warning DODGE MAGNUM SRT 2007 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: MAGNUM SRT, Model: DODGE MAGNUM SRT 2007 1.GPages: 380, PDF Size: 6.63 MB

Page 261 of 380

²Month Day and Hour of Manufacture (MDH)

The bar code allows a computer scanner to read the

Vehicle Identification Number (VIN).

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your vehicle.

This includes driver, passengers, and cargo. The total

load must be limited so that you do not exceed the

GVWR.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front and rear

axles. Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either front or

rear GAWR.

WARNING!

Because the front wheels steer the vehicle, it is

important that you do not exceed the maximum front

or rear GAWR. A dangerous driving condition can

result if either rating is exceeded. You could lose

control of the vehicle and have an accident.

Overloading

The load carrying components (axle, springs, tires,

wheels, etc.) of your vehicle will provide satisfactory

service as long as you do not exceed the GVWR and the

front and rear GAWR.

The best way to figure out the total weight of your

vehicle is to weigh it when it is fully loaded and ready for

operation. Weigh it on a commercial scale to insure that it

is not over the GVWR.

Figure out the weight on the front and rear of the vehicle

separately. It is important that you distribute the load

evenly over the front and rear axles.

Overloading can cause potential safety hazards and

shorten useful service life. Heavier axles or suspension

components do not necessarily increase the vehicle's

GVWR.

260 STARTING AND OPERATING

Page 264 of 380

WARNING!

It is important that you do not exceed the maximum

front or rear GAWR. A dangerous driving condition

can result if either rating is exceeded. You could lose

control of the vehicle and have an accident.

Tongue Weight (TW)

Tongue weight (TW) is the downward force exerted on

the hitch ball by the trailer. In most cases it should not be

less than 10% or more than 15% of the trailer load. You

must consider this as part of the load on your vehicle.

Frontal Area

Frontal area is the maximum height and maximum width

of the front of a trailer.

Trailer Sway Control

The trailer sway control is a telescoping link that can be

installed between the hitch receiver and the trailer tongue

that typically provides adjustable friction associated with

the telescoping motion to dampen any unwanted trailer

swaying motions while traveling.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch ball or

some other connecting point of the vehicle. These kinds

of hitches are the most popular on the market today and

they're commonly used to tow small- and medium-sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying lever-

age through spring (load) bars. They are typically used

for heavier loads, to distribute trailer tongue weight to

the tow vehicle's front axle and the trailer axle(s). When

used in accordance with the manufacturers' directions, it

provides for a more level ride, offering more consistent

steering and brake control thereby enhancing towing

safety. The addition of a friction / hydraulic sway control

also dampens sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer stability.

Trailer sway control and a weight distributing (load

equalizing) hitch are recommended for heavier Tongue

Weights (TW) and may be required depending on Vehicle

and Trailer configuration / loading to comply with gross

axle weight rating (GAWR) requirements.

STARTING AND OPERATING 263

5

Page 265 of 380

WARNING!

²An improperly adjusted Weight Distributing

Hitch system may reduce handling, stability,

braking performance, and could result in an acci-

dent.

²Weight Distributing Systems may not be compat-

ible with Surge Brake Couplers. Consult with

your hitch and trailer manufacturer or a reputable

Recreational Vehicle dealer for additional infor-

mation.

Weight Distributing Hitch System

264 STARTING AND OPERATING

Page 269 of 380

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

²When hauling cargo, or towing a trailer, do not

overload your vehicle or trailer. Overloading can cause

a loss of control, poor performance, or damage to

brakes, axle, engine, transmission, steering, suspen-

sion, chassis structure, or tires.

²Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

frame or hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

²Vehicles with trailers should not be parked on a grade.

When parking, apply the parking brake on the tow

vehicle. Put the tow vehicle automatic transmission in

P for Park. Always, block or9chock9the trailer wheels.

²GCWR must not be exceeded.

²Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded:

1. GVWR

2. GTW

3. GAWR

4. Tongue weight rating for the trailer hitch utilized

(This requirement may limit the ability to always

achieve the 10% to 15% range of tongue weight as a

percentage of total trailer weight).

Towing Requirements Ð Tires

þ

Do not attempt to tow a trailer while using a compact

spare tire.

268 STARTING AND OPERATING

Page 271 of 380

WARNING!

Do not connect trailer brakes to your vehicle's hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping dis-

tance. When towing, you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

Towing Requirements Ð Trailer Lights & Wiring

Whenever you pull a trailer, regardless of the trailer size,

stop lights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may includea4and7pin

wiring harness. Use a factory approved trailer harness

and connector.

NOTE:Do not cut or splice wiring into the vehicles

wiring harness.The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following illustrations.

4 - Pin Connector

270 STARTING AND OPERATING

Page 276 of 380

WHAT TO DO IN EMERGENCIES

CONTENTS

mHazard Warning Flasher.................276

mIf Your Engine Overheats................276

mTIREFIT Tire Repair....................277

mJump-Starting Procedures................282

mFreeing A Stuck Vehicle.................285

mTowing A Disabled Vehicle...............286NWithout The Ignition Key...............286

NTowing This Vehicle Behind Another Vehicle

(Flat Towing With All Four Wheels On The

Ground)............................286

NTowing This Vehicle Behind Another Vehicle

With A Tow Dolly.....................287

6

Page 277 of 380

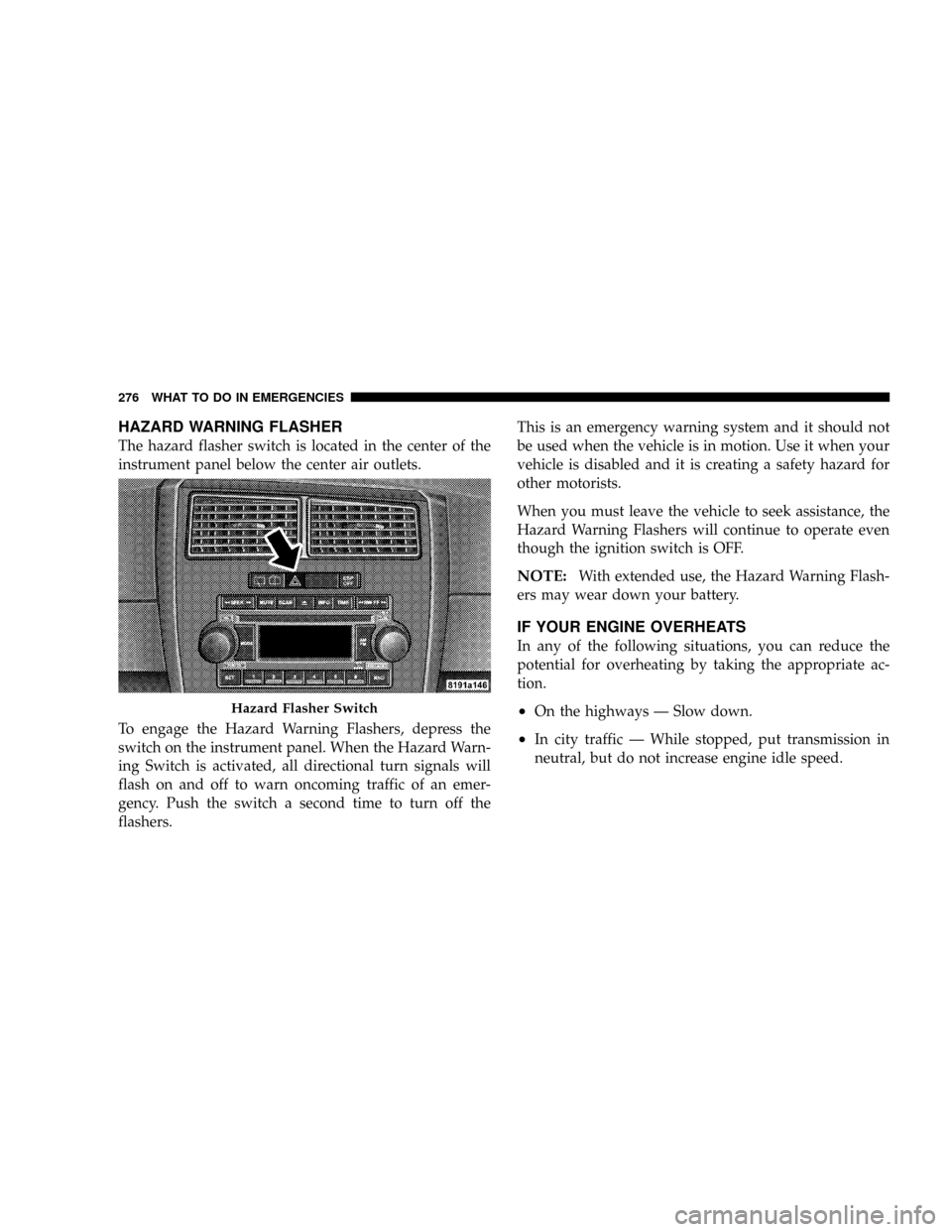

HAZARD WARNING FLASHER

The hazard flasher switch is located in the center of the

instrument panel below the center air outlets.

To engage the Hazard Warning Flashers, depress the

switch on the instrument panel. When the Hazard Warn-

ing Switch is activated, all directional turn signals will

flash on and off to warn oncoming traffic of an emer-

gency. Push the switch a second time to turn off the

flashers.This is an emergency warning system and it should not

be used when the vehicle is in motion. Use it when your

vehicle is disabled and it is creating a safety hazard for

other motorists.

When you must leave the vehicle to seek assistance, the

Hazard Warning Flashers will continue to operate even

though the ignition switch is OFF.

NOTE:With extended use, the Hazard Warning Flash-

ers may wear down your battery.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the

potential for overheating by taking the appropriate ac-

tion.

²On the highways Ð Slow down.

²In city traffic Ð While stopped, put transmission in

neutral, but do not increase engine idle speed.

Hazard Flasher Switch

276 WHAT TO DO IN EMERGENCIES

Page 278 of 380

NOTE:There are steps that you can take to slow down

an impending overheat condition. If your air conditioner

is on, turn it off. The air conditioning system adds heat to

the engine cooling system and turning off the A/C

removes this heat. You can also turn the Temperature

control to maximum heat, the Mode control to floor, and

the fan control to HI. This allows the heater core to act as

a supplement to the radiator and aids in removing heat

from the engine cooling system.

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If temperature gauge reads 240ÉF

(116ÉC) or greater pull over and stop the vehicle. Idle

the vehicle with the air conditioner turned off until

the pointer drops back into the normal range 200±

230ÉF (93±110ÉC). If the pointer remains at 240ÉF

(116ÉC) or greater and you hear a chime, turn the

engine off immediately, and call for service.

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, see Section 7, Maintenance, of this

manual. Follow the warnings under the Cooling

System Pressure Cap paragraph.

TIREFIT TIRE REPAIR

Small punctures, particularly those in the tread, can be

sealed with TIREFIT. Foreign objects (e.g., screws or

nails) should not be removed from the tire. TIREFIT can

be used in outside temperatures down to approximately

-4ÉF (-20ÉC).

The TIREFIT system is located under a hinged access

cover in the load floor in the cargo area.

WHAT TO DO IN EMERGENCIES 277

6

Page 280 of 380

WARNING!

²Do not attempt to repair a tire on the side of the vehicle

close to traffic. Pull far enough off the road to avoid the

danger of being hit when operating the jack or repairing

a tire.

²Cuts or punctures larger than approximately 0.16 in. (4

mm), tire damage caused by driving with extremely low

tire pressure or on a flat tire, or a damaged wheel can

pose a hazard while driving. TIREFIT should not be

used in such circumstances. Do not drive the vehicle

under such circumstances. Contact your nearest autho-

rized dealer for assistance.

²Take care not to allow the contents of TIREFIT to come

in contact with hair, eyes or clothing. TIREFIT is harm-

ful if inhaled, swallowed or absorbed through the skin:

It causes skin, eye and respiratory irritation. Any contact

with eyes or skin should be flushed immediately with

plenty of water. If clothing comes in contact with

TIREFIT, change clothing as soon as possible.

²In case of allergic reaction or rash, consult a physician

immediately. Keep TIREFIT out of reach of children. If

swallowed, rinse mouth immediately with plenty of

water and drink plenty of water. Do not induce vomit-

ing! Consult a physician immediately.

Keep away from open flame or heat source.

Sealing tire with TIREFIT

1. Turn on the hazard warning flashers.

2. Move the transmission selector lever to the PARK

position, turn off the engine, and set the parking brake.

3. Open the hinged cover in the load floor in the cargo

area and remove the TIREFIT kit from its storage bin.

Close the load floor cover.

4. Pull the power plug (2) and the TIREFIT sealant hose

(6) out from the TIREFIT kit.

Hazard Flasher Switch

WHAT TO DO IN EMERGENCIES 279

6

Page 281 of 380

5. Unscrew the valve cap from the valve on the deflated

tire.

6. Screw the fitting at the end of TIREFIT sealant hose (6)

coming from the sealant bottle (5) onto the tire valve.

7. Insert the power plug (2) into the power point on the

instrument panel.

8. Leave the parking brake set and the transmission

selector lever in PARK and start the engine.

9. Press the switch (3) on the air pump to I (ON). The air

pump should start to inflate the tire and the tire sealant

(white fluid) will flow from the sealant bottle (5) through

the TIREFIT sealant hose (6) and into the tire.

10. Allow the air pump to run for five minutes and then

read the pressure gauge (4). If the tire inflates to 26 psi

(1.8 bar) or greater, proceed to Step 19 of this procedure.

If not, proceed to the following step.

11. Press the air pump switch (3) to 0 (OFF). Then,

disconnect the TIREFIT system from the tire and place it

back in the vehicle.12. Release the parking brake and drive the vehicle back

and forth approximately 30 feet (9.1 m) to distribute the

sealant more evenly within the tire.

13. Turn on the hazard warning flashers.

14. Move the transmission selector lever to the PARK

position, turn off the engine, and set the parking brake.

15. Disconnect the air pump hose (1) from the underside

of the sealant bottle (5) by flipping the hose valve open.

16. Connect the air pump hose valve to the tire valve and

flip the hose valve closed.

17. Leave the parking brake set and the transmission

selector lever in PARK and start the engine.

18. Press the switch (3) on the air pump to I (ON). The air

pump should inflate the tire to at least 26 psi (1.8 bar)

within five minutes. If the tire inflates to this level,

proceed to the following step.NOTE:If a tire pressure of

26 psi (1.8 bar) is not obtained within five minutes, the

tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.

280 WHAT TO DO IN EMERGENCIES