check engine DODGE JOURNEY 2020 Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: JOURNEY, Model: DODGE JOURNEY 2020Pages: 396, PDF Size: 25.53 MB

Page 218 of 396

216

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

i n

dicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the

oil change indicator message will illuminate.

This means that service is required for your

v e

hicle. Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E-85 fuel usage will

influence when the “Change Oil” or “Oil Change

Required” message is displayed. Severe

operating conditions can cause the change oil

message to illuminate as early as 3,500 miles

(5,600 km) since last reset. Have your vehicle

s e

rviced as soon as possible, within the next

500 miles (805 km).

An authorized dealer will reset the oil change

i

n

dicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset

by referring to the steps described under

“ I

nstrument Cluster Display” in “Getting To

Know Your Instrument Panel” for further

information.

NOTE:

Under no circumstances should oil change

i n

tervals exceed 10,000 miles (16,000 km),

1 2

months or 350 hours of engine run time,

w h

ichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change engine oil at 4,000 miles (6,500 km) or

3 5

0 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering, and

transmission (4-speed only) and fill as

needed.

Check function of all interior and exterior

lights.

Page 223 of 396

SERVICING AND MAINTENANCE 221

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine

oil must be maintained at the correct level.

Check the oil level at regular intervals, such as

every fuel stop. The best time to check the

engine oil level is about five minutes after a fully

warmed engine is shut off. Checking engine oil

level when the engine is cold will give you an

incorrect reading.

Checking the oil while the vehicle is on level

gr

ound and only when the engine is hot, will

improve the accuracy of the oil level readings.

Maintain the oil level between the range

markings on the dipstick. Either the range

markings consist of a crosshatch zone marked

SAFE or a crosshatch zone marked with MIN at

the low end of the range and MAX at the high

end of the range. Adding 1 Quart (1 Liter) of oil

when the reading is at the low end of the range

marking will raise the oil level to the high end of

the range marking.

ADDING WASHER FLUID

The windshield washer and the rear window

washer share the same fluid reservoir. The fluid

reservoir is located in the engine compartment.

Be sure to check the fluid level in the reservoir

at regular intervals. Fill the reservoir with

windshield washer solvent (not radiator

antifreeze) and operate the system for a few

seconds to flush out the residual water.

When refilling the washer fluid reservoir, apply

s o

me washer fluid to a cloth or towel and wipe

the wiper blades clean. This will help blade

performance.

To prevent freeze-up of your windshield washer

s y

stem in cold weather, select a solution or

mixture that meets or exceeds the temperature

range of your climate. This rating information

can be found on most washer fluid containers. The fluid reservoir will hold nearly 1 Gallon

(4 Liters) of washer fluid when the message

“ Lo

WASH” appears in the instrument cluster.

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free

battery. You will never have to add water, nor is

periodic maintenance required.

NOTE:

The battery is stored in a compartment that is

lo

cated behind the left front fender and is

accessible through the wheel well. The wheel

and tire assembly do not need to be removed to

access the compartment. Remote battery termi -

nals are located in the engine compartment for

j u

mp starting. Refer to “Jump Starting Proce -

dure” in “In Case Of Emergency” for further

i n

formation.

CAUTION!

Do not overfill the engine with oil. Overfilling

the engine with oil will cause oil aeration,

which can lead to loss of oil pressure and an

increase in oil temperature. This loss of oil

pressure and increased oil temperature could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling

or working around the washer solution.

7

Page 226 of 396

224 SERVICING AND MAINTENANCE

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used

engine oil and oil filters from your vehicle.

Used oil and oil filters, indiscriminately

d i

scarded, can present a problem to the

environment. Contact an authorized dealer,

service station or governmental agency for

advice on how and where used oil and oil filters

can be safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a

new filter at every engine oil change.

Engine Oil Filter Selection

This manufacturer's engines have a full-flow

ty

pe disposable oil filter. Use a filter of this type

for replacement. The quality of replacement

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine oil filters are high quality

oil filters and are recommended.

ENGINE AIR CLEANER FILTER

Refer to the “Maintenance Plan” in “Servicing

and Maintenance” for the proper maintenance

intervals.

NOTE:

Be sure to follow the “Severe Duty Conditions”

ma

intenance interval if applicable.

Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner

f i

lters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine air cleaner filters are a

high quality filter and are recommended.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air

conditioner should be checked and serviced by

an authorized dealer at the start of each warm

season. This service should include cleaning of

the condenser fins and a performance test.

Drive belt tension should also be checked at

this time.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in the

case of engine backfire. Do not remove the air

induction system (air cleaner, hoses, etc.)

unless such removal is necessary for repair or

maintenance. Make sure that no one is near

the engine compartment before starting the

vehicle with the air induction system (air

cleaner, hoses, etc.) removed. Failure to do so

can result in serious personal injury.

WARNING!

Use only refrigerants and compressor lubri -

cants approved by the manufacturer for

y o

ur air conditioning system. Some unap -

proved refrigerants are flammable and can

e x

plode, injuring you. Other unapproved

refrigerants or lubricants can cause the

system to fail, requiring costly repairs.

Refer to Warranty Information Book, for

further warranty information.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

p e

rsonal injury or damage to the system,

adding refrigerant or any repair requiring

lines to be disconnected should be done by

an experienced technician.

Page 230 of 396

228 SERVICING AND MAINTENANCE

(Continued)

Under normal operating conditions, the catalytic

converter will not require maintenance. However,

it is important to keep the engine properly tuned

to ensure proper catalyst operation and prevent

possible catalyst damage.

NOTE:

Intentional tampering with emissions control

s y

stems can result in civil penalties being

assessed against you.

In unusual situations involving grossly

m a

lfunctioning engine operation, a scorching odor

may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn off

the engine and allow it to cool. Service, including a

tune-up to manufacturer's specifications, should be

obtained immediately.

To minimize the possibility of catalytic converter

d a

mage:

Do not interrupt the ignition when the trans -

mission is in gear and the vehicle is in

m o

tion.

Do not try to start the vehicle by pushing or

towing the vehicle.

Do not idle the engine with any ignition

components disconnected or removed, such

as when diagnostic testing, or for prolonged

periods during very rough idle or malfunc -

tioning operating conditions.

COOLING SYSTEM

Coolant Checks

Check the engine coolant (antifreeze) protection

every 12 months (before the onset of freezing

w e

ather, where applicable). If the engine coolant

(antifreeze) is dirty or rusty in appearance, the

system should be drained, flushed, and refilled

with fresh engine coolant (antifreeze). Check the

front of the A/C condenser for any accumulation

of bugs, leaves, etc. If dirty, clean by gently

spraying water from a garden hose vertically

down the face of the condenser.

Check the coolant recovery bottle tubing for

b r

ittle rubber, cracking, tears, cuts, and

tightness of the connection at the bottle and

radiator. Inspect the entire system for leaks.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from your

radiator. If you see or hear steam coming from

under the hood, do not open the hood until the

radiator has had time to cool. Never open a

cooling system pressure cap when the radiator

or coolant bottle is hot.

Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts automati -

cally and may start at any time, whether the

e n

gine is running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the

ignition to the OFF mode. The fan is

temperature controlled and can start at any

time the ignition is in the ON mode.

WARNING!

The warning words “DO NOT OPEN HOT” on

the cooling system pressure cap are a

safety precaution. Never add engine

coolant (antifreeze) when the engine is

overheated. Do not loosen or remove the

cap to cool an overheated engine. Heat

causes pressure to build up in the cooling

system. To prevent scalding or injury, do not

remove the pressure cap while the system

is hot or under pressure.

Page 232 of 396

230 SERVICING AND MAINTENANCE

Please review these recommendations for

using Organic Additive Technology (OAT)

engine coolant (antifreeze) that meets the

r e

quirements of FCA Material Standard

MS.90032. When adding engine coolant

(antifreeze):

We recommend using Mopar Antifreeze/

Coolant 10 Year/150,000 Mile (240,000 km)

F o

rmula OAT (Organic Additive Technology)

that meets the requirements of FCA Material

Standard MS.90032.

Mix a minimum solution of 50% OAT engine

coolant that meets the requirements of FCA

Material Standard MS.90032 and distilled

water. Use higher concentrations (not to

exceed 70%) if temperatures below −34°F

(−37°C) are anticipated. Please contact an

authorized dealer for assistance.

Use only high purity water such as distilled or

deionized water when mixing the water/

engine coolant (antifreeze) solution. The use

of lower quality water will reduce the amount

of corrosion protection in the engine cooling

system. NOTE:

It is the owner's responsibility to maintain the

proper level of protection against freezing

according to the temperatures occurring in

the area where the vehicle is operated.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added

to the system, please contact a local autho

-

rized dealer.

Mixing engine coolant (antifreeze) types is

not recommended and can result in cooling

system damage. If HOAT and OAT coolant are

mixed in an emergency, have a authorized

dealer drain, flush, and refill with OAT coolant

(conforming to MS.90032) as soon as

possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss

of engine coolant (antifreeze), and to ensure

that engine coolant (antifreeze) will return to

the radiator from the coolant recovery bottle.

The cap should be inspected and cleaned if

t h

ere is any accumulation of foreign material on

the sealing surfaces.

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) is

a regulated substance requiring proper disposal.

Check with your local authorities to determine the

disposal rules for your community. To prevent

ingestion by animals or children, do not store

ethylene glycol-based coolant in open containers

or allow it to remain in puddles on the ground.

If ingested by a child or pet, seek emergency

as

sistance immediately. Clean up any ground

spills immediately.

WARNING!

The warning words “DO NOT OPEN HOT” on

the cooling system pressure cap are a

safety precaution. Never add engine

coolant (antifreeze) when the engine is

overheated. Do not loosen or remove the

cap to cool an overheated engine. Heat

causes pressure to build up in the cooling

system. To prevent scalding or injury, do not

remove the pressure cap while the system

is hot or under pressure.

Do not use a pressure cap other than the

one specified for your vehicle. Personal

injury or engine damage may result.

Page 233 of 396

SERVICING AND MAINTENANCE 231

Coolant Level

The coolant bottle provides a quick visual

method for determining that the coolant level is

adequate. With the engine idling and warm to

normal operating temperature, the level of the

coolant in the bottle should be between the

“ADD” and “FULL” lines, shown on the bottle.

The radiator normally remains completely full,

so

there is no need to remove the radiator cap

unless checking for coolant freeze point or

replacing engine coolant (antifreeze). Advise

your service attendant of this. As long as the

engine operating temperature is satisfactory,

the coolant bottle need only be checked once a

month. When additional engine coolant

(antifreeze) is needed to maintain the proper

level, it should be added to the coolant bottle.

Do not overfill. See “Adding Coolant” in

“Servicing and Maintenance” for further

information.

Points To Remember

NOTE:

When the vehicle is stopped after a few miles/

k i

lometers of operation, you may observe vapor

coming from the front of the engine compart -

ment. This is normally a result of moisture from

r a

in, snow, or high humidity accumulating on

the radiator and being vaporized when the ther -

mostat opens, allowing hot engine coolant (anti -

freeze) to enter the radiator.

If an examination of your engine compartment

s h

ows no evidence of radiator or hose leaks,

the vehicle may be safely driven. The vapor will

soon dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant (antifreeze) needs to be added, the

contents of the coolant expansion bottle

must also be protected against freezing.

If frequent engine coolant (antifreeze) addi-

tions are required, the cooling system should

b e

pressure tested for leaks.

Maintain engine coolant (antifreeze) concen -

tration at a minimum of 50% OAT coolant

( c

onforming to MS.90032) and distilled water

for proper corrosion protection of your engine

which contains aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther -

mostat. Other designs may result in unsatis -

factory engine coolant (antifreeze)

p e

rformance, poor gas mileage, and

increased emissions.

7

Page 234 of 396

232 SERVICING AND MAINTENANCE

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. Refer to the “Maintenance Plan” in

“Servicing and Maintenance” for the proper

maintenance intervals.

Master Cylinder — Brake Fluid Level Check

Check the fluid level in the master cylinder

immediately if the “Brake Warning Light”

indicates system failure.

Check the fluid level in the master cylinder

wh

en performing underhood services.

Clean the top of the master cylinder area before

r e

moving the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. Overfilling of fluid is not recommended because

i

t

may cause leaking in the system.

Fluid level can be expected to fall as the brake

p a

ds wear. Brake fluid level should be checked

when pads are replaced. However, low fluid

level may be caused by a leak and a checkup

may be needed.

Use only manufacturer's recommended brake

fl

uid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further infor-

mation. Using the wrong type of brake fluid

c a

n severely damage your brake system

and/or impair its performance. The proper

type of brake fluid for your vehicle is also

identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a

open container absorbs moisture from

the air resulting in a lower boiling point.

This may cause it to boil unexpectedly

d u

ring hard or prolonged braking, resulting

in sudden brake failure. This could result in

a collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

Page 235 of 396

SERVICING AND MAINTENANCE 233

AUTOMATIC TRANSMISSION

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid.

NOTE:

No chemical flushes should be used in any

t r

ansmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance

may be impaired by supplemental additives.

T h

erefore, do not add any fluid additives to the

transmission. The only exception to this policy is

the use of special dyes for diagnosing fluid leaks.

Avoid using transmission sealers as they may

adversely affect seals.

Fluid Level Check

Use the following procedure to check the

transmission fluid level properly:

1. P ark the vehicle on level ground.

2

. R un the engine at normal idle speed for at

l

east 60 seconds, and leave the engine

running for the rest of this procedure. 3. F

ully apply the parking brake, and press the

b

rake pedal.

4. P lace the gear selector momentarily into

e

ach gear position (allowing time for the

transmission to fully engage in each

position), ending with the transmission in

PARK.

5. W ipe the area around the dipstick clean to

p

revent dirt from entering the transmission.

6. R emove the dipstick and determine if the

f

luid is hot or cold. You can also read the

transmission fluid temperature using the

instrument cluster. Refer to "Instrument

Cluster Display" in "Getting To Know Your

Instrument Panel" for further information.

Hot fluid is approximately 180°F (82°C),

which is the normal operating temperature

after the vehicle is driven at least 15 miles

( 2

4 km). Hot fluid cannot be held

c o

mfortably between the fingertips. Cold

fluid is at a temperature of approximately

80°F (27°C).

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/

or torque converter shudder, and will require

more frequent fluid and filter changes. Refer to

“Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

7

Page 258 of 396

256

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

VEHICLE IDENTIFICATION NUMBER

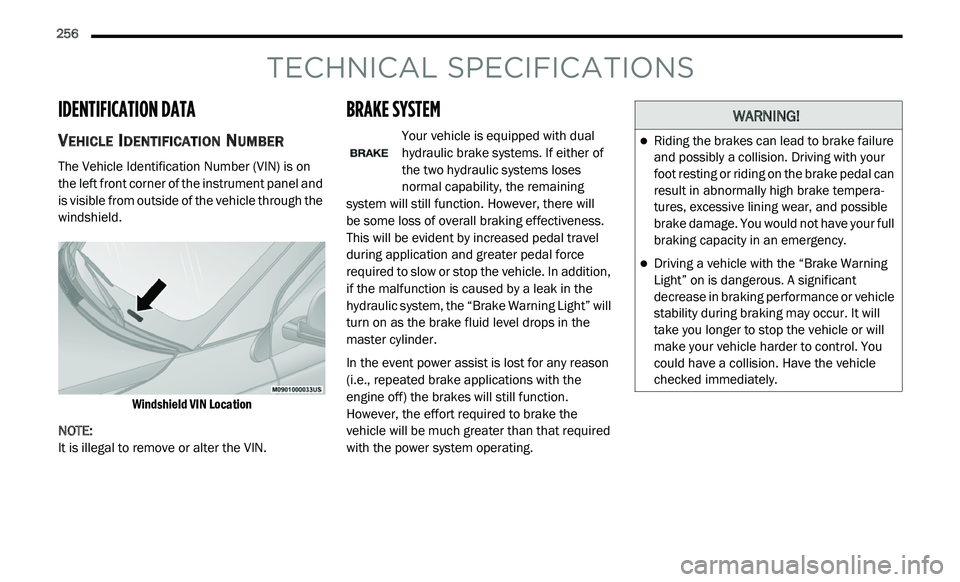

The Vehicle Identification Number (VIN) is on

the left front corner of the instrument panel and

is visible from outside of the vehicle through the

windshield.

Windshield VIN Location

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual

hydraulic brake systems. If either of

t h

e two hydraulic systems loses

normal capability, the remaining

system will still function. However, there will

be some loss of overall braking effectiveness.

T h

is will be evident by increased pedal travel

during application and greater pedal force

required to slow or stop the vehicle. In addition,

if the malfunction is caused by a leak in the

hydraulic system, the “Brake Warning Light” will

turn on as the brake fluid level drops in the

master cylinder.

In the event power assist is lost for any reason

( i

.e., repeated brake applications with the

engine off) the brakes will still function.

However, the effort required to brake the

vehicle will be much greater than that required

with the power system operating.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal can

result in abnormally high brake tempera -

tures, excessive lining wear, and possible

b r

ake damage. You would not have your full

braking capacity in an emergency.

Driving a vehicle with the “Brake Warning

Light” on is dangerous. A significant

decrease in braking performance or vehicle

stability during braking may occur. It will

take you longer to stop the vehicle or will

make your vehicle harder to control. You

could have a collision. Have the vehicle

checked immediately.

Page 259 of 396

TECHNICAL SPECIFICATIONS 257

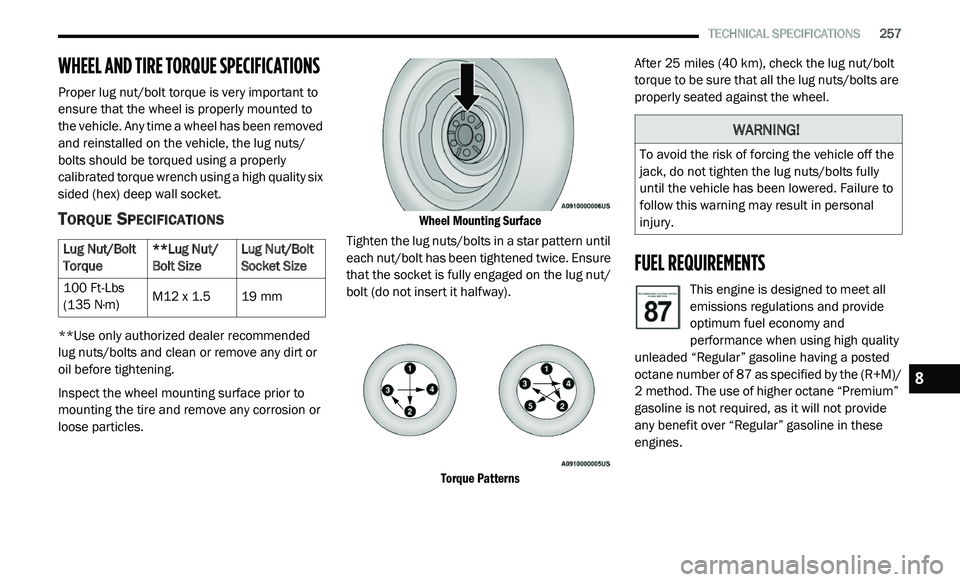

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mo

unting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

ea

ch nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/

bolt (do not insert it halfway).

Torque Patterns

After 25

miles (40 km), check the lug nut/bolt

t o

rque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

FUEL REQUIREMENTS

This engine is designed to meet all

emissions regulations and provide

o p

timum fuel economy and

performance when using high quality

unleaded “Regular” gasoline having a posted

octane number of 87 as specified by the (R+M)/

2 method. The use of higher octane “Premium”

g a

soline is not required, as it will not provide

any benefit over “Regular” gasoline in these

engines.

Lug Nut/Bolt

T

o

rque **Lug Nut/

Bo

lt Size Lug Nut/Bolt

So

cket Size

100 Ft-Lbs

( 1

35 N·m) M12 x 1.5

19 mm

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully

until the vehicle has been lowered. Failure to

follow this warning may result in personal

injury.

8