glove box DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 220 of 1200

NOTE: BLACK OR DARK=0to75%state-of-charge

The battery is INADEQUATELY charged and must

be charged until green dot is visible, (12.4 volts or

greater) before the battery is tested or returned to

use. Refer to Causes of Battery Discharging in this

Group for more information.

NOTE: CLEAR COLOR = Replace Battery

WARNING: DO NOT CHARGE, ASSIST BOOST,

LOAD TEST, OR ADD WATER TO THE BATTERY

WHEN CLEAR COLOR DOT IS VISIBLE. PERSONAL

INJURY MAY OCCUR.

A clear color dot shows electrolyte level in battery

is below the test indicator (Fig. 1). Water cannot be

added to a maintenance free battery. The battery

must be replaced. A low electrolyte level may be

caused by an over charging condition. Refer to Gen-

erator Test Procedures on Vehicle.

CAUSES OF BATTERY DISCHARGING

It is normal to have a small 5 to 25 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF

position, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The con-

tinuous draw is due to various electronic features or

accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

not used over an extended period of approximately 20

days the IOD fuse should be pulled. The fuse is

located in the power distribution center. removal of

this fuse will reduce the level of battery discharge.

Refer to the Battery Diagnosis and Testing Table for

proper diagnosis.

ABNORMAL BATTERY DISCHARGING

²Corroded battery posts, cables or terminals.

²Loose or worn generator drive belt.

²Electrical loads that exceed the output of the

charging system due to equipment or accessories

installed after delivery.

²Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use.

²Defective electrical circuit or component causing

excess Ignition Off Draw (IOD). Refer to Battery

Ignition Off Draw (IOD).

²Defective charging system.

²Defective battery.

BATTERY IGNITION OFF DRAW (IOD)

High current draw on the battery with the ignition

OFF will discharge a battery. After a dead battery is

recharged, the vehicle ignition off draw (IOD) shouldbe checked. To determine if a high current draw con-

dition exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Trunk lid is closed

²Engine compartment hood lamp is disconnected

or lamp removed

²Glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the ignition key lamp system to time out

in approximately 30 seconds, if equipped.

(2) Disconnect battery negative cable (Fig. 4).

(3) Connect a 12 Volt test lamp, with a cold resis-

tance of 5-7 ohms, between the battery negative cable

clamp and the negative post (Fig. 5). If test lamp

goes out system is OK. If test lamp lights and stays

ON, go to Test Lamp Stays ON procedure.

TEST LAMP STAYS ON

There is either a short circuit or a fault in an elec-

tronic module. Two fuses in the Power Distribution

Center (PDC) feed the modules with ignition off

draw.

²Interior lamps fuse (10 Amp) (IOD) PDC.

²Fuel pump fuse (20 Amp) in PDC

(1) Remove interior lamp and fuel pump fuses. By

removing these fuses all ignition off draw from the

vehicle electronics will be disconnected. The test

lamp should go out. If test lamp goes out go to Step

2. If test lamp does not go out there is a current

draw or short circuit. Refer to Group 8W, Wiring Dia-

grams.

(2) Install the fuel pump fuse. If test lamp lights,

there is a current draw or short circuit in the A14

wiring circuit feed.

(a) Disconnect Powertrain Control Module.

(b) If test lamp goes out, replace Powertrain

Control Module.

(c) If test lamp does not go out, there is a cur-

rent draw or short circuit in the A14 circuit feed.

Refer to Group 8W, Wiring Diagrams.

(3) Install the interior lamp fuse. If test lamp

lights, there is a current draw or short circuit in the

M01 circuit. Refer to Group 8W, Wiring Diagrams. If

test lamp stays out, go to Step 4

(4) Use a multi-meter that has at least a range of

200 milliamperes. Install meter between the battery

negative cable and battery negative post (Fig. 6).

Carefully remove the test lamp without disconnecting

the meter. After all modules time-out the total vehi-

cle IOD should be less than 10 milliamperes. If igni-

tion off draw is more than 10 milliamperes go to Step

5.

(5) Remove both fuses from the Power Distribution

Center:

PLBATTERY 8A - 3

DIAGNOSIS AND TESTING (Continued)

Page 270 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

DOME LAMP............................ 1

ELECTRONIC DIGITAL CLOCK.............. 1

INSTRUMENT CLUSTER................... 2

WARNING AND INDICATOR LAMPS......... 2

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM............... 2

BRAKE SYSTEM WARNING LAMP TEST...... 2

FOG LAMP SWITCH TEST................. 2

FUEL TANK SENDING UNIT TEST........... 3

HEADLAMP SWITCH TEST................. 3

HEATER A/C BLOWER SWITCH TEST........ 3

HEATER BLOWER SWITCH TEST............ 3

INDIVIDUAL GAUGE INOPERATIVE.......... 4

INSTRUMENT PANEL AND COMPONENTS.... 4

LOW OIL PRESSURE WARNING LAMP TEST . . 4

MULTIPLE GAUGE INOPERATIVE TEST....... 4

SEAT BELT REMINDER SYSTEM TEST....... 6

SENDING UNIT......................... 6

SERVICE ENGINE SOON INDICATOR......... 6

VEHICLE SPEED SENSOR TEST............. 6

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP....... 6

CENTER BEZEL.......................... 6

CIGAR LIGHTER RECEPTACLE.............. 6

CLUSTER LAMP......................... 7

CLUSTER PRINTED CIRCUIT BOARD........ 7CLUSTER.............................. 7

DOME LENS/LAMP....................... 8

FLOOR CONSOLE........................ 8

GAUGE................................ 8

GLOVE BOX DOOR/BIN................... 8

GLOVE BOX SWITCH/LAMP................ 9

HEADLAMP SWITCH..................... 9

HEATER A/C CONTROL BLOWER SWITCH . . . 10

HEATER A/C CONTROL LAMP............ 10

HEATER A/C CONTROL................... 9

HEATER CONTROL BLOWER SWITCH....... 10

IGNITION KEY LAMP.................... 10

INSTRUMENT PANEL.................... 10

LEFT TRIM PANEL...................... 10

ODOMETER............................ 10

RADIO................................ 12

REAR WINDOW DEFOGGER AND/OR FOG

LAMP SWITCH....................... 12

RIGHT TRIM PANEL..................... 12

SHIFTER KNOB......................... 13

STEERING COLUMN COVER LINER......... 13

STEERING COLUMN COVER.............. 13

STEERING COLUMN SHROUDS............ 13

TOP COVER AND CLUSTER BEZEL

REMOVAL........................... 14

TRANSMISSION RANGE INDICATOR LAMP . . 14

TRUNK LAMP/LENS..................... 14

VEHICLE SPEED SENSOR................ 14

GENERAL INFORMATION

INTRODUCTION

The purpose of the dash gauges and indicator

lamps is to keep the driver informed about the oper-

ating condition of the vehicle. If an abnormal condi-

tion occurs, the driver is informed by indicator lamp.

The driver can seek service before damage occurs.

Indicator lamps use ON/OFF switch functions for

operation, while gauges use a sending unit or sensor.

DESCRIPTION AND OPERATION

DOME LAMP

The Dome Lamp operates when a door is open or

when the headlamp switch is placed in courtesy posi-

tion.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position.

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 277 of 1200

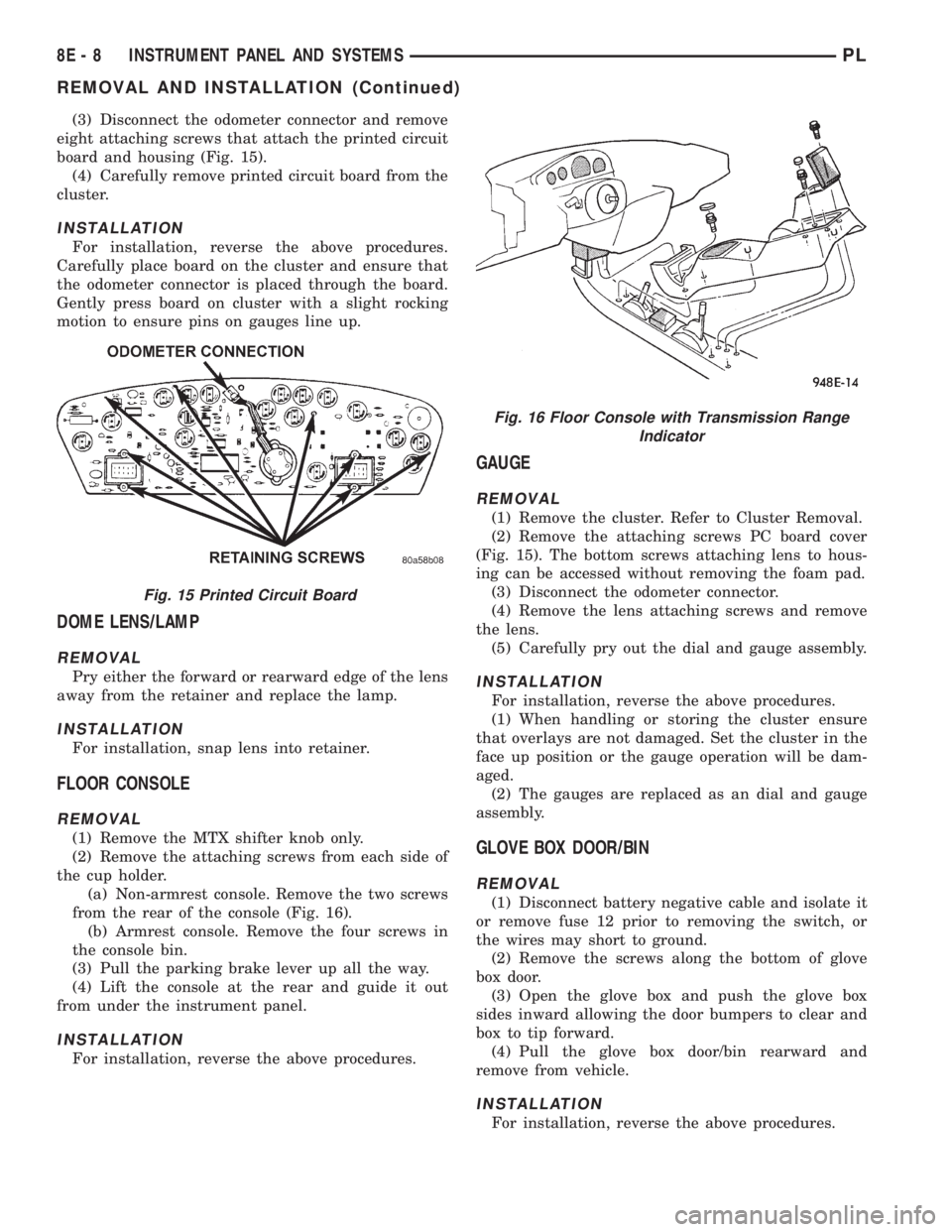

(3) Disconnect the odometer connector and remove

eight attaching screws that attach the printed circuit

board and housing (Fig. 15).

(4) Carefully remove printed circuit board from the

cluster.

INSTALLATION

For installation, reverse the above procedures.

Carefully place board on the cluster and ensure that

the odometer connector is placed through the board.

Gently press board on cluster with a slight rocking

motion to ensure pins on gauges line up.

DOME LENS/LAMP

REMOVAL

Pry either the forward or rearward edge of the lens

away from the retainer and replace the lamp.

INSTALLATION

For installation, snap lens into retainer.

FLOOR CONSOLE

REMOVAL

(1) Remove the MTX shifter knob only.

(2) Remove the attaching screws from each side of

the cup holder.

(a) Non-armrest console. Remove the two screws

from the rear of the console (Fig. 16).

(b) Armrest console. Remove the four screws in

the console bin.

(3) Pull the parking brake lever up all the way.

(4) Lift the console at the rear and guide it out

from under the instrument panel.

INSTALLATION

For installation, reverse the above procedures.

GAUGE

REMOVAL

(1) Remove the cluster. Refer to Cluster Removal.

(2) Remove the attaching screws PC board cover

(Fig. 15). The bottom screws attaching lens to hous-

ing can be accessed without removing the foam pad.

(3) Disconnect the odometer connector.

(4) Remove the lens attaching screws and remove

the lens.

(5) Carefully pry out the dial and gauge assembly.

INSTALLATION

For installation, reverse the above procedures.

(1) When handling or storing the cluster ensure

that overlays are not damaged. Set the cluster in the

face up position or the gauge operation will be dam-

aged.

(2) The gauges are replaced as an dial and gauge

assembly.

GLOVE BOX DOOR/BIN

REMOVAL

(1) Disconnect battery negative cable and isolate it

or remove fuse 12 prior to removing the switch, or

the wires may short to ground.

(2) Remove the screws along the bottom of glove

box door.

(3) Open the glove box and push the glove box

sides inward allowing the door bumpers to clear and

box to tip forward.

(4) Pull the glove box door/bin rearward and

remove from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Fig. 15 Printed Circuit Board

Fig. 16 Floor Console with Transmission Range

Indicator

8E - 8 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 278 of 1200

GLOVE BOX SWITCH/LAMP

REMOVAL

(1) Disconnect battery negative cable and isolate it

or remove fuse 12 prior to removing the switch, or

wires may short to ground.

(2) Open the glove box and push the glove box

sides inward allowing the door bumpers to clear and

the box to tip rearward.

(3) Reach inside the opening and squeeze the

lamp/switch retainers until they are disengage.

(4) Pull the switch/lamp rearward and remove it.

Replace the lamp. To replace the switch disconnect

wire and replace the switch.

INSTALLATION

For installation, reverse the above procedures.

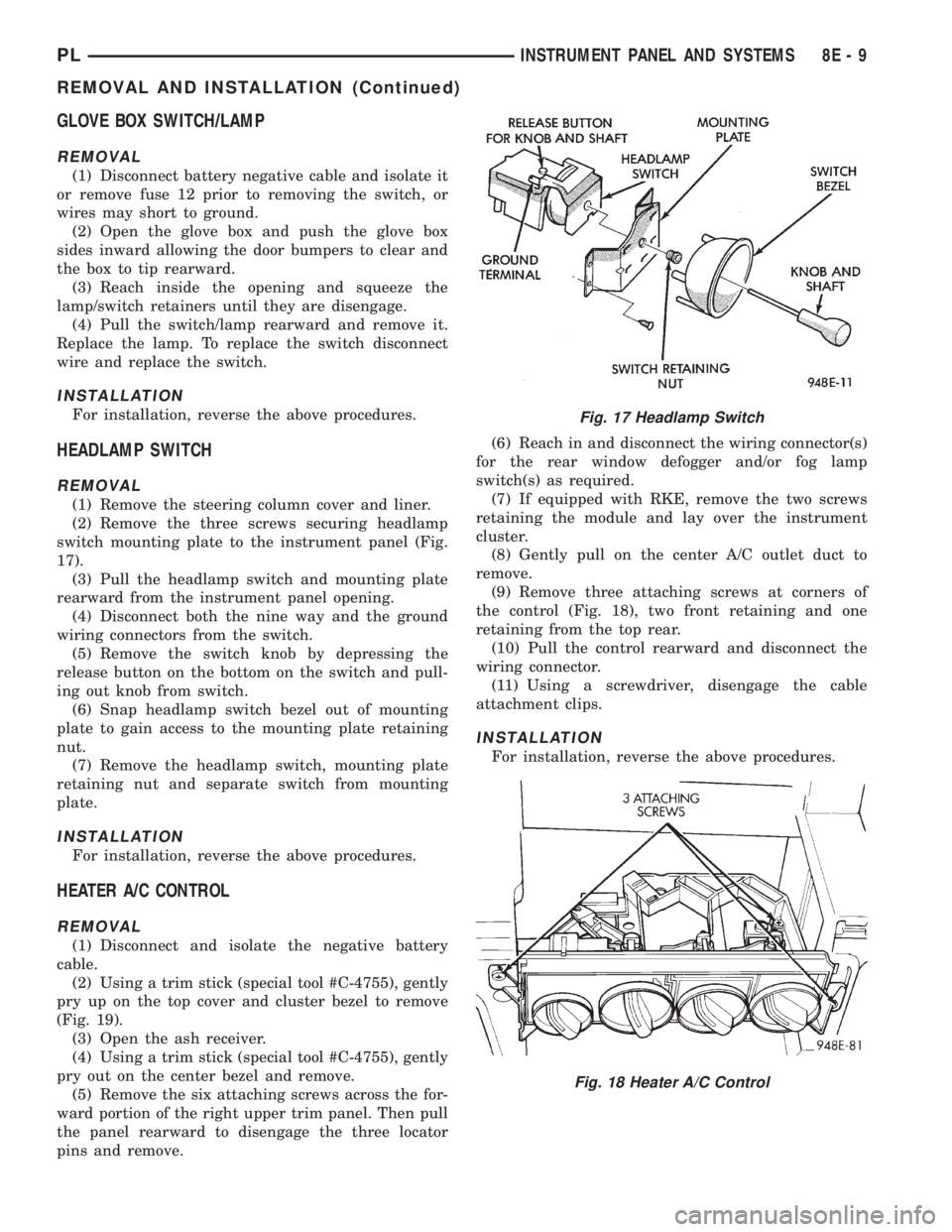

HEADLAMP SWITCH

REMOVAL

(1) Remove the steering column cover and liner.

(2) Remove the three screws securing headlamp

switch mounting plate to the instrument panel (Fig.

17).

(3) Pull the headlamp switch and mounting plate

rearward from the instrument panel opening.

(4) Disconnect both the nine way and the ground

wiring connectors from the switch.

(5) Remove the switch knob by depressing the

release button on the bottom on the switch and pull-

ing out knob from switch.

(6) Snap headlamp switch bezel out of mounting

plate to gain access to the mounting plate retaining

nut.

(7) Remove the headlamp switch, mounting plate

retaining nut and separate switch from mounting

plate.

INSTALLATION

For installation, reverse the above procedures.

HEATER A/C CONTROL

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick (special tool #C-4755), gently

pry up on the top cover and cluster bezel to remove

(Fig. 19).

(3) Open the ash receiver.

(4) Using a trim stick (special tool #C-4755), gently

pry out on the center bezel and remove.

(5) Remove the six attaching screws across the for-

ward portion of the right upper trim panel. Then pull

the panel rearward to disengage the three locator

pins and remove.(6) Reach in and disconnect the wiring connector(s)

for the rear window defogger and/or fog lamp

switch(s) as required.

(7) If equipped with RKE, remove the two screws

retaining the module and lay over the instrument

cluster.

(8) Gently pull on the center A/C outlet duct to

remove.

(9) Remove three attaching screws at corners of

the control (Fig. 18), two front retaining and one

retaining from the top rear.

(10) Pull the control rearward and disconnect the

wiring connector.

(11) Using a screwdriver, disengage the cable

attachment clips.

INSTALLATION

For installation, reverse the above procedures.

Fig. 17 Headlamp Switch

Fig. 18 Heater A/C Control

PLINSTRUMENT PANEL AND SYSTEMS 8E - 9

REMOVAL AND INSTALLATION (Continued)

Page 285 of 1200

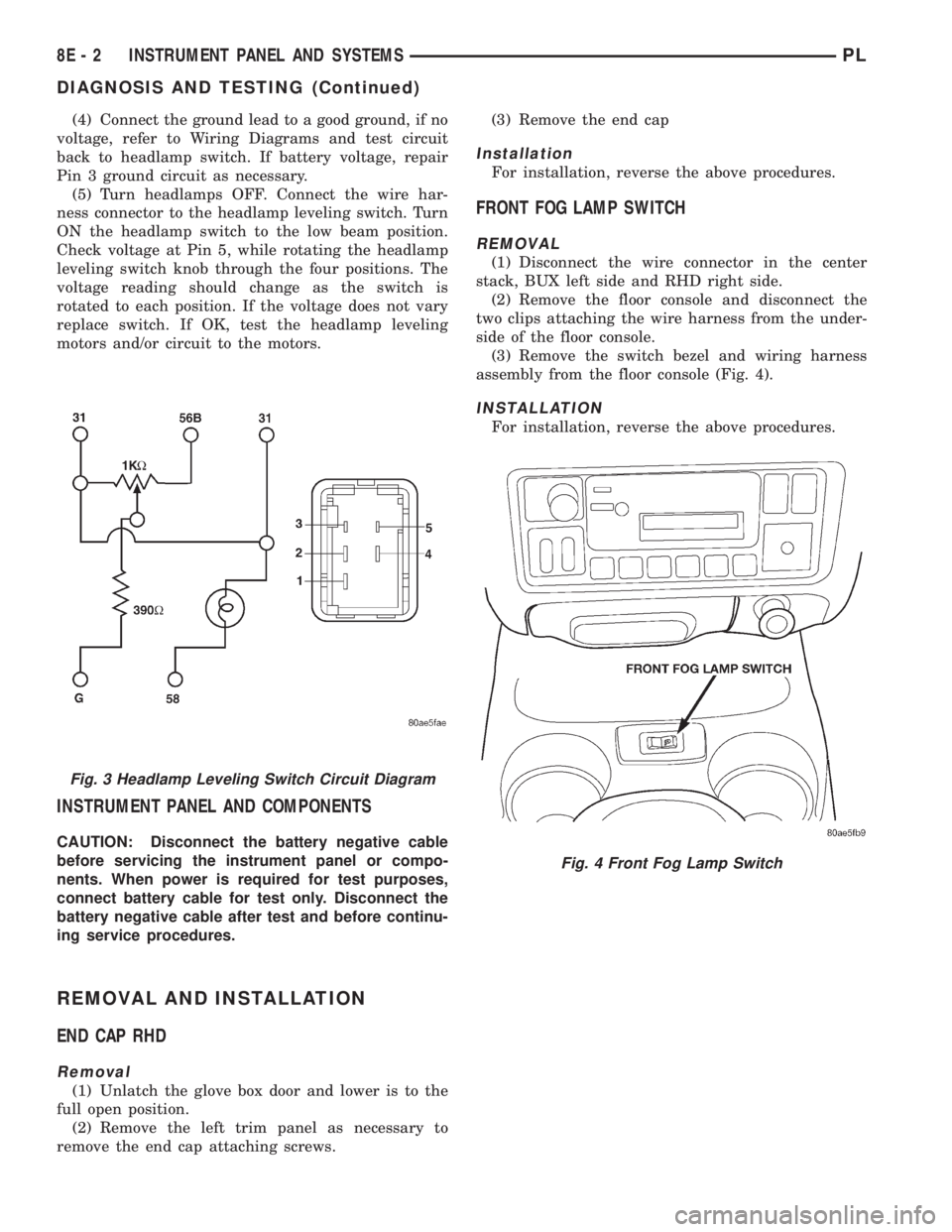

(4) Connect the ground lead to a good ground, if no

voltage, refer to Wiring Diagrams and test circuit

back to headlamp switch. If battery voltage, repair

Pin 3 ground circuit as necessary.

(5) Turn headlamps OFF. Connect the wire har-

ness connector to the headlamp leveling switch. Turn

ON the headlamp switch to the low beam position.

Check voltage at Pin 5, while rotating the headlamp

leveling switch knob through the four positions. The

voltage reading should change as the switch is

rotated to each position. If the voltage does not vary

replace switch. If OK, test the headlamp leveling

motors and/or circuit to the motors.

INSTRUMENT PANEL AND COMPONENTS

CAUTION: Disconnect the battery negative cable

before servicing the instrument panel or compo-

nents. When power is required for test purposes,

connect battery cable for test only. Disconnect the

battery negative cable after test and before continu-

ing service procedures.

REMOVAL AND INSTALLATION

END CAP RHD

Removal

(1) Unlatch the glove box door and lower is to the

full open position.

(2) Remove the left trim panel as necessary to

remove the end cap attaching screws.(3) Remove the end cap

Installation

For installation, reverse the above procedures.

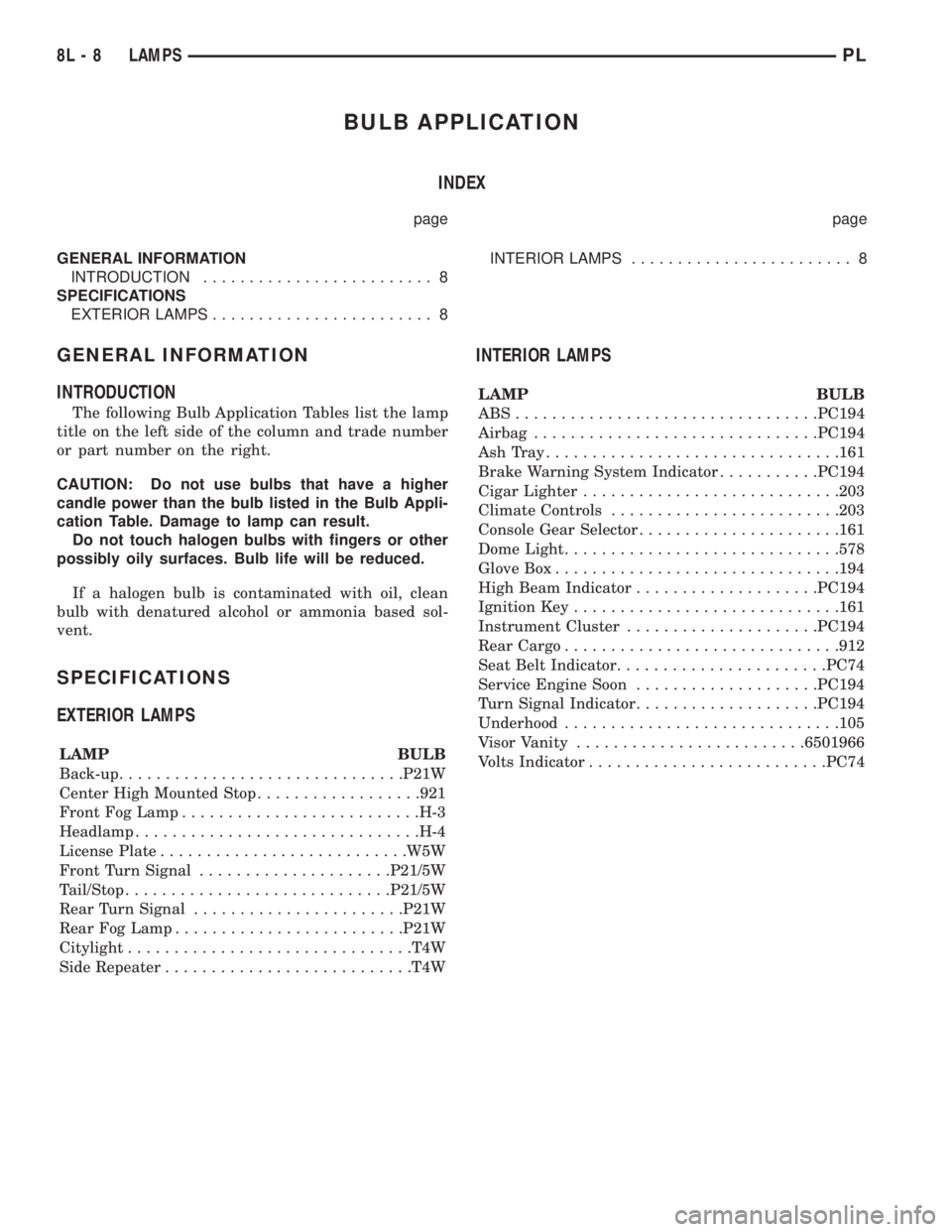

FRONT FOG LAMP SWITCH

REMOVAL

(1) Disconnect the wire connector in the center

stack, BUX left side and RHD right side.

(2) Remove the floor console and disconnect the

two clips attaching the wire harness from the under-

side of the floor console.

(3) Remove the switch bezel and wiring harness

assembly from the floor console (Fig. 4).

INSTALLATION

For installation, reverse the above procedures.

Fig. 3 Headlamp Leveling Switch Circuit Diagram

Fig. 4 Front Fog Lamp Switch

8E - 2 INSTRUMENT PANEL AND SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 351 of 1200

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 8

SPECIFICATIONS

EXTERIOR LAMPS........................ 8INTERIOR LAMPS........................ 8

GENERAL INFORMATION

INTRODUCTION

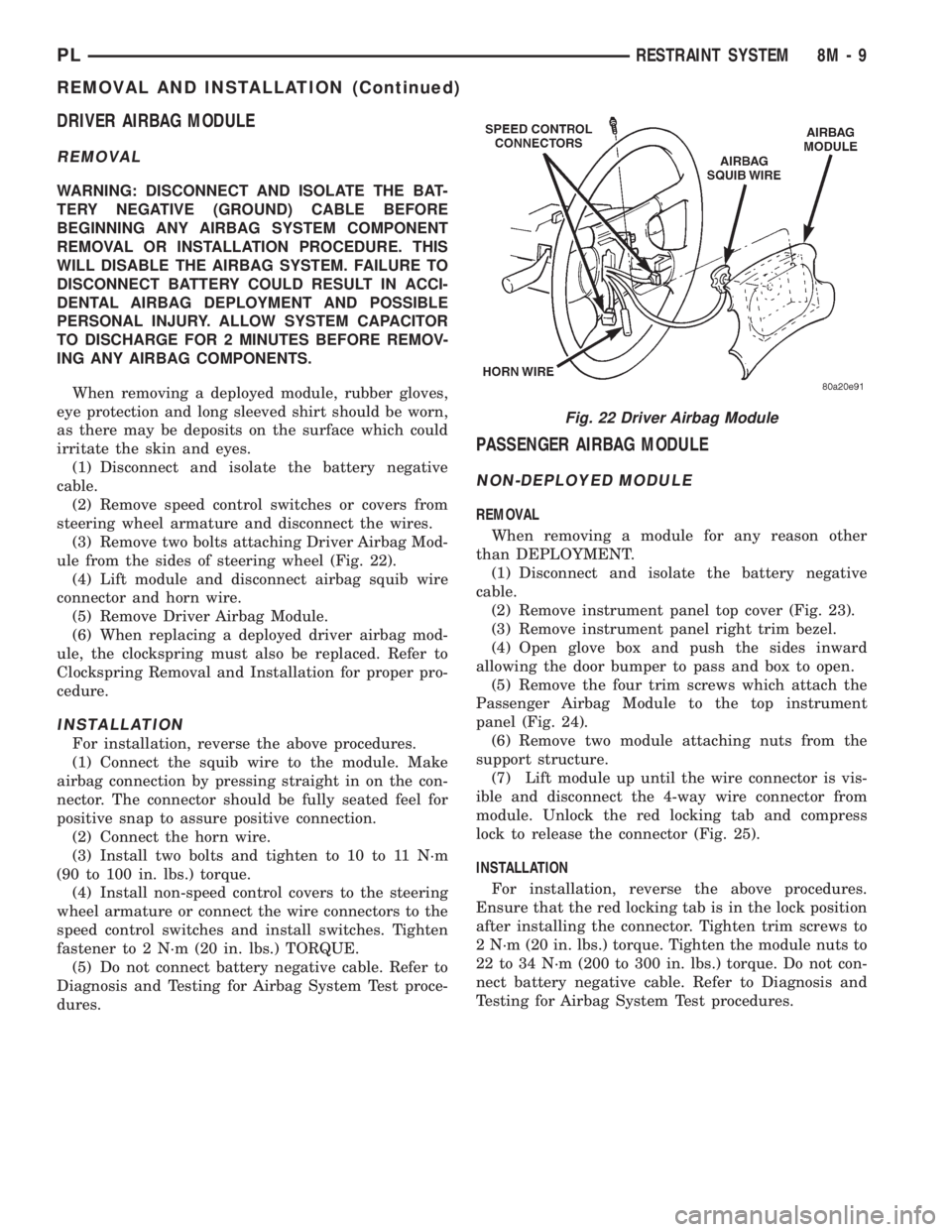

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up...............................P21W

Center High Mounted Stop..................921

Front Fog Lamp..........................H-3

Headlamp...............................H-4

License Plate...........................W5W

Front Turn Signal.....................P21/5W

Tail/Stop.............................P21/5W

Rear Turn Signal.......................P21W

Rear Fog Lamp.........................P21W

Citylight...............................T4W

Side Repeater...........................T4W

INTERIOR LAMPS

LAMP BULB

ABS.................................PC194

Airbag...............................PC194

AshTray................................161

Brake Warning System Indicator...........PC194

Cigar Lighter............................203

Climate Controls.........................203

Console Gear Selector......................161

Dome Light..............................578

Glove Box...............................194

High Beam Indicator....................PC194

Ignition Key.............................161

Instrument Cluster.....................PC194

Rear Cargo..............................912

Seat Belt Indicator.......................PC74

Service Engine Soon....................PC194

Turn Signal Indicator....................PC194

Underhood..............................105

Visor Vanity.........................6501966

Volts Indicator..........................PC74

8L - 8 LAMPSPL

Page 360 of 1200

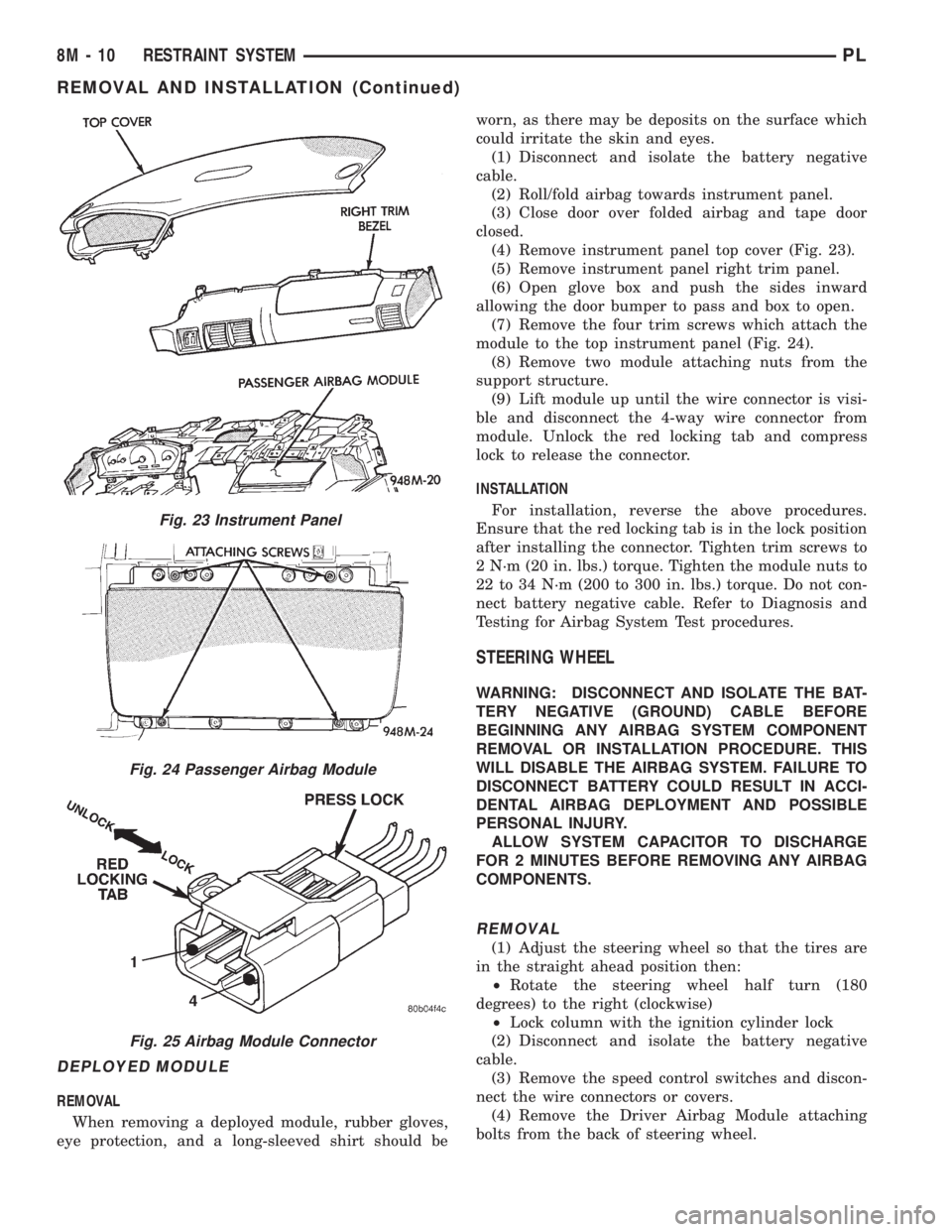

DRIVER AIRBAG MODULE

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

When removing a deployed module, rubber gloves,

eye protection and long sleeved shirt should be worn,

as there may be deposits on the surface which could

irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove speed control switches or covers from

steering wheel armature and disconnect the wires.

(3) Remove two bolts attaching Driver Airbag Mod-

ule from the sides of steering wheel (Fig. 22).

(4) Lift module and disconnect airbag squib wire

connector and horn wire.

(5) Remove Driver Airbag Module.

(6) When replacing a deployed driver airbag mod-

ule, the clockspring must also be replaced. Refer to

Clockspring Removal and Installation for proper pro-

cedure.

INSTALLATION

For installation, reverse the above procedures.

(1) Connect the squib wire to the module. Make

airbag connection by pressing straight in on the con-

nector. The connector should be fully seated feel for

positive snap to assure positive connection.

(2) Connect the horn wire.

(3) Install two bolts and tighten to 10 to 11 N´m

(90 to 100 in. lbs.) torque.

(4) Install non-speed control covers to the steering

wheel armature or connect the wire connectors to the

speed control switches and install switches. Tighten

fastener to 2 N´m (20 in. lbs.) TORQUE.

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test proce-

dures.

PASSENGER AIRBAG MODULE

NON-DEPLOYED MODULE

REMOVAL

When removing a module for any reason other

than DEPLOYMENT.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel top cover (Fig. 23).

(3) Remove instrument panel right trim bezel.

(4) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(5) Remove the four trim screws which attach the

Passenger Airbag Module to the top instrument

panel (Fig. 24).

(6) Remove two module attaching nuts from the

support structure.

(7) Lift module up until the wire connector is vis-

ible and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector (Fig. 25).

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

Fig. 22 Driver Airbag Module

PLRESTRAINT SYSTEM 8M - 9

REMOVAL AND INSTALLATION (Continued)

Page 361 of 1200

DEPLOYED MODULE

REMOVAL

When removing a deployed module, rubber gloves,

eye protection, and a long-sleeved shirt should beworn, as there may be deposits on the surface which

could irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

(2) Roll/fold airbag towards instrument panel.

(3) Close door over folded airbag and tape door

closed.

(4) Remove instrument panel top cover (Fig. 23).

(5) Remove instrument panel right trim panel.

(6) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(7) Remove the four trim screws which attach the

module to the top instrument panel (Fig. 24).

(8) Remove two module attaching nuts from the

support structure.

(9) Lift module up until the wire connector is visi-

ble and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector.

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

STEERING WHEEL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 2 MINUTES BEFORE REMOVING ANY AIRBAG

COMPONENTS.

REMOVAL

(1) Adjust the steering wheel so that the tires are

in the straight ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise)

²Lock column with the ignition cylinder lock

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the speed control switches and discon-

nect the wire connectors or covers.

(4) Remove the Driver Airbag Module attaching

bolts from the back of steering wheel.

Fig. 23 Instrument Panel

Fig. 24 Passenger Airbag Module

Fig. 25 Airbag Module Connector

8M - 10 RESTRAINT SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 410 of 1200

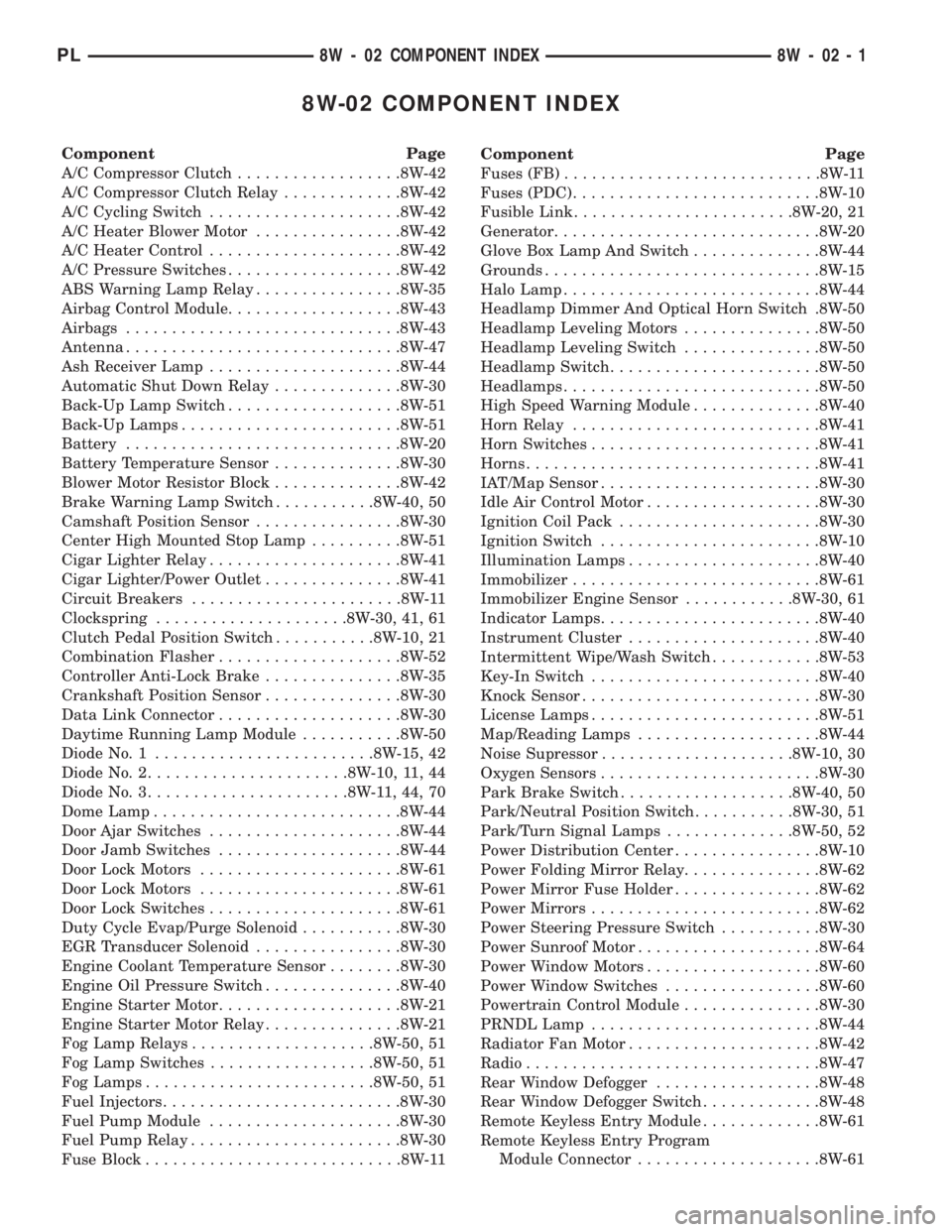

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch..................8W-42

A/C Compressor Clutch Relay.............8W-42

A/C Cycling Switch.....................8W-42

A/C Heater Blower Motor................8W-42

A/C Heater Control.....................8W-42

A/C Pressure Switches...................8W-42

ABS Warning Lamp Relay................8W-35

Airbag Control Module...................8W-43

Airbags..............................8W-43

Antenna..............................8W-47

Ash Receiver Lamp.....................8W-44

Automatic Shut Down Relay..............8W-30

Back-Up Lamp Switch...................8W-51

Back-Up Lamps........................8W-51

Battery..............................8W-20

Battery Temperature Sensor..............8W-30

Blower Motor Resistor Block..............8W-42

Brake Warning Lamp Switch...........8W-40, 50

Camshaft Position Sensor................8W-30

Center High Mounted Stop Lamp..........8W-51

Cigar Lighter Relay.....................8W-41

Cigar Lighter/Power Outlet...............8W-41

Circuit Breakers.......................8W-11

Clockspring.....................8W-30, 41, 61

Clutch Pedal Position Switch...........8W-10, 21

Combination Flasher....................8W-52

Controller Anti-Lock Brake...............8W-35

Crankshaft Position Sensor...............8W-30

Data Link Connector....................8W-30

Daytime Running Lamp Module...........8W-50

Diode No. 1........................8W-15, 42

Diode No. 2......................8W-10, 11, 44

Diode No. 3......................8W-11,44,70

Dome Lamp...........................8W-44

Door Ajar Switches.....................8W-44

Door Jamb Switches....................8W-44

Door Lock Motors......................8W-61

Door Lock Motors......................8W-61

Door Lock Switches.....................8W-61

Duty Cycle Evap/Purge Solenoid...........8W-30

EGR Transducer Solenoid................8W-30

Engine Coolant Temperature Sensor........8W-30

Engine Oil Pressure Switch...............8W-40

Engine Starter Motor....................8W-21

Engine Starter Motor Relay...............8W-21

Fog Lamp Relays....................8W-50, 51

Fog Lamp Switches..................8W-50, 51

Fog Lamps.........................8W-50, 51

Fuel Injectors..........................8W-30

Fuel Pump Module.....................8W-30

Fuel Pump Relay.......................8W-30

Fuse Block............................8W-11Component Page

Fuses (FB)............................8W-11

Fuses (PDC)...........................8W-10

Fusible Link........................8W-20, 21

Generator.............................8W-20

Glove Box Lamp And Switch..............8W-44

Grounds..............................8W-15

Halo Lamp............................8W-44

Headlamp Dimmer And Optical Horn Switch .8W-50

Headlamp Leveling Motors...............8W-50

Headlamp Leveling Switch...............8W-50

Headlamp Switch.......................8W-50

Headlamps............................8W-50

High Speed Warning Module..............8W-40

Horn Relay...........................8W-41

Horn Switches.........................8W-41

Horns................................8W-41

IAT/Map Sensor........................8W-30

Idle Air Control Motor...................8W-30

Ignition Coil Pack......................8W-30

Ignition Switch........................8W-10

Illumination Lamps.....................8W-40

Immobilizer...........................8W-61

Immobilizer Engine Sensor............8W-30, 61

Indicator Lamps........................8W-40

Instrument Cluster.....................8W-40

Intermittent Wipe/Wash Switch............8W-53

Key-In Switch.........................8W-40

Knock Sensor..........................8W-30

License Lamps.........................8W-51

Map/Reading Lamps....................8W-44

Noise Supressor.....................8W-10, 30

Oxygen Sensors........................8W-30

Park Brake Switch...................8W-40, 50

Park/Neutral Position Switch...........8W-30, 51

Park/Turn Signal Lamps..............8W-50, 52

Power Distribution Center................8W-10

Power Folding Mirror Relay...............8W-62

Power Mirror Fuse Holder................8W-62

Power Mirrors.........................8W-62

Power Steering Pressure Switch...........8W-30

Power Sunroof Motor....................8W-64

Power Window Motors...................8W-60

Power Window Switches.................8W-60

Powertrain Control Module...............8W-30

PRNDL Lamp.........................8W-44

Radiator Fan Motor.....................8W-42

Radio................................8W-47

Rear Window Defogger..................8W-48

Rear Window Defogger Switch.............8W-48

Remote Keyless Entry Module.............8W-61

Remote Keyless Entry Program

Module Connector....................8W-61

PL8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 412 of 1200

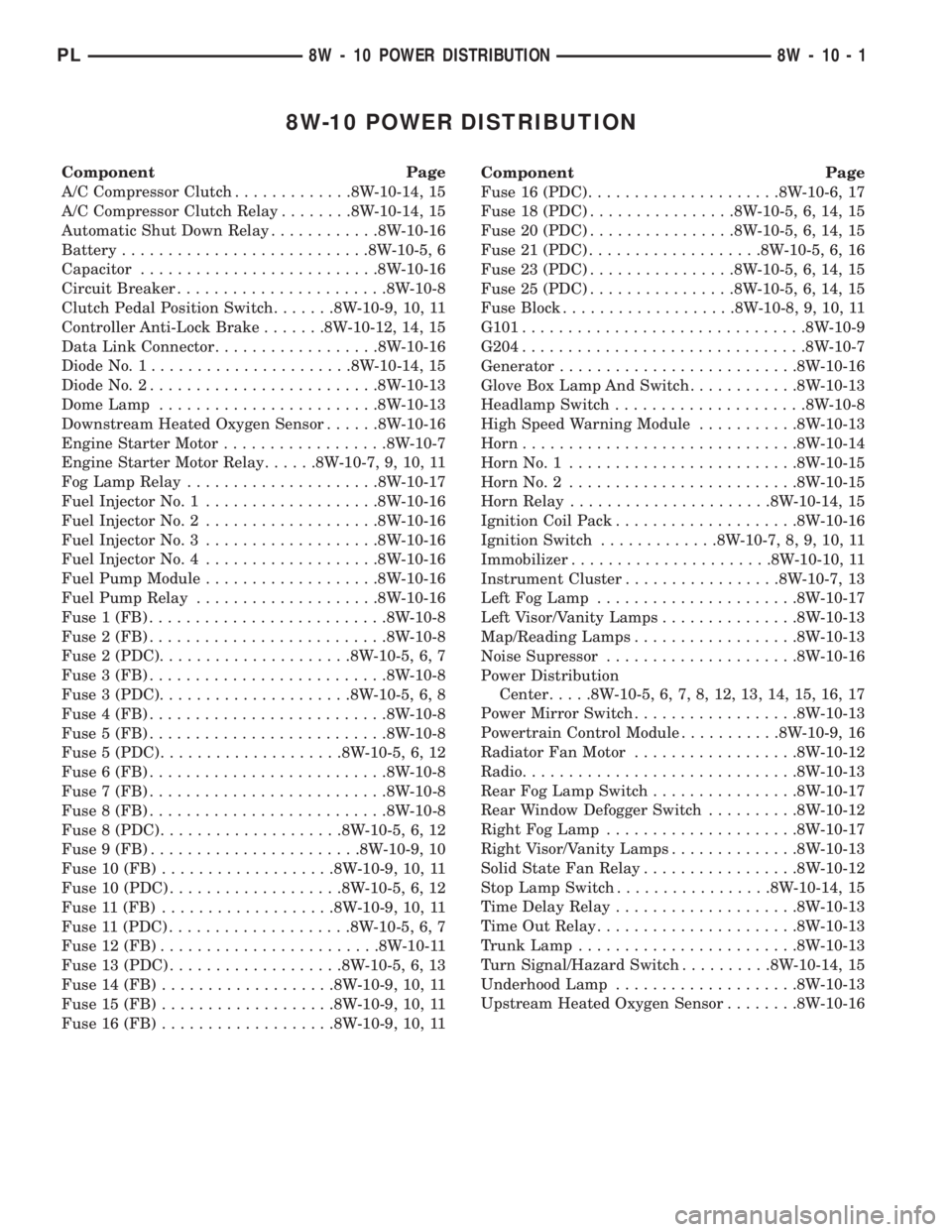

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch.............8W-10-14, 15

A/C Compressor Clutch Relay........8W-10-14, 15

Automatic Shut Down Relay............8W-10-16

Battery...........................8W-10-5, 6

Capacitor..........................8W-10-16

Circuit Breaker.......................8W-10-8

Clutch Pedal Position Switch.......8W-10-9, 10, 11

Controller Anti-Lock Brake.......8W-10-12, 14, 15

Data Link Connector..................8W-10-16

Diode No. 1......................8W-10-14, 15

Diode No. 2.........................8W-10-13

Dome Lamp........................8W-10-13

Downstream Heated Oxygen Sensor......8W-10-16

Engine Starter Motor..................8W-10-7

Engine Starter Motor Relay......8W-10-7, 9, 10, 11

Fog Lamp Relay.....................8W-10-17

Fuel Injector No. 1...................8W-10-16

Fuel Injector No. 2...................8W-10-16

Fuel Injector No. 3...................8W-10-16

Fuel Injector No. 4...................8W-10-16

Fuel Pump Module...................8W-10-16

Fuel Pump Relay....................8W-10-16

Fuse 1 (FB)..........................8W-10-8

Fuse 2 (FB)..........................8W-10-8

Fuse 2 (PDC).....................8W-10-5, 6, 7

Fuse 3 (FB)..........................8W-10-8

Fuse 3 (PDC).....................8W-10-5, 6, 8

Fuse 4 (FB)..........................8W-10-8

Fuse 5 (FB)..........................8W-10-8

Fuse 5 (PDC)....................8W-10-5, 6, 12

Fuse 6 (FB)..........................8W-10-8

Fuse 7 (FB)..........................8W-10-8

Fuse 8 (FB)..........................8W-10-8

Fuse 8 (PDC)....................8W-10-5, 6, 12

Fuse 9 (FB).......................8W-10-9, 10

Fuse 10 (FB)...................8W-10-9, 10, 11

Fuse 10 (PDC)...................8W-10-5, 6, 12

Fuse 11 (FB)...................8W-10-9, 10, 11

Fuse 11 (PDC)....................8W-10-5, 6, 7

Fuse 12 (FB)........................8W-10-11

Fuse 13 (PDC)...................8W-10-5, 6, 13

Fuse 14 (FB)...................8W-10-9, 10, 11

Fuse 15 (FB)...................8W-10-9, 10, 11

Fuse 16 (FB)...................8W-10-9, 10, 11Component Page

Fuse 16 (PDC).....................8W-10-6, 17

Fuse 18 (PDC)................8W-10-5, 6, 14, 15

Fuse 20 (PDC)................8W-10-5, 6, 14, 15

Fuse 21 (PDC)...................8W-10-5, 6, 16

Fuse 23 (PDC)................8W-10-5, 6, 14, 15

Fuse 25 (PDC)................8W-10-5, 6, 14, 15

Fuse Block...................8W-10-8, 9, 10, 11

G101...............................8W-10-9

G204...............................8W-10-7

Generator..........................8W-10-16

Glove Box Lamp And Switch............8W-10-13

Headlamp Switch.....................8W-10-8

High Speed Warning Module...........8W-10-13

Horn..............................8W-10-14

Horn No. 1.........................8W-10-15

Horn No. 2.........................8W-10-15

Horn Relay......................8W-10-14, 15

Ignition Coil Pack....................8W-10-16

Ignition Switch.............8W-10-7, 8, 9, 10, 11

Immobilizer......................8W-10-10, 11

Instrument Cluster.................8W-10-7, 13

Left Fog Lamp......................8W-10-17

Left Visor/Vanity Lamps...............8W-10-13

Map/Reading Lamps..................8W-10-13

Noise Supressor.....................8W-10-16

Power Distribution

Center.....8W-10-5, 6, 7, 8, 12, 13, 14, 15, 16, 17

Power Mirror Switch..................8W-10-13

Powertrain Control Module...........8W-10-9, 16

Radiator Fan Motor..................8W-10-12

Radio..............................8W-10-13

Rear Fog Lamp Switch................8W-10-17

Rear Window Defogger Switch..........8W-10-12

Right Fog Lamp.....................8W-10-17

Right Visor/Vanity Lamps..............8W-10-13

Solid State Fan Relay.................8W-10-12

Stop Lamp Switch.................8W-10-14, 15

Time Delay Relay....................8W-10-13

Time Out Relay......................8W-10-13

Trunk Lamp........................8W-10-13

Turn Signal/Hazard Switch..........8W-10-14, 15

Underhood Lamp....................8W-10-13

Upstream Heated Oxygen Sensor........8W-10-16

PL8W - 10 POWER DISTRIBUTION 8W - 10 - 1