ESP DODGE NEON 1997 1.G Wiring Diagrams Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1997, Model line: NEON, Model: DODGE NEON 1997 1.GPages: 256, PDF Size: 2.99 MB

Page 4 of 256

Downloaded from www.Manualslib.com manuals search engine NOTES, CAUTIONS, and WARNINGS

Throughout this group additional important infor-

mation is presented in three ways; Notes, Cautions,

and Warnings.

NOTESare used to help describe how switches or

components operate to complete a particular circuit.

They are also used to indicate different conditions

that may appear on the vehicle. For example, an

up-to and after condition.

CAUTIONSare used to indicate information that

could prevent making an error that may damage the

vehicle.

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER, AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY, AND LOOSE CLOTH-

ING.

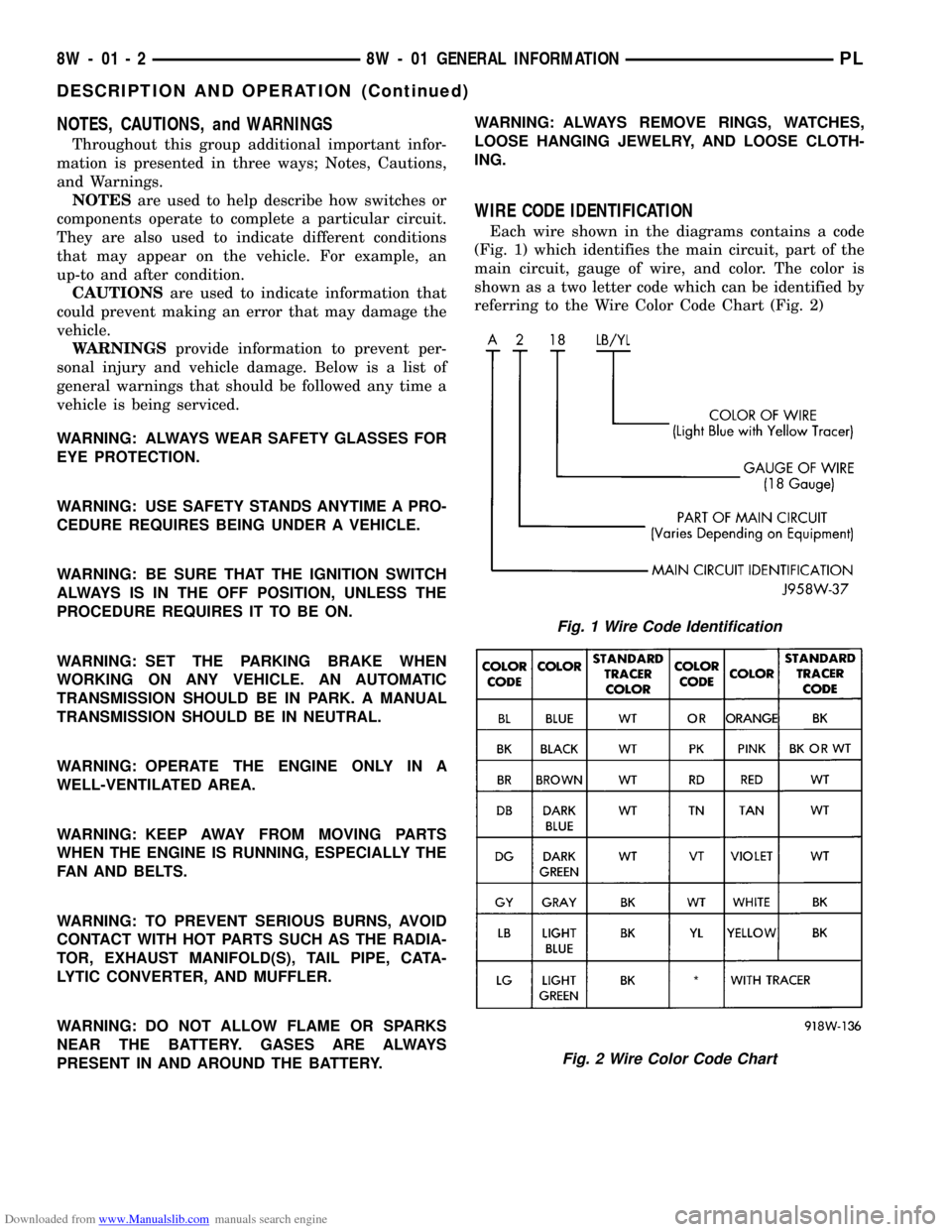

WIRE CODE IDENTIFICATION

Each wire shown in the diagrams contains a code

(Fig. 1) which identifies the main circuit, part of the

main circuit, gauge of wire, and color. The color is

shown as a two letter code which can be identified by

referring to the Wire Color Code Chart (Fig. 2)

Fig. 1 Wire Code Identification

Fig. 2 Wire Color Code Chart

8W - 01 - 2 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 85 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-35 ANTI-LOCK BRAKES

INDEX

page

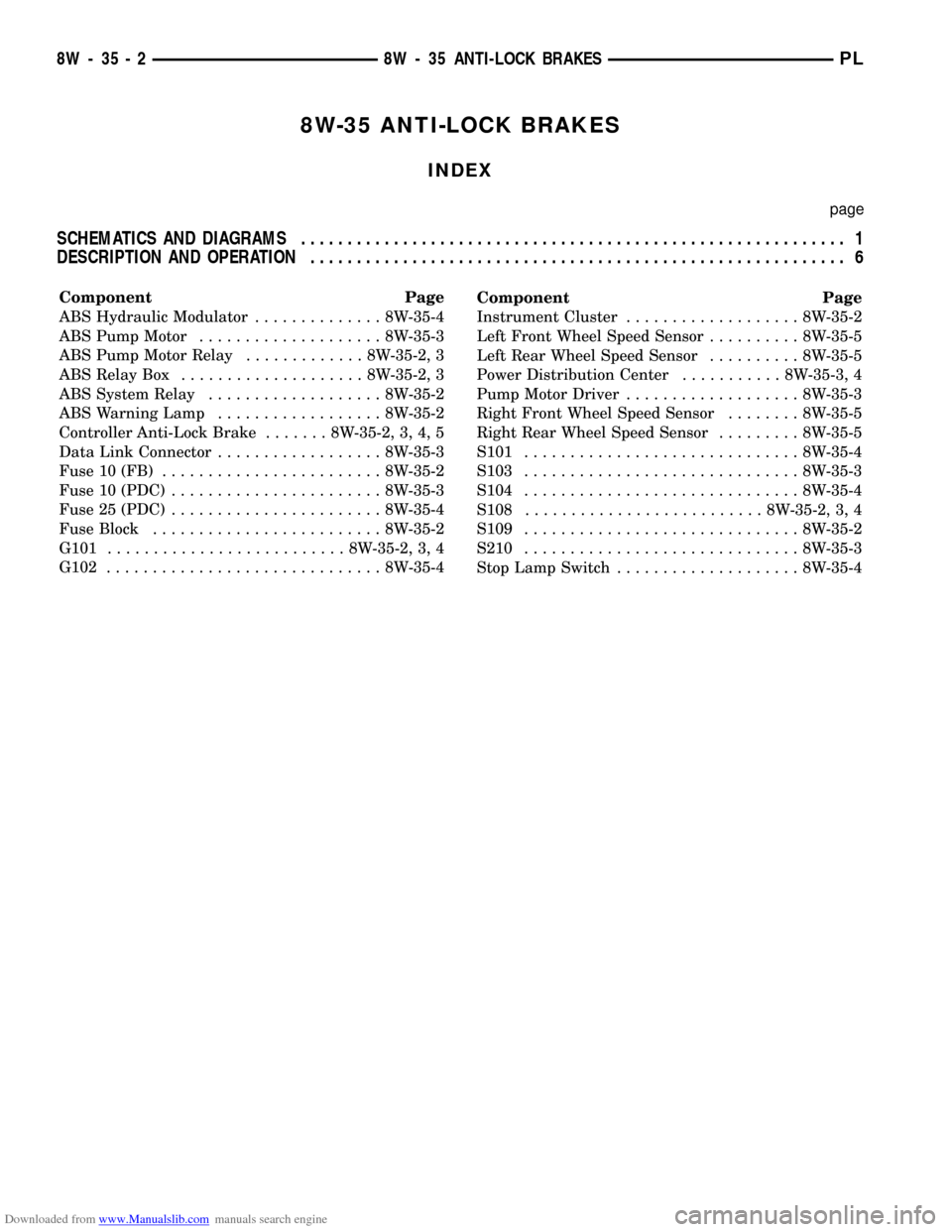

SCHEMATICS AND DIAGRAMS........................................................... 1

DESCRIPTION AND OPERATION.......................................................... 6

Component Page

ABS Hydraulic Modulator..............8W-35-4

ABS Pump Motor....................8W-35-3

ABS Pump Motor Relay.............8W-35-2, 3

ABS Relay Box....................8W-35-2, 3

ABS System Relay...................8W-35-2

ABS Warning Lamp..................8W-35-2

Controller Anti-Lock Brake.......8W-35-2, 3, 4, 5

Data Link Connector..................8W-35-3

Fuse 10 (FB)........................8W-35-2

Fuse 10 (PDC).......................8W-35-3

Fuse 25 (PDC).......................8W-35-4

Fuse Block.........................8W-35-2

G101..........................8W-35-2, 3, 4

G102..............................8W-35-4Component Page

Instrument Cluster...................8W-35-2

Left Front Wheel Speed Sensor..........8W-35-5

Left Rear Wheel Speed Sensor..........8W-35-5

Power Distribution Center...........8W-35-3, 4

Pump Motor Driver...................8W-35-3

Right Front Wheel Speed Sensor........8W-35-5

Right Rear Wheel Speed Sensor.........8W-35-5

S101..............................8W-35-4

S103..............................8W-35-3

S104..............................8W-35-4

S108..........................8W-35-2, 3, 4

S109..............................8W-35-2

S210..............................8W-35-3

Stop Lamp Switch....................8W-35-4

8W - 35 - 2 8W - 35 ANTI-LOCK BRAKESPL

Page 86 of 256

Downloaded from www.Manualslib.com manuals search engine 10FUSE15A

10

30

1

10

ABS

RELAY

BOX

F12

18

DG/WT

1547

CONTROLLER

ANTI-LOCK

BRAKEABS

SYSTEM

RELAY

OUTPUT

G101

Z1

14

BK

Z1

14

BK

S108 BLOCK FUSE

ST-RUN A21

7

9

C22

CLUSTER

INSTRUMENT

G19

22

LG/OR

G19

20

LG/BR

1C103

ABS

SYSTEM

RELAY

CONTROL

G19

20

LG/BR

F12

20

DG/WT

6C101

S109

F12

20

DG/WT

B47

20

RD/LB

60

B57

20

BR/BK

ABS

SYSTEM

RELAY LAMP WARNING

ABSABS

PUMP

MOTOR

RELAY

4

57

CONTROLRELAY SYSTEMABSDRIVERLAMP WARNINGABS(8W-11-9)

(8W-15-2) (8W-15-2) (8W-11-2)

(8W-40-5)

(8W-11-9) (8W-10-12)

8W - 35 - 2 8W-35 ANTI-LOCK BRAKESPL-RHD

978W-1PLR03501

Page 88 of 256

Downloaded from www.Manualslib.com manuals search engine LEFT

FRONT

DECAY

SOLENOID

CONTROL CONTROLSOLENOIDDECAYREARLEFT RIGHT

REAR

DECAY

SOLENOID

CONTROL CONTROL SOLENOIDDECAY FRONTRIGHT

LEFT

FRONT

DECAY

SOLENOID

CONTROL CONTROLSOLENOIDDECAYREARLEFT RIGHT

FRONT

DECAY

SOLENOID

CONTROL CONTROLSOLENOIDDECAYREAR RIGHT

65OUTPUTSWITCHLAMPSTOP

S108

5 GROUND

15A

FUSE

25

POWER

DISTRIBUTION

CENTER

25

26

F32

18

PK/DB

5 6

STOP

LAMP

SWITCH

L50

20

WT/TN

S101

L50

20

WT/TN

Z1

18

BKZ1

18

BK

Z1

14

BK

G101

Z12

18

BK/TN

Z12

18

BK/OR

13

B142

20

BR/YL

B146

20

BR/LBB143

20

DG/YLB148

20

DB/LB

42464348

G102 S104 MODULATOR HYDRAULIC

ABSBRAKE ANTI-LOCK

CONTROLLER

BATT A0

4 2 3 1

(8W-15-2)(8W-10-9)(8W-10-4)

(8W-30-12)

(8W-30-12)

(8W-15-2) (8W-15-3)(8W-15-3) (8W-10-4)

8W - 35 - 4 8W-35 ANTI-LOCK BRAKESPL-RHD

978W-1PLR03503

Page 90 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-35 ANTI-LOCK BRAKES

INDEX

page page

DESCRIPTION AND OPERATION

ABS PUMP MOTOR RELAY................ 6

ABS SYSTEM RELAY..................... 6

ABS WARNING LAMP..................... 6

ANTI-LOCK BRAKES..................... 6BRAKE SWITCH INPUT................... 7

DATA LINK CONNECTOR.................. 7

HELPFUL INFORMATION.................. 7

HYDRAULIC MODULATOR................. 6

WHEEL SPEED SENSORS................. 7

DESCRIPTION AND OPERATION

ANTI-LOCK BRAKES

Power for the Anti-Lock brake system is supplied

by two fuses. There is a 15 amp fuse located in the

fuse block cavity 10. This fuse supplies power to the

Controller Anti Lock Brake (CAB), and the ABS sys-

tem relay on the F12 circuit. The F12 circuit also

supplies power to the Powertrain Control Module

(PCM). Power for the fuse is supplied on the A21 cir-

cuit from the ignition switch. This fuse is HOT in the

START/RUN position.

The second fuse is located in the Power Distribu-

tion Center (PDC). It is a 40 amp fuse. This fuse is

HOT at all times and supplies power to the contact

side of the ABS pump motor relay.

There are three grounding points used in the ABS

system. One is a case ground on the CAB. The sec-

ond is the Z12 circuit at the CAB connector cavity 5.

This ground is spliced, and terminates at the left side

of the radiator closure panel.

The third ground is on the Z1 circuit. This ground

is used for the ABS hydraulic modulator, ABS system

relay, and the ABS pump motor. This ground, like the

Z12 ground splices and terminates at the left head-

lamp ground.

Additional information on the circuit function of

the ABS system is listed below. For diagnostic and

testing procedures, refer to the appropriate section of

the Service Manual or the Diagnostic Test Proce-

dures Manual.

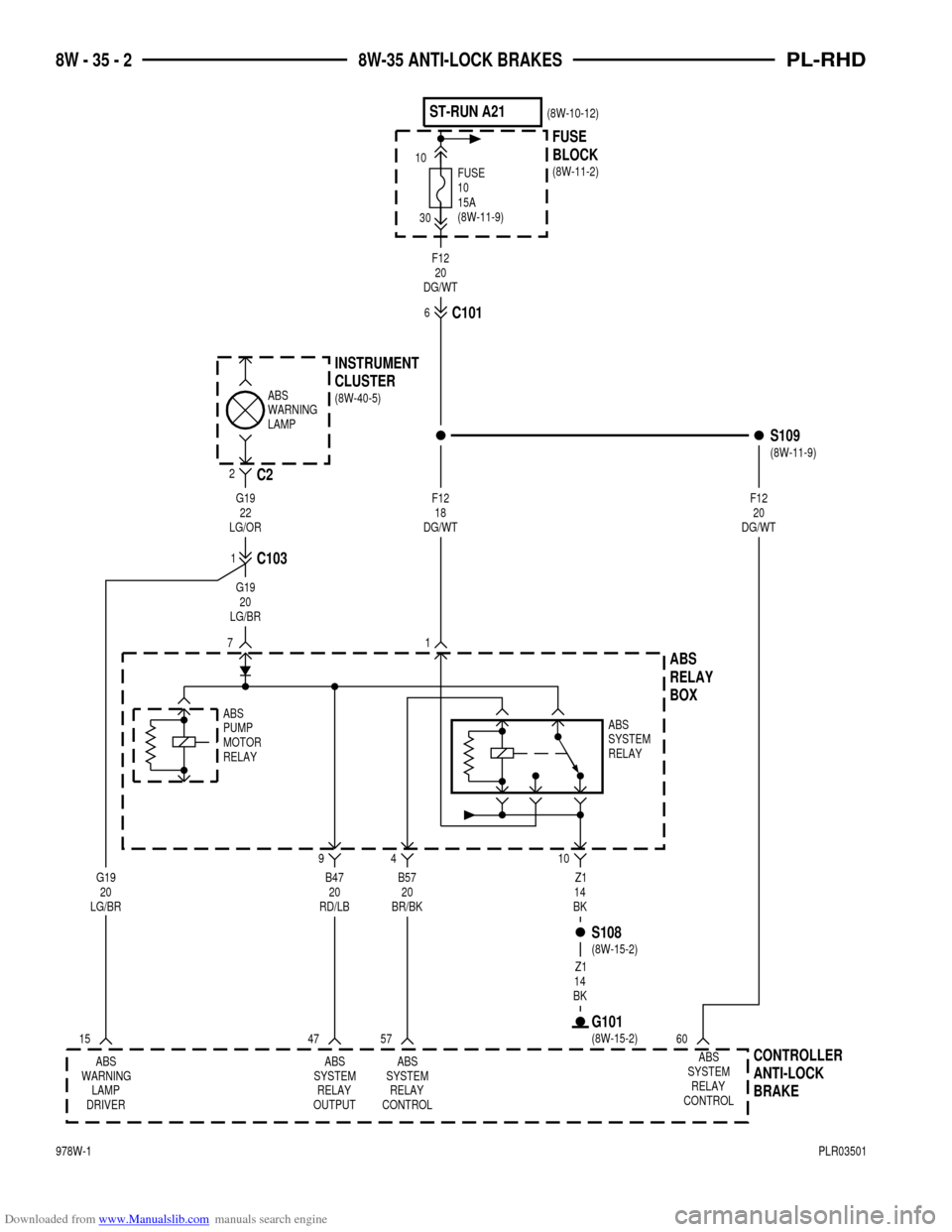

ABS WARNING LAMP

The ABS warning lamp is an output from the Con-

troller Anti Lock Brake (CAB) and the ABS relay

box. It is used to alert the operator of a problem in

the ABS system. The G19 circuit from the CAB and

the ABS system relay is used to detect a problem. If

a problem is detected, the CAB grounds the G19 cir-

cuit and illuminates the lamp in the instrument clus-

ter.

Circuit G19 is also an output of the CAB to the

ABS system relay contact side.

ABS SYSTEM RELAY

The system relay is used for the operation of the

ABS system. Power for the relay is supplied on the

B57 circuit from cavity 57 of the Controller Anti Lock

Brake (CAB).

Ground for the relay is on the Z1 circuit. This

ground is spliced in with the pump motor and termi-

nates at the left headlamp ground.

When the system is operating normally power for

the contact side of the relay is supplied from the

CAB on the B57 circuit. It passes through the relay

to the Z1 ground and terminates at the left headlamp

ground. If a problem is detected in the system, the

contact side of the relay switches from the Z1 to the

F12 circuit. This causes the ABS warning lamp in

the instrument cluster to illuminate.

ABS PUMP MOTOR RELAY

The ABS pump motor relay controls when the

pump motor runs. Power for the coil side of the relay

is supplied from cavity 47 of the Controller Anti Lock

Brake (CAB) on the B47 circuit. This circuit also sup-

plies voltage for the contact side of the system relay.

The ground side of the coil is controlled by the B116

circuit. Circuit B116 connects to cavity 16 of the CAB

connector.

Circuit B120 from cavity 20 of the CAB connector

powers the ABS pump motor. This circuit is also used

as an input to the CAB for pump motor monitoring.

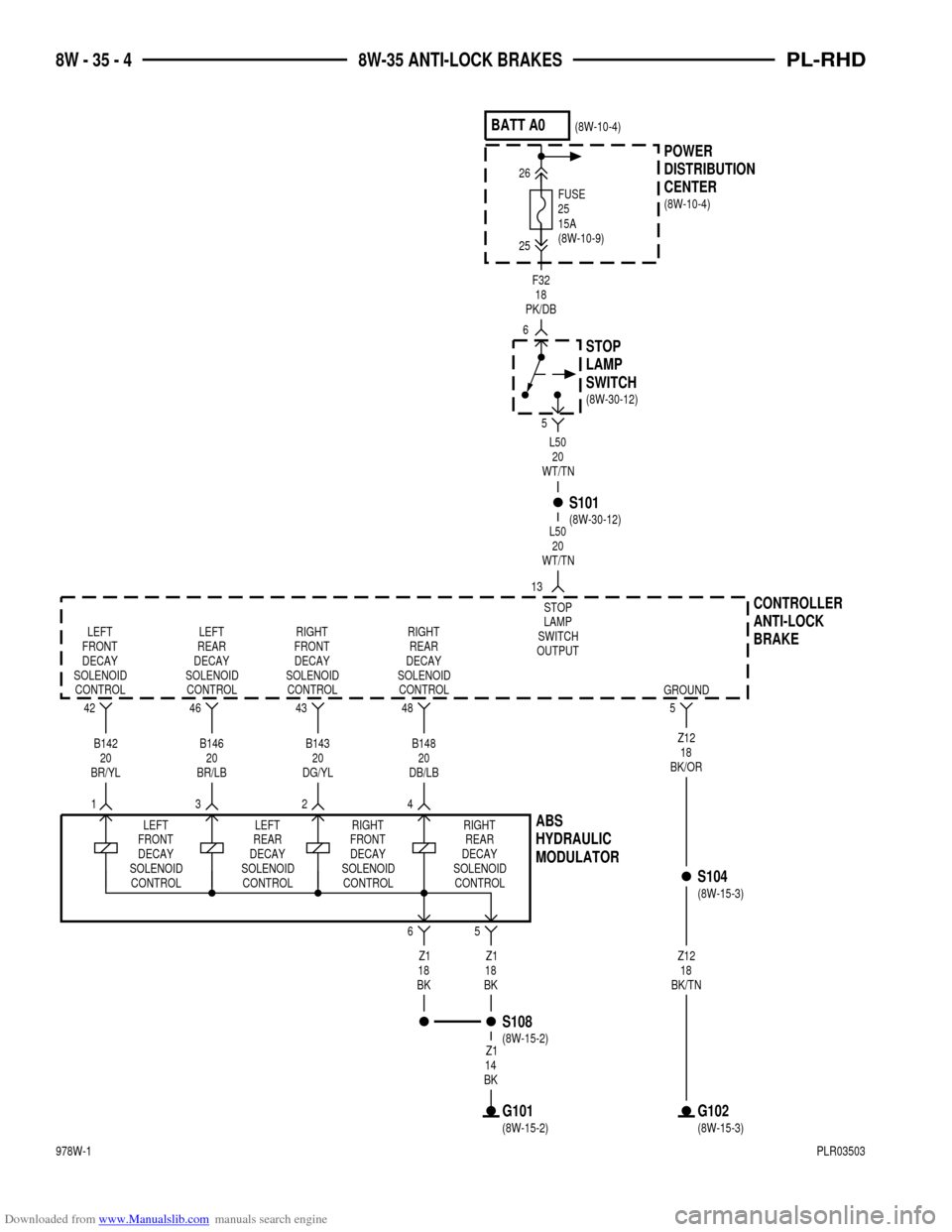

HYDRAULIC MODULATOR

The hydraulic modulator is used for the controlling

of the brake system pressure to the wheels. The mod-

ulator is made up of four solenoids.

Circuits involved are, B142 for the left front wheel,

B143 for the right front wheel, B146 for the left rear

wheel, and B148 for the right rear wheel.

The solenoids use a common ground on the Z1 cir-

cuit. There are two Z1 circuits from the modulator.

Both of these grounds terminate at the left headlamp

ground, and are spliced in with the ABS pump motor

and the ABS system relay.

8W - 35 - 6 8W - 35 ANTI-LOCK BRAKESPL

Page 99 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-40 INSTRUMENT CLUSTER

INDEX

page page

DESCRIPTION AND OPERATION

AIRBAG WARNING LAMP.................. 8

ANTI-LOCK WARNING LAMP............... 9

BRAKE WARNING INDICATOR LAMP......... 8

CHARGE INDICATOR LAMP................ 8

ENGINE COOLANT TEMPERATURE GAUGE . . . 7

FUEL GAUGE........................... 7

HEADLAMP ON CHIME.................... 8

HELPFUL INFORMATION.................. 9

HIGH BEAM INDICATOR LAMP.............. 8

INSTRUMENT CLUSTER.................. 7KEY-IN CHIME.......................... 8

LOW FUEL LAMP........................ 8

LOW OIL PRESSURE LAMP................ 8

ODOMETER............................ 8

RIGHT AND LEFT TURN

SIGNAL INDICATORS................... 8

SEAT BELT WARNING INDICATOR........... 8

SERVICE ENGINE SOON LAMP............. 8

SPEEDOMETER......................... 7

TACHOMETER.......................... 7

DESCRIPTION AND OPERATION

INSTRUMENT CLUSTER

The Instrument Cluster, located on the right side

of the instrument panel, provides the operator with

gauges and warning lamps relating to vehicle opera-

tion. All gauges in the standard and optional cluster

are magnetic type and logic driven.

Battery voltage for the clusters warning lamps and

gauges is provided on the G5 circuit. This circuit con-

nects from the fuse block and is protected bya5amp

fuse located in cavity 11. The cluster is powered only

when the ignition switch is in the START or RUN

position. The cluster is also powered on initial driv-

er's door opening.

Illumination lamps, internal to the cluster, receive

battery voltage on the E2 circuit from the 4 amp fuse

located in cavity 12 of the fuse block. This circuit is

HOT only when the headlamp switch is in the ON

position. Grounding for the cluster is provided on the

Z3 circuit and terminates at the instrument panel

left center support.

The M1 circuit also feeds the cluster through a 10

amp fuse in the Power Distribution Center (PDC).

This fuse is HOT at all times and also used to power

the underhood lamp, and the interior lamps. The

fuse is also lifted OPEN during vehicle shipping to

reduce battery draw.

SPEEDOMETER

The speedometer and odometer receive their infor-

mation on the G7 circuit from the Vehicle Speed Sen-

sor (VSS) on manual and 3±spd automatic

transmission applications. The G7 circuit also pro-

vides a signal to the Powertrain Control Module

(PCM).Logic internal to the instrument cluster adjusts the

position of the gauge pointer to the correct vehicle

speed using the signal on the G7 circuit.

TACHOMETER

The tachometer is connected to the Powertrain

Control Module (PCM) on the G21 circuit. It uses

solid state circuity to decode the ignition pulses

received from the PCM to adjust the gauge pointer to

the proper position.

ENGINE COOLANT TEMPERATURE GAUGE

The temperature gauge is connected to the engine

coolant temperature sensor on the G20 circuit. The

engine coolant temperature sensor for the gauge is a

combination unit. One side of the unit is used for the

Powertrain Control Module (PCM) and the other side

for the cluster. The sending unit is case grounded to

the engine.

The logic driven gauge moves in response to the

measured resistance of the engine coolant tempera-

ture sending unit.

FUEL GAUGE

The fuel level gauge is connected to the fuel pump

module on the G4 circuit. The fuel pump module con-

tains the fuel pump and a variable resistor for the

gauge. Grounding for the fuel pump module is pro-

vided on the Z2 circuit and terminates at the left

rear wheel house.

The logic driven gauge moves in response to the

measured resistance of the fuel tank sending unit.

The fuel level sensor contains a variable resistor.

As the position of the float arm on the level sensor

changes, the resistor changes the current flow

through the fuel gauge circuit. A change in current

flow alters the magnetic field in the fuel gauge which

changes the pointer position.

PL8W - 40 INSTRUMENT CLUSTER 8W - 40 - 7

Page 144 of 256

Downloaded from www.Manualslib.com manuals search engine Circuit L2 connects to the multi- function switch and

feeds the L4 circuit (for low beam operation). The L4

circuit connects to a bus bar in the fuse block. Cir-

cuits L43 and L44 connect to the bus bar in fuse

block and power the low beam headlamps. Circuit

L43 supplies voltage to the left headlamp. Circuit

L44 supplies voltage to the right headlamp. Both the

L43 and L44 circuits have separate 10 amp fuses

located in fuse block. Fuse 17 protects circuit L43,

and fuse 18 protects circuit L44.

When the operator selects high beam operation

with the turn signal stalk of the multi-function

switch, circuit L2 connects to the L3 Circuit L3 pow-

ers high beam operation.

HEADLAMP GROUND

Although circuit Z1 provides ground for the right

and left headlamps it has different termination

points for both. For the right headlamp the Z1 circuit

terminates at the right inner fender shield. For the

left headlamp the Z1 circuit terminates at the left

side of the radiator closure panel.

HELPFUL INFORMATION

²Check for a blown fuse in cavity 17 for L43 and

cavity 18 for L44.

²Check the 40 amp fuse located in the PDC.

²The headlamp switch has a 24 amp internal cir-

cuit breaker.

²For the left front parking lamp, turn signal, side

marker lamp and left headlamp, the Z1 circuit

grounding point is the left side of the radiator closure

panel.

²For the right front parking lamp, turn signal,

side marker lamp and right headlamp, the Z1 circuit

grounding point is in the right fender side shield.

HEADLAMP LEVELING MOTORS

The headlamp leveling system used in this vehicle

uses a variable position switch located in the instru-

ment panel along with headlamp leveling motors

located at the headlamps.

Power for the switch and the leveling motors is

supplied on circuit L43. This circuit is HOT when the

headlamp switch is in the ON position and the oper-

ator has selected LOW beam operation. In addition,circuit L43 is protected by a 10 amp fuse located in

the fuse block and is the feed for the left LOW beam

headlamp.

Ground for the switch is supplied on circuit Z1.

When the operator moves the switch, power is sup-

plied on circuit L13 from the switch to the headlamp

leveling motors. Ground for the leveling motors is

supplied on circuit Z1 and has the same termination

point as the respective headlamps.

The headlamp leveling switch also has a lamp

located in it for night illumination. Power for the

lamp is supplied on circuit E2. The E2 circuit is HOT

when the operator has turned the headlamp switch

to the PARK or ON position. The E2 circuit is pro-

tected by a 4 amp fuse located in the fuse block.

FOG LAMPS (FRONT)

The fog lamp system in this vehicle uses a switch

located in the instrument panel along with a relay

located in the Power Distribution Center (PDC).

Power for the switch is supplied on circuit L7. This

circuit is the feed for the front and rear parking

lamps and is HOT when the headlamp switch is in

the PARK position.

Power for the contact side of the relay is supplied

on circuit F61. This circuit is HOT at all times and

protected by a 20 amp fuse in the PDC. Ground for

the coil side of the relay is supplied in circuit Z1.

When the operator turns the lamps ON by closing

the switch, power flows on circuit L7 through the

switch to circuit L35. Circuit L35 connects from the

switch to the coil side of the fog lamp relay. With this

input the contacts in the fog lamp relay CLOSE con-

necting circuits F61 and L39.

Circuit L39 connects from the relay to the fog

lamps. Ground for the lamps is supplied on circuit

Z1.

HELPFUL INFORMATION

²Check the 20 amp fuse located in the PDC for

the fog lamps

²Check the lamp filament

²Check the grounding points for the lamps,

switch and relay

8W - 50 - 8 8W - 50 FRONT LIGHTINGPL

DESCRIPTION AND OPERATION (Continued)