light DODGE GRAND CARAVAN 2017 5.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2017, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2017 5.GPages: 530, PDF Size: 5.01 MB

Page 403 of 530

gasoline may not be indicated on the gasoline pump,

therefore, you should ask your gasoline retailer whether

the gasoline contains MMT. MMT is prohibited in Federal

and California reformulated gasoline.

Materials Added To Fuel

Besides using unleaded gasoline with the proper octane

rating, gasolines that contain detergents, corrosion and

stability additives are recommended. Using gasolines that

have these additives will help improve fuel economy,

reduce emissions, and maintain vehicle performance.Designated TOP TIER Detergent Gaso-

line contains a higher level of detergents

to further aide in minimizing engine

and fuel system deposits. When avail-

able, the usage of Top Tier Detergent

gasoline is recommended. Visit

www.toptiergas.com for a list of TOP

TIER Detergent Gasoline Retailers.

Indiscriminate use of fuel system cleaning agents should be

avoided. Many of these materials intended for gum and

varnish removal may contain active solvents or similar

ingredients. These can harm fuel system gasket and dia-

phragm materials.

Fuel System Cautions

CAUTION!

Follow these guidelines to maintain your vehicle’s

performance:

• The use of leaded gasoline is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance and damage the emissions control system.

• An out-of-tune engine or certain fuel or ignition

malfunctions can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your authorized dealer for service assistance.

• The use of fuel additives, which are now being sold

as octane enhancers, is not recommended. Most of

these products contain high concentrations of metha-

nol. Fuel system damage or vehicle performance

problems resulting from the use of such fuels or

additives is not the responsibility of the manufac-

turer and may void or not be covered under the New

Vehicle Limited Warranty.

5

STARTING AND OPERATING 401

Page 407 of 530

NOTE:The driver’s side sliding door cannot be opened

while the fuel door is open. This feature operates only

when the sliding door is fully closed prior to opening the

fuel door.

CAUTION!

• Damage to the fuel system or emissions control

system could result from using an improper fuel

tank filler tube cap. A poorly fitting cap could let

impurities into the fuel system and may cause the

“Malfunction Indicator Light (MIL)” to turn on, due

to fuel vapors escaping from the system.

• To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

•Never have any smoking materials lit in or near the

vehicle when the gas cap is removed or the tank is

being filled.

• Never add fuel when the engine is running. This is

in violation of most state and federal fire regulations

and may cause the MIL to turn on.

• A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on the

ground while filling.

Fuel Filler Cap

5

STARTING AND OPERATING 405

Page 413 of 530

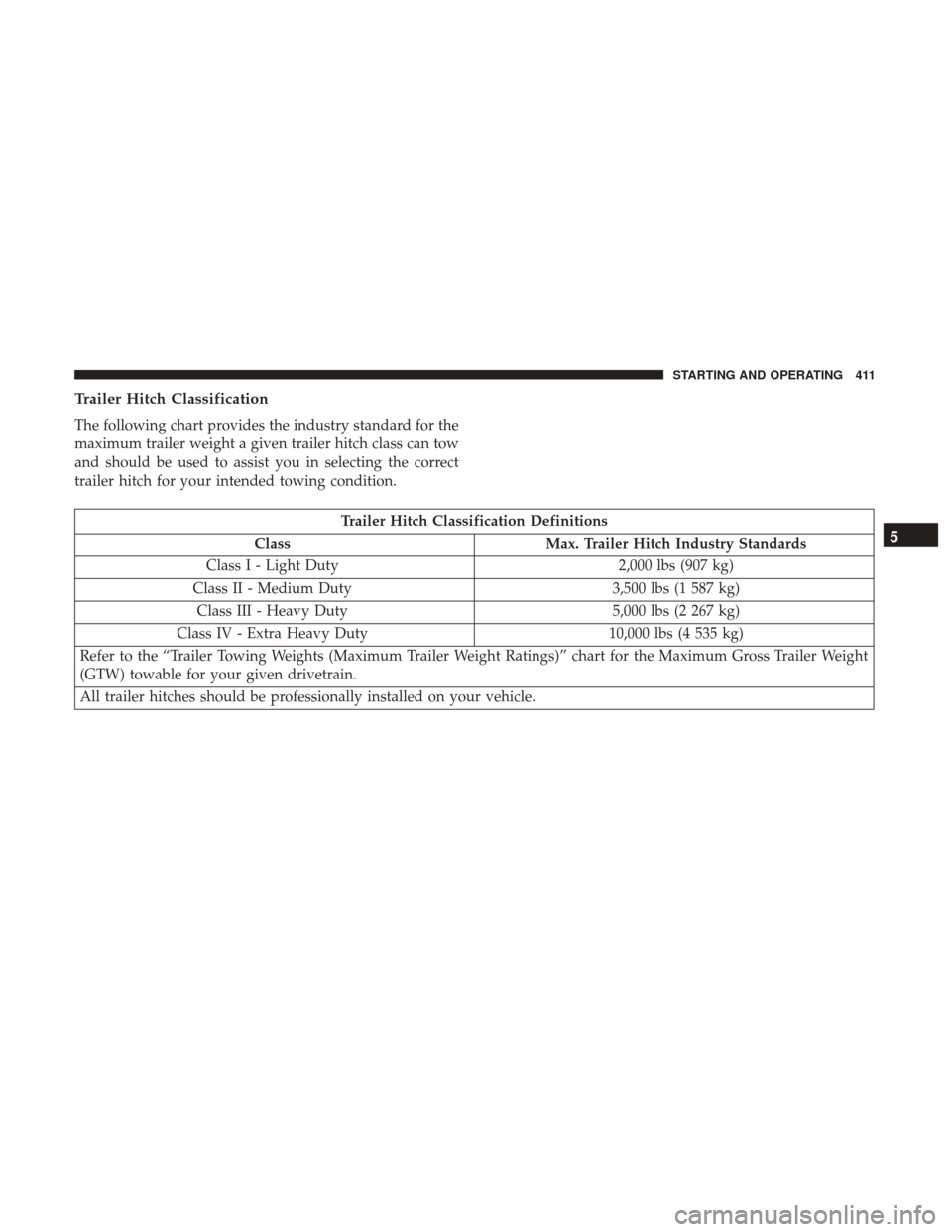

Trailer Hitch Classification

The following chart provides the industry standard for the

maximum trailer weight a given trailer hitch class can tow

and should be used to assist you in selecting the correct

trailer hitch for your intended towing condition.

Trailer Hitch Classification Definitions

Class Max. Trailer Hitch Industry Standards

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium Duty 3,500 lbs (1 587 kg)

Class III - Heavy Duty 5,000 lbs (2 267 kg)

Class IV - Extra Heavy Duty 10,000 lbs (4 535 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” chart for the Maximum Gross Trailer Weight

(GTW) towable for your given drivetrain.

All trailer hitches should be professionally installed on your vehicle.

5

STARTING AND OPERATING 411

Page 418 of 530

CAUTION!

If the trailer weighs more than 1,000 lbs (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

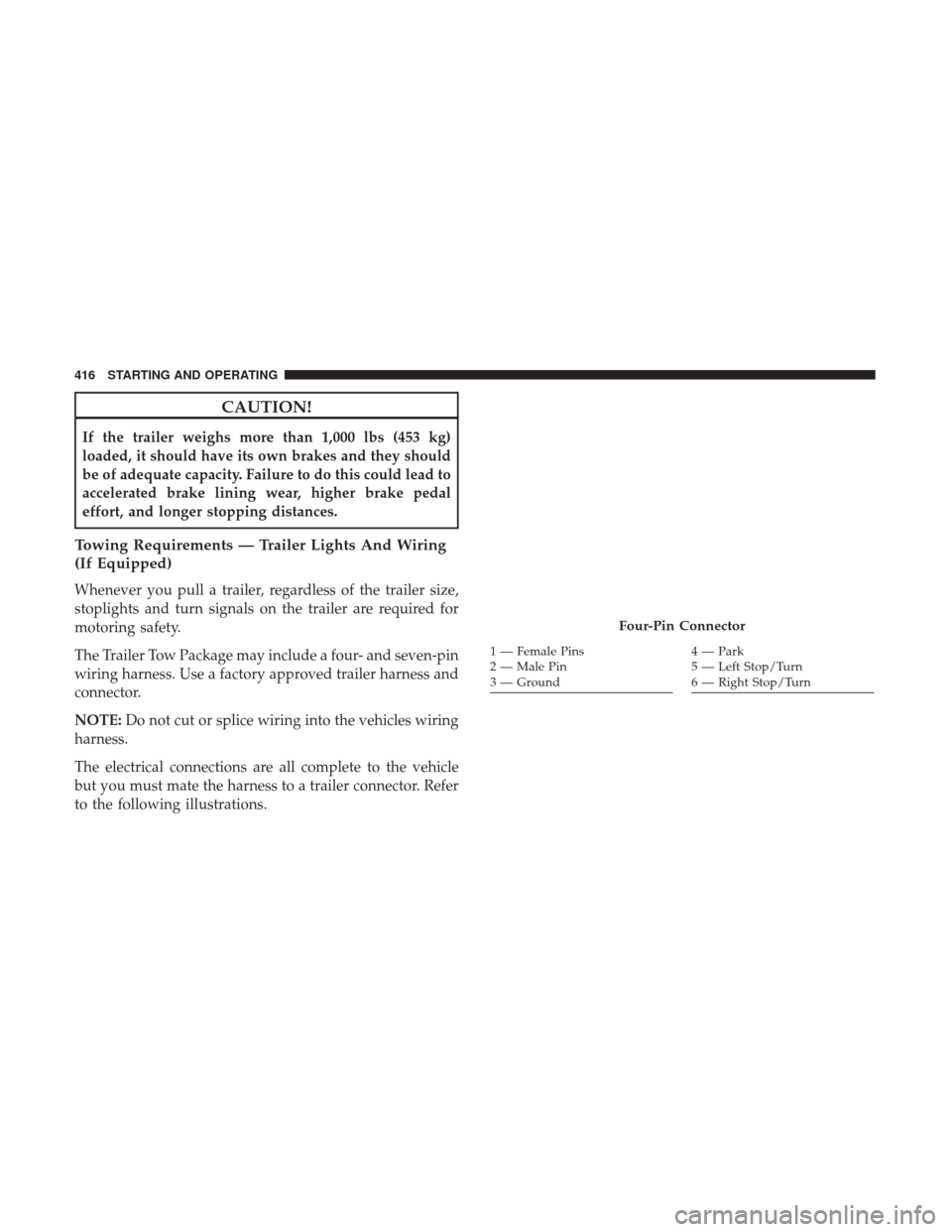

Towing Requirements — Trailer Lights And Wiring

(If Equipped)

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-pin

wiring harness. Use a factory approved trailer harness and

connector.

NOTE:Do not cut or splice wiring into the vehicles wiring

harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector. Refer

to the following illustrations.

Four-Pin Connector

1 — Female Pins

2 — Male Pin

3 — Ground4 — Park

5 — Left Stop/Turn

6 — Right Stop/Turn

416 STARTING AND OPERATING

Page 419 of 530

Towing Tips

Before setting out on a trip, practice turning, stopping, and

backing up the trailer in an area located away from heavy

traffic.

Automatic Transmission

The DRIVE range can be selected when towing. However,

if frequent shifting occurs while in DRIVE, use the Elec-

tronic Range Select (ERS) shift control to select a lower gear

range.

NOTE:Using a lower gear range while operating the

vehicle under heavy loading conditions will improve per-

formance and extend transmission life by reducing exces-

sive shifting and heat build up. This action will also

provide better engine braking.

If you REGULARLY tow a trailer for more than 45 minutes

of continuous operation, then change the transmission

fluid and filter as specified for “police, taxi, fleet, or

frequent trailer towing”. Refer to the “Maintenance Sched-

ule” for the proper maintenance intervals.

Electronic Speed Control — If Equipped

• Do not use in hilly terrain or with heavy loads.

• When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

• Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

Seven-Pin Connector

1 — Battery

2 — Backup Lamps

3 — Right Stop/Turn

4 — Electric Brakes5 — Ground

6 — Left Stop/Turn

7 — Running Lamps

5

STARTING AND OPERATING 417

Page 445 of 530

WARNING!(Continued)

under a raised vehicle, take it to a service center where

it can be raised on a lift.

3. Place the wrench on the jack screw and turn to the right until the jack head is properly engaged in the described

location. Do not raise the vehicle until you are sure the

jack is securely engaged.

4. Raise the vehicle by turning the jack screw to the right, using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the compact spare tire. Minimum tire

lift provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

5.

Remove the wheel lug nuts, for vehicles with wheel covers,

remove the cover from the wheel by hand. Do not pry the

wheel cover off. Then pull the wheel off the hub.

6. Install the compact spare tire. Lightly tighten the lug nuts.

CAUTION!

Be sure to mount the compact spare tire with the valve

stem facing outward. The vehicle could be damaged if

the compact spare tire is mounted incorrectly.

Mounting Compact Spare Tire

6

WHAT TO DO IN EMERGENCIES 443

Page 448 of 530

CAUTION!(Continued)

this cover could drastically reduce the life of the

compact spare tire.

4. Using the winch T-handle, rotate the drive nut to the right until the compact spare tire/cover assembly is

drawn into place against the underside of the vehicle.

5. Continue to rotate the nut to the right until you hear the winch mechanism click three times. It cannot be over-

tightened. Check under the vehicle to ensure the com-

pact spare tire/cover assembly is positioned correctly

against the underside of the vehicle.

CAUTION!

The winch mechanism is designed specifically to stow

a compact spare tire only. Do not attempt to use the

winch to stow the full size deflated tire, or any other

full-size tire, as the tire may not be held securely.

Vehicle damage may result.

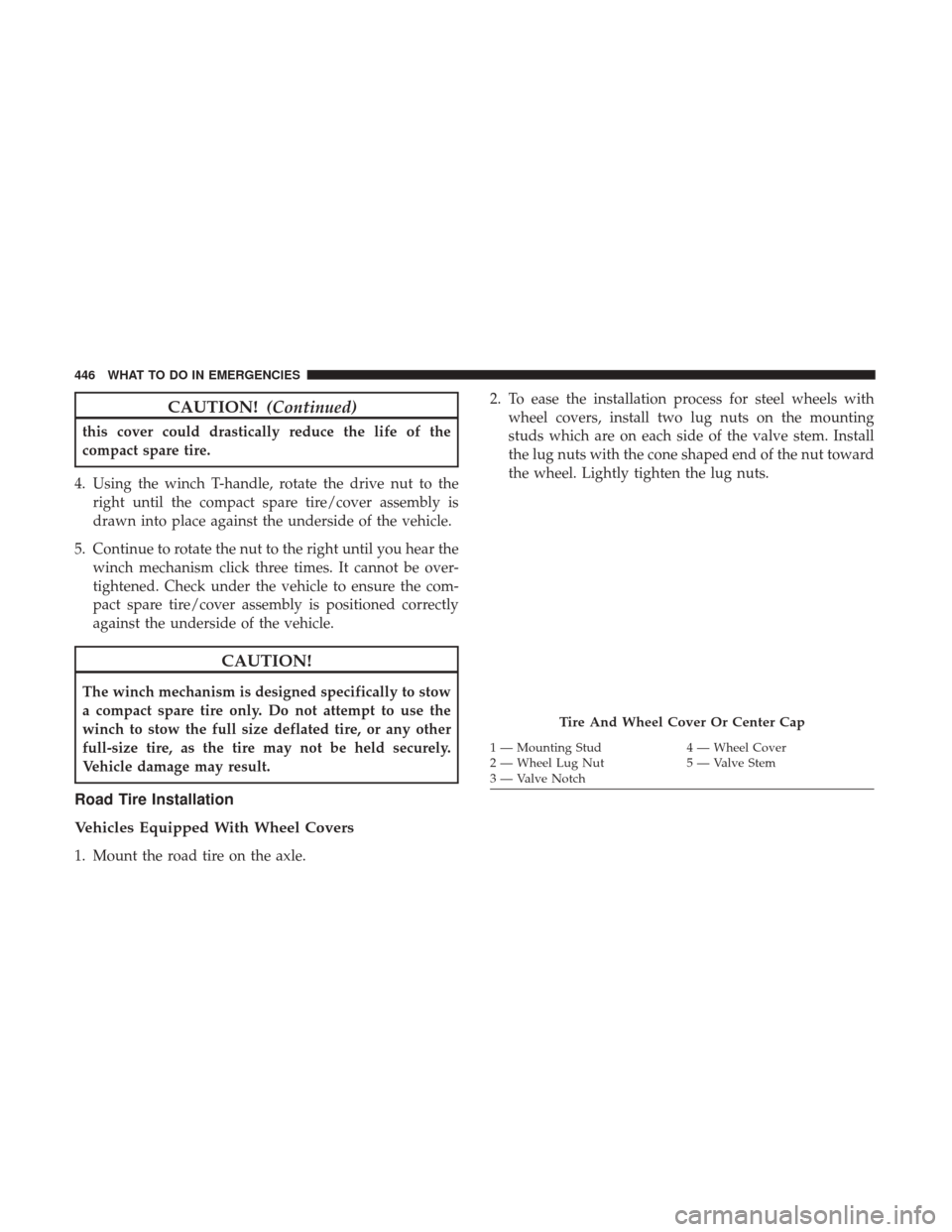

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle. 2. To ease the installation process for steel wheels with

wheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut toward

the wheel. Lightly tighten the lug nuts.

Tire And Wheel Cover Or Center Cap

1 — Mounting Stud 4 — Wheel Cover

2 — Wheel Lug Nut 5 — Valve Stem

3 — Valve Notch

446 WHAT TO DO IN EMERGENCIES

Page 449 of 530

3. Align the valve notch in the wheel cover with the valvestem on the wheel. Install the cover by hand, snapping

the cover over the two lug nuts. Do not use a hammer or

excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. For correct lug nut torque

refer to Torque Specifications in this section. If in doubt

about the correct tightness, have them checked with a

torque wrench by your Authorized Dealer or at a service

station.. 7. After 25 miles (40 km) check the lug nut torque with a

torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped endof the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. For correct lug nut torque

refer to Torque Specifications in this section. If in doubt

6

WHAT TO DO IN EMERGENCIES 447

Page 462 of 530

ONBOARD DIAGNOSTIC SYSTEM — OBD II

Your vehicle is equipped with a sophisticated Onboard

Diagnostic system called OBD II. This system monitors the

performance of the emissions, engine, and automatic trans-

mission control systems. When these systems are operating

properly, your vehicle will provide excellent performance

and fuel economy, as well as engine emissions well within

current government regulations.

If any of these systems require service, the OBD II system

will turn on the “Malfunction Indicator Light (MIL).” It

will also store diagnostic codes and other information to

assist your service technician in making repairs. Although

your vehicle will usually be drivable and not need towing,

see your authorized dealer for service as soon as possible.

CAUTION!

•Prolonged driving with the MIL on could cause

further damage to the emission control system. It

could also affect fuel economy and driveability. The

vehicle must be serviced before any emissions tests

can be performed.

• If the MIL is flashing while the engine is running,

severe catalytic converter damage and power loss

will soon occur. Immediate service is required.

Onboard Diagnostic System (OBD II) Cybersecurity

Your vehicle is required to have an Onboard Diagnostic

system (OBD II) and a connection port to allow access to

information related to the performance of your emissions

controls. Authorized service technicians may need to ac-

cess this information to assist with the diagnosis and

service of your vehicle and emissions system.

WARNING!

•ONLY an authorized service technician should con-

nect equipment to the OBD II connection port in

order to diagnose or service your vehicle.

• If unauthorized equipment is connected to the OBD

II connection port, such as a driver-behavior tracking

device, it may:

• Be possible that vehicle systems, including safety

related systems, could be impaired or a loss of

vehicle control could occur that may result in an

accident involving serious injury or death.

• Access, or allow others to access, information

stored in your vehicle systems, including personal

information.

For further information, refer to “Cybersecurity” in the

“Understanding Your Instrument Panel” section.

460 MAINTAINING YOUR VEHICLE

Page 463 of 530

Loose Fuel Filler Cap Message

If the vehicle diagnostic system determines that the fuel

filler cap is loose, improperly installed, or damaged, a

“gASCAP” message will display in the odometer or a

“CHECK GASCAP” message will be displayed in the

instrument cluster display. Refer to “Instrument Cluster

Display” in “Understanding Your Instrument Panel” for

further information. Tighten the gas cap until a “clicking”

sound is heard. This is an indication that the gas cap is

properly tightened.

Push the odometer reset button to turn the message off. If

the problem persists, the message will appear the next time

the vehicle is started. This might indicate a damaged cap. If

the problem is detected twice in a row, the system will turn

on the MIL. Resolving the problem will turn the MIL light

off.

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass an

inspection of your vehicle’s emissions control system.

Failure to pass could prevent vehicle registration.For states that require an Inspection and Mainte-

nance (I/M), this check verifies the “Malfunction

Indicator Light (MIL)” is functioning and is not on

when the engine is running, and that the OBD II system is

ready for testing.

Normally, the OBD II system will be ready. The OBD II

system may notbe ready if your vehicle was recently

serviced, recently had a dead battery or a battery replace-

ment. If the OBD II system should be determined not ready

for the I/M test, your vehicle may fail the test.

Your vehicle has a simple ignition actuated test, which you

can use prior to going to the test station. To check if your

vehicle’s OBD II system is ready, you must do the follow-

ing:

1. Cycle the ignition switch to the ON position, but do not crank or start the engine.

NOTE: If you crank or start the engine, you will have to

start this test over.

2. As soon as you cycle the ignition switch to the ON position, you will see the “Malfunction Indicator Light

(MIL)” symbol come on as part of a normal bulb check.

7

MAINTAINING YOUR VEHICLE 461