technical specifications DODGE GRAND CARAVAN 2020 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2020Pages: 380, PDF Size: 14.92 MB

Page 3 of 380

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

10

11

1 INTRODUCTION .............................................................................................................................. 7

2 GETTING TO KNOW YOUR VEHICLE ................................................................................... 9

3 GETTING TO KNOW YOUR INSTRUMENT PANEL ........................................................82

4 SAFETY .........................................................................................................................................103 5 STARTING AND OPERATING ............................................................................................... 162

6 IN CASE OF EMERGENCY .....................................................................................................194 7 SERVICING AND MAINTENANCE ...................................................................................... 226

8 TECHNICAL SPECIFICATIONS ............................................................................................ 266

9 MULTIMEDIA .............................................................................................................................. 275

10 CUSTOMER ASSISTANCE .....................................................................................................364

11 INDEX ............................................................................................................................................. 368

20_RT_OM_EN_USC_t.book Page 1

Page 7 of 380

5

SERVICING AND MAINTENANCE

SCHEDULED SERVICING .................................. 226Maintenance Plan......................................227

ENGINE COMPARTMENT .................................. 231

Engine Compartment — 3.6L ....................231

Checking Oil Level......................................232

Adding Washer Fluid .................................232

Maintenance-Free Battery .......................232

Pressure Washing ......................................233

DEALER SERVICE .............................................. 233

Engine Oil .................................................. 233Engine Oil Filter ..........................................234Engine Air Cleaner Filter ...........................235

Air Conditioner Maintenance ...................235Accessory Drive Belt Inspection................236Body Lubrication ........................................237

Windshield Wiper Blades ..........................238

Exhaust System ........................................238

Cooling System ..........................................239Brake System ............................................242

Automatic Transmission ............................243

RAISING THE VEHICLE ...................................... 244

TIRES ................................................................... 245

Tire Safety Information .............................245Tires — General Information .....................252Tire Types ...................................................256

Spare Tires — If Equipped .........................257

Wheel And Wheel Trim Care ....................259

Tire Chains and Traction Devices ............260

Tire Rotation Recommendations .............261 DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES .................. 261

Treadwear .................................................. 261

Traction Grades ......................................... 261

Temperature Grades ................................. 262

VEHICLE STORAGE .............................................262

BODYWORK ........................................................ 262

Protection From Atmospheric Agents....... 262

Body And Underbody Maintenance .......... 263Preserving The Bodywork .......................... 263

INTERIORS ......................................................... 264

Seats And Fabric Parts .............................. 264

Plastic And Coated Parts ........................... 264

Glass Surfaces .......................................... 265Cleaning The Instrument Panel

Cupholders ................................................. 265

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA .......................................266

Vehicle Identification Number .................. 266

BRAKE SYSTEM .................................................. 266

WHEEL AND TIRE TORQUE

SPECIFICATIONS ................................................ 266

Torque Specifications ................................ 266

FUEL REQUIREMENTS ......................................267

3.6L Engine ................................................ 267

Reformulated Gasoline ............................ 268

Materials Added To Fuel ........................... 268

Gasoline/Oxygenate Blends ..................... 268 Do Not Use E-85 In Non-Flex Fuel

Vehicles ...................................................... 269 CNG And LP Fuel System

Modifications ............................................. 269 MMT In Gasoline........................................ 269

Fuel System Cautions................................ 270

Carbon Monoxide Warnings...................... 270

FLUID CAPACITIES ............................................ 271

FLUIDS AND LUBRICANTS ................................ 272

Engine ........................................................ 272

Chassis ....................................................... 274

MULTIMEDIA

CYBERSECURITY ............................................... 275

SAFETY AND GENERAL INFORMATION .......... 276Safety Guidelines....................................... 276

RADIO 430/430 NAV........................................ 277

General Handling....................................... 277

Getting Started .......................................... 279

Radio Mode ................................................ 281

Media Mode ............................................... 286

Remote Devices......................................... 299Uconnect Phone— If Equipped ................. 304

Navigation — If Equipped .......................... 317

STEERING WHEEL AUDIO CONTROLS — IF

EQUIPPED .......................................................... 340

Radio Operation......................................... 340CD Player.................................................... 340

20_RT_OM_EN_USC_t.book Page 5

Page 59 of 380

GETTING TO KNOW YOUR VEHICLE57

3. When the system is set up for your comfort

level, it is not necessary to change the

settings. You will experience the greatest

efficiency by simply allowing the system to

function automatically.

NOTE:

It is not necessary to move the temperature

settings for cold or hot vehicles. The system

automatically adjusts the temperature,

mode, and blower speed to provide comfort

as quickly as possible.

The temperature can be displayed in U.S. or

Metric units by selecting the U.S./Metric

customer programmable feature. To provide

you with maximum comfort in the Automatic

mode during cold start-ups, the blower fan

will remain on low until the engine warms up.

The blower will increase in speed and transi -

tion into AUTO mode.

Manual Operation Override

This system offers a full complement of manual

override features. The AUTO symbol in the front

ATC display will be turned off when the system

is being used in the manual mode.

Operating Tips

NOTE:

Refer to the chart at the end of this section for

suggested control settings for various weather

conditions.

Summer Operation

The engine cooling system must be protected

with a high-quality antifreeze coolant to provide

proper corrosion protection and to protect

against engine overheating. OAT coolant

(conforming to MS.90032) is recommended.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for proper coolant selection.

Winter Operation

To ensure the best possible heater and

defroster performance, make sure the engine

cooling system is functioning properly and the

proper amount, type, and concentration of

coolant is used. Refer to “Fluids And

Lubricants” in “Technical Specifications” for

proper coolant selection. Use of the air Recircu -

lation mode during Winter months is not

recommended, because it may cause window

fogging.

Vacation/Storage

Before you store your vehicle, or keep it out of

service (i.e., vacation) for two weeks or more,

run the air conditioning system at idle for about

five minutes, in fresh air with the blower setting

on high. This will ensure adequate system

lubrication to minimize the possibility of

compressor damage when the system is started

again.

2

20_RT_OM_EN_USC_t.book Page 57

Page 175 of 380

STARTING AND OPERATING173

Power Steering Fluid Check

Checking the power steering fluid level at a

defined service interval is not required. The fluid

should only be checked if a leak is suspected,

abnormal noises are apparent, and/or the

system is not functioning as anticipated.

Coordinate inspection efforts through an

authorized dealer. If necessary, add fluid to restore to the proper

indicated level. With a clean cloth, wipe any

spilled fluid from all surfaces. Refer to “Fluids

And Lubricants” in “Technical Specifications”

for the correct fluid type.

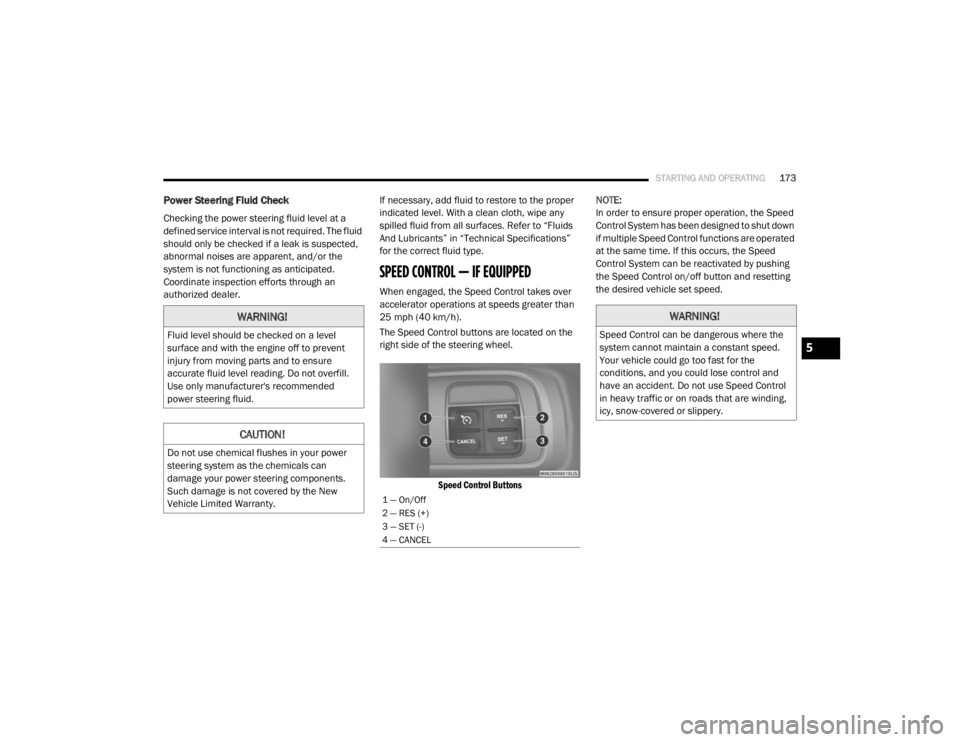

SPEED CONTROL — IF EQUIPPED

When engaged, the Speed Control takes over

accelerator operations at speeds greater than

25 mph (40 km/h).

The Speed Control buttons are located on the

right side of the steering wheel.

Speed Control Buttons

NOTE:

In order to ensure proper operation, the Speed

Control System has been designed to shut down

if multiple Speed Control functions are operated

at the same time. If this occurs, the Speed

Control System can be reactivated by pushing

the Speed Control on/off button and resetting

the desired vehicle set speed.

WARNING!

Fluid level should be checked on a level

surface and with the engine off to prevent

injury from moving parts and to ensure

accurate fluid level reading. Do not overfill.

Use only manufacturer's recommended

power steering fluid.

CAUTION!

Do not use chemical flushes in your power

steering system as the chemicals can

damage your power steering components.

Such damage is not covered by the New

Vehicle Limited Warranty.

1 — On/Off

2 — RES (+)

3 — SET (-)

4 — CANCEL

WARNING!

Speed Control can be dangerous where the

system cannot maintain a constant speed.

Your vehicle could go too fast for the

conditions, and you could lose control and

have an accident. Do not use Speed Control

in heavy traffic or on roads that are winding,

icy, snow-covered or slippery.

5

20_RT_OM_EN_USC_t.book Page 173

Page 211 of 380

IN CASE OF EMERGENCY209

5. Remove the wheel lug nuts. For vehicles

with wheel covers, remove the cover from

the wheel by hand by holding down the

wheel and pulling on convenient features

on the cover. Do not pry the wheel cover off.

Then pull the wheel off the hub.

6. Install the compact spare tire. Lightly tighten all the lug nuts until the wheel sits

flush onto the hub and there is no play. The

nuts will have to be fully tightened once the

vehicle is lowered. Tightening an improperly

seated wheel under vehicle load can

damage the threads, cause vibration, and

undermine safety.

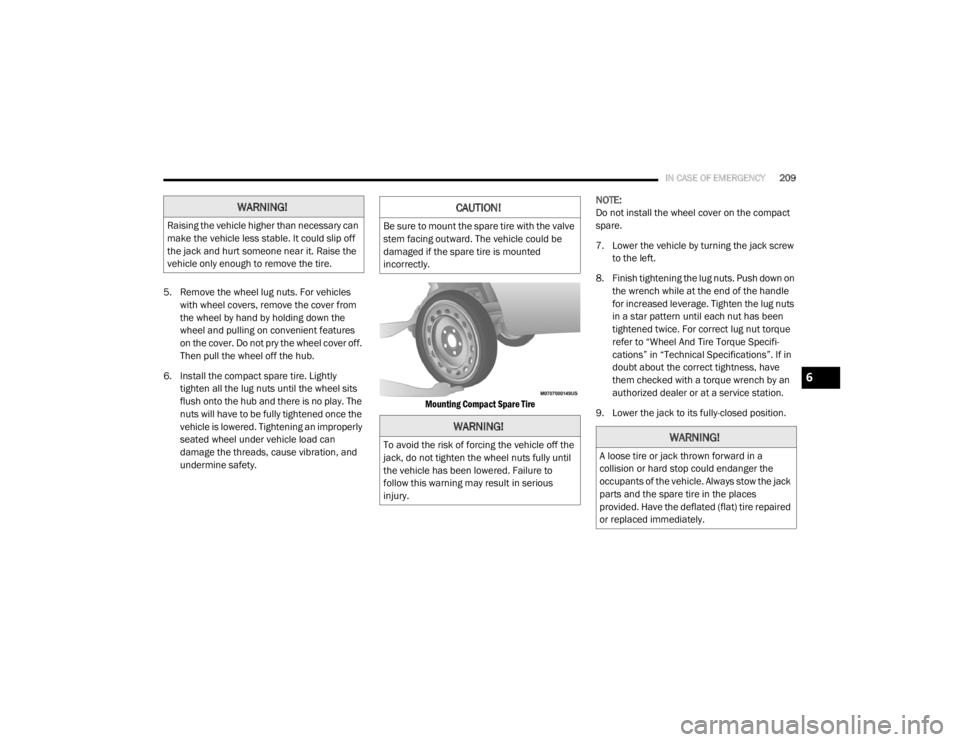

Mounting Compact Spare Tire

NOTE:

Do not install the wheel cover on the compact

spare.

7. Lower the vehicle by turning the jack screw

to the left.

8. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. For correct lug nut torque

refer to “Wheel And Tire Torque Specifi -

cations” in “Technical Specifications”. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or at a service station.

9. Lower the jack to its fully-closed position.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted

incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

6

20_RT_OM_EN_USC_t.book Page 209

Page 214 of 380

212IN CASE OF EMERGENCY

6. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Wheel And Tire

Torque Specifications” in “Technical

Specifications” for proper wheel lug nut

torque. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten all the lug nuts until the

wheel sits flush onto the hub and there is no

play. The nuts will have to be fully tightened

once the vehicle is lowered. Tightening an

improperly seated wheel under vehicle load

can damage the threads, cause vibration,

and undermine safety. 3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Wheel And Tire

Torque Specifications” in the “Technical

Specifications” section for proper wheel lug

nut torque. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

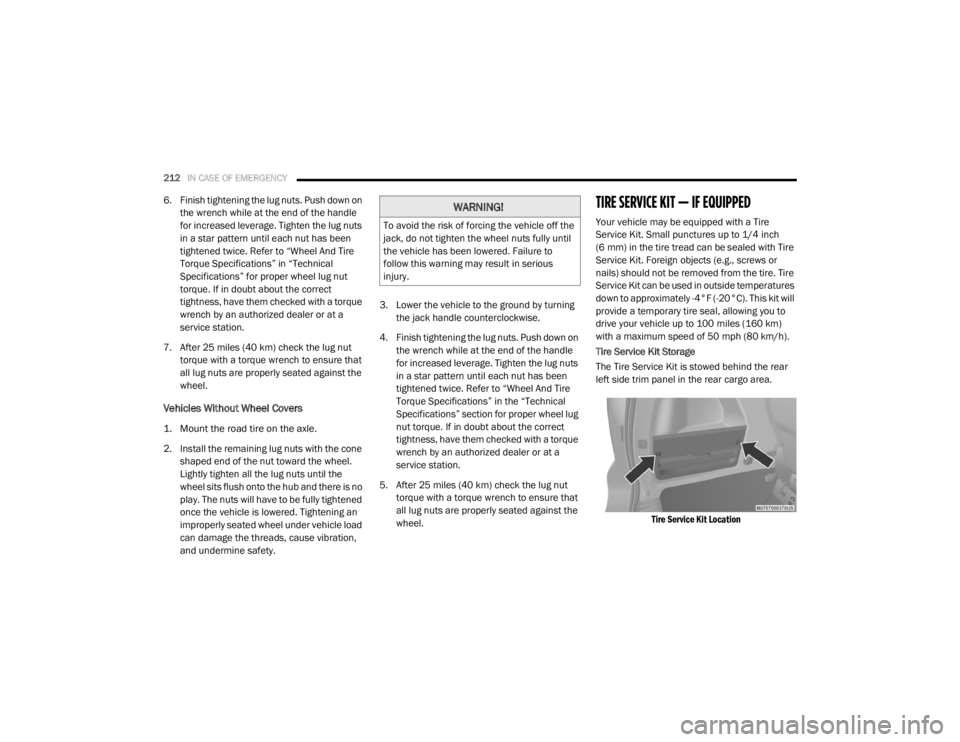

TIRE SERVICE KIT — IF EQUIPPED

Your vehicle may be equipped with a Tire

Service Kit. Small punctures up to 1/4 inch

(6 mm) in the tire tread can be sealed with Tire

Service Kit. Foreign objects (e.g., screws or

nails) should not be removed from the tire. Tire

Service Kit can be used in outside temperatures

down to approximately -4°F (-20°C). This kit will

provide a temporary tire seal, allowing you to

drive your vehicle up to 100 miles (160 km)

with a maximum speed of 50 mph (80 km/h).

Tire Service Kit Storage

The Tire Service Kit is stowed behind the rear

left side trim panel in the rear cargo area.

Tire Service Kit Location

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

20_RT_OM_EN_USC_t.book Page 212

Page 242 of 380

240SERVICING AND MAINTENANCE

Engine Coolant Checks

Check the engine coolant (antifreeze)

protection every 12 months (before the onset of

freezing weather, where applicable). If the

engine coolant (antifreeze) is dirty, the system

should be drained, flushed, and refilled with

fresh OAT coolant (conforming to MS.90032) by

an authorized dealer. Check the front of the

A/C condenser for any accumulation of bugs,

leaves, etc. If dirty, clean by gently spraying

water from a garden hose vertically down the

face of the condenser.

Check the engine cooling system hoses for

brittle rubber, cracking, tears, cuts, and

tightness of the connection at the coolant

recovery bottle and radiator. Inspect the entire

system for leaks. DO NOT REMOVE THE

COOLANT PRESSURE CAP WHEN THE COOLING

SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system please contact an authorized

dealer. If the engine coolant (antifreeze) is dirty or

contains visible sediment, have an authorized

dealer clean and flush with OAT coolant

(antifreeze) (conforming to MS.90032).

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

NOTE:

Mixing of engine coolant (antifreeze) other

than specified Organic Additive Technology

(OAT) engine coolant (antifreeze), may result

in engine damage and may decrease corro

-

sion protection. Organic Additive Technology

(OAT) engine coolant is different and should

not be mixed with Hybrid Organic Additive

Technology (HOAT) engine coolant (anti -

freeze) or any “globally compatible” coolant

(antifreeze). If a non-OAT engine coolant

(antifreeze) is introduced into the cooling

system in an emergency, the cooling system

will need to be drained, flushed, and refilled

with fresh OAT coolant (conforming to

MS.90032), by an authorized dealer as soon

as possible.

Do not use water alone or alcohol-based

engine coolant (antifreeze) products. Do not

use additional rust inhibitors or antirust prod -

ucts, as they may not be compatible with the

radiator engine coolant and may plug the

radiator.

This vehicle has not been designed for use

with propylene glycol-based engine coolant

(antifreeze). Use of propylene glycolbased

engine coolant (antifreeze) is not

recommended.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added

to the system please contact an authorized

dealer.

Adding Coolant

Your vehicle has been built with an improved

engine coolant (OAT coolant conforming to

MS.90032) that allows extended maintenance

intervals. This engine coolant (antifreeze) can

be used up to ten years or 150,000 miles

(240,000 km) before replacement.

20_RT_OM_EN_USC_t.book Page 240

Page 245 of 380

SERVICING AND MAINTENANCE243

(Continued)

Master Cylinder — Brake Fluid Level Check

The fluid level in the master cylinder should be

checked when performing underhood services,

or immediately if the “Brake System Warning

Light” indicates system failure.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up

to the top of the “FULL” mark on the side of the

master cylinder reservoir.

Overfilling of fluid is not recommended because

it may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear.

However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer's recommended brake

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid.

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

20_RT_OM_EN_USC_t.book Page 243

Page 246 of 380

244SERVICING AND MAINTENANCE

Special Additives

The manufacturer strongly recommends

against using any special additives in the

transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supplemental

additives. Therefore, do not add any fluid

additives to the transmission. The only

exception to this policy is the use of special dyes

for diagnosing fluid leaks. Avoid using

transmission sealers as they may adversely

affect seals.

Fluid Level Check

The fluid level is preset at the factory and does

not require adjustment under normal operating

conditions. Routine fluid level checks are not

required, therefore the transmission fill tube is

capped and no dipstick is provided. An

authorized dealer can check your transmission

fluid level using a special service dipstick. If you

notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an

improper fluid level can cause severe

transmission damage.

Fluid And Filter Changes

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

In addition, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if

the transmission is disassembled for any

reason.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder, and

will require more frequent fluid and filter

changes. Refer to “Fluids And Lubricants” in

“Technical Specifications” for fluid

specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An

authorized dealer has the proper tools to

adjust the fluid level accurately.

20_RT_OM_EN_USC_t.book Page 244

Page 268 of 380

266

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

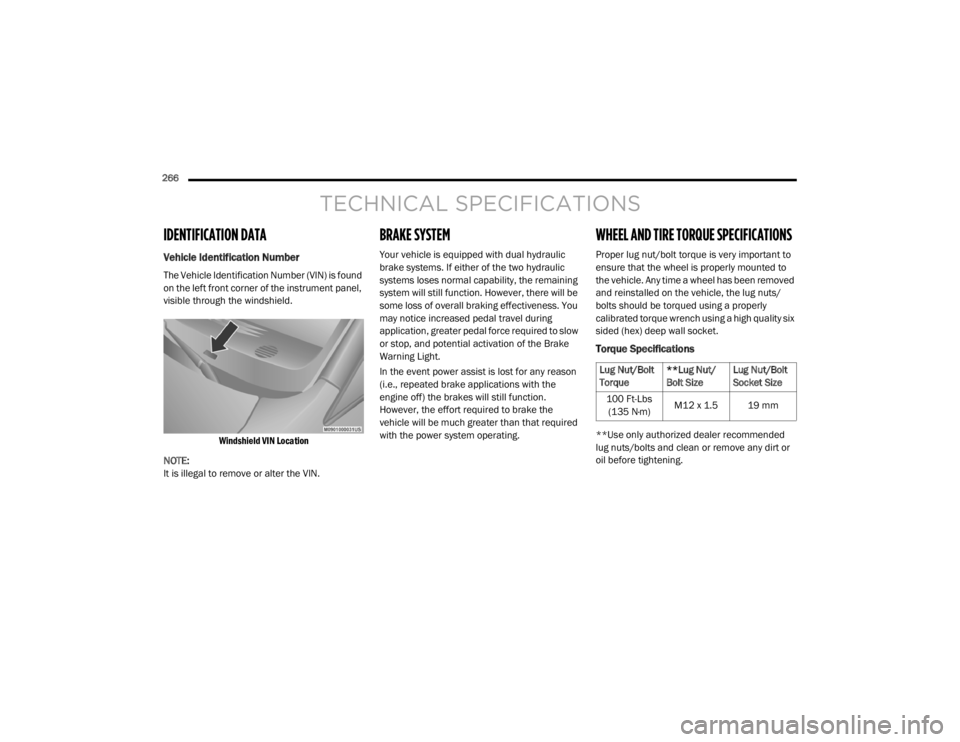

Vehicle Identification Number

The Vehicle Identification Number (VIN) is found

on the left front corner of the instrument panel,

visible through the windshield.

Windshield VIN Location

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems loses normal capability, the remaining

system will still function. However, there will be

some loss of overall braking effectiveness. You

may notice increased pedal travel during

application, greater pedal force required to slow

or stop, and potential activation of the Brake

Warning Light.

In the event power assist is lost for any reason

(i.e., repeated brake applications with the

engine off) the brakes will still function.

However, the effort required to brake the

vehicle will be much greater than that required

with the power system operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

Torque Specifications

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs (135 N·m) M12 x 1.5 19 mm

20_RT_OM_EN_USC_t.book Page 266