torque DODGE JOURNEY 2015 1.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2015, Model line: JOURNEY, Model: DODGE JOURNEY 2015 1.GPages: 140, PDF Size: 23.09 MB

Page 99 of 140

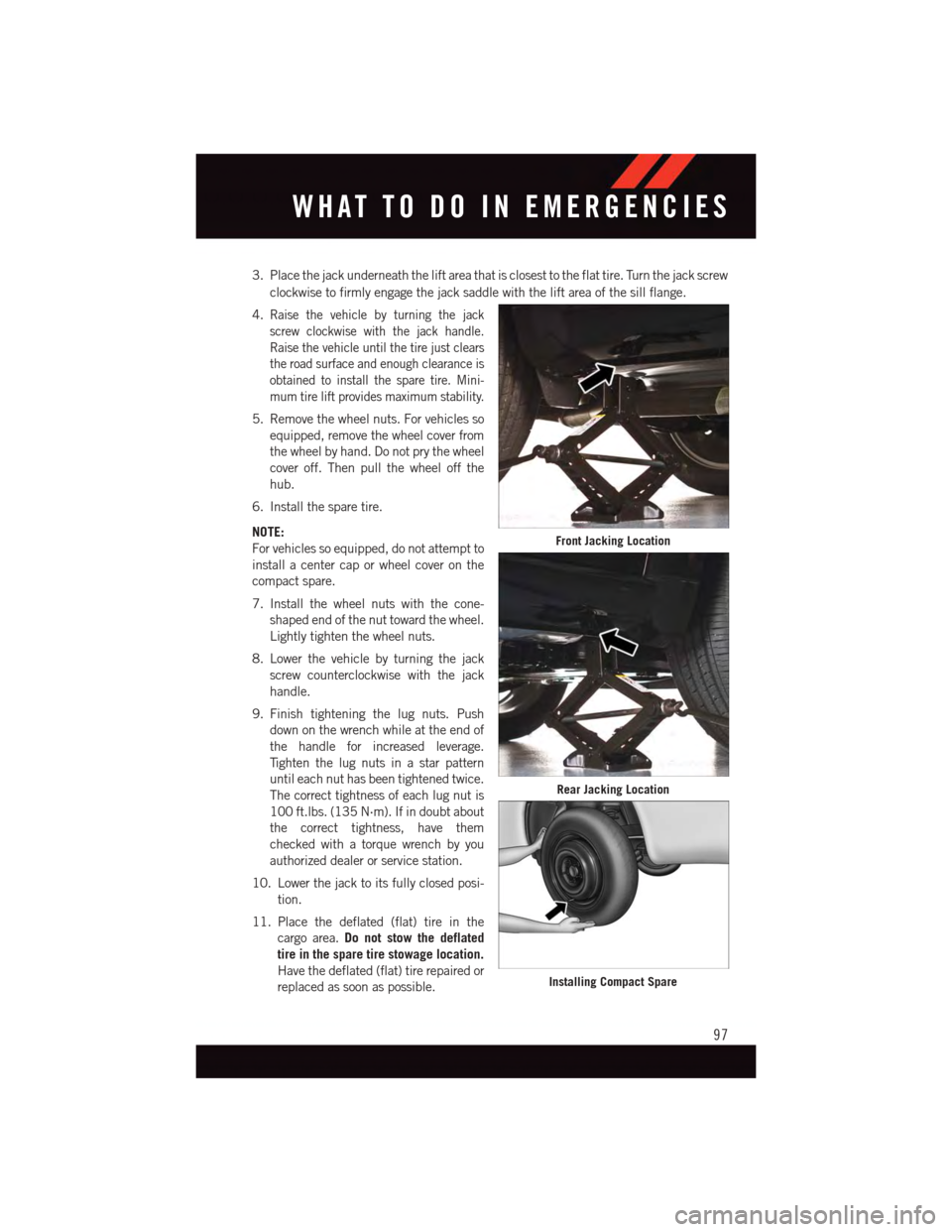

3. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw

clockwise to firmly engage the jack saddle with the lift area of the sill flange.

4.Raise the vehicle by turning the jack

screw clockwise with the jack handle.

Raise the vehicle until the tire just clears

the road surface and enough clearance is

obtained to install the spare tire. Mini-

mum tire lift provides maximum stability.

5. Remove the wheel nuts. For vehicles so

equipped, remove the wheel cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the

hub.

6. Install the spare tire.

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

7. Install the wheel nuts with the cone-

shaped end of the nut toward the wheel.

Lightly tighten the wheel nuts.

8. Lower the vehicle by turning the jack

screw counterclockwise with the jack

handle.

9. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e l u g n u t s i n a s t a r p a t t e r n

until each nut has been tightened twice.

The correct tightness of each lug nut is

100 ft.lbs. (135 N·m). If in doubt about

the correct tightness, have them

checked with a torque wrench by you

authorized dealer or service station.

10. Lower the jack to its fully closed posi-

tion.

11. Place the deflated (flat) tire in the

cargo area.Do not stow the deflated

tire in the spare tire stowage location.

Have the deflated (flat) tire repaired or

replaced as soon as possible.

Front Jacking Location

Rear Jacking Location

Installing Compact Spare

WHAT TO DO IN EMERGENCIES

97

Page 100 of 140

12. To stow the winch cable and retainer, fit the assembled jack-handle over the winch

drive nut. Rotate the jack-handle assembly clockwise until you hear the winch

mechanism click three times. It cannot be over tightened.

13. Stow the jack-handle and jack.

14. Check the tire pressure as soon as possible. Adjust the tire pressure as required.

Road Tire Installation

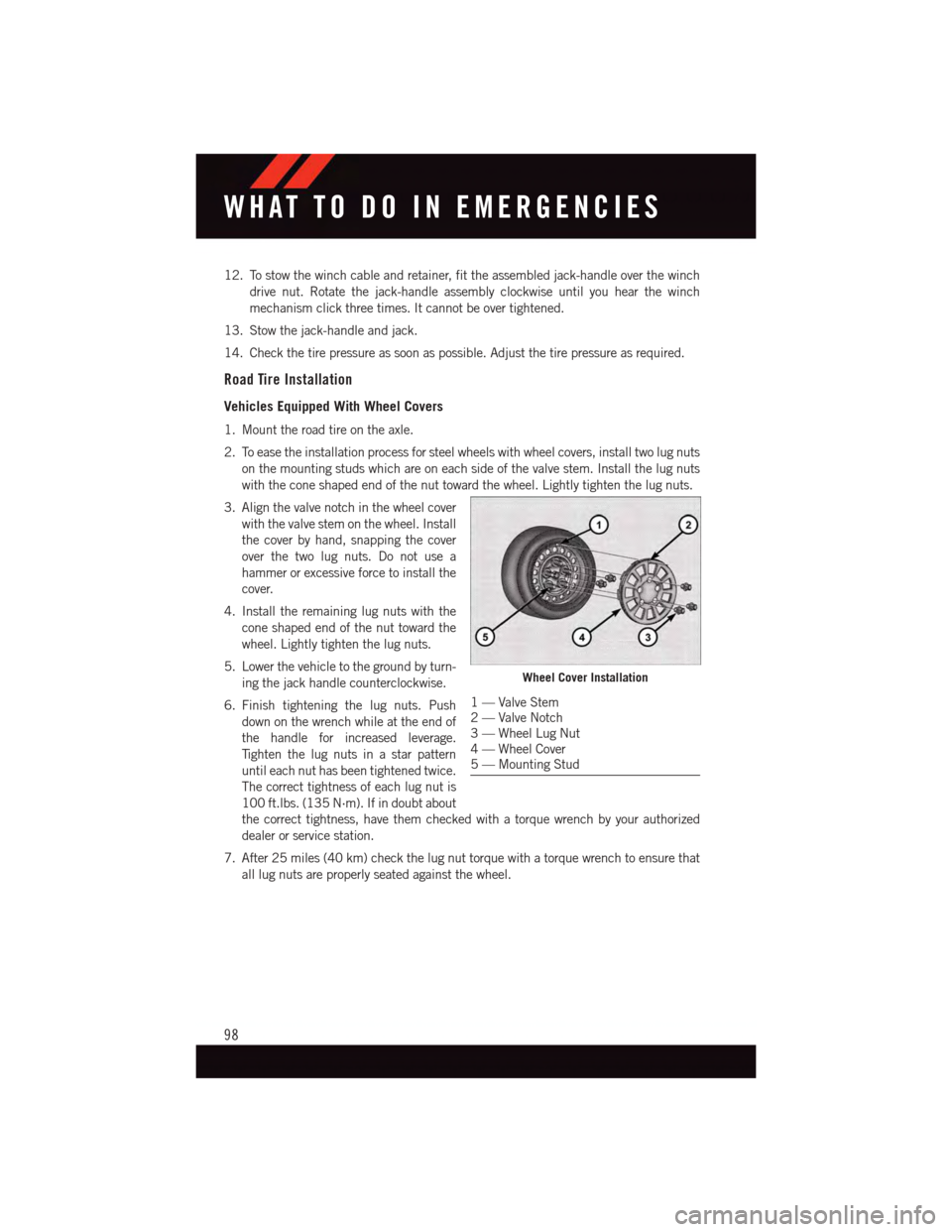

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts

on the mounting studs which are on each side of the valve stem. Install the lug nuts

with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Align the valve notch in the wheel cover

with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two lug nuts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e l u g n u t s i n a s t a r p a t t e r n

until each nut has been tightened twice.

The correct tightness of each lug nut is

100 ft.lbs. (135 N·m). If in doubt about

the correct tightness, have them checked with a torque wrench by your authorized

dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the wheel.

Wheel Cover Installation

1—ValveStem2—ValveNotch3—WheelLugNut4—WheelCover5—MountingStud

WHAT TO DO IN EMERGENCIES

98

Page 101 of 140

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts in a star pattern until each nut has been

tightened twice. The correct tightness of each lug nut is 100 ft.lbs. (135 N·m). If in

doubt about the correct tightness, have them checked with a torque wrench by your

authorized dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the wheel.

CAUTION!

•Thewinchmechanismisdesignedforusewiththejack-handleonly.Useofanair

wrench or other power tools is not recommended and they can damage the winch.•Donotattempttoraisethevehiclebyjackingonlocationsotherthanthose

indicated in the Jacking Instructions for this vehicle.

•Besuretomountthesparetirewiththevalvestemfacingoutward.Thevehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

99