warning light DODGE GRAND CARAVAN 2019 Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2019, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2019Pages: 490, PDF Size: 3.84 MB

Page 255 of 490

To exit ERS mode, simply hold the gear selector to the right

(+) until the gear limit display disappears from the instru-

ment cluster.WARNING!

Do not downshift for additional engine braking on a

slippery surface. The drive wheels could lose their grip

and the vehicle could skid, causing a collision or

personal injury.

Transmission Gear Position Dis-

play123456D

Actual Gear(s) Allowed 1 1–2 1–3 1–4 1–5 1–6 1–6

NOTE: To select the proper gear position for maximum

deceleration (engine braking), tap the gear selector to the

left (-) repeatedly as the vehicle slows. The transmission

will shift to the range from which the vehicle can best be

slowed down.

Overdrive Operation

The automatic transmission includes an electronically con-

trolled Overdrive (sixth gear). The transmission will auto-

matically shift into Overdrive if the following conditions

are present:

• The gear selector is in the DRIVE position. •

The transmission fluid has reached an adequate tem-

perature.

• The engine coolant has reached an adequate tempera-

ture.

• The vehicle speed is sufficiently high.

• The driver is not heavily pressing the accelerator.Torque Converter Clutch

A feature designed to improve fuel economy has been

included in the automatic transmission on your vehicle. A

clutch within the torque converter engages automatically

at calibrated speeds. This may result in a slightly different

6

STARTING AND OPERATING 253

Page 258 of 490

WARNING!

Speed Control can be dangerous where the system

cannot maintain a constant speed. Your vehicle could

go too fast for the conditions, and you could lose

control and have an accident. Do not use Speed Control

in heavy traffic or on roads that are winding, icy,

snow-covered or slippery.

To Activate

Push the ON/OFF button. The Cruise Indicator Light in

the instrument cluster display will illuminate. To turn the

system off, push the ON/OFF button a second time. The

Cruise Indicator Light will turn off. The system should be

turned off when not in use.

WARNING!

Leaving the Speed Control system on when not in use

is dangerous. You could accidentally set the system or

cause it to go faster than you want. You could lose

control and have an accident. Always leave the system

off when you are not using it.

To Set A Desired Speed

Turn the Speed Control on. When the vehicle has reached

the desired speed, push the SET (-) button and release.

Release the accelerator and the vehicle will operate at the

selected speed.

NOTE:The vehicle should be traveling at a steady speed

and on level ground before pushing the SET (-) button.

To Vary The Speed Setting

To Increase Speed

When the Speed Control is set, you can increase speed by

pushing the RES (+) button.

The driver ’s preferred units can be selected through the

instrument panel settings if equipped. Refer to “Getting To

Know Your Instrument Panel” for more information. The

speed decrement shown is dependant on the chosen speed

unit of U.S. (mph) or Metric (km/h):

U.S. Speed (mph)

• Pushing the RES (+) button once will result ina1mph

increase in set speed. Each subsequent tap of the button

results in an increase of 1 mph.

256 STARTING AND OPERATING

Page 269 of 490

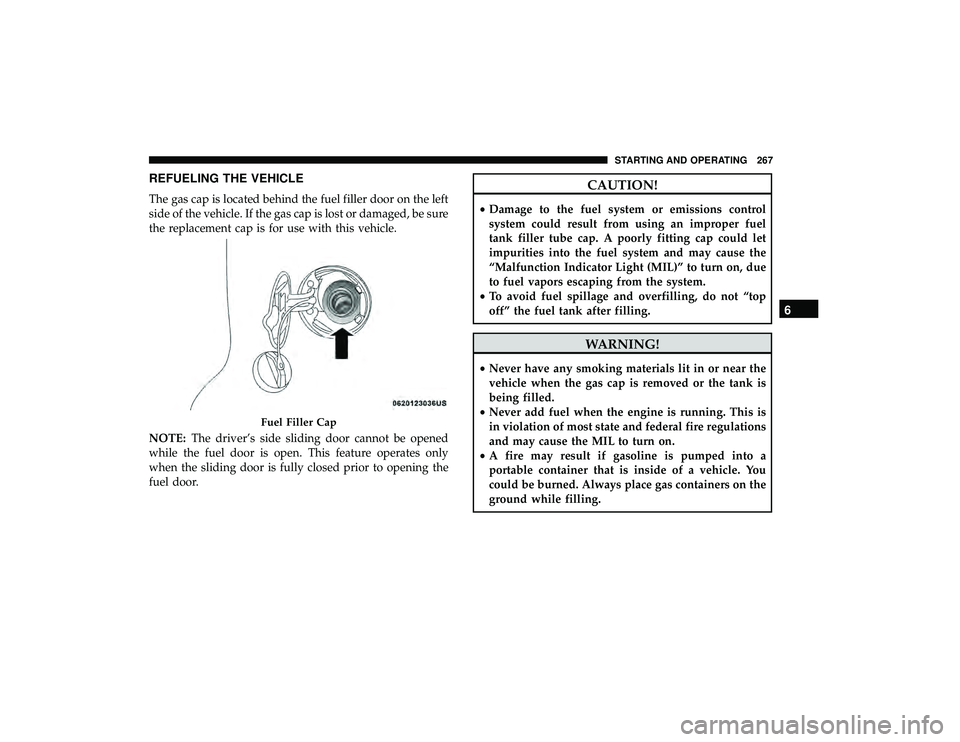

REFUELING THE VEHICLE

The gas cap is located behind the fuel filler door on the left

side of the vehicle. If the gas cap is lost or damaged, be sure

the replacement cap is for use with this vehicle.

NOTE:The driver’s side sliding door cannot be opened

while the fuel door is open. This feature operates only

when the sliding door is fully closed prior to opening the

fuel door.

CAUTION!

• Damage to the fuel system or emissions control

system could result from using an improper fuel

tank filler tube cap. A poorly fitting cap could let

impurities into the fuel system and may cause the

“Malfunction Indicator Light (MIL)” to turn on, due

to fuel vapors escaping from the system.

• To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

• Never have any smoking materials lit in or near the

vehicle when the gas cap is removed or the tank is

being filled.

• Never add fuel when the engine is running. This is

in violation of most state and federal fire regulations

and may cause the MIL to turn on.

• A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on the

ground while filling.

Fuel Filler Cap

6

STARTING AND OPERATING 267

Page 280 of 490

Towing Requirements — Trailer Brakes

•Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible per-

sonal injury.

• An electronically actuated trailer brake controller is

required when towing a trailer with electronically actu-

ated brakes. When towing a trailer equipped with a

hydraulic surge actuated brake system, an electronic

brake controller is not required.

• Trailer brakes are recommended for trailers over

1,000 lbs (453 kg) and required for trailers in excess of

2,000 lbs (907 kg).

WARNING!

• Do not connect trailer brakes to your vehicle’s hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

• Towing any trailer will increase your stopping dis-

tance. When towing, you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lbs (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-pin

wiring harness. Use a factory approved trailer harness and

connector.

NOTE: Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector. Refer

to the following illustrations.

278 STARTING AND OPERATING

Page 285 of 490

•Maintain sufficient distance between your vehicle and

the vehicle in front of you to avoid a collision in a

sudden stop.

Driving Through Water

Driving through water more than a few inches/centimeters

deep will require extra caution to ensure safety and pre-

vent damage to your vehicle.

Flowing/Rising Water

WARNING!

Do not drive on or across a road or path where water is

flowing and/or rising (as in storm run-off). Flowing

water can wear away the road or path’s surface and

cause your vehicle to sink into deeper water. Further-

more, flowing and/or rising water can carry your ve-

hicle away swiftly. Failure to follow this warning may

result in injuries that are serious or fatal to you, your

passengers, and others around you.

Shallow Standing Water

Although your vehicle is capable of driving through shal-

low standing water, consider the following Cautions and

Warnings before doing so.

WARNING!

• Driving through standing water limits your vehicle’s

traction capabilities. Do not exceed 5 mph (8 km/h)

when driving through standing water.

• Driving through standing water limits your vehicle’s

braking capabilities, which increases stopping dis-

tances. Therefore, after driving through standing

water, drive slowly and lightly press on the brake

pedal several times to dry the brakes.

• Failure to follow these warnings may result in inju-

ries that are serious or fatal to you, your passengers,

and others around you.

6

STARTING AND OPERATING 283

Page 292 of 490

NOTE:•If a screwdriver is used, make sure a soft material is

placed between the vehicle body and tool so not to

scratch the paint.

• The PRY location is best closest to the studs while

dislodging them separately.

3. Twist the socket and remove from the lamp assembly.

4. Pull the bulb to remove it from the socket.

5. Replace the bulb, reinstall the socket, and reattach the lamp assembly.

Center High-Mounted Stop Lamp (CHMSL)

The CHMSL uses LED lamps that are not serviceable

separately. The CHMSL must be replaced as an assembly.

See your authorized dealer.

License Lamp

The license plate lamp is located under the tailgate light

bar and above the license plate.

1. Using a small screwdriver, press inward the locking tabon the outboard side of the lamp assembly and pull

down on the lamp assembly for removal. 2. Twist and remove the socket from the lamp assembly

and pull the bulb out to remove.

3. Push the bulb into the socket, twist the socket into the lamp assembly and reinstall the lamp assembly into

place ensuring the locking tab is secure.

FUSES

WARNING!

•When replacing a blown fuse, always use an appro-

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown

fuse with metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity or vice

versa. Failure to use proper fuses may result in

serious personal injury, fire and/or property damage.

• Before replacing a fuse, make sure that the ignition is

off and that all the other services are switched off

and/or disengaged.

• If the replaced fuse blows again, contact an autho-

rized dealer.

(Continued)

290 IN CASE OF EMERGENCY

Page 310 of 490

WARNING!

Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center where

it can be raised on a lift.

3. Place the wrench on the jack screw and turn to the right until the jack head is properly engaged in the appropri-

ate location. Do not raise the vehicle until you are sure

the jack is securely engaged.

4. Raise the vehicle by turning the jack screw to the right, using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the compact spare tire. Minimum tire

lift provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire. 5. Remove the wheel lug nuts. For vehicles with wheel

covers, remove the cover from the wheel by hand by

holding down the wheel and pulling on convenient

features on the cover. Do not pry the wheel cover off.

Then pull the wheel off the hub.

6. Install the compact spare tire. Lightly tighten all the lug nuts until the wheel sits flush onto the hub and there is

no play. The nuts will have to be fully tightened once the

vehicle is lowered. Tightening an improperly seated

wheel under vehicle load can damage the threads, cause

vibration, and undermine safety.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

308 IN CASE OF EMERGENCY

Page 313 of 490

WARNING!

Verify that both retainer tabs of the wheel spacer have

been properly extended through the center of the

wheel and compact spare tire/cover assembly. Failure

to properly engage both retainer tabs could result in

loss of the compact spare tire and cover assembly,

which will cause vehicle damage and may cause loss of

vehicle control and serious personal injury.

CAUTION!

The compact spare tire/cover assembly must be used

when the compact spare tire is stored. Failure to use

this cover could drastically reduce the life of the

compact spare tire.

4. Using the winch T-handle, rotate the drive nut to the right until the compact spare tire/cover assembly is

drawn into place against the underside of the vehicle. 5. Continue to rotate the nut to the right until you hear the

winch mechanism click three times. It cannot be over-

tightened. Check under the vehicle to ensure the com-

pact spare tire/cover assembly is positioned correctly

against the underside of the vehicle.

CAUTION!

The winch mechanism is designed specifically to stow

a compact spare tire only. Do not attempt to use the

winch to stow the full size deflated tire, or any other

full-size tire, as the tire may not be held securely.

Vehicle damage may result.

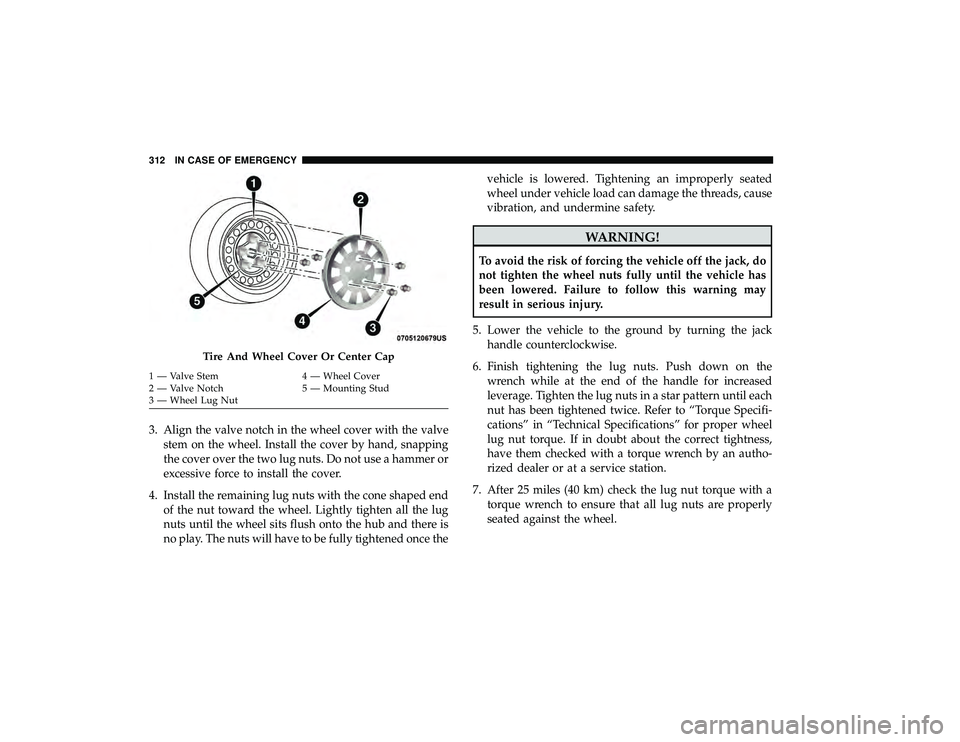

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels withwheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut toward

the wheel. Lightly tighten the lug nuts.

7

IN CASE OF EMERGENCY 311

Page 314 of 490

3. Align the valve notch in the wheel cover with the valvestem on the wheel. Install the cover by hand, snapping

the cover over the two lug nuts. Do not use a hammer or

excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten all the lug

nuts until the wheel sits flush onto the hub and there is

no play. The nuts will have to be fully tightened once the vehicle is lowered. Tightening an improperly seated

wheel under vehicle load can damage the threads, cause

vibration, and undermine safety.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. Refer to “Torque Specifi-

cations” in “Technical Specifications” for proper wheel

lug nut torque. If in doubt about the correct tightness,

have them checked with a torque wrench by an autho-

rized dealer or at a service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut 312 IN CASE OF EMERGENCY

Page 315 of 490

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped endof the nut toward the wheel. Lightly tighten all the lug

nuts until the wheel sits flush onto the hub and there is

no play. The nuts will have to be fully tightened once the

vehicle is lowered. Tightening an improperly seated

wheel under vehicle load can damage the threads, cause

vibration, and undermine safety.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise. 4. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. Refer to “Torque Specifi-

cations” in the “Technical Specifications” section for

proper wheel lug nut torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.TIRE SERVICE KIT — IF EQUIPPED

Your vehicle may be equipped with a Tire Service Kit.

Small punctures up to 1/4 inch (6 mm) in the tire tread can

be sealed with Tire Service Kit. Foreign objects (e.g., screws

or nails) should not be removed from the tire. Tire Service

Kit can be used in outside temperatures down to approxi-

mately -4°F (-20°C). This kit will provide a temporary tire

seal, allowing you to drive your vehicle up to 100 miles

(160 km) with a maximum speed of 50 mph (80 km/h).

7

IN CASE OF EMERGENCY 313