ABS DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1033 of 1285

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Transfer shaft

²Transfer shaft gear

²Transfer shaft bearings

²Governor support retainer

²Transfer shaft bearing retainer

²Retainer snap ring

²Governor support

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.

STIRRUP AND STRAP INSTALLATION

Once bearing shim selection has been adjusted,

install stirrup and strap assembly onto transfer gear.

NOTE: Once the stirrup assembly is positioned

onto the transfer gear, it is necessary to ªclockº the

stirrup against the flats of the transfer gear retain-

ing nut.

(1) Position the stirrup on the transfer gear.

(2) Position strap.

(3) Install retaining bolts into transfer gear. Fin-

ger±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

transfer gear retaining nut.

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.).(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

ASSEMBLY

To install transfer shaft, reverse the above proce-

dure.

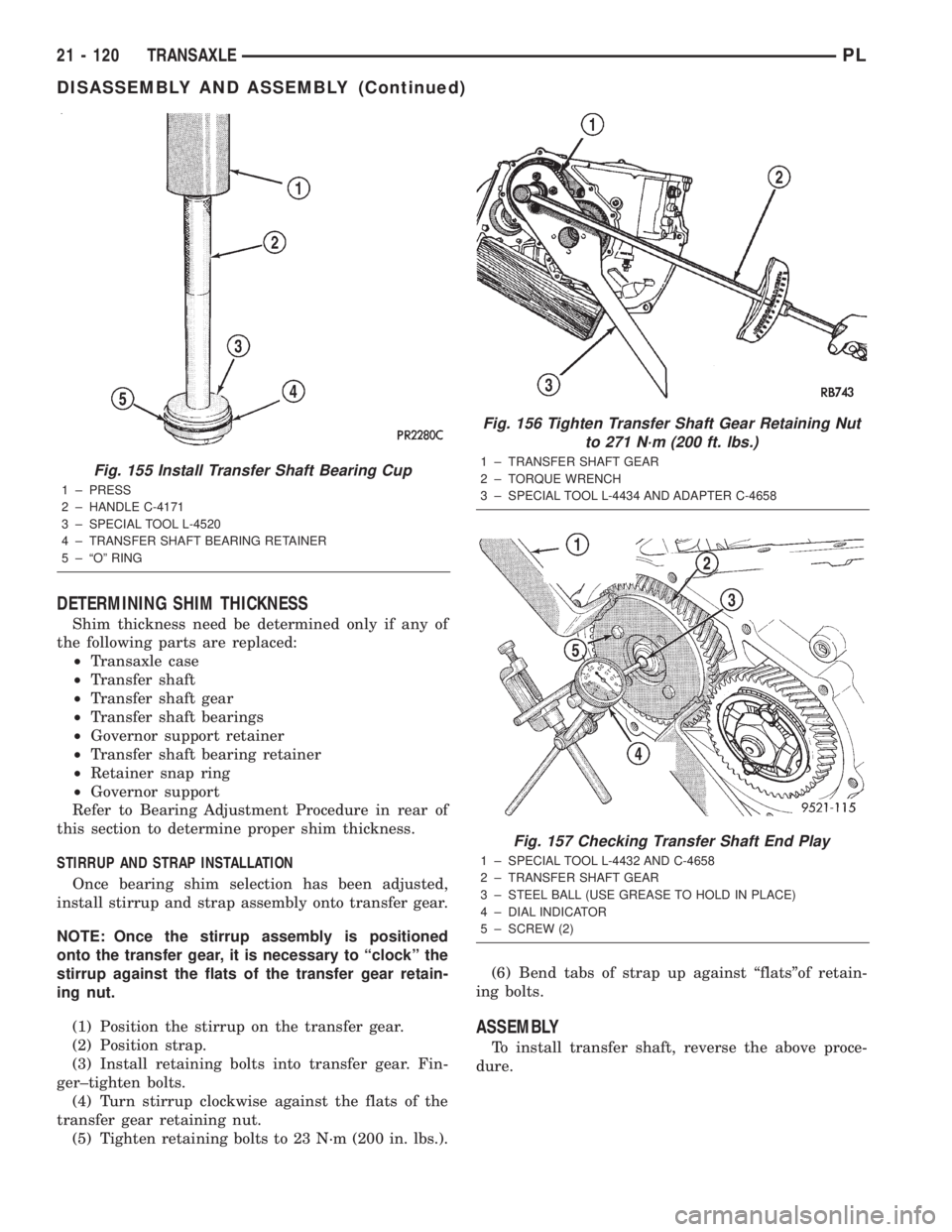

Fig. 155 Install Transfer Shaft Bearing Cup

1 ± PRESS

2 ± HANDLE C-4171

3 ± SPECIAL TOOL L-4520

4 ± TRANSFER SHAFT BEARING RETAINER

5 ± ªOº RING

Fig. 156 Tighten Transfer Shaft Gear Retaining Nut

to 271 N´m (200 ft. lbs.)

1 ± TRANSFER SHAFT GEAR

2 ± TORQUE WRENCH

3 ± SPECIAL TOOL L-4434 AND ADAPTER C-4658

Fig. 157 Checking Transfer Shaft End Play

1 ± SPECIAL TOOL L-4432 AND C-4658

2 ± TRANSFER SHAFT GEAR

3 ± STEEL BALL (USE GREASE TO HOLD IN PLACE)

4 ± DIAL INDICATOR

5 ± SCREW (2)

21 - 120 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1035 of 1285

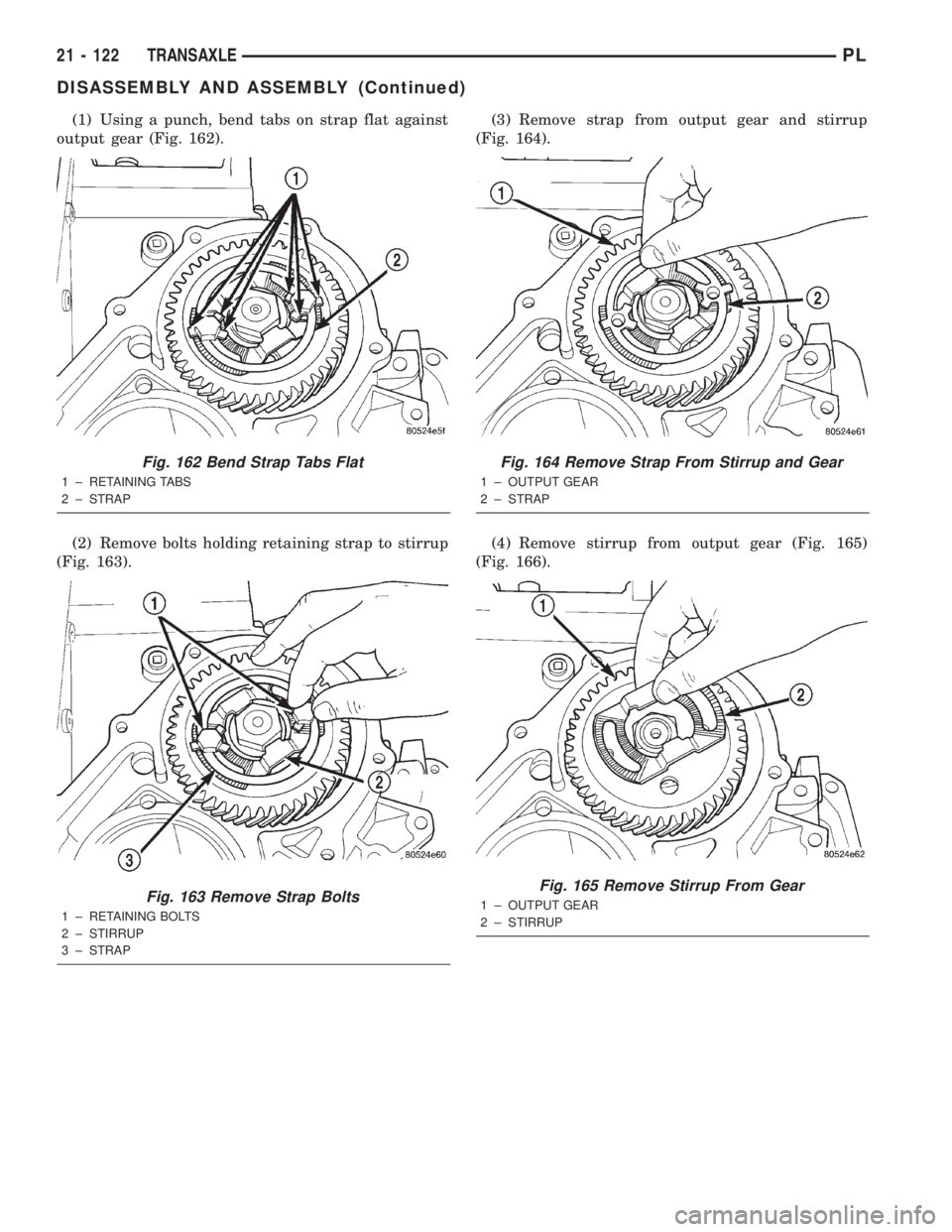

(1) Using a punch, bend tabs on strap flat against

output gear (Fig. 162).

(2) Remove bolts holding retaining strap to stirrup

(Fig. 163).(3) Remove strap from output gear and stirrup

(Fig. 164).

(4) Remove stirrup from output gear (Fig. 165)

(Fig. 166).

Fig. 162 Bend Strap Tabs Flat

1 ± RETAINING TABS

2 ± STRAP

Fig. 163 Remove Strap Bolts

1 ± RETAINING BOLTS

2 ± STIRRUP

3 ± STRAP

Fig. 164 Remove Strap From Stirrup and Gear

1 ± OUTPUT GEAR

2 ± STRAP

Fig. 165 Remove Stirrup From Gear

1 ± OUTPUT GEAR

2 ± STIRRUP

21 - 122 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1041 of 1285

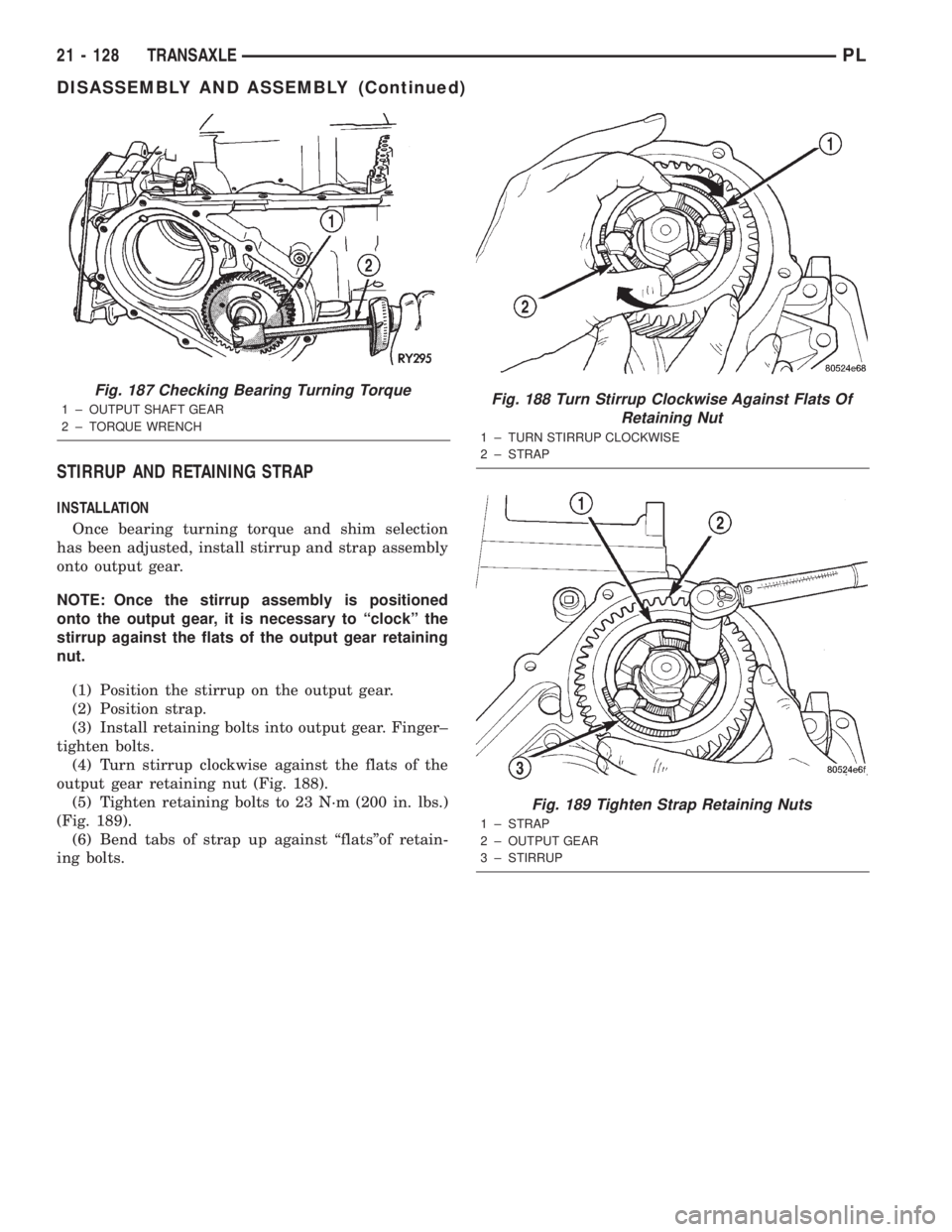

STIRRUP AND RETAINING STRAP

INSTALLATION

Once bearing turning torque and shim selection

has been adjusted, install stirrup and strap assembly

onto output gear.

NOTE: Once the stirrup assembly is positioned

onto the output gear, it is necessary to ªclockº the

stirrup against the flats of the output gear retaining

nut.

(1) Position the stirrup on the output gear.

(2) Position strap.

(3) Install retaining bolts into output gear. Finger±

tighten bolts.

(4) Turn stirrup clockwise against the flats of the

output gear retaining nut (Fig. 188).

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.)

(Fig. 189).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

Fig. 187 Checking Bearing Turning Torque

1 ± OUTPUT SHAFT GEAR

2 ± TORQUE WRENCHFig. 188 Turn Stirrup Clockwise Against Flats Of

Retaining Nut

1 ± TURN STIRRUP CLOCKWISE

2 ± STRAP

Fig. 189 Tighten Strap Retaining Nuts

1 ± STRAP

2 ± OUTPUT GEAR

3 ± STIRRUP

21 - 128 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1084 of 1285

REMOVAL AND INSTALLATION

WHEEL COVER (LOCK-ON)

REMOVE

NOTE: When unthreading the wheel cover retaining

nuts (Fig. 12) from the wheel nuts it is recom-

mended that a hand wrench be used and not an

impact wrench. Use of an impact wrench could

result in damage to the lock-on wheel cover retain-

ing nuts.

(1) Un-thread the 5 nuts (Fig. 12) attaching the

wheel cover to the wheel nuts.

(2) Grasp the wheel cover and pull straight out-

ward from the wheel. This will remove the wheel

cover from the wheel.

INSTALL

(1) Align the valve notch in the wheel cover with

the valve stem on the wheel (Fig. 12). Align the

wheel cover retaining nuts with the externally

threaded wheel nuts.

(2) By hand, start to thread all 5 of the wheel

cover retaining nuts onto the externally threaded

wheel nuts.

NOTE: When tightening the wheel cover retaining

nuts it is recommended that a hand wrench be used

and not an impact wrench. Use of an impact wrenchcould result in damage to the lock-on wheel cover

retaining nuts.

(3) Tighten each of the wheel cover retaining nuts.

If the retaining nut ªjumpsº a thread (slips), which is

an override feature of the retaining nut, retighten

the retaining nut to a point just prior to this occur-

ring. To avoid rattling of the wheel cover be sure all

five retaining nuts are correctly tightened.

WHEEL COVER RETAINING NUT

If a retaining nut for the lock-on wheel cover is

damaged, it can be replaced as a separate component

of the wheel cover. Use the following procedure for

replacing a wheel cover retaining nut.

REMOVE

(1) If required, remove the wheel cover from the

wheel. Refer to Wheel Cover Lock-On in the Removal

And Installation Section in this group of the service

manual for the procedure.

NOTE: The retaining nut flange can not be forced

past the large retaining tab. When removing retain-

ing nut from wheel cover, the flange on the retain-

ing nut must be forced past the 2 small retaining

tabs on wheel cover.

(2) From the back side of the wheel cover, push

outward and tilt the retaining nut sideways forcing

the flange on the retaining nut past the 2 small

retaining tabs in the retaining nut hole of the wheel

cover (Fig. 13).

Fig. 12 Wheel Cover Retaining Nuts

1 ± TIRE

2 ± VALVE STEM

3 ± LOCK-ON WHEEL COVER

4 ± WHEEL

5 ± WHEEL COVER RETAINING NUTS

Fig. 13 Wheel Cover Retaining Nut Retention

1 ± WHEEL COVER

2 ± WHEEL COVER RETAINING NUT

3 ± SMALL RETAINING TABS

4 ± LARGE RETAINING TAB

PLTIRES AND WHEELS 22 - 15

Page 1085 of 1285

(3) When flange on retaining nut is past the 2

retaining tabs on the wheel cover, remove retaining

nut from wheel cover by pushing or pulling from hole

in wheel cover.

INSTALL

(1) Install retaining nut in hole of wheel cover

with retaining nut flange positioned under the large

retaining flange (Fig. 13).

(2) Push on hex of retaining nut forcing the retain-

ing nut flange past the 2 small retaining tabs in

wheel cover.

TIRE AND WHEEL ASSEMBLY

CAST WHEEL

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE section.

(2) Remove the wheel mounting nuts from the

studs.

(3) Remove the tire and wheel assembly from the

hub.

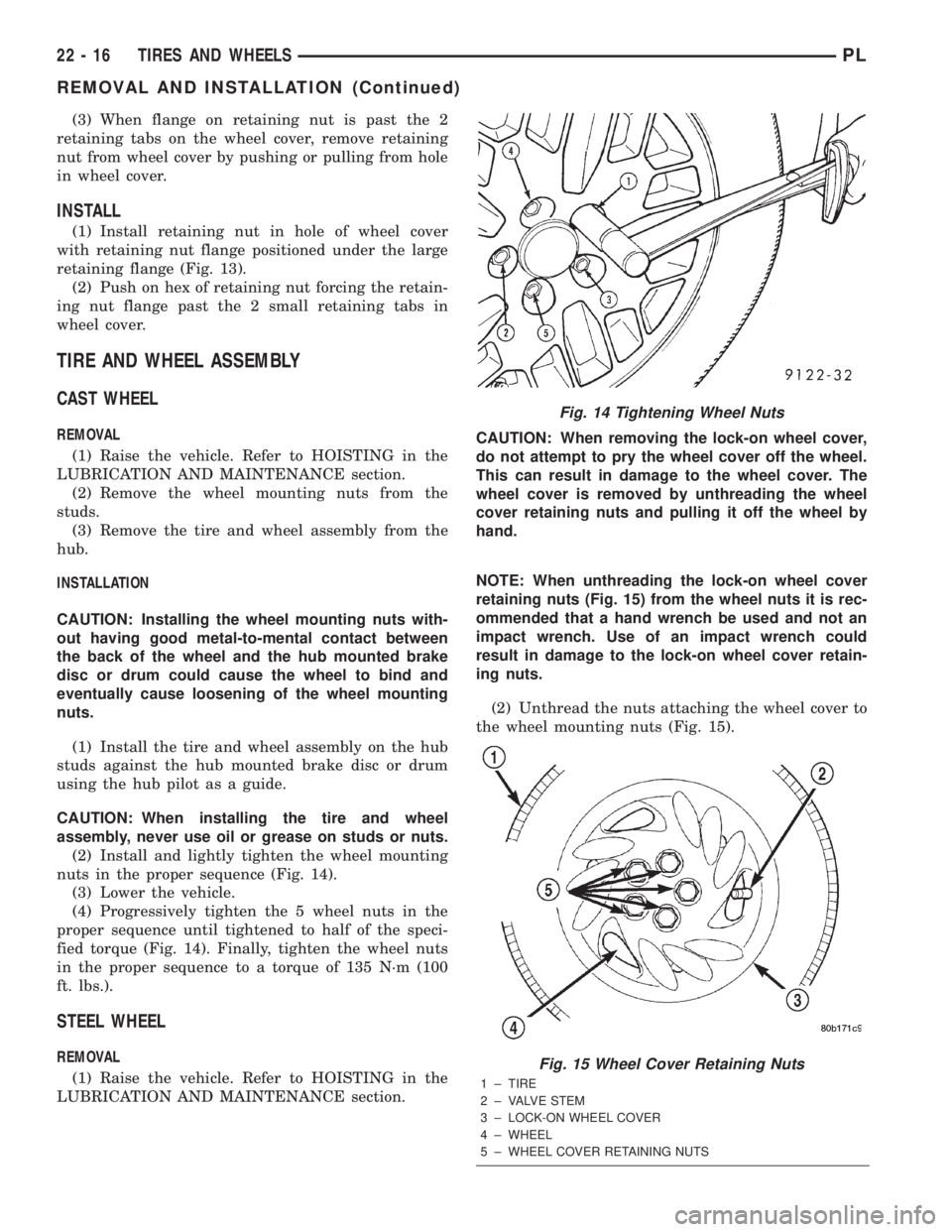

INSTALLATION

CAUTION: Installing the wheel mounting nuts with-

out having good metal-to-mental contact between

the back of the wheel and the hub mounted brake

disc or drum could cause the wheel to bind and

eventually cause loosening of the wheel mounting

nuts.

(1) Install the tire and wheel assembly on the hub

studs against the hub mounted brake disc or drum

using the hub pilot as a guide.

CAUTION: When installing the tire and wheel

assembly, never use oil or grease on studs or nuts.

(2) Install and lightly tighten the wheel mounting

nuts in the proper sequence (Fig. 14).

(3) Lower the vehicle.

(4) Progressively tighten the 5 wheel nuts in the

proper sequence until tightened to half of the speci-

fied torque (Fig. 14). Finally, tighten the wheel nuts

in the proper sequence to a torque of 135 N´m (100

ft. lbs.).

STEEL WHEEL

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE section.CAUTION: When removing the lock-on wheel cover,

do not attempt to pry the wheel cover off the wheel.

This can result in damage to the wheel cover. The

wheel cover is removed by unthreading the wheel

cover retaining nuts and pulling it off the wheel by

hand.

NOTE: When unthreading the lock-on wheel cover

retaining nuts (Fig. 15) from the wheel nuts it is rec-

ommended that a hand wrench be used and not an

impact wrench. Use of an impact wrench could

result in damage to the lock-on wheel cover retain-

ing nuts.

(2) Unthread the nuts attaching the wheel cover to

the wheel mounting nuts (Fig. 15).

Fig. 14 Tightening Wheel Nuts

Fig. 15 Wheel Cover Retaining Nuts

1 ± TIRE

2 ± VALVE STEM

3 ± LOCK-ON WHEEL COVER

4 ± WHEEL

5 ± WHEEL COVER RETAINING NUTS

22 - 16 TIRES AND WHEELSPL

REMOVAL AND INSTALLATION (Continued)

Page 1091 of 1285

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Alternate Good Trip

Alternate Good Trips are used in place of Global

Good Trips for Comprehensive Components and

Major Monitors. If the Task Manager cannot run a

Global Good Trip because a component fault is stop-

ping the monitor from running, it will attempt to

count an Alternate Good Trip.

The Task Manager counts an Alternate Good Trip

for Comprehensive components when the following

conditions are met:

²Two minutes of engine run time

²No other faults occur

The Task Manager counts an Alternate Good Trip

for a Major Monitor when the monitor runs and

passes. Only the Major Monitor that failed needs to

pass to count an Alternate Good Trip.

Warm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for twotrip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-

lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM uti-

lizes both Short Term Compensation and Long Term

Adaptive to calculate the Adaptive Memory Factor

for total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factor

must stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

25 - 4 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1092 of 1285

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Misfire OccurredÐ

The stored MAP reading at the time of failure.

Informs the user at what engine load the failure

occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Misfire OccurredÐ The stored

RPM reading at the time of failure. Informs the user

at what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM uti-

lizes both Short Term Compensation and Long Term

Adaptive to calculate the Adaptive Memory Factor

for total fuel correction.

²200 Rev CounterÐ Counts 0±100 720 degree

cycles.

²SCW Cat 200 Rev CounterÐ Counts when in

similar conditions.

²SCW FTP 1000 Rev CounterÐ Counts 0±4

when in similar conditions.

²Misfire Good Trip CounterÐ Counts up to

three to turn OFF the MIL.

MALFUNCTION INDICATOR LAMP (MIL)

OPERATION

As a functional test, the Malfunction Indicator

Lamp (MIL) illuminates at key-on before engine

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the PCI Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

DRB III STATE DISPLAY TEST MODE

OPERATION

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

DRB III CIRCUIT ACTUATION TEST MODE

OPERATION

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly.

DIAGNOSTIC TROUBLE CODES

DESCRIPTION

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

PLEMISSION CONTROL SYSTEMS 25 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1104 of 1285

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S output. The programmed memory

acts as a self calibration tool that the engine control-

ler uses to compensate for variations in engine spec-

ifications, sensor tolerances and engine fatigue over

the life span of the engine. By monitoring the actual

air-fuel ratio with the O2S (short term) and multiply-

ing that with the program long-term (adaptive) mem-

ory and comparing that to the limit, it can be

determined whether it will pass an emissions test. If

a malfunction occurs such that the PCM cannot

maintain the optimum A/F ratio, then the MIL will

be illuminated.

Monitor OperationÐFuel systems monitors do

not have a pre-test because they are continuously

running monitors. Therefore, the PCM constantly

monitors Short Term Compensation and Long Term

Adaptive memory.

Lean: If at anytime during a lean engine operation,

short term compensation multiplied by long term

adaptive exceeds a certain percentage for an

extended period, the PCM sets a Fuel System Lean

Fault for that trip and a Freeze Frame is entered.

Rich: If at anytime during a rich operation, Short

Term Compensation multiplied by Long Term Adap-

tive is less than a predetermined value, the PCM

checks the Purge Free Cells.

Purge Free Cells are values placed in Adaptive

Memory cells when the EVAP Purge Solenoid is OFF.

Two, three or four Purge Free cells are used. One cor-

responds to an Adaptive Memory cell at idle, the

other to a cell that is off-idle. For example, if a Purge

Free cell is labeled PFC1, it would hold the value for

Adaptive Memory cell C1 under non-purge condi-

tions.

If all Purge Free Cells are less than a certain per-

centage, and the Adaptive Memory factor is less than

a certain percentage, the PCM sets a Fuel System

Rich fault for that trip and a Freeze Frame is

entered.

The Fuel Monitor is a two trip monitor. The PCM

records engine data in Freeze Frame upon setting of

the first fault, or maturing code. When the fuel mon-

itor fails on a second consecutive trip, the code is

matured and the MIL is illuminated. The stored

Freeze Frame data is still from the first fault.

In order for the PCM to extinguish the MIL, the

Fuel Monitor must pass in a Similar Condition Win-

dow. The similar conditions relate to RPM and load.

The engine must be within a predetermined percent-

age of both RPM and load when the monitor runs to

count a good trip. As with all DTCs, three good tripsare required to extinguish the MIL and 40 warm up

cycles are required to erase the DTC. If the engine

does not run in a Similar Conditions Window, the

Task Manager extinguishes the MIL after 80 good

trips.

Enabling ConditionsÐThe following conditions

must be met to operate the fuel control monitor:

²PCM not in fuel crank mode (engine running)

²PCM in Closed Loop fuel control

²Fuel system updating Long Term Adaptive

²Fuel level above 15% of capacity

²Fuel level below 85% of capacity

Pending ConditionsÐThe Fuel Control Monitor

does not operate if the MIL is illuminated for any of

the following:

²Misfire Monitor

²Upstream O2S

²EVAP Purge Solenoid Electrical PCM Self Test

Fault

²Camshaft or Crankshaft Position Sensor

²Fuel Injectors

²Ignition Coil Primary

²Throttle Position (TPS) Sensor

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Idle Air Control (IAC)

²5V Output Too Low

²EGR Monitor

²EGR Solenoid Circuit

²Vehicle Speed Sensor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Oxygen Sensor Electrical

²Idle Speed Rationality

²Intake Air Temperature

SuspendÐThe Task Manager will suspend

maturing a Fuel System fault if any of the following

are present:

²Oxygen Sensor Response, Priority 1

²O2 Heater, Priority 1

²Misfire Monitor, Priority 2

EVAPORATIVE EMISSIONS MONITOR

LEAK DETECTION PUMP MONITORÐThe

leak detection assembly incorporates two primary

functions: it must detect a leak in the evaporative

system and seal the evaporative system so the leak

detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

PLEMISSION CONTROL SYSTEMS 25 - 17

DESCRIPTION AND OPERATION (Continued)

Page 1107 of 1285

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Leak Detection Pump Switch

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²LDP Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen inthe exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 air fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrous oxide (NOx)

from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse

rate is the time required for the sensor to switch

from lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Each

time the voltage signal surpasses the threshold, a

counter is incremented by one. This is called the Half

Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Monitor is a two trip monitor

that is tested only once per trip. When the Oxygen

Sensor fails the test in two consecutive trips, the

MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

25 - 20 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1109 of 1285

Pending ConditionsÐThere are not conditions

or situations that prompt conflict or suspension of

testing. The oxygen sensor heater test is not run

pending resolution of MIL illumination due to oxygen

sensor failure.

SuspendÐThere are no conditions which exist for

suspending the Heater Monitor.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S strategy is based on the fact that as a cat-

alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For atotally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL (check

engine lamp) will be illuminated.

Monitor OperationÐTo monitor catalyst effi-

ciency, the PCM expands the rich and lean switch

points of the heated oxygen sensor. With extended

switch points, the air/fuel mixture runs richer and

leaner to overburden the catalytic converter. Once

the test is started, the air/fuel mixture runs rich and

lean and the O2 switches are counted. A switch is

counted when an oxygen sensor signal goes from

below the lean threshold to above the rich threshold.

The number of Rear O2 sensor switches is divided by

the number of Front O2 sensor switches to determine

the switching ratio.

The test runs for 20 seconds. As catalyst efficiency

deteriorated over the life of the vehicle, the switch

rate at the downstream sensor approaches that of the

upstream sensor. If at any point during the test

period the switch ratio reaches a predetermined

value, a counter is incremented by one. The monitor

is enabled to run another test during that trip. When

the test fails three times, the counter increments to

three, a malfunction is entered, and a Freeze Frame

is stored. When the counter increments to three dur-

ing the next trip, the code is matured and the MIL is

illuminated. If the test passes the first, no further

testing is conducted during that trip.

The MIL is extinguished after three consecutive

good trips. The good trip criteria for the catalyst

monitor is more stringent than the failure criteria. In

order to pass the test and increment one good trip,

the downstream sensor switch rate must be less than

80% of the upstream rate (60% for manual transmis-

sions). The failure percentages are 90% and 70%

respectively.

Enabling ConditionsÐThe following conditions

must typically be met before the PCM runs the cat-

alyst monitor. Specific times for each parameter may

be different from engine to engine.

²Accumulated drive time

²Enable time

²Ambient air temperature

²Barometric pressure

²Catalyst warm-up counter

²Engine coolant temperature

²Accumulated throttle position sensor

²Vehicle speed

²MAP

²RPM

²Engine in closed loop

²Fuel level

25 - 22 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)