overheating DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 168 of 1285

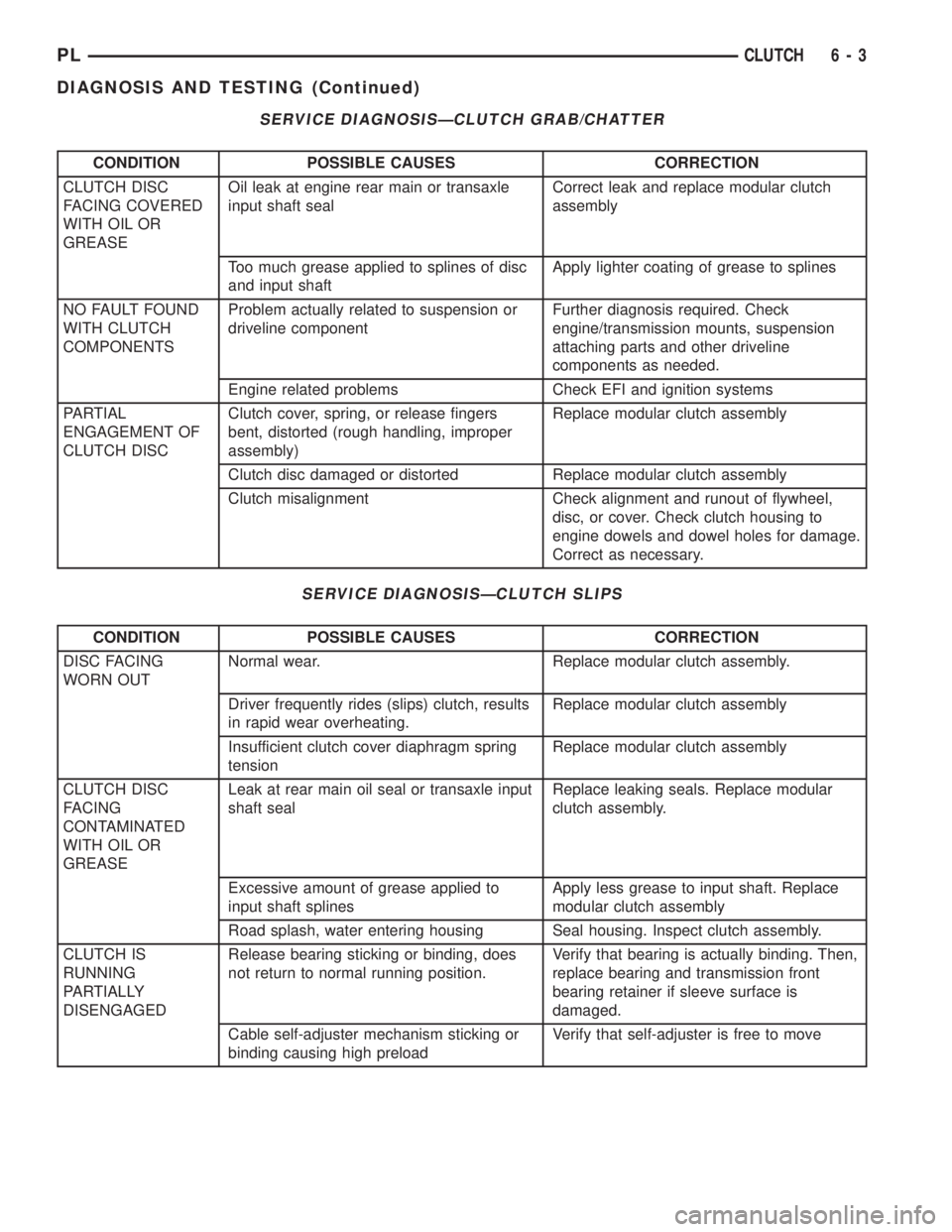

SERVICE DIAGNOSISÐCLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC

FACING COVERED

WITH OIL OR

GREASEOil leak at engine rear main or transaxle

input shaft sealCorrect leak and replace modular clutch

assembly

Too much grease applied to splines of disc

and input shaftApply lighter coating of grease to splines

NO FAULT FOUND

WITH CLUTCH

COMPONENTSProblem actually related to suspension or

driveline componentFurther diagnosis required. Check

engine/transmission mounts, suspension

attaching parts and other driveline

components as needed.

Engine related problems Check EFI and ignition systems

PARTIAL

ENGAGEMENT OF

CLUTCH DISCClutch cover, spring, or release fingers

bent, distorted (rough handling, improper

assembly)Replace modular clutch assembly

Clutch disc damaged or distorted Replace modular clutch assembly

Clutch misalignment Check alignment and runout of flywheel,

disc, or cover. Check clutch housing to

engine dowels and dowel holes for damage.

Correct as necessary.

SERVICE DIAGNOSISÐCLUTCH SLIPS

CONDITION POSSIBLE CAUSES CORRECTION

DISC FACING

WORN OUTNormal wear. Replace modular clutch assembly.

Driver frequently rides (slips) clutch, results

in rapid wear overheating.Replace modular clutch assembly

Insufficient clutch cover diaphragm spring

tensionReplace modular clutch assembly

CLUTCH DISC

FACING

CONTAMINATED

WITH OIL OR

GREASELeak at rear main oil seal or transaxle input

shaft sealReplace leaking seals. Replace modular

clutch assembly.

Excessive amount of grease applied to

input shaft splinesApply less grease to input shaft. Replace

modular clutch assembly

Road splash, water entering housing Seal housing. Inspect clutch assembly.

CLUTCH IS

RUNNING

PARTIALLY

DISENGAGEDRelease bearing sticking or binding, does

not return to normal running position.Verify that bearing is actually binding. Then,

replace bearing and transmission front

bearing retainer if sleeve surface is

damaged.

Cable self-adjuster mechanism sticking or

binding causing high preloadVerify that self-adjuster is free to move

PLCLUTCH 6 - 3

DIAGNOSIS AND TESTING (Continued)

Page 186 of 1285

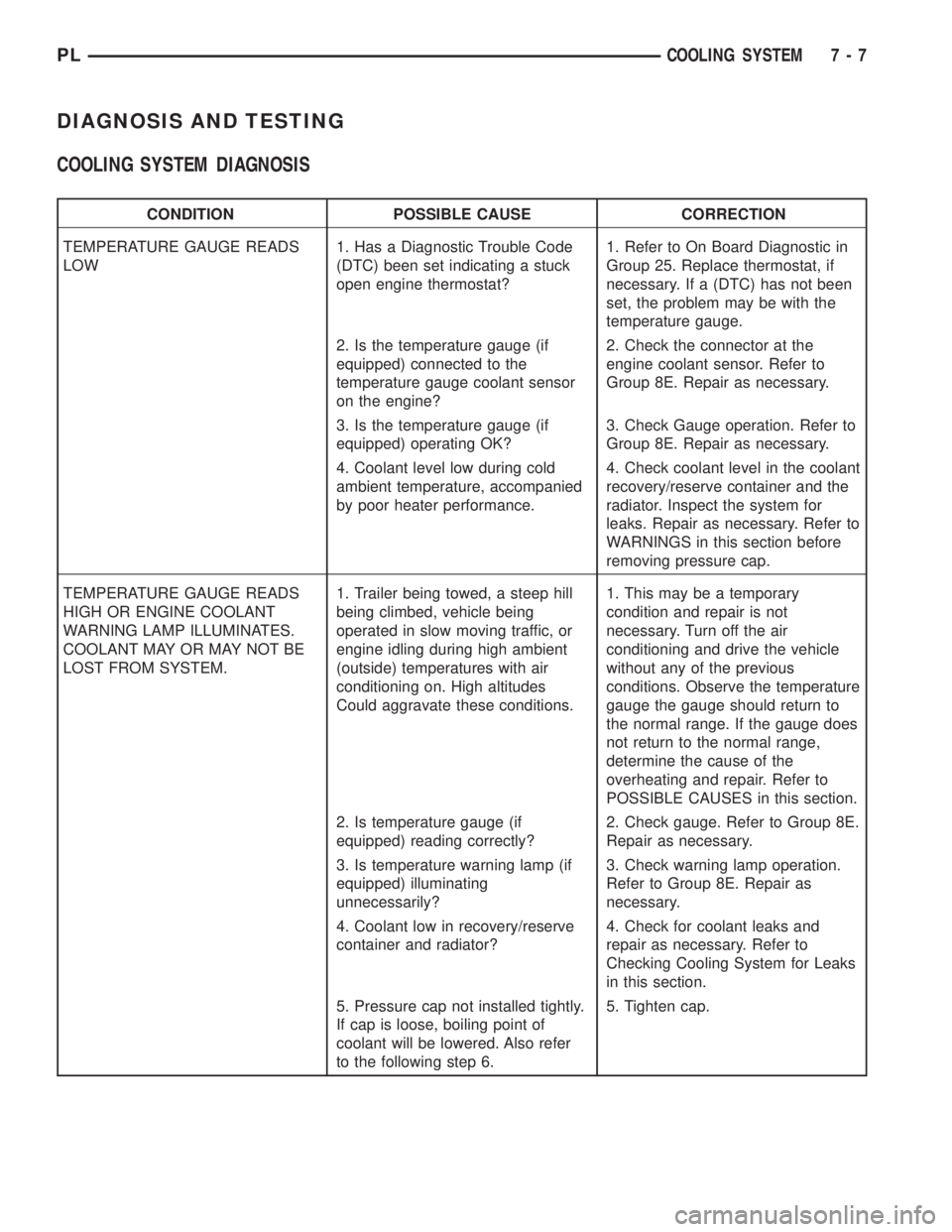

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

TEMPERATURE GAUGE READS

LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open engine thermostat?1. Refer to On Board Diagnostic in

Group 25. Replace thermostat, if

necessary. If a (DTC) has not been

set, the problem may be with the

temperature gauge.

2. Is the temperature gauge (if

equipped) connected to the

temperature gauge coolant sensor

on the engine?2. Check the connector at the

engine coolant sensor. Refer to

Group 8E. Repair as necessary.

3. Is the temperature gauge (if

equipped) operating OK?3. Check Gauge operation. Refer to

Group 8E. Repair as necessary.

4. Coolant level low during cold

ambient temperature, accompanied

by poor heater performance.4. Check coolant level in the coolant

recovery/reserve container and the

radiator. Inspect the system for

leaks. Repair as necessary. Refer to

WARNINGS in this section before

removing pressure cap.

TEMPERATURE GAUGE READS

HIGH OR ENGINE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST FROM SYSTEM.1. Trailer being towed, a steep hill

being climbed, vehicle being

operated in slow moving traffic, or

engine idling during high ambient

(outside) temperatures with air

conditioning on. High altitudes

Could aggravate these conditions.1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and drive the vehicle

without any of the previous

conditions. Observe the temperature

gauge the gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause of the

overheating and repair. Refer to

POSSIBLE CAUSES in this section.

2. Is temperature gauge (if

equipped) reading correctly?2. Check gauge. Refer to Group 8E.

Repair as necessary.

3. Is temperature warning lamp (if

equipped) illuminating

unnecessarily?3. Check warning lamp operation.

Refer to Group 8E. Repair as

necessary.

4. Coolant low in recovery/reserve

container and radiator?4. Check for coolant leaks and

repair as necessary. Refer to

Checking Cooling System for Leaks

in this section.

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following step 6.5. Tighten cap.

PLCOOLING SYSTEM 7 - 7

Page 189 of 1285

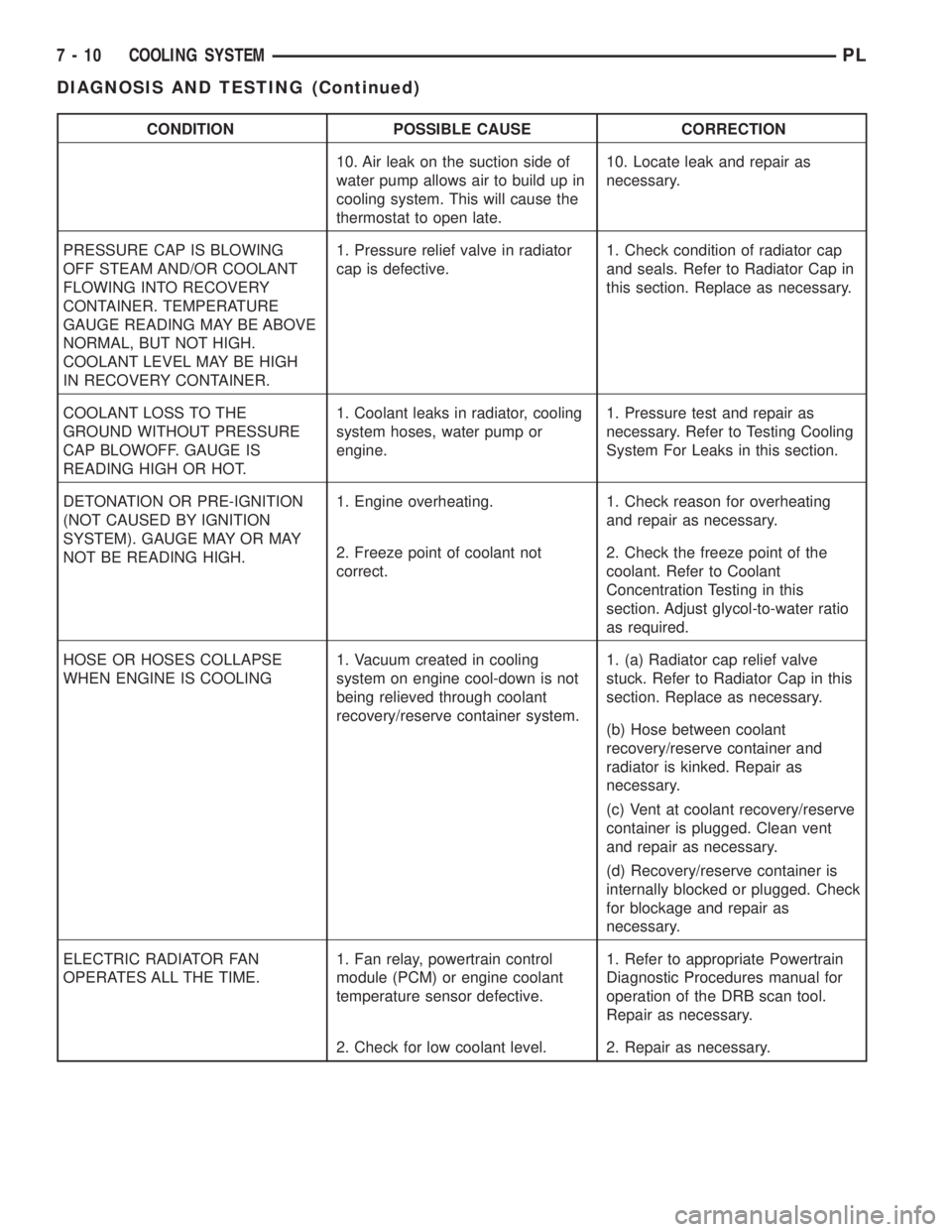

CONDITION POSSIBLE CAUSE CORRECTION

10. Air leak on the suction side of

water pump allows air to build up in

cooling system. This will cause the

thermostat to open late.10. Locate leak and repair as

necessary.

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT

FLOWING INTO RECOVERY

CONTAINER. TEMPERATURE

GAUGE READING MAY BE ABOVE

NORMAL, BUT NOT HIGH.

COOLANT LEVEL MAY BE HIGH

IN RECOVERY CONTAINER.1. Pressure relief valve in radiator

cap is defective.1. Check condition of radiator cap

and seals. Refer to Radiator Cap in

this section. Replace as necessary.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. Refer to Testing Cooling

System For Leaks in this section.

DETONATION OR PRE-IGNITION

(NOT CAUSED BY IGNITION

SYSTEM). GAUGE MAY OR MAY

NOT BE READING HIGH.1. Engine overheating. 1. Check reason for overheating

and repair as necessary.

2. Freeze point of coolant not

correct.2. Check the freeze point of the

coolant. Refer to Coolant

Concentration Testing in this

section. Adjust glycol-to-water ratio

as required.

HOSE OR HOSES COLLAPSE

WHEN ENGINE IS COOLING1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

recovery/reserve container system.1. (a) Radiator cap relief valve

stuck. Refer to Radiator Cap in this

section. Replace as necessary.

(b) Hose between coolant

recovery/reserve container and

radiator is kinked. Repair as

necessary.

(c) Vent at coolant recovery/reserve

container is plugged. Clean vent

and repair as necessary.

(d) Recovery/reserve container is

internally blocked or plugged. Check

for blockage and repair as

necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME.1. Fan relay, powertrain control

module (PCM) or engine coolant

temperature sensor defective.1. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

2. Check for low coolant level. 2. Repair as necessary.

7 - 10 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 190 of 1285

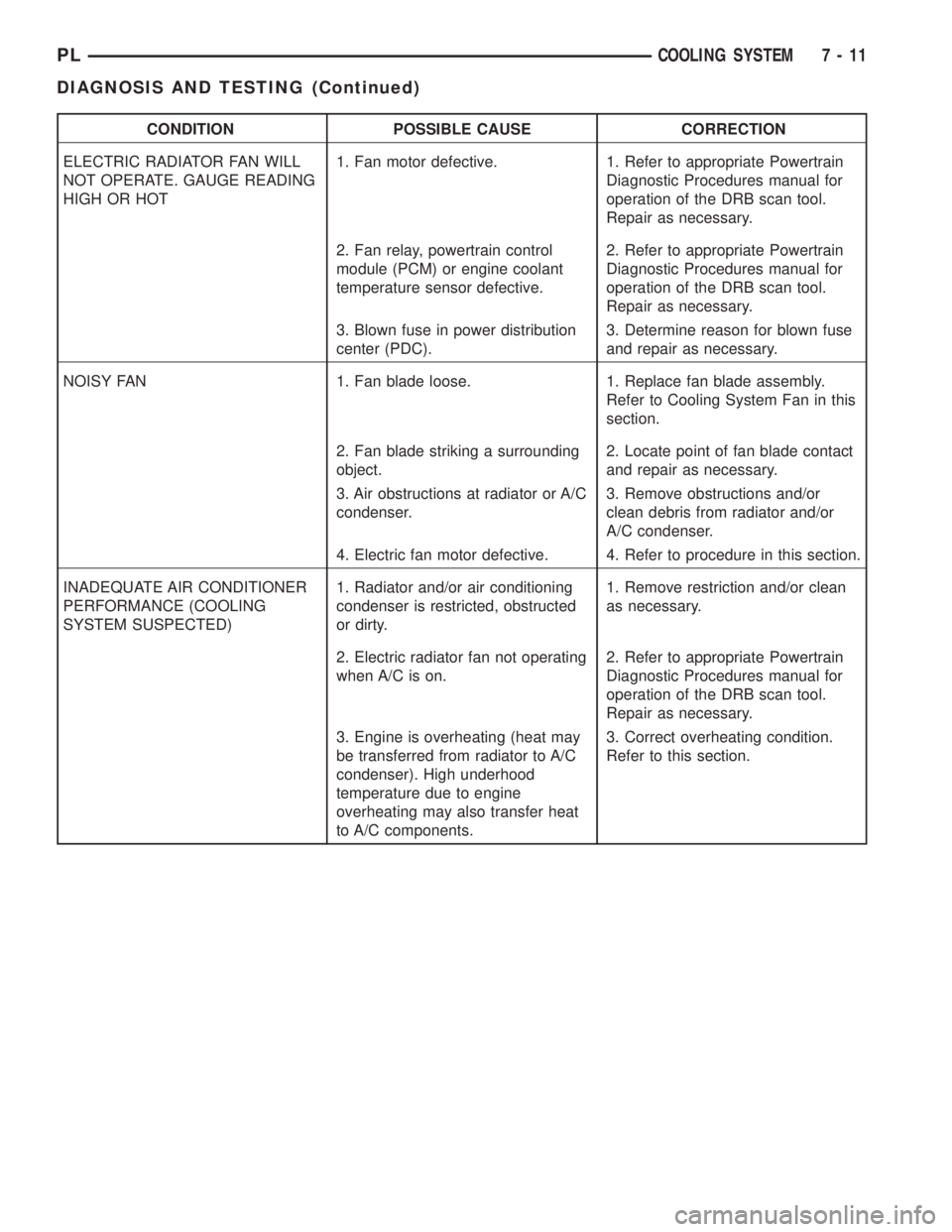

CONDITION POSSIBLE CAUSE CORRECTION

ELECTRIC RADIATOR FAN WILL

NOT OPERATE. GAUGE READING

HIGH OR HOT1. Fan motor defective. 1. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

2. Fan relay, powertrain control

module (PCM) or engine coolant

temperature sensor defective.2. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

3. Blown fuse in power distribution

center (PDC).3. Determine reason for blown fuse

and repair as necessary.

NOISY FAN 1. Fan blade loose. 1. Replace fan blade assembly.

Refer to Cooling System Fan in this

section.

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris from radiator and/or

A/C condenser.

4. Electric fan motor defective. 4. Refer to procedure in this section.

INADEQUATE AIR CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED)1. Radiator and/or air conditioning

condenser is restricted, obstructed

or dirty.1. Remove restriction and/or clean

as necessary.

2. Electric radiator fan not operating

when A/C is on.2. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

3. Engine is overheating (heat may

be transferred from radiator to A/C

condenser). High underhood

temperature due to engine

overheating may also transfer heat

to A/C components.3. Correct overheating condition.

Refer to this section.

PLCOOLING SYSTEM 7 - 11

DIAGNOSIS AND TESTING (Continued)

Page 968 of 1285

GENERAL INFORMATION

IN VEHICLE SERVICE

The following components are serviceable in the

vehicle without transaxle removal:

²Valve Body Assembly

²Converter Clutch Solenoid

²Governor

²Vehicle Speed Sensor & Pinion

²Park/Neutral & Back-up Lamp Switch

²Transfer Gears and Transfer Shaft

²Low/Reverse Servo

²Kickdown Servo

²Accumulator

FLUID REQUIREMENTS

NOTE: The transmission and differential have a

common oil sump with an opening between the

two.

TRANSMISSION/DIFFERENTIAL

MopartATF+4 (Automatic Transmission Fluid

Type 9602) is required in this transaxle. Substitute

fluids must meet fluid specification MS-9602.

FLUID ADDITIVES

Chrysler Corporation strongly recommends against

the addition of any fluids to the transmission, other

than those automatic transmission fluids listed

above. Exceptions to this policy are the use of special

dyes to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel/quality and converter

clutch operation, inhibit overheating, oxidation, var-

nish and sludge. These claims have not been sup-

ported to Chrysler's satisfaction and these additives

must not be used. The use of transmission ªsealersº

should also be avoided, since they may adversely

affect the integrity of tranmission seals.

DESCRIPTION AND OPERATION

31TH GENERAL INFORMATION

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system.

NOTE: Transaxle operation requirements are differ-

ent for each vehicle and engine combination. Some

internal parts will be different to provide for this.Therefore, when replacing parts, refer to the seven

digit part number stamped on rear of the transaxle

oil pan flange.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heat

exchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.

Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

ries the governor and parking sprag. An integral heli-

cal gear on the transfer shaft drives the differential

ring gear.

PLTRANSAXLE 21 - 55