length DODGE NEON 1997 1.G Wiring Diagrams Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1997, Model line: NEON, Model: DODGE NEON 1997 1.GPages: 256, PDF Size: 2.99 MB

Page 11 of 256

Downloaded from www.Manualslib.com manuals search engine CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half/component

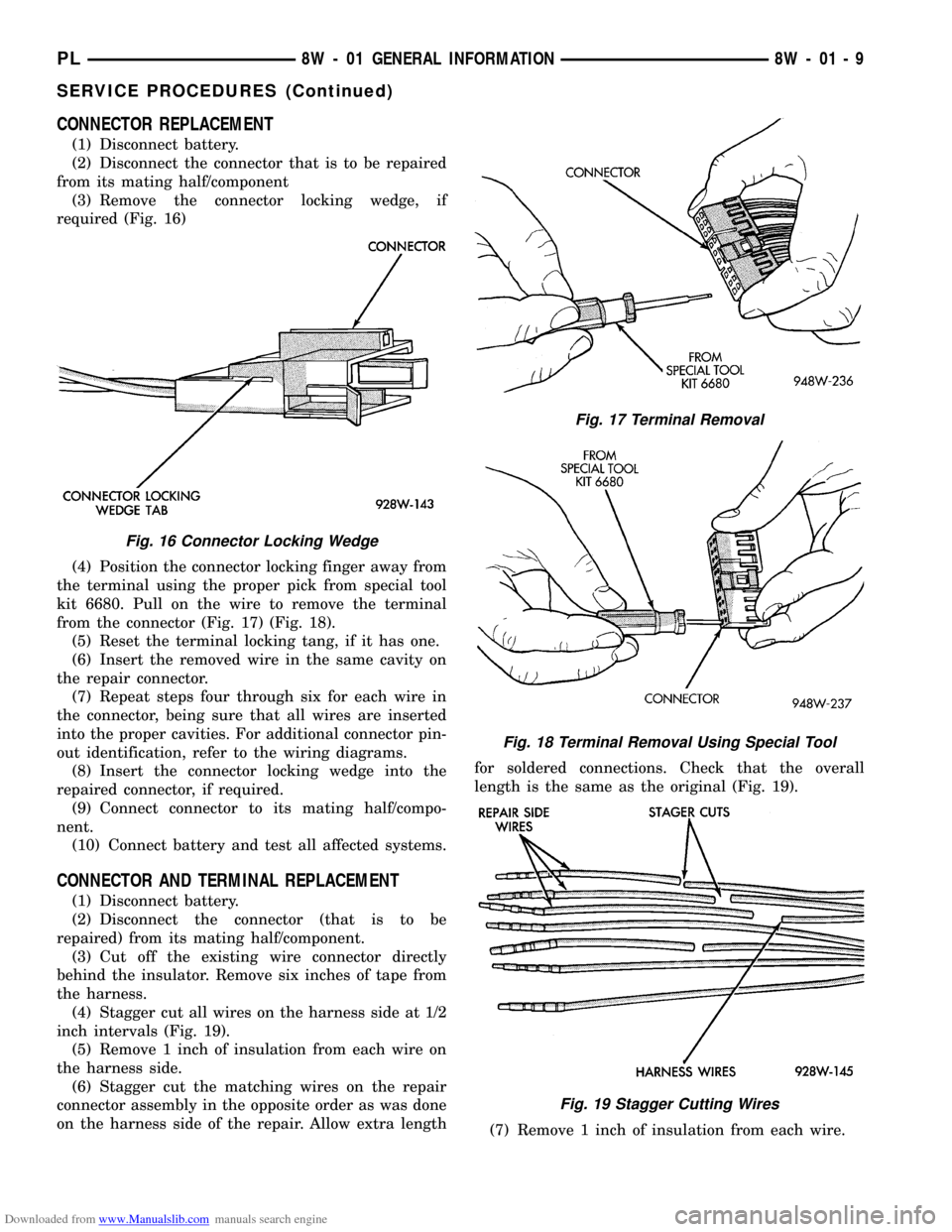

(3) Remove the connector locking wedge, if

required (Fig. 16)

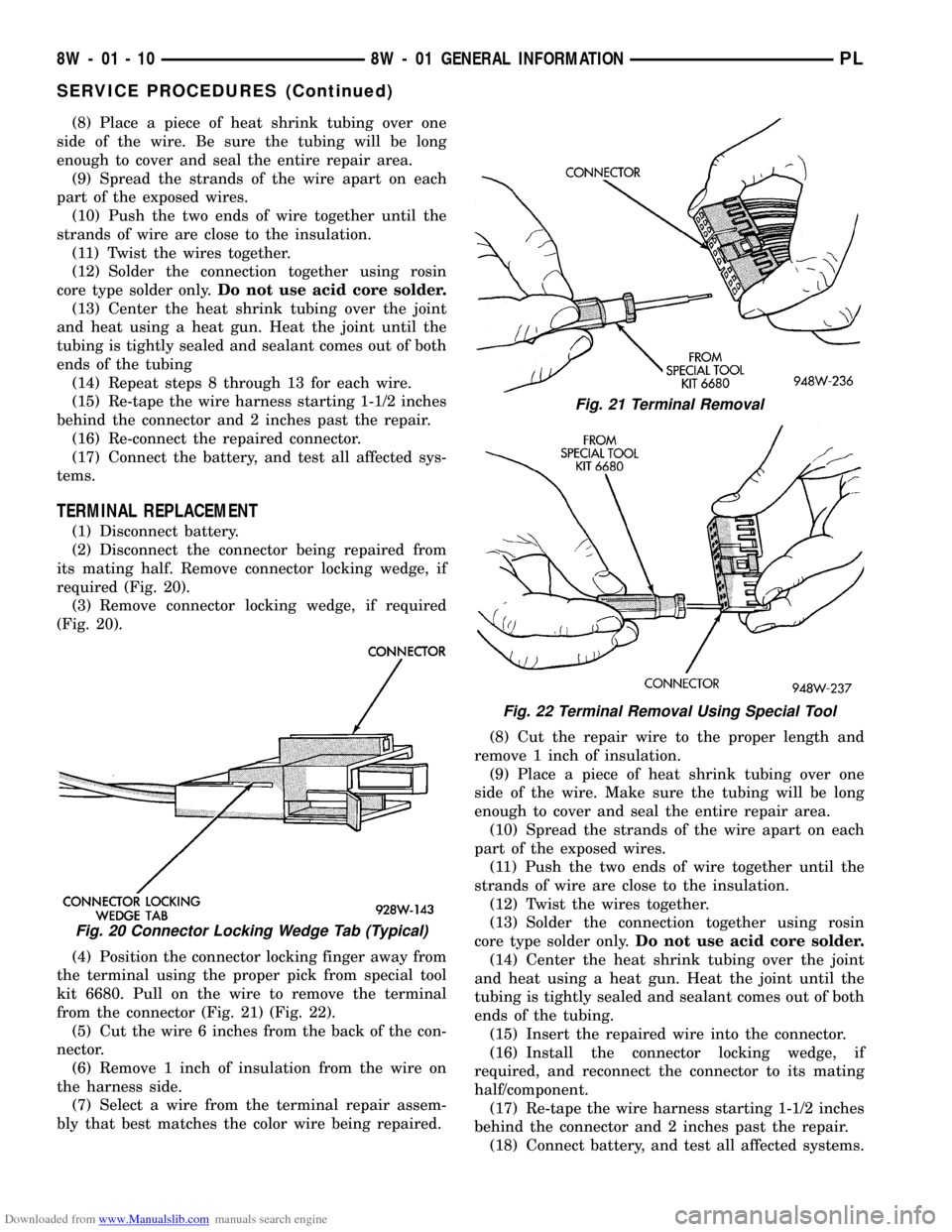

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 17) (Fig. 18).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the

repaired connector, if required.

(9) Connect connector to its mating half/compo-

nent.

(10) Connect battery and test all affected systems.

CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be

repaired) from its mating half/component.

(3) Cut off the existing wire connector directly

behind the insulator. Remove six inches of tape from

the harness.

(4) Stagger cut all wires on the harness side at 1/2

inch intervals (Fig. 19).

(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra lengthfor soldered connections. Check that the overall

length is the same as the original (Fig. 19).

(7) Remove 1 inch of insulation from each wire.

Fig. 16 Connector Locking Wedge

Fig. 17 Terminal Removal

Fig. 18 Terminal Removal Using Special Tool

Fig. 19 Stagger Cutting Wires

PL8W - 01 GENERAL INFORMATION 8W - 01 - 9

SERVICE PROCEDURES (Continued)

Page 12 of 256

Downloaded from www.Manualslib.com manuals search engine (8) Place a piece of heat shrink tubing over one

side of the wire. Be sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires.

(10) Push the two ends of wire together until the

strands of wire are close to the insulation.

(11) Twist the wires together.

(12) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

(17) Connect the battery, and test all affected sys-

tems.

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired from

its mating half. Remove connector locking wedge, if

required (Fig. 20).

(3) Remove connector locking wedge, if required

(Fig. 20).

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 21) (Fig. 22).

(5) Cut the wire 6 inches from the back of the con-

nector.

(6) Remove 1 inch of insulation from the wire on

the harness side.

(7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired.(8) Cut the repair wire to the proper length and

remove 1 inch of insulation.

(9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires.

(11) Push the two ends of wire together until the

strands of wire are close to the insulation.

(12) Twist the wires together.

(13) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge, if

required, and reconnect the connector to its mating

half/component.

(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(18) Connect battery, and test all affected systems.

Fig. 20 Connector Locking Wedge Tab (Typical)

Fig. 21 Terminal Removal

Fig. 22 Terminal Removal Using Special Tool

8W - 01 - 10 8W - 01 GENERAL INFORMATIONPL

SERVICE PROCEDURES (Continued)

Page 100 of 256

Downloaded from www.Manualslib.com manuals search engine ODOMETER

The speedometer and odometer receive their infor-

mation on the G7 circuit from the Vehicle Speed Sen-

sor (VSS) on vehicles equipped with the manual or

3±spd automatic transmission. This circuit also pro-

vides a signal to the Powertrain Control Module

(PCM).

Logic internal to the cluster steps the odometer at

a high rate to indicate the proper mileage.

SERVICE ENGINE SOON LAMP

The Service Engine Soon lamp illuminates when

the ignition switch is in the ON position and prior to

starting the vehicle. The lamp will turn off after the

vehicle is started.

If while the vehicle is running a problem is

detected in the engine control system the lamp is

illuminated. This is accomplished by the Powertrain

Control Module (PCM) grounding the G3 circuit.

SEAT BELT WARNING INDICATOR

The fasten seat belt indicator is used with the

warning chime to indicate to the operator to fasten

the seat belt. There is a switch located in the drivers

side B-pillar that is normally OPEN with the seat

belt buckled.

If the seat belt is not buckled the switch CLOSES

and a ground path is completed from the G10 circuit

to the Z1 circuit. This will illuminate the lamp in the

instrument cluster.

When the ignition switch is moved to the START

position the lamp will illuminate. Logic internal to

the instrument cluster determines the length of time.

LOW FUEL LAMP

The low fuel lamp is used to indicate to the opera-

tor that the fuel level is below a predetermined level.

This lamp is logic driven by the instrument cluster.

When the instrument cluster determines a low fuel

condition based on an input from the fuel tank gauge

level sending unit (circuit G4) it illuminates the

lamp.

HEADLAMP ON CHIME

The headlamp ON chime is used to indicate to the

operator that the headlamps or parking lamps are

ON when the drivers door is OPEN. If the lamps are

ON and the drivers door is opened, a ground path is

completed from the G26 circuit at the cluster,

through the headlamp switch, to the G16 circuit and

ending at the door ajar switch. The door ajar switch

is case grounded.

KEY-IN CHIME

The key-in chime is used to indicate to the opera-

tor that the key is in the ignition with the driversdoor OPEN. If the key is in the ignition and the driv-

ers door is OPEN, a ground path is completed from

the G26 circuit at the cluster, through the CLOSED

key-in switch, to the G16 circuit and terminating at

the door ajar switch which is case grounded.

CHARGE INDICATOR LAMP

The Charge Indicator lamp is used to alert the

operator that the charging system voltage has fallen

below the normal operating range. This circuit is con-

trolled by the Powertrain Control Module (PCM).

When the PCM determines a problem, it grounds the

G12 circuit.

AIRBAG WARNING LAMP

The Airbag Warning lamp is used to alert the oper-

ator of a problem with the Airbag system. The lamp

is illuminated when the Airbag Control Module

(ACM) grounds the R41 circuit. Refer to the appro-

priate section of the Service Manual or Diagnostic

Test Procedures Manual to diagnosis this system.

LOW OIL PRESSURE LAMP

The low oil pressure lamp is used to indicate to the

operator that the engine oil pressure has dropped

below a predetermined pressure. Power for the lamp

is provided on the G5 circuit which also powers the

other warning lamps.

When the oil pressure is low the normally OPEN

oil pressure switch CLOSES completing a path to

ground on circuit G6. The oil pressure switch is case

grounded to the engine block.

HIGH BEAM INDICATOR LAMP

The High Beam Indicator Lamp is used to indicate

to the operator that the high beam headlamps are

ON. Power is supplied to the cluster on the L3 cir-

cuit. Ground is provided on the Z3 circuit.

Circuit L3 connects from the headlamp dimmer

switch to the instrument cluster.

RIGHT AND LEFT TURN SIGNAL INDICATORS

These lamps are used to indicate to the operator

which turn signal is ON. Power for the lamps comes

from the turn signal switch. The L60 circuit is for the

right turn indicator, and the L61 circuit is used for

the left turn signal indicator. Ground for the circuits

is provided on the Z3 circuit.

BRAKE WARNING INDICATOR LAMP

The Brake Warning Indicator lamp is used to alert

the operator of a problem with the vehicles braking

system. The lamp illuminates when the ignition

switch is turned to START position to perform a self

check.

8W - 40 - 8 8W - 40 INSTRUMENT CLUSTERPL

DESCRIPTION AND OPERATION (Continued)