engine DODGE MAGNUM SRT 2007 1.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: MAGNUM SRT, Model: DODGE MAGNUM SRT 2007 1.GPages: 380, PDF Size: 6.63 MB

Page 312 of 380

humidity accumulating on the radiator and being vapor-

ized when the thermostat opens, allowing hot coolant to

enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

²Do not overfill the coolant recovery bottle.

²Check coolant freeze point in the radiator and in the

coolant recovery bottle. If antifreeze needs to be

added, contents of coolant recovery bottle must also be

protected against freezing.

²If frequent coolant additions are required, or if the

level in the coolant recovery bottle does not drop when

the engine cools, the cooling system should be pres-

sure tested for leaks.

²Maintain coolant concentration at 50% HOAT engine

coolant (minimum) and distilled water for proper

corrosion protection of your engine, which contains

aluminum components.

²Make sure that the radiator and coolant recovery

bottle overflow hoses are not kinked or obstructed.

²Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean, also.

²Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor gas

mileage, and increased emissions.

Hoses and Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not come in contact with any

heat source or moving component, which may cause heat

damage or mechanical wear.

MAINTAINING YOUR VEHICLE 311

7

Page 314 of 380

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:

²

Often, fluid such as oil, power steering fluid, and

brake fluid are used during assembly plant operations

to facilitate the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping

of hot fluid when systems are under pressure (during

vehicle operation), should be noted before a hose is

replaced based on leakage.

²Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replaced

immediately! Eventual deterioration of the hose can

take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder - Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the brake system warning light indicates system fail-

ure.

Check the fluid level in the master cylinder when per-

forming underhood services.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

ªFULLº mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

MAINTAINING YOUR VEHICLE 313

7

Page 315 of 380

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid. Re-

fer to ªFluids, Lubricants, and Genuine Partsº for the

correct fluid type.

WARNING!

²Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

²Use of a brake fluid that has a lower initial boiling

point than the recommended MOPARtDOT 3

product or a brake fluid that is unidentified as to

FMVSS specification may result in sudden brake

failure during hard prolonged braking. You could

have an accident.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter or

moisture.

CAUTION!

Do not allow petroleum base fluid to contaminate

the brake fluid, all brake seal components could be

damaged causing partial or complete brake failure.

Automatic Transmission

Fluid Level Check

Regular automatic transmission fluid level checks are not

required. For this reason, the dipstick is omitted.

If you notice fluid loss or gear shift malfunction, have

your authorized dealer check the transmission fluid level.

314 MAINTAINING YOUR VEHICLE

Page 316 of 380

CAUTION!

²Using a transmission fluid other than the manu-

facturer's recommended fluid may cause deterio-

ration in transmission shift quality and/or torque

converter shudder. Using a transmission fluid

other than that recommended by the manufac-

turer will result in more frequent fluid and filter

changes. Refer to ªFluids, Lubricants, and Genu-

ine Partsº for the correct fluid type.

²The fluid level is preset at the factory and it does

not require adjustment under normal operating

conditions. If a transmission fluid leak occurs,

visit your authorized dealer immediately. Severe

damage to the transmission may occur. Your au-

thorized dealer has the proper tools to adjust the

fluid level accurately.

Fluid and Filter Changes

Automatic transmission fluid and filter should be

changed as follows:

Normal Usage Ð No change necessarySevere Usage (fluid and filter) Ð Refer to Maintenance

Schedule ªBº

Severe Usage is defined as:

²Police, taxi, limousine, commercial type operation, or

trailer towing where the vehicle is drivenregularlyfor

more than 45 minutes of continuous operation.

If the transmission is disassembled for any reason, the

fluid and filter should be changed.

Special Additives

Automatic Transmission Fluid (ATF) is an engineered

product and its performance may be impaired by supple-

mental additives. Therefore, do not add any fluid addi-

tives to the transmission. The only exception to this

policy is the use of special dyes to aid in detecting fluid

leaks. In addition, avoid using transmission sealers as

they may adversely affect seals.

Front and Rear Wheel Bearings

Front and rear wheel bearings are permanently sealed.

No regular maintenance is required for these compo-

nents.

MAINTAINING YOUR VEHICLE 315

7

Page 321 of 380

²Carefully tuck the front, followed by the rear, then side

edges of the cup holder into the center console.

FUSES (POWER DISTRIBUTION CENTERS)

Fuses (Front Power Distribution Center)

A power distribution center is located in the engine

compartment. This center contains fuses and relays.

Cavity Car-

tridge

FuseMini

FuseDescription

1ÐÐÐ

2ÐÐÐ

3 Ð 15 Amp

BlueAdjustable Pedals - if

equipped

4 Ð 20 Amp

YellowAC Clutch/Horn

5ÐÐÐ

6 Ð 15 Amp

BlueFront Control Module

(FCM)

7 Ð 20 Amp

YellowFog Lights

8 Ð 15 Amp

BlueLights ± License, Park,

Side Marker, Stop, Turn

9 Ð 15 Amp

BlueFront Control Module

(FCM)

10 Ð 5 Amp

OrangePowertrain Control

Module (PCM)/Starter

Front Power Distribution Center

320 MAINTAINING YOUR VEHICLE

Page 332 of 380

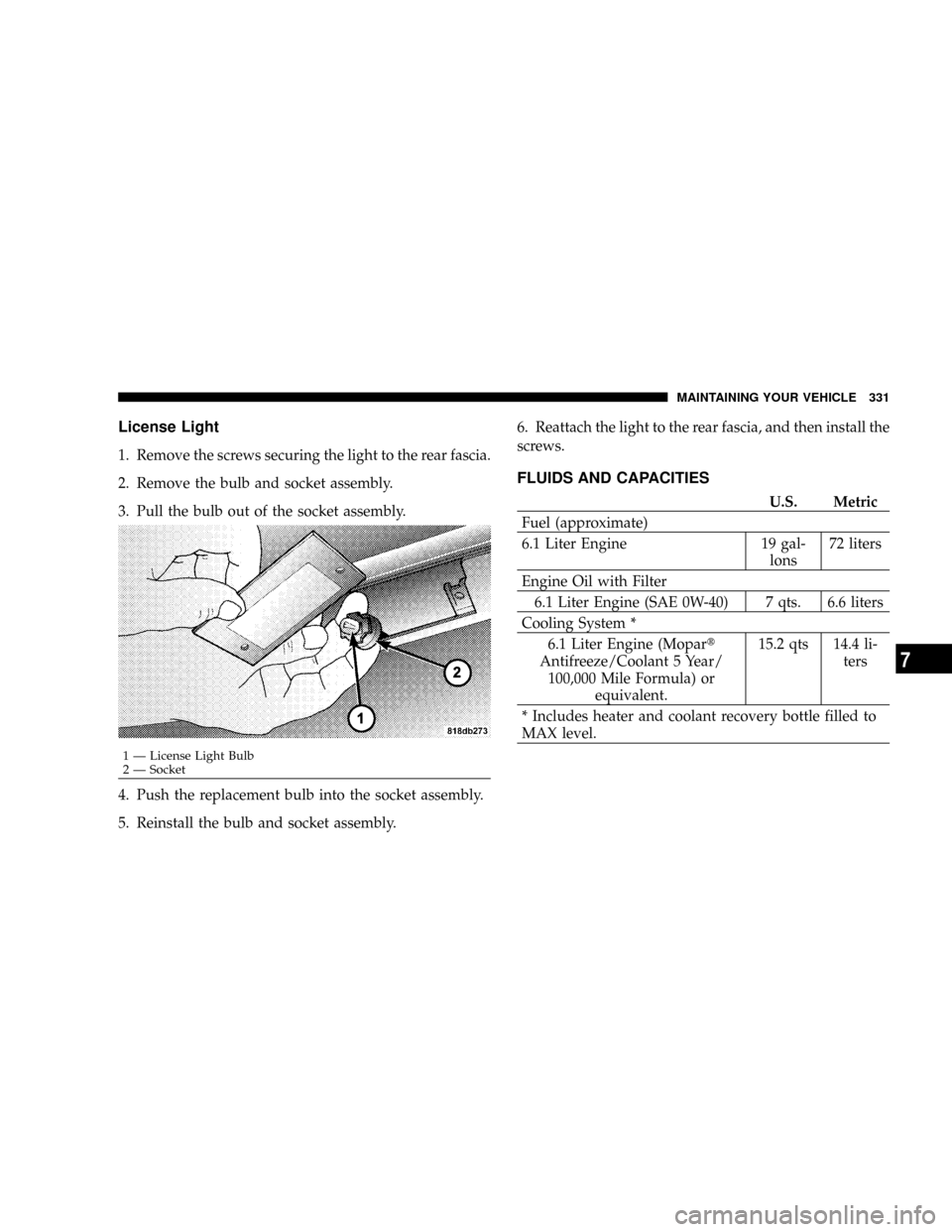

License Light

1. Remove the screws securing the light to the rear fascia.

2. Remove the bulb and socket assembly.

3. Pull the bulb out of the socket assembly.

4. Push the replacement bulb into the socket assembly.

5. Reinstall the bulb and socket assembly.6. Reattach the light to the rear fascia, and then install the

screws.

FLUIDS AND CAPACITIES

U.S. Metric

Fuel (approximate)

6.1 Liter Engine 19 gal-

lons72 liters

Engine Oil with Filter

6.1 Liter Engine (SAE 0W-40) 7 qts. 6.6 liters

Cooling System *

6.1 Liter Engine (Mopart

Antifreeze/Coolant 5 Year/

100,000 Mile Formula) or

equivalent.15.2 qts 14.4 li-

ters

* Includes heater and coolant recovery bottle filled to

MAX level.

1 Ð License Light Bulb

2 Ð SocketMAINTAINING YOUR VEHICLE 331

7

Page 333 of 380

FLUIDS, LUBRICANTS, AND GENUINE PARTS

Engine

Component Fluids, Lubricants, and Genuine Parts

Engine Coolant MopartAntifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or-

ganic Additive Technology) or equivalent

Engine Oil (6.1 Liter) For best performance and maximum protection under all types of operating

conditions, the manufacturer only recommends full synthetic engine oils that

meet the American Petroleum Institute (API) categories of SM or SM/CF, and

meet the requirements of DaimlerChrysler Material Standard MS-10725. The

manufacturer recommends the use of a full synthetic engine oil, such as Mo-

bil 1tSAE 0W-40 or equivalent. For additional information, refer to the ªEn-

gine Oil Selectionº and ªEngine Oil Viscosity (SAE Grade)º in the ªMainte-

nance Proceduresº section of this manual.

Oil Filter (6.1 Liter) Mopart05281090 or equivalent.

Spark Plugs Refer to the ªVehicle Emission Control Informationº label in the engine com-

partment.

Fuel Selection (6.1 Liter) Premium Unleaded 91 Octane Only or higher.

332 MAINTAINING YOUR VEHICLE

Page 337 of 380

EMISSION CONTROL SYSTEM MAINTENANCE

The ªScheduledº maintenance services, listed inbold

typemust be done at the times or mileages specified to

assure the continued proper functioning of the emission

control system. These, and all other maintenance services

included in this manual, should be done to provide best

vehicle performance and reliability. More frequent main-

tenance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

Inspection and service also should be done any time a

malfunction is suspected.

NOTE:Maintenance, replacement, or repair of the

emission control devices and systems on your vehicle

may be performed by any automotive repair establish-

ment or individual using any automotive part, which has

been certified pursuant to U.S. EPA or, in the State of

California, California Air Resources Board regulations.

MAINTENANCE SCHEDULES

There are two maintenance schedules that show the

requiredservice for your vehicle.

First is ScheduleªB.ºIt is for vehicles that are operated

under the conditions that are listed below and at the

beginning of the schedule.

Change the automatic transmission fluid and filter every

60,000 miles (100 000 km) if the vehicle is usually

operated under one or more of the conditions marked

with anL.

²Day or night temperatures are below 32ÉF (0ÉC).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16 km).

²More than 50% of your driving is at sustained high

speeds during hot weather, above 90ÉF (32ÉC).

²Trailer towing.L

336 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 338 of 380

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

NOTE:IfANYof these apply to you, then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first, and follow the maintenance rec-

ommendations in Schedule ªBº in this section.

NOTE:IfANYof these apply to you, then flush and

replace the engine coolant every 102,000 miles (170 000

km) or 60 months, whichever comes first, and follow the

maintenance recommendations in Schedule ªBº in this

section.

NOTE:Most vehicles are operated under the conditions

listed for Schedule9B.9

Second is ScheduleªA.ºIt is for vehicles that are not

operated under any of the conditions listed under Sched-

ule9B.9

Use the schedule that best describes your driving condi-

tions. Where time and mileage are listed, follow the

interval that occurs first.

NOTE:Under no circumstances should oil change

intervals exceed 6,000 miles (10 000 km) or 6 months

whichever comes first.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²

Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

MAINTENANCE SCHEDULES 337

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 339 of 380

Once a Month

²

Check tire pressure and look for unusual wear or

damage.

²Inspect the battery, and clean, and tighten the termi-

nals as required.

²Check the fluid levels of coolant reservoir and brake

master cylinder, and add as needed.

²Check all lights and all other electrical items for correct

operation.

²Check rubber seals on each side of the radiator for

proper fit.

At Each Oil Change

²

Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front and rear suspension

components.

²Check the coolant level, hoses, and clamps.

338 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S