clock DODGE HORNET 2023 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: HORNET, Model: DODGE HORNET 2023Pages: 288, PDF Size: 14.2 MB

Page 24 of 288

22GETTING TO KNOW YOUR VEHICLE

(Continued)

DOORS

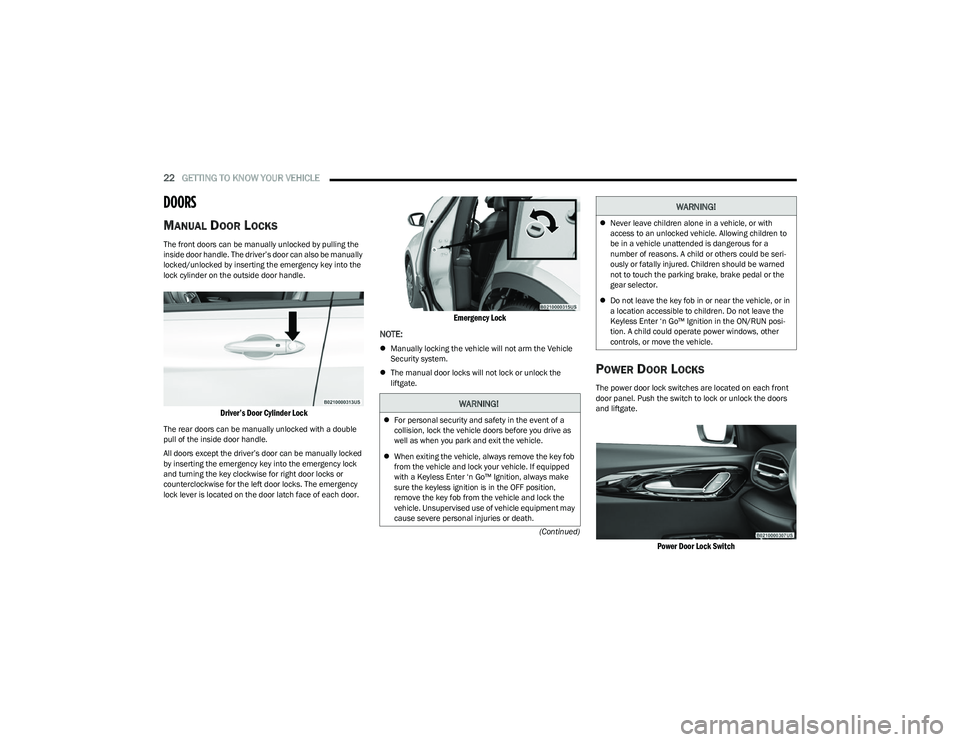

MANUAL DOOR LOCKS

The front doors can be manually unlocked by pulling the

inside door handle. The driver’s door can also be manually

locked/unlocked by inserting the emergency key into the

lock cylinder on the outside door handle.

Driver’s Door Cylinder Lock

The rear doors can be manually unlocked with a double

pull of the inside door handle.

All doors except the driver’s door can be manually locked

by inserting the emergency key into the emergency lock

and turning the key clockwise for right door locks or

counterclockwise for the left door locks. The emergency

lock lever is located on the door latch face of each door.

Emergency Lock

NOTE:

Manually locking the vehicle will not arm the Vehicle

Security system.

The manual door locks will not lock or unlock the

liftgate.

POWER DOOR LOCKS

The power door lock switches are located on each front

door panel. Push the switch to lock or unlock the doors

and liftgate.

Power Door Lock Switch

WARNING!

For personal security and safety in the event of a

collision, lock the vehicle doors before you drive as

well as when you park and exit the vehicle.

When exiting the vehicle, always remove the key fob

from the vehicle and lock your vehicle. If equipped

with a Keyless Enter ‘n Go™ Ignition, always make

sure the keyless ignition is in the OFF position,

remove the key fob from the vehicle and lock the

vehicle. Unsupervised use of vehicle equipment may

cause severe personal injuries or death.

Never leave children alone in a vehicle, or with

access to an unlocked vehicle. Allowing children to

be in a vehicle unattended is dangerous for a

number of reasons. A child or others could be seri -

ously or fatally injured. Children should be warned

not to touch the parking brake, brake pedal or the

gear selector.

Do not leave the key fob in or near the vehicle, or in

a location accessible to children. Do not leave the

Keyless Enter ‘n Go™ Ignition in the ON/RUN posi -

tion. A child could operate power windows, other

controls, or move the vehicle.

WARNING!

23_GG_OM_EN_USC_t.book Page 22

Page 42 of 288

40GETTING TO KNOW YOUR VEHICLE

EXTERIOR LIGHTS

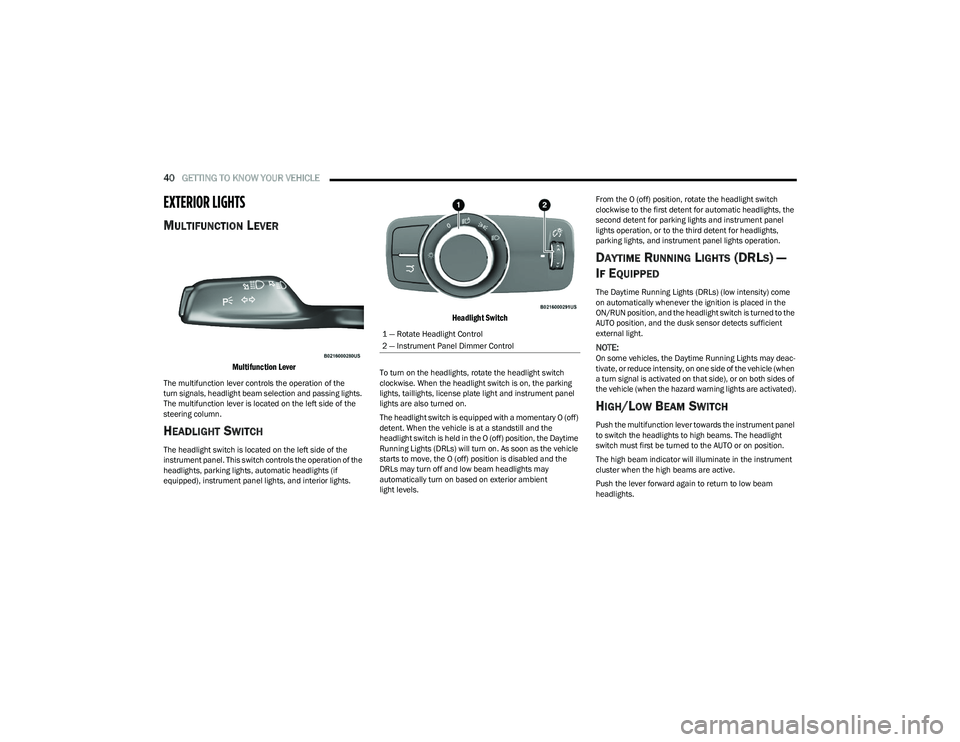

MULTIFUNCTION LEVER

Multifunction Lever

The multifunction lever controls the operation of the

turn signals, headlight beam selection and passing lights.

The multifunction lever is located on the left side of the

steering column.

HEADLIGHT SWITCH

The headlight switch is located on the left side of the

instrument panel. This switch controls the operation of the

headlights, parking lights, automatic headlights (if

equipped), instrument panel lights, and interior lights.

Headlight Switch

To turn on the headlights, rotate the headlight switch

clockwise. When the headlight switch is on, the parking

lights, taillights, license plate light and instrument panel

lights are also turned on.

The headlight switch is equipped with a momentary O (off)

detent. When the vehicle is at a standstill and the

headlight switch is held in the O (off) position, the Daytime

Running Lights (DRLs) will turn on. As soon as the vehicle

starts to move, the O (off) position is disabled and the

DRLs may turn off and low beam headlights may

automatically turn on based on exterior ambient

light levels. From the O (off) position, rotate the headlight switch

clockwise to the first detent for automatic headlights, the

second detent for parking lights and instrument panel

lights operation, or to the third detent for headlights,

parking lights, and instrument panel lights operation.

DAYTIME RUNNING LIGHTS (DRLS) —

I

F EQUIPPED

The Daytime Running Lights (DRLs) (low intensity) come

on automatically whenever the ignition is placed in the

ON/RUN position, and the headlight switch is turned to the

AUTO position, and the dusk sensor detects sufficient

external light.

NOTE:On some vehicles, the Daytime Running Lights may deac -

tivate, or reduce intensity, on one side of the vehicle (when

a turn signal is activated on that side), or on both sides of

the vehicle (when the hazard warning lights are activated).

HIGH/LOW BEAM SWITCH

Push the multifunction lever towards the instrument panel

to switch the headlights to high beams. The headlight

switch must first be turned to the AUTO or on position.

The high beam indicator will illuminate in the instrument

cluster when the high beams are active.

Push the lever forward again to return to low beam

headlights.

1 — Rotate Headlight Control

2 — Instrument Panel Dimmer Control

23_GG_OM_EN_USC_t.book Page 40

Page 43 of 288

GETTING TO KNOW YOUR VEHICLE41

AUTOMATIC HIGH BEAM HEADLAMP

C

ONTROL — IF EQUIPPED

The Automatic High Beam Headlamp Control system

provides increased forward lighting at night by automating

high beam control through the use of a digital camera

mounted on the windshield. This camera detects vehicle

specific light and automatically switches from high beams

to low beams until the approaching vehicle is out of view.

NOTE:

The Automatic High Beam Headlamp Control can be

turned on or off through Uconnect Settings.

This function can only be activated with the headlight

switch in the AUTO position.

Broken, muddy, or obstructed headlights and taillights

of vehicles in the field of view will cause headlights to

remain on longer (closer to the vehicle). Also, dirt, film,

and other obstructions on the windshield or camera

lens will cause the system to function improperly.

FLASH-TO-PASS

You can signal another vehicle with your headlights by

lightly pulling the multifunction lever toward you. This will

cause the high beam headlights to turn on, and remain on,

until the lever is released.

AUTOMATIC HEADLIGHTS — IF EQUIPPED

This system automatically turns the headlights

on or off according to ambient light levels. To

turn the system on, rotate the headlight switch

clockwise to the AUTO position.

When the system is on, the headlight time delay feature is

also on. This means the headlights will stay on for up to

90 seconds after you place the ignition into the OFF

position. To turn the automatic system off, move the

headlight switch out of the AUTO position.

NOTE:The engine must be running before the headlights will

come on in the automatic mode.

HEADLIGHTS ON AUTOMATICALLY WITH

W

IPERS — IF EQUIPPED

If your vehicle is equipped with Automatic Headlights, it

also has this customer-programmable feature. When your

headlights are in the automatic mode and the engine is

running, they will automatically turn on when the wiper

system is on. This feature is programmable through the

Uconnect system.

NOTE:When your headlights come on during the daytime, the

vehicle will monitor outside brightness and decide if the

instrument panel needs to be dimmed.

HEADLIGHT DELAY

To aid in your exit, your vehicle is equipped with a

headlight delay that will leave the headlights on for

approximately 90 seconds. This delay is initiated when the

ignition is placed in the OFF position while the headlight

switch is on, and then the headlight switch is cycled off.

Headlight delay can be canceled by either turning the

headlight switch on then off, or by placing the ignition in

the ON/RUN position.

NOTE:The headlight delay time is programmable through

Uconnect Settings Úpage 130.

LIGHTS-ON REMINDER

If the headlights or parking lights are on after the ignition

is in the OFF position, a chime will sound to alert the driver

when the driver's door is opened.

CORNERING LIGHTS — IF EQUIPPED

The cornering lights are a feature to improve visibility at

night while turning the vehicle. When activated, a light

incorporated in the headlight assembly will illuminate on

the side of the vehicle the steering wheel is rotated, or that

the turn signal indicator is on. It can be activated through

the Uconnect system

Úpage 130.

2

23_GG_OM_EN_USC_t.book Page 41

Page 139 of 288

MULTIMEDIA137

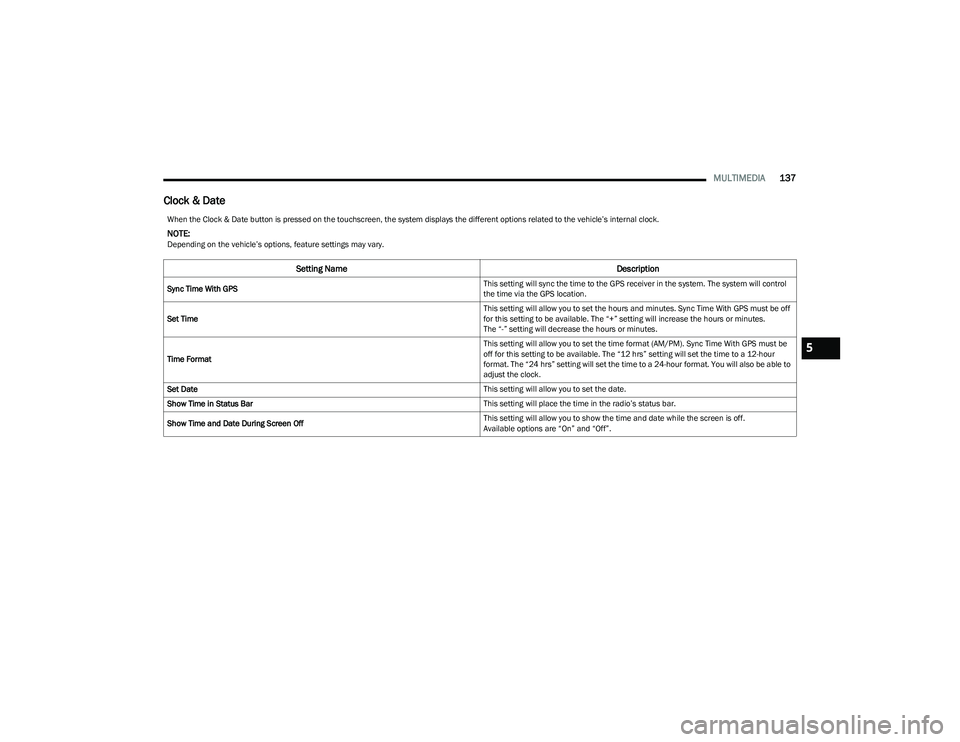

Clock & Date

When the Clock & Date button is pressed on the touchscreen, the system displays the different options related to the vehicle’s internal clock.

NOTE:Depending on the vehicle’s options, feature settings may vary.

Setting Name Description

Sync Time With GPS This setting will sync the time to the GPS receiver in the system. The system will control

the time via the GPS location.

Set Time This setting will allow you to set the hours and minutes. Sync Time With GPS must be off

for this setting to be available. The “+” setting will increase the hours or minutes.

The “-” setting will decrease the hours or minutes.

Time Format This setting will allow you to set the time format (AM/PM). Sync Time With GPS must be

off for this setting to be available. The “12 hrs” setting will set the time to a 12-hour

format. The “24 hrs” setting will set the time to a 24-hour format. You will also be able to

adjust the clock.

Set Date This setting will allow you to set the date.

Show Time in Status Bar This setting will place the time in the radio’s status bar.

Show Time and Date During Screen Off This setting will allow you to show the time and date while the screen is off.

Available options are “On” and “Off”.

5

23_GG_OM_EN_USC_t.book Page 137

Page 209 of 288

IN CASE OF EMERGENCY207

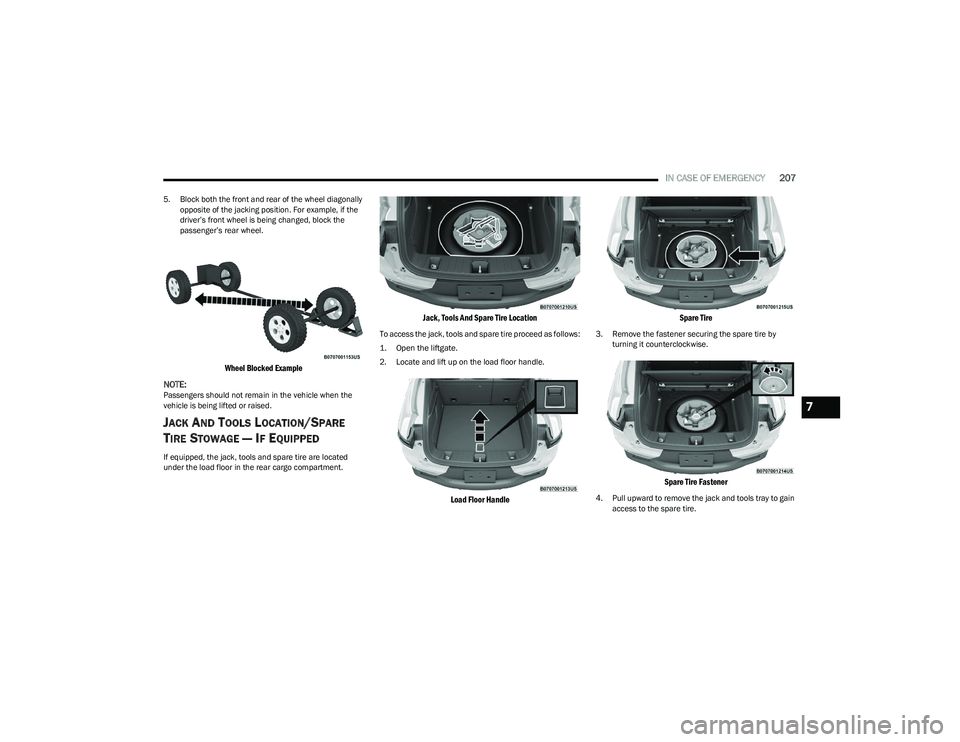

5. Block both the front and rear of the wheel diagonally

opposite of the jacking position. For example, if the

driver’s front wheel is being changed, block the

passenger’s rear wheel.

Wheel Blocked Example

NOTE:

Passengers should not remain in the vehicle when the

vehicle is being lifted or raised.

JACK AND TOOLS LOCATION/SPARE

T

IRE STOWAGE — IF EQUIPPED

If equipped, the jack, tools and spare tire are located

under the load floor in the rear cargo compartment.

Jack, Tools And Spare Tire Location

To access the jack, tools and spare tire proceed as follows:

1. Open the liftgate.

2. Locate and lift up on the load floor handle.

Load Floor Handle Spare Tire

3. Remove the fastener securing the spare tire by

turning it counterclockwise.

Spare Tire Fastener

4. Pull upward to remove the jack and tools tray to gain access to the spare tire.

7

23_GG_OM_EN_USC_t.book Page 207

Page 211 of 288

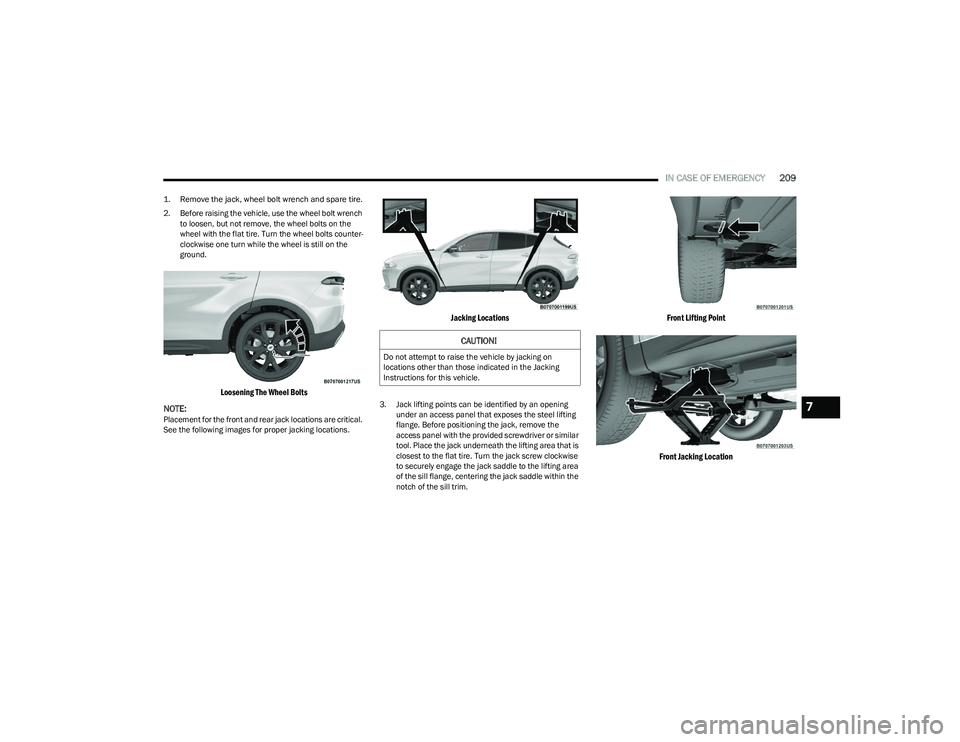

IN CASE OF EMERGENCY209

1. Remove the jack, wheel bolt wrench and spare tire.

2. Before raising the vehicle, use the wheel bolt wrench

to loosen, but not remove, the wheel bolts on the

wheel with the flat tire. Turn the wheel bolts counter -

clockwise one turn while the wheel is still on the

ground.

Loosening The Wheel Bolts

NOTE:

Placement for the front and rear jack locations are critical.

See the following images for proper jacking locations.

Jacking Locations

3. Jack lifting points can be identified by an opening under an access panel that exposes the steel lifting

flange. Before positioning the jack, remove the

access panel with the provided screwdriver or similar

tool. Place the jack underneath the lifting area that is

closest to the flat tire. Turn the jack screw clockwise

to securely engage the jack saddle to the lifting area

of the sill flange, centering the jack saddle within the

notch of the sill trim.

Front Lifting Point

Front Jacking Location

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

7

23_GG_OM_EN_USC_t.book Page 209

Page 212 of 288

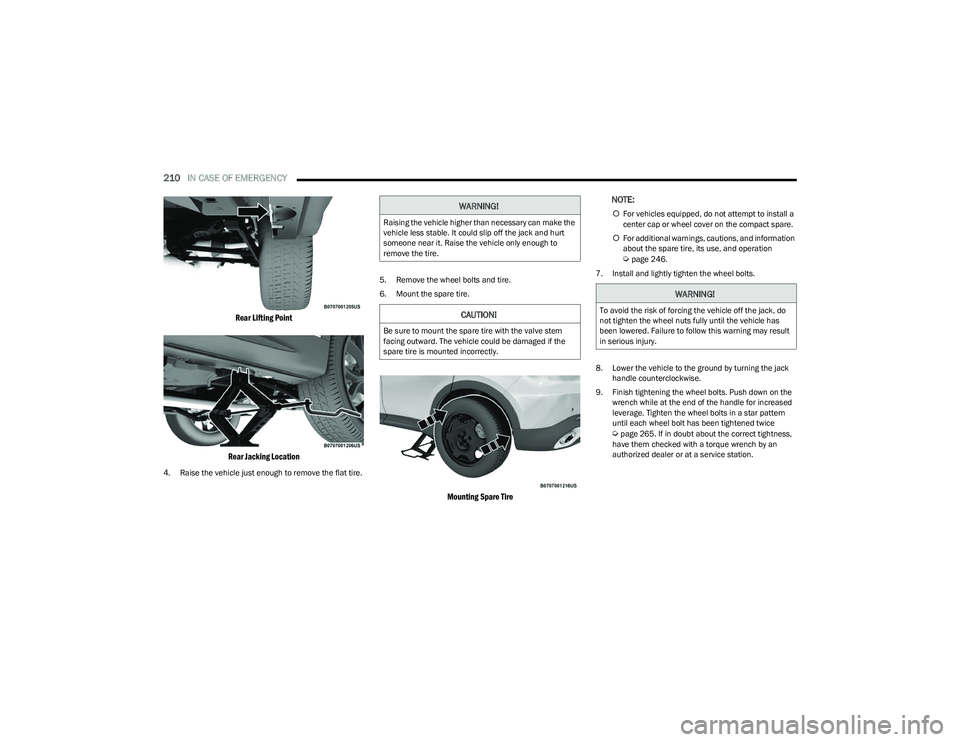

210IN CASE OF EMERGENCY

Rear Lifting Point

Rear Jacking Location

4. Raise the vehicle just enough to remove the flat tire. 5. Remove the wheel bolts and tire.

6. Mount the spare tire.

Mounting Spare Tire

NOTE:

For vehicles equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

For additional warnings, cautions, and information

about the spare tire, its use, and operation

Úpage 246.

7. Install and lightly tighten the wheel bolts.

8. Lower the vehicle to the ground by turning the jack handle counterclockwise.

9. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice

Úpage 265. If in doubt about the correct tightness,

have them checked with a torque wrench by an

authorized dealer or at a service station.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may result

in serious injury.

23_GG_OM_EN_USC_t.book Page 210

Page 241 of 288

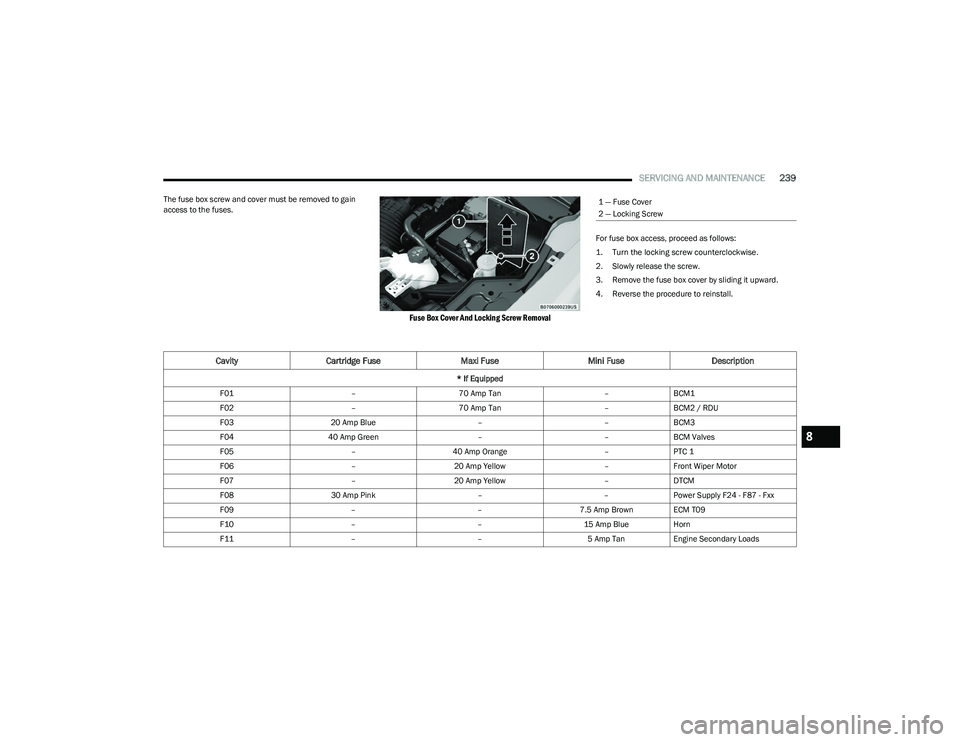

SERVICING AND MAINTENANCE239

The fuse box screw and cover must be removed to gain

access to the fuses.

Fuse Box Cover And Locking Screw Removal

For fuse box access, proceed as follows:

1. Turn the locking screw counterclockwise.

2. Slowly release the screw.

3. Remove the fuse box cover by sliding it upward.

4. Reverse the procedure to reinstall.

1 — Fuse Cover

2 — Locking Screw

CavityCartridge Fuse Maxi FuseMini FuseDescription

* If Equipped

F01 –70 Amp Tan –BCM1

F02 –70 Amp Tan –BCM2 / RDU

F03 20 Amp Blue ––BCM3

F04 40 Amp Green ––BCM Valves

F05 –40 Amp Orange –PTC 1

F06 –20 Amp Yellow –Front Wiper Motor

F07 –20 Amp Yellow –DTCM

F08 30 Amp Pink ––Power Supply F24 - F87 - Fxx

F09 ––7.5 Amp Brown ECM T09

F10 ––15 Amp BlueHorn

F11 ––5 Amp TanEngine Secondary Loads

8

23_GG_OM_EN_USC_t.book Page 239