle

storage location. Quickly proceed to (D) “Drive Ve-

hicle.”

CAUTION!

•The metal end fitting from Power Plug (8) may get

hot after use, so it should be handled carefully.

•Failure to reinstall the cap on the fitting at the end

of the Sealant Hose (6) can result in sealant con-

tacting your skin, clothing, and the vehicle’s inte-

rior. It can also result in sealant contacting internal

Tire Service Kit components which may cause

permanent damage to the kit.

570 WHAT TO DO IN EMERGENCIES

Page 573 of 703

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the tire,

drive the vehicle 5 miles (8 km) or 10 minutes to ensure

distribution of the Tire Service Kit Sealant within the tire.

Do not exceed 55 mph (90 km/h).

WARNING!

Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced after

using Tire Service Kit. Do not exceed 55 mph (90

km/h) until the tire is repaired or replaced. Failure to

follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others

around you.

(E) After Driving:

Pull over to a safe location. Refer to “Whenever You Stop

to Use Tire Service Kit” before continuing.

1. Push in the Mode Select Knob (5) and turn to the Air

Mode position.

2. Uncoil the power plug and insert the plug into the

vehicle’s 12 Volt power outlet.

3. Uncoil the Air Pump Hose (7) (black in color) and

screw the fitting at the end of hose (7) onto the valve

stem.

4. Check the pressure in the tire by reading the Pressure

Gauge (3).

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

6

WHAT TO DO IN EMERGENCIES 571

Page 574 of 703

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Press the Power Button (4) to turn on Tire Service Kit

and inflate the tire to the pressure indicated on the tire

and loading information label on the driver-side door

opening.

NOTE:If the tire becomes over-inflated, press the Defla-

tion Button to reduce the tire pressure to the recom-

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem,

reinstall the cap on the valve stem and unplug from 12

Volt outlet.

3. Place the Tire Service Kit in its proper storage area in

the vehicle.

4. Have the tire inspected and repaired or replaced at the

earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the instrument

panel after the tire has been repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (6)

assembly at your authorized dealer as soon as pos-

sible. Refer to (F) “Sealant Bottle and Hose Replace-

ment”.

NOTE:When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the

recessed area under the sealant bottle.

3. Press the Sealant Bottle release button. The Sealant

Bottle (1) will pop up. Remove the bottle and dispose

of it accordingly.

572 WHAT TO DO IN EMERGENCIES

Page 592 of 703

NOTE:Refer to the “Spare Tire Tools” section for in-

structions on assembling the T-handle.

12. Stow the jack, jack handle and winch handle tools

back in the stowage compartment.

13. Check the compact spare tire pressure as soon as

possible. Correct the tire pressure, as required.

Securing The Compact Spare Tire

1. Assemble the winch handle extensions to form a

T-handle and fit the winch T-handle over the drive

nut. Rotate the nut to the left until the winch mecha-

nism stops turning freely. This will allow enough slack

in the cable to allow you to pull the wheel spacer out

from under the vehicle.

WARNING!

A loose compact spare tire/cover assembly, thrown

forward in a collision or hard stop could endanger

the occupants of the vehicle. Always stow the com-

pact spare tire with the cover assembly in the place

provided.

CAUTION!

The winch mechanism is designed for use with the

winch T-handle only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

2. Assemble the winch handle extensions to form the

spare tire hook, and pull the wheel spacer from under

the vehicle.

590 WHAT TO DO IN EMERGENCIES

Page 626 of 703

with water as directed on the container, aids cleaning

action, reduces the freezing point to avoid line clogging,

and is not harmful to paint or trim.

Cooling System

WARNING!

•When working near the radiator cooling fan,

disconnect the fan motor lead or turn the ignition

switch to the OFF position. The fan is temperature

controlled and can start at anytime the ignition

switch is in the ON position.

•You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If

you see or hear steam coming from under the hood,

do not open the hood until the radiator has had

time to cool. Never try to open a cooling system

pressure cap when the radiator is hot.

Coolant Checks

Check the engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If the engine coolant (antifreeze) is dirty, the

system should be drained, flushed, and refilled with

fresh OAT coolant (conforming to MS-12106) only by an

authorized dealer. Check the front of the A/C condenser

for any accumulation of bugs, leaves, etc. If dirty, clean by

gently spraying water from a garden hose vertically

down the face of the condenser.

Check the coolant recovery bottle tubing for brittle rub-

ber, cracking, tears, cuts and tightness of the connection

at the bottle and radiator. Inspect the entire system for

leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

624 MAINTAINING YOUR VEHICLE

Page 649 of 703

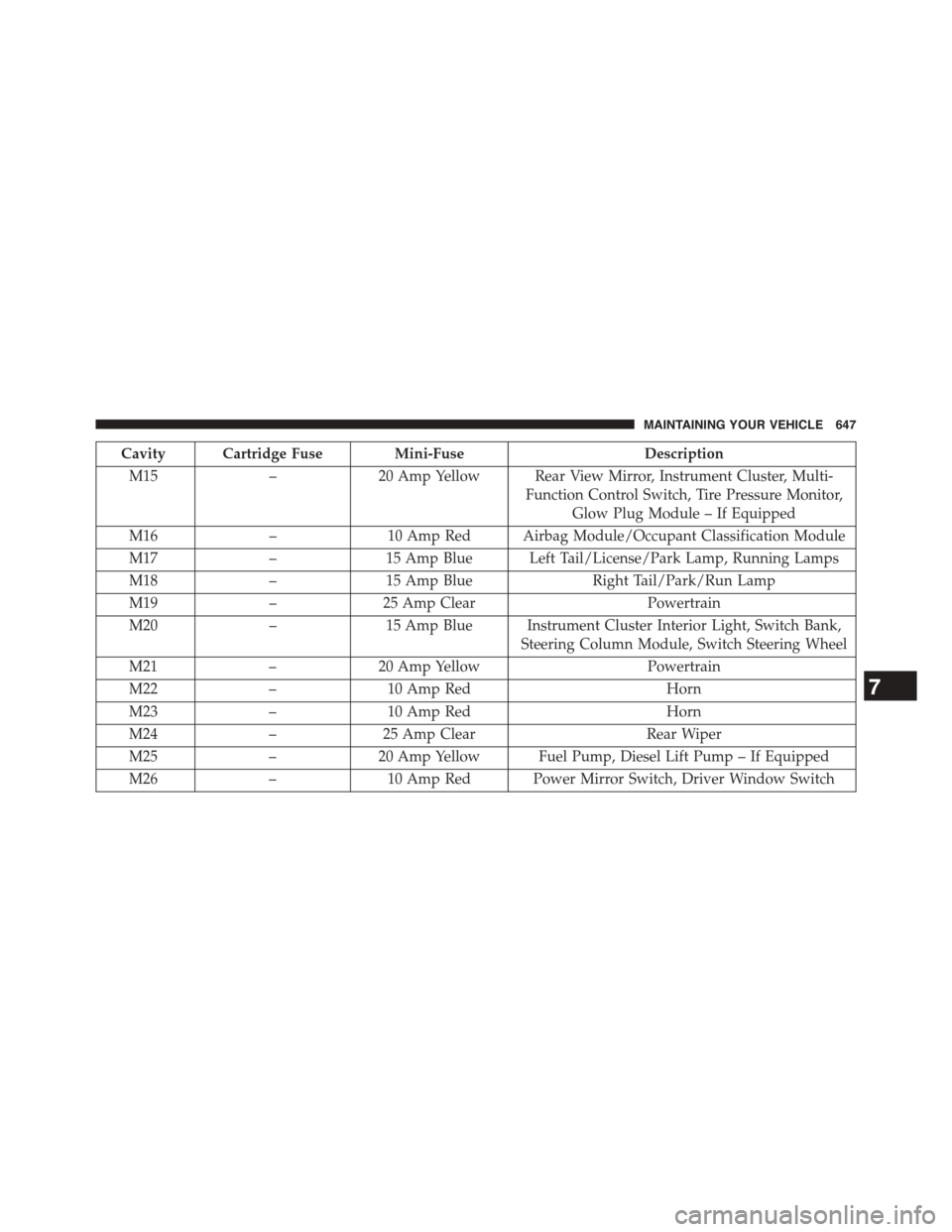

Cavity Cartridge Fuse Mini-FuseDescription

M15–20 Amp Yellow Rear View Mirror, Instrument Cluster, Multi-

Function Control Switch, Tire Pressure Monitor,

Glow Plug Module – If Equipped

M16–10 Amp Red Airbag Module/Occupant Classification Module

M17–15 Amp Blue Left Tail/License/Park Lamp, Running Lamps

M18–15 Amp BlueRight Tail/Park/Run Lamp

M19–25 Amp ClearPowertrain

M20–15 Amp Blue Instrument Cluster Interior Light, Switch Bank,

Steering Column Module, Switch Steering Wheel

M21–20 Amp YellowPowertrain

M22–10 Amp RedHorn

M23–10 Amp RedHorn

M24–25 Amp ClearRear Wiper

M25–20 Amp Yellow Fuel Pump, Diesel Lift Pump – If Equipped

M26–10 Amp Red Power Mirror Switch, Driver Window Switch

7

MAINTAINING YOUR VEHICLE 647

Page 665 of 703

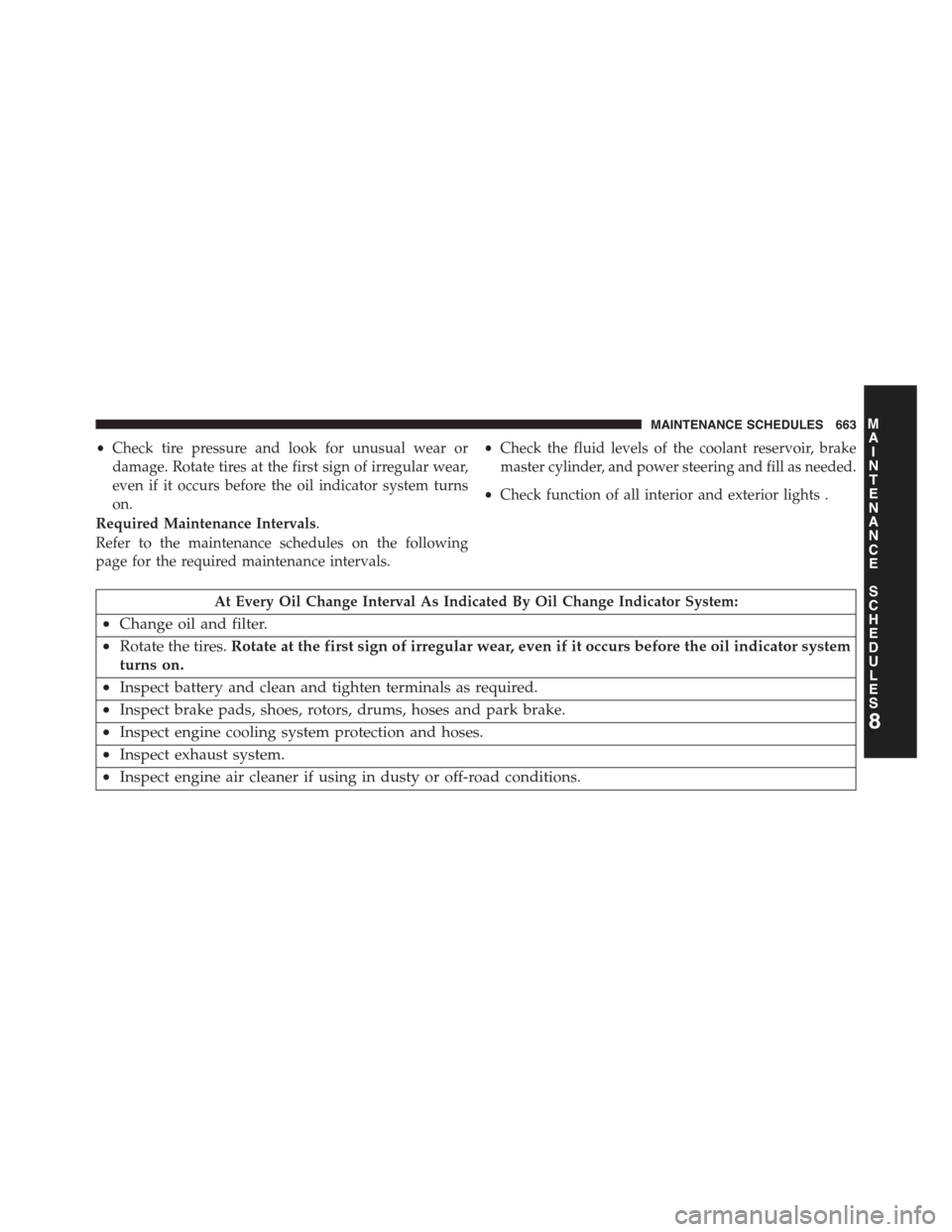

•Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before the oil indicator system turns

on.

•Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering and fill as needed.

•Check function of all interior and exterior lights .

Required Maintenance Intervals.

Refer to the maintenance schedules on the following

page for the required maintenance intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

•Change oil and filter.

•Rotate the tires.Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system

turns on.

•Inspect battery and clean and tighten terminals as required.

•Inspect brake pads, shoes, rotors, drums, hoses and park brake.

•Inspect engine cooling system protection and hoses.

•Inspect exhaust system.

•Inspect engine air cleaner if using in dusty or off-road conditions.

8

MAINTENANCE

SCHEDULES

MAINTENANCE SCHEDULES 663

Page 682 of 703

About Your Brakes........................482

Adding Engine Coolant (Antifreeze)............626

Adding Fuel.............................540

Adding Washer Fluid......................623

Additives, Fuel...........................534

Air bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Air Bag

Advance Front Air Bag....................81

Air Bag Components.....................80

Air bag Operation.......................83

Air Bag Warning Light....................92

Enhanced Accident Response................91

Event Data Recorder (EDR).................95

Front Air Bag . . . . . . . . . . . . . . . . . . . . . . . . . . .80

If A Deployment Occurs...................90

Knee Impact Bolsters.....................84

Maintaining Your Air Bag System............94

Side Air Bags...........................85

Air bag Deployment........................80

Air bag Light.............................92

Air bag Maintenance........................94

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . .615

Air Conditioner Maintenance.................619

Air Conditioning..........................433

Air Conditioning Controls...................433

Air Conditioning Filter.....................452

Air Conditioning, Operating Tips..............451

Air Conditioning, Rear Zone.................438

Air Conditioning Refrigerant.................619

Air Conditioning System....................433

Air Conditioning System, Zone Control..........433

Air Pressure, Tires.........................508

Alarm Light.............................319

Alarm (Security Alarm)......................17

Alterations/Modifications, Vehicle...............7

Antenna, Satellite Radio.....................374

Antifreeze (Engine Coolant)..................625

Disposal..............................628

680 INDEX