light DODGE GRAND CARAVAN 2017 5.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2017, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2017 5.GPages: 530, PDF Size: 5.01 MB

Page 473 of 530

also be given to hood latching components to ensure

proper function. When performing other underhood ser-

vices, the hood latch, release mechanism and safety catch

should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as MOPAR Lock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use washer

fluid when using the wipers to remove salt or dirt from a

dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.NOTE:

Life expectancy of wiper blades varies depending

on geographical area and frequency of use. Poor perfor-

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary.

Adding Washer Fluid

The fluid reservoir for the windshield washers and the rear

window washer is shared. It is located in the engine

compartment and should be checked at regular intervals.

Fill the reservoir with windshield washer solvent (not

radiator antifreeze) and operate the system for a few

seconds to flush out any residual water.

The washer fluid reservoir will hold a full gallon of fluid

when the Low Washer Fluid Light illuminates.

WARNING!

Commercially available windshield washer solvents

are flammable. They could ignite and burn you. Care

must be exercised when filling or working around the

washer solution.

7

MAINTAINING YOUR VEHICLE 471

Page 479 of 530

WARNING!

Riding the brakes can lead to brake failure and possi-

bly a collision. Driving with your foot resting or riding

on the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible

brake damage. You would not have your full braking

capacity in an emergency.

Master Cylinder — Brake Fluid Level Check

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the “Brake System Warning Light” indicates system failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the requirements

described on the brake fluid reservoir. With disc brakes,

fluid level can be expected to fall as the brake pads wear.

However, low fluid level may be caused by a leak and a

checkup may be needed.Use only manufacturer’s recommended brake fluid. Refer

to “Fluids, Lubricants, And Genuine Parts” in “Maintain-

ing Your Vehicle” for further information.

WARNING!

•

Use only manufacturer’s recommended brake fluid.

Refer to “Fluids, Lubricants, And Genuine Parts” in

“Maintaining Your Vehicle” for further information.

Using the wrong type of brake fluid can severely

damage your brake system and/or impair its perfor-

mance. The proper type of brake fluid for your

vehicle is also identified on the original factory

installed hydraulic master cylinder reservoir.

• To avoid contamination from foreign matter or mois-

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master cylin-

der reservoir cap secured at all times. Brake fluid in

a open container absorbs moisture from the air

resulting in a lower boiling point. This may cause it

to boil unexpectedly during hard or prolonged brak-

ing, resulting in sudden brake failure. This could

result in a collision.

(Continued)

7

MAINTAINING YOUR VEHICLE 477

Page 485 of 530

Cleaning Headlights

Your vehicle is equipped with plastic headlights and fog

lights that are lighter and less susceptible to stone breakage

than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution followed

by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

Glass Surfaces

All glass surfaces should be cleaned on a regular basis with

MOPAR Glass Cleaner, or any commercial household-type

glass cleaner. Never use an abrasive type cleaner. Use

caution when cleaning the inside rear window equipped

with electric defrosters or windows equipped with radio

antennas. Do not use scrapers or other sharp instrument

that may scratch the elements.When cleaning the rear view mirror, spray cleaner on the

towel or cloth that you are using. Do not spray cleaner

directly on the mirror.

Cleaning Plastic Instrument Cluster Lenses

The lenses in front of the instruments in this vehicle are

molded in clear plastic. When cleaning the lenses, care

must be taken to avoid scratching the plastic.

1. Clean with a wet soft cloth. A mild soap solution may be

used, but do not use high alcohol content or abrasive

cleaners. If soap is used, wipe clean with a clean damp

cloth.

2. Dry with a soft cloth.

Seat Belt Maintenance

Do not bleach, dye, or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the fabric.

Sun damage can also weaken the fabric.

If the belts need cleaning, use MOPAR Total Clean, a mild

soap solution, or lukewarm water. Do not remove the belts

from the vehicle to wash them. Dry with a soft cloth.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

7

MAINTAINING YOUR VEHICLE 483

Page 489 of 530

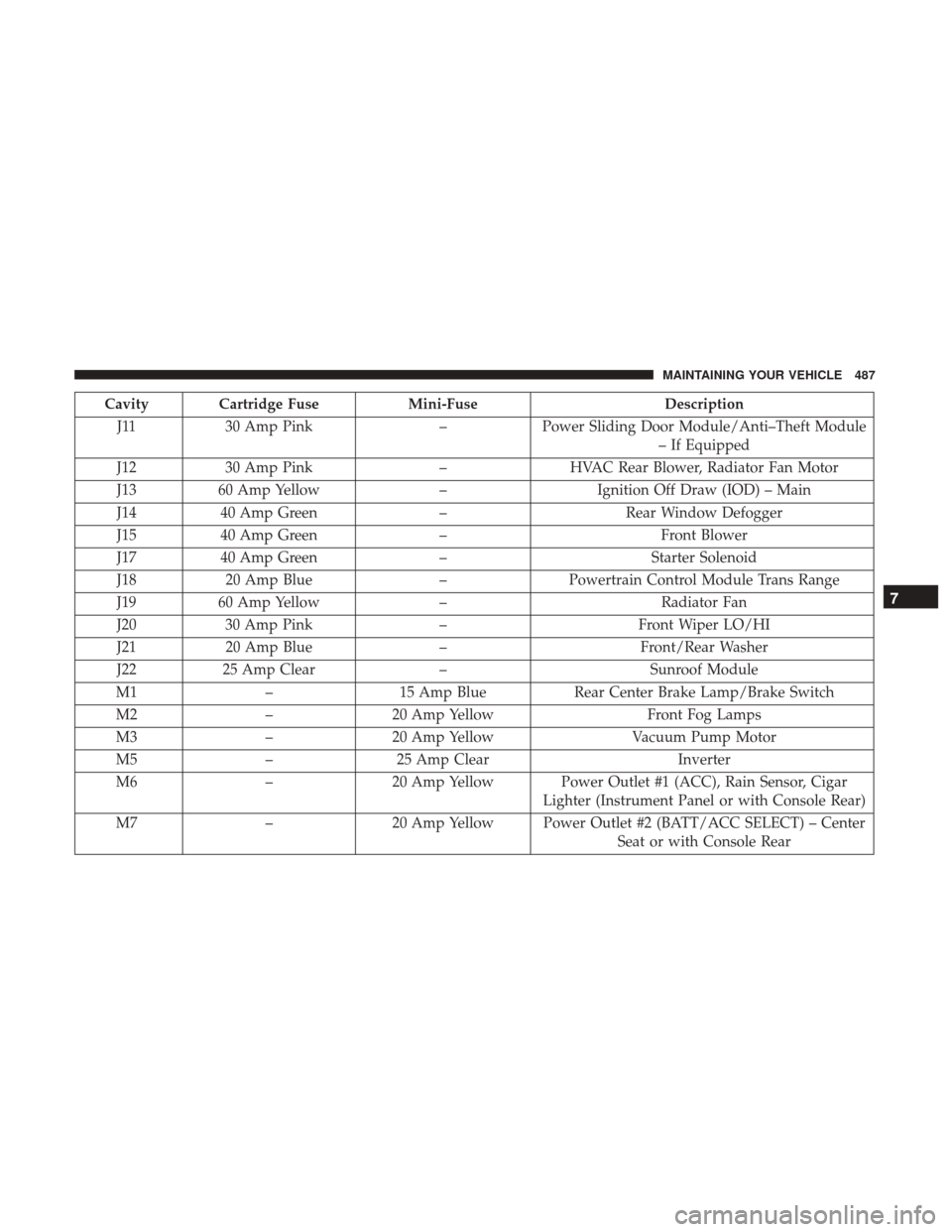

Cavity Cartridge FuseMini-FuseDescription

J11 30 Amp Pink –Power Sliding Door Module/Anti–Theft Module

– If Equipped

J12 30 Amp Pink –HVAC Rear Blower, Radiator Fan Motor

J13 60 Amp Yellow –Ignition Off Draw (IOD) – Main

J14 40 Amp Green –Rear Window Defogger

J15 40 Amp Green – Front Blower

J17 40 Amp Green –Starter Solenoid

J18 20 Amp Blue –Powertrain Control Module Trans Range

J19 60 Amp Yellow – Radiator Fan

J20 30 Amp Pink –Front Wiper LO/HI

J21 20 Amp Blue –Front/Rear Washer

J22 25 Amp Clear –Sunroof Module

M1 –15 Amp Blue Rear Center Brake Lamp/Brake Switch

M2 –20 Amp Yellow Front Fog Lamps

M3 –20 Amp Yellow Vacuum Pump Motor

M5 –25 Amp Clear Inverter

M6 –20 Amp Yellow Power Outlet #1 (ACC), Rain Sensor, Cigar

Lighter (Instrument Panel or with Console Rear)

M7 –20 Amp Yellow Power Outlet #2 (BATT/ACC SELECT) – Center

Seat or with Console Rear

7

MAINTAINING YOUR VEHICLE 487

Page 490 of 530

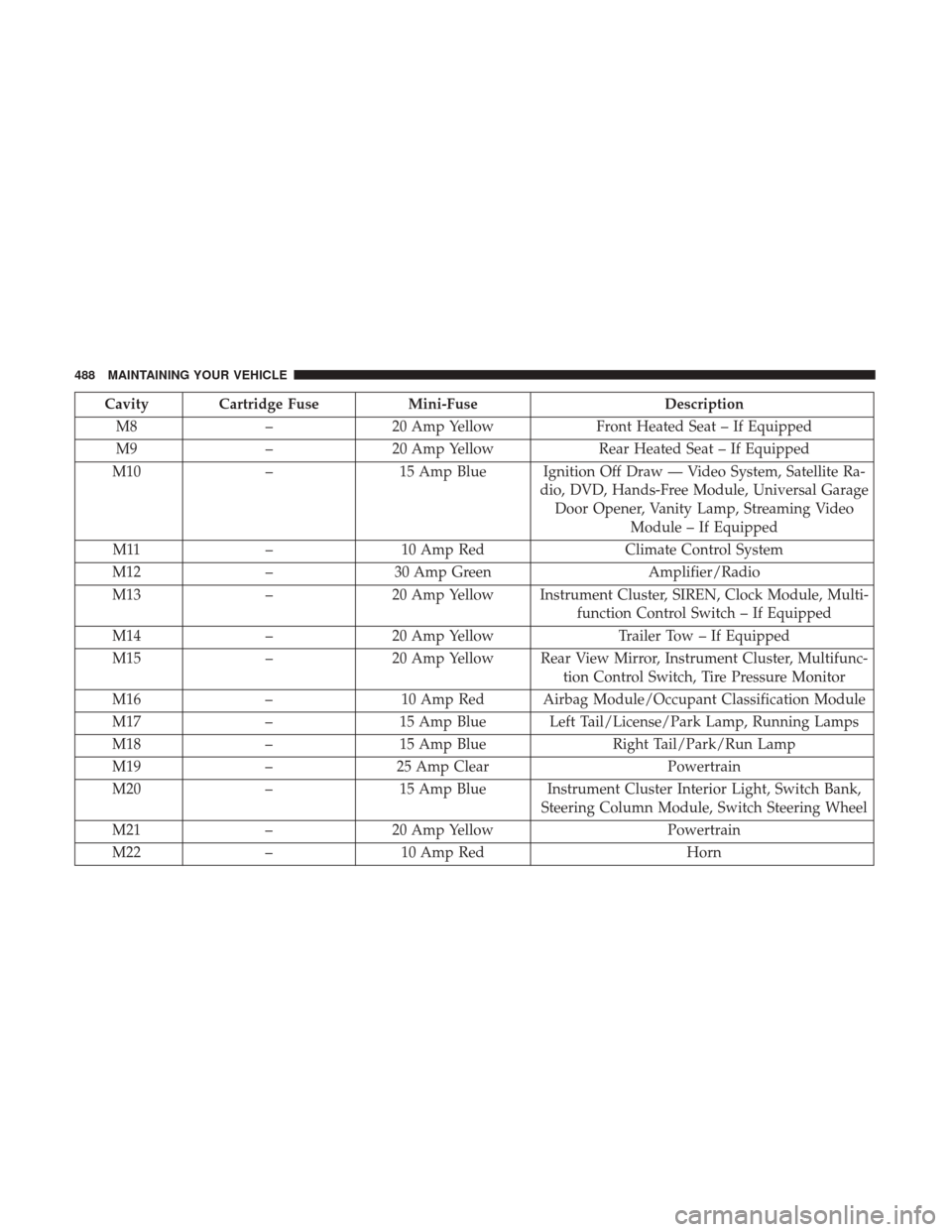

Cavity Cartridge FuseMini-FuseDescription

M8 –20 Amp Yellow Front Heated Seat – If Equipped

M9 –20 Amp Yellow Rear Heated Seat – If Equipped

M10 –15 Amp Blue Ignition Off Draw — Video System, Satellite Ra-

dio, DVD, Hands-Free Module, Universal GarageDoor Opener, Vanity Lamp, Streaming Video Module – If Equipped

M11 –10 Amp Red Climate Control System

M12 –30 Amp Green Amplifier/Radio

M13 –20 Amp Yellow Instrument Cluster, SIREN, Clock Module, Multi-

function Control Switch – If Equipped

M14 –20 Amp Yellow Trailer Tow – If Equipped

M15 –20 Amp Yellow Rear View Mirror, Instrument Cluster, Multifunc-

tion Control Switch, Tire Pressure Monitor

M16 –10 Amp Red Airbag Module/Occupant Classification Module

M17 –15 Amp Blue Left Tail/License/Park Lamp, Running Lamps

M18 –15 Amp Blue Right Tail/Park/Run Lamp

M19 –25 Amp Clear Powertrain

M20 –15 Amp Blue Instrument Cluster Interior Light, Switch Bank,

Steering Column Module, Switch Steering Wheel

M21 –20 Amp Yellow Powertrain

M22 –10 Amp Red Horn

488 MAINTAINING YOUR VEHICLE

Page 491 of 530

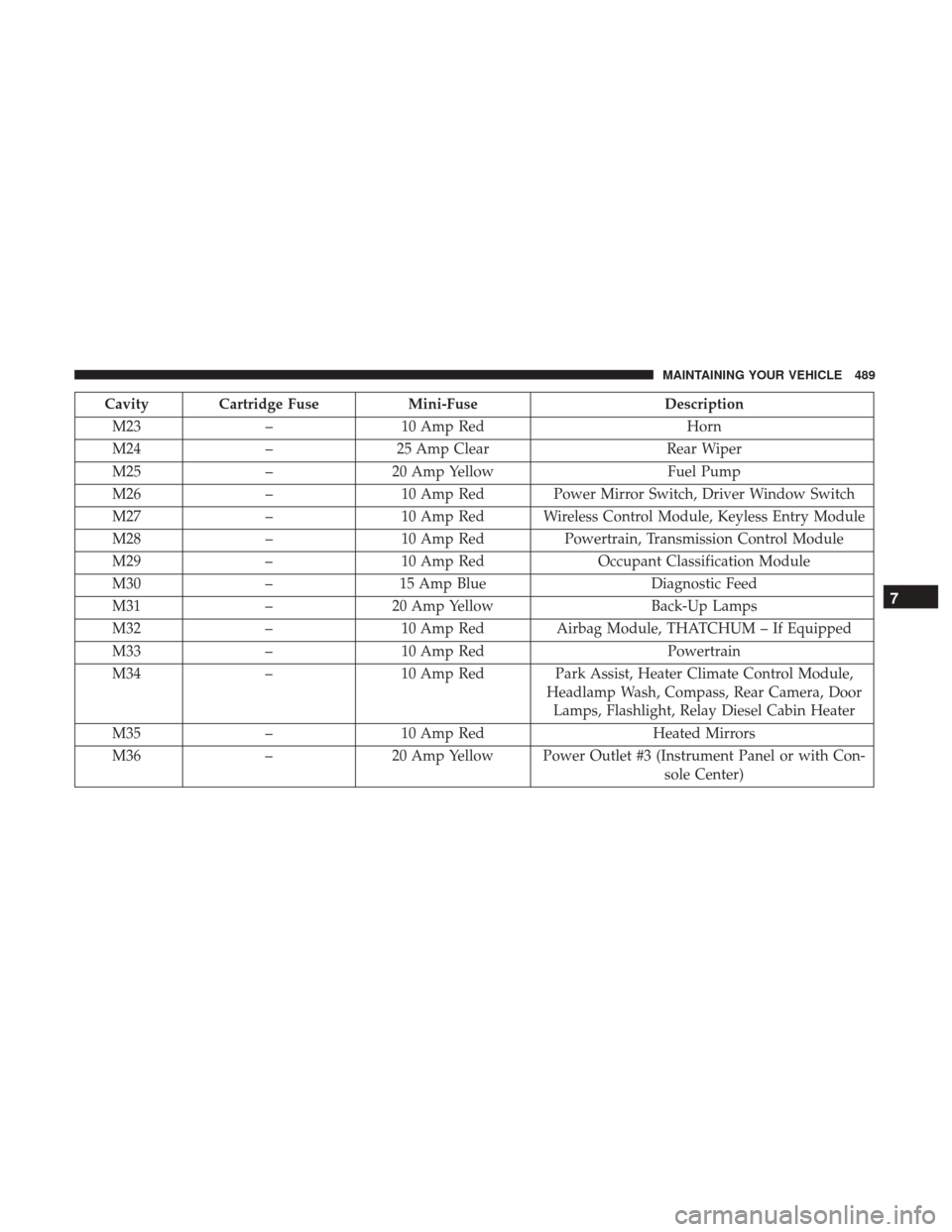

Cavity Cartridge FuseMini-FuseDescription

M23 –10 Amp Red Horn

M24 –25 Amp Clear Rear Wiper

M25 –20 Amp Yellow Fuel Pump

M26 –10 Amp Red Power Mirror Switch, Driver Window Switch

M27 –10 Amp Red Wireless Control Module, Keyless Entry Module

M28 –10 Amp Red Powertrain, Transmission Control Module

M29 –10 Amp Red Occupant Classification Module

M30 –15 Amp Blue Diagnostic Feed

M31 –20 Amp Yellow Back-Up Lamps

M32 –10 Amp Red Airbag Module, THATCHUM – If Equipped

M33 –10 Amp Red Powertrain

M34 –10 Amp Red Park Assist, Heater Climate Control Module,

Headlamp Wash, Compass, Rear Camera, DoorLamps, Flashlight, Relay Diesel Cabin Heater

M35 –10 Amp Red Heated Mirrors

M36 –20 Amp Yellow Power Outlet #3 (Instrument Panel or with Con-

sole Center)

7

MAINTAINING YOUR VEHICLE 489

Page 493 of 530

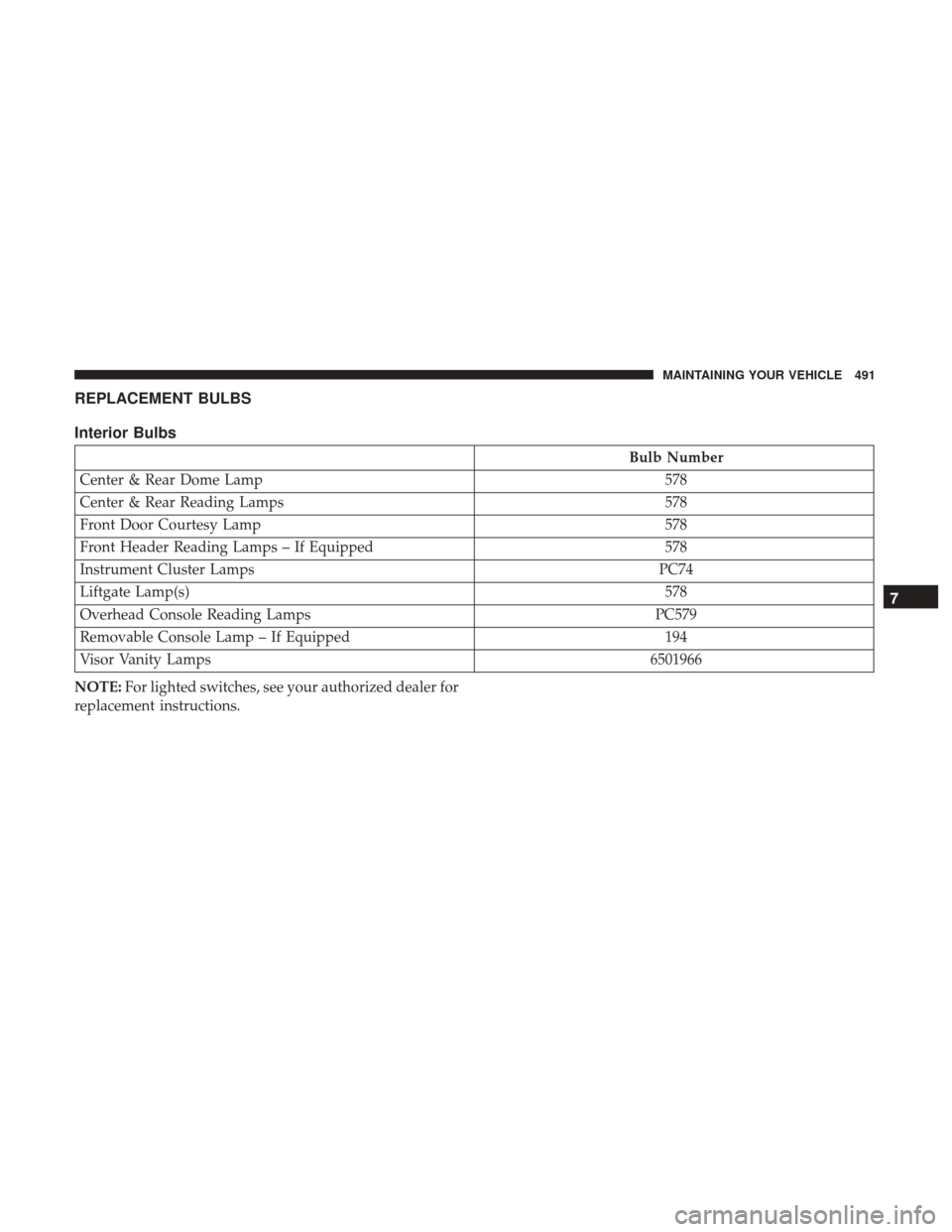

REPLACEMENT BULBS

Interior Bulbs

Bulb Number

Center & Rear Dome Lamp 578

Center & Rear Reading Lamps 578

Front Door Courtesy Lamp 578

Front Header Reading Lamps – If Equipped 578

Instrument Cluster Lamps PC74

Liftgate Lamp(s) 578

Overhead Console Reading Lamps PC579

Removable Console Lamp – If Equipped 194

Visor Vanity Lamps 6501966

NOTE: For lighted switches, see your authorized dealer for

replacement instructions.

7

MAINTAINING YOUR VEHICLE 491

Page 495 of 530

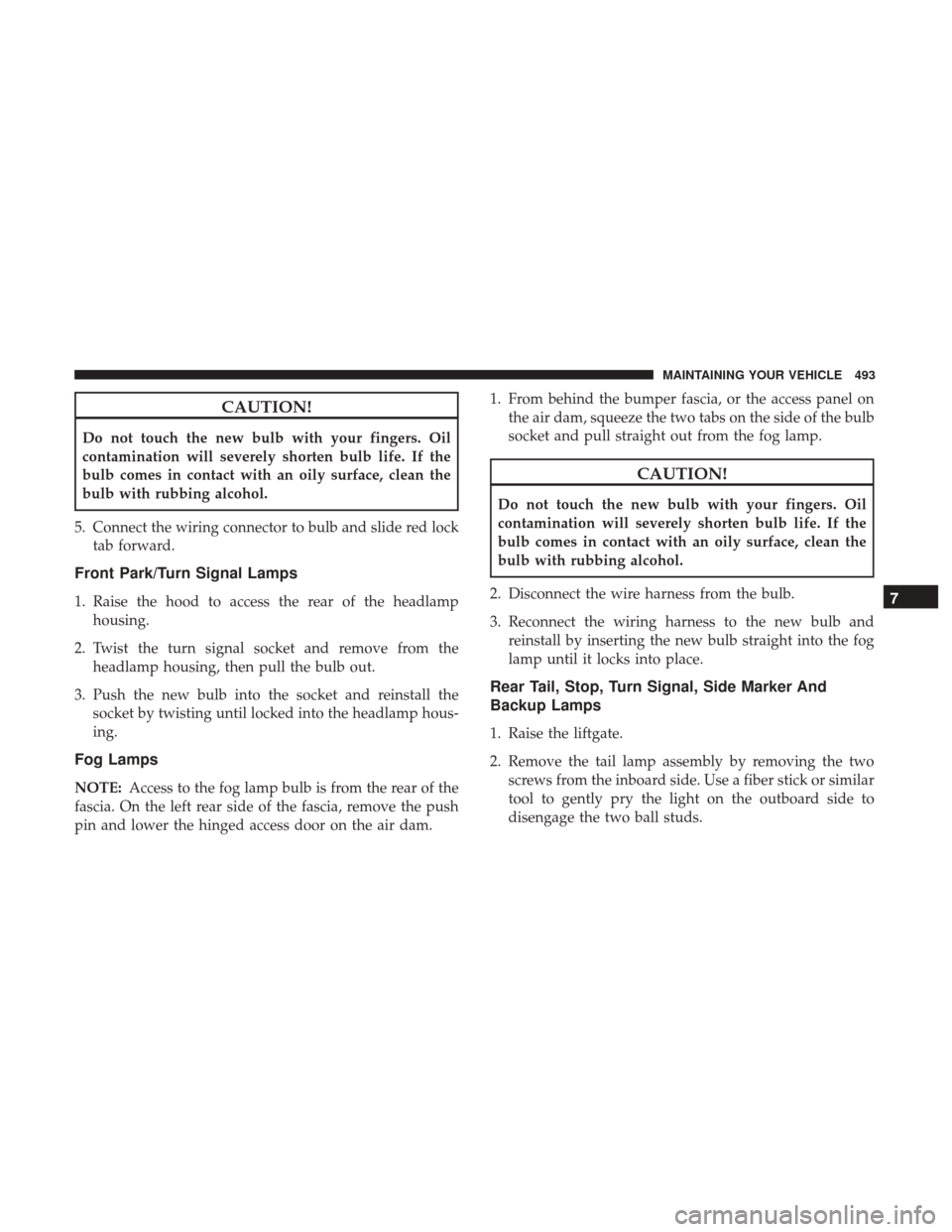

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

5. Connect the wiring connector to bulb and slide red lock tab forward.

Front Park/Turn Signal Lamps

1. Raise the hood to access the rear of the headlamphousing.

2. Twist the turn signal socket and remove from the headlamp housing, then pull the bulb out.

3. Push the new bulb into the socket and reinstall the socket by twisting until locked into the headlamp hous-

ing.

Fog Lamps

NOTE: Access to the fog lamp bulb is from the rear of the

fascia. On the left rear side of the fascia, remove the push

pin and lower the hinged access door on the air dam. 1. From behind the bumper fascia, or the access panel on

the air dam, squeeze the two tabs on the side of the bulb

socket and pull straight out from the fog lamp.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

2. Disconnect the wire harness from the bulb.

3. Reconnect the wiring harness to the new bulb and reinstall by inserting the new bulb straight into the fog

lamp until it locks into place.

Rear Tail, Stop, Turn Signal, Side Marker And

Backup Lamps

1. Raise the liftgate.

2. Remove the tail lamp assembly by removing the twoscrews from the inboard side. Use a fiber stick or similar

tool to gently pry the light on the outboard side to

disengage the two ball studs.

7

MAINTAINING YOUR VEHICLE 493

Page 496 of 530

NOTE:•If a screwdriver is used, make sure a soft material is

placed between the vehicle body and tool so not to

scratch the paint.

• The PRY location is best closest to the studs while

dislodging them separately.

3. Twist the socket and remove from the lamp assembly.

4. Pull the bulb to remove it from the socket.

5. Replace the bulb, reinstall the socket, and reattach the lamp assembly.

Center High-Mounted Stop Lamp (CHMSL)

The CHMSL uses LED lamps that are not serviceable

separately. The CHMSL must be replaced as an assembly.

See your authorized dealer.

License Lamp

The license plate lamp is located under the tailgate light

bar and above the license plate.

1. Using a small screwdriver, press inward the locking tabon the outboard side of the lamp assembly and pull

down on the lamp assembly for removal.

2. Twist and remove the socket from the lamp assembly and pull the bulb out to remove.

3. Push the bulb into the socket, twist the socket into the lamp assembly and reinstall the lamp assembly into

place ensuring the locking tab is secure.

Tail Lamp Assembly Screws

494 MAINTAINING YOUR VEHICLE

Page 502 of 530

MAINTENANCE SCHEDULE

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will influence

when the “Oil Change Required” message is displayed.

Severe Operating Conditions can cause the change oil

message to illuminate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).

Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

your authorized dealer, the message can be reset by

referring to the steps described under “Instrument Cluster

Display” in “Understanding Your Instrument Panel” for

further information.NOTE:

Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km), twelve months or 350

hours of engine run time, whichever comes first. The 350

hours of engine run or idle time is generally only a concern

for fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) if the vehicle

is operated in a dusty and off road environment or is

operated predominately at idle or only very low engine

RPM’s. This type of vehicle use is considered Severe Duty.

Once A Month Or Before A Long Trip:

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before the oil indicator system turns on.

• Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering and fill as needed.

• Check function of all interior and exterior lights.

500 MAINTENANCE SCHEDULES