tire DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1092 of 1285

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Misfire OccurredÐ

The stored MAP reading at the time of failure.

Informs the user at what engine load the failure

occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Misfire OccurredÐ The stored

RPM reading at the time of failure. Informs the user

at what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM uti-

lizes both Short Term Compensation and Long Term

Adaptive to calculate the Adaptive Memory Factor

for total fuel correction.

²200 Rev CounterÐ Counts 0±100 720 degree

cycles.

²SCW Cat 200 Rev CounterÐ Counts when in

similar conditions.

²SCW FTP 1000 Rev CounterÐ Counts 0±4

when in similar conditions.

²Misfire Good Trip CounterÐ Counts up to

three to turn OFF the MIL.

MALFUNCTION INDICATOR LAMP (MIL)

OPERATION

As a functional test, the Malfunction Indicator

Lamp (MIL) illuminates at key-on before engine

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the PCI Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

DRB III STATE DISPLAY TEST MODE

OPERATION

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

DRB III CIRCUIT ACTUATION TEST MODE

OPERATION

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly.

DIAGNOSTIC TROUBLE CODES

DESCRIPTION

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

PLEMISSION CONTROL SYSTEMS 25 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1137 of 1285

SAFETY PRECAUTION AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING RTM AND SMC COMPONENTS.

PERSONAL INJURE CAN RESULT.

USE AN OSHA APPROVED BREATHING DEVICE

WHEN MIXING EPOXY, GRINDING RTM AND SMC,

AND SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

EPOXY RESIN, PETROLEUM, OR ALCOHOL BASED

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components and

electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds on

undamaged painted surfaces around repair areas.

Damage to finish can result.

PANEL SECTIONING

If it is required to section a large panel for an SMC

or RTM repair, it will be necessary to reinforce the

panel with epoxy structural adhesive (rigid repair

adhesive) (Fig. 2). To bond two plastic panels

together, a reinforcement must overlap both panels.

The panels must be ªV'dº at a 20 degree angle. The

area to be reinforced should be washed, then sanded.

Be sure to wipe off any excess soap and water when

finished. Lightly sand or abrade the plastic with an

abrasive pad or sandpaper. Blow off any dust with

compressed air or wipe with a clean dry rag.When bonding SMC or RTM panels, use a two-part

epoxy adhesive. Properly mix parts A and B, and

apply it to the panels being repaired. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.

After the parts have been bonded and have had

time to cure, rough sand the seam and apply the

final adhesive filler to the area being repaired.

Smooth the filler with a spatula, wooden tongue

depressor, or squeegee. For fine texturing, a small

amount of water can be applied to the filler surface

while smoothing. The cured filler can be sanded as

necessary and, as a final step, cleanup can be done

withy soapy water. Wipe the surface clean with a dry

cloth allowing time for the panel to dry before mov-

ing on with the repair.

PANEL REINFORCEMENT

Structural repair procedures for rigid panels such

as Sheet Molded compound (SMC) or Resin Transfer

Molded (RTM) with large cracks and holes will

require a reinforcement backing. Reinforcements can

be made with several applications of glass cloth sat-

urated with epoxy structural adhesive, semirigid or

flexible repair materials should be used for semirigid

or flexible part repairs (Fig. 3) and (Fig. 4). Open

meshed fiberglass dry wall tape can be used to form

a reinforcement. The dry wall tape allows the resin

to penetrate through and make a good bond between

the panel and the epoxy adhesive. Structurally, the

more dry wall tape used, the stronger the repair.

Another kind of repair that can be done to repair

large cracks and holes is to use a scrap piece of sim-

ilar plastic and bond with structural adhesive. The

reinforcement should cover the entire break and

should have a generous amount of overlap on either

side of the cracked or broken area.

When repairing plastic, the damaged area is first

ªV'dº out, or beveled. Large bonding areas are desir-

able when repairing plastic because small repairs are

less likely to hold permanently. Beveling the area

around a crack at a 20 degree angle will increase the

bonding surface for a repair (Fig. 5). It is recom-

mended that sharp edges be avoided because the

joint may show through after the panel is refinished.

²Panel repair for both flexible and rigid panels

are basically the same. The primary difference

between flexible panel repair and rigid panel repair

is in the adhesive materials used (Fig. 6).

²The technician should first decide what needs to

be done when working on any type of body panel.

One should determine if it is possible to return the

Fig. 2 Panel Sectioning

1 ± EXISTING PANEL

2 ± NEW PANEL

3 ± PANEL ADHESIVE

4 ± BONDING STRIP

23 - 20 BODYPL

SERVICE PROCEDURES (Continued)

Page 1140 of 1285

(12) Position patch in cutout against support

squares and adjust patch until the gap is equal along

all sides (Fig. 11).

(13) Drill 3 mm (0.125 in.) holes in the support

squares through the pre-drilled holes in the patch.

(14) Apply a coat of epoxy to the exposed ends of

the support squares (Fig. 12).

(15) Install screws to hold the patch to support

squares (Fig. 13). Tighten screws until patch surface

is flush with panel surface.

(16) Allow epoxy to cure, and remove all screws.

(17) Using a 125 mm (5 in.) 24 grit disc grinder,

grind a 50 mm (2 in.) to 75 mm (3 in.) wide and 2

mm (0.080 in.) deep path across the gaps around the

patch (Fig. 14). With compressed air, blow dust from

around patch.

(18) Apply adhesive backed nylon mesh (dry wall

tape) over gaps around patch (Fig. 15).

(19) Mix enough epoxy to cover the entire patch

area.

(20) Apply epoxy over the mesh around patch, and

smooth epoxy with a wide spreader to reduce finish

grinding. Use two to three layers of mesh and epoxy

to create a stronger repair (Fig. 16).

PATCHED PANEL SURFACING

After patch panel is installed, the patch area can

be finished using the same methods as finishing

other types of body panels. If mesh material is

exposed in the patched area, grind surface down, and

apply a coat of high quality rigid plastic body filler.

Prime, block sand, and paint as required.

REMOVAL AND INSTALLATION

GRILLE

REMOVAL

(1) Release hood latch, open and support hood on

prop rod.

(2) Remove screws attaching grille to parking

lamps (Fig. 17).

(3) Remove screw attaching grille to radiator clo-

sure panel.

(4) Remove grille from vehicle.

INSTALLATION

(1) Place grille into position on vehicle.

Fig. 10 Secure Support Squares To Body Panel

1 ± SUPPORT SQUARES

2 ± SCREWS

3 ± DAMAGED BODY PANEL

Fig. 11 Position Patch In Cutout And Align

1 ± CUTOUT

2 ± SUPPORT SQUARES

Fig. 12 Apply Epoxy To Support Squares

1 ± APPLICATOR

2 ± SUPPORT SQUARES

3 ± EPOXY

PLBODY 23 - 23

SERVICE PROCEDURES (Continued)

Page 1220 of 1285

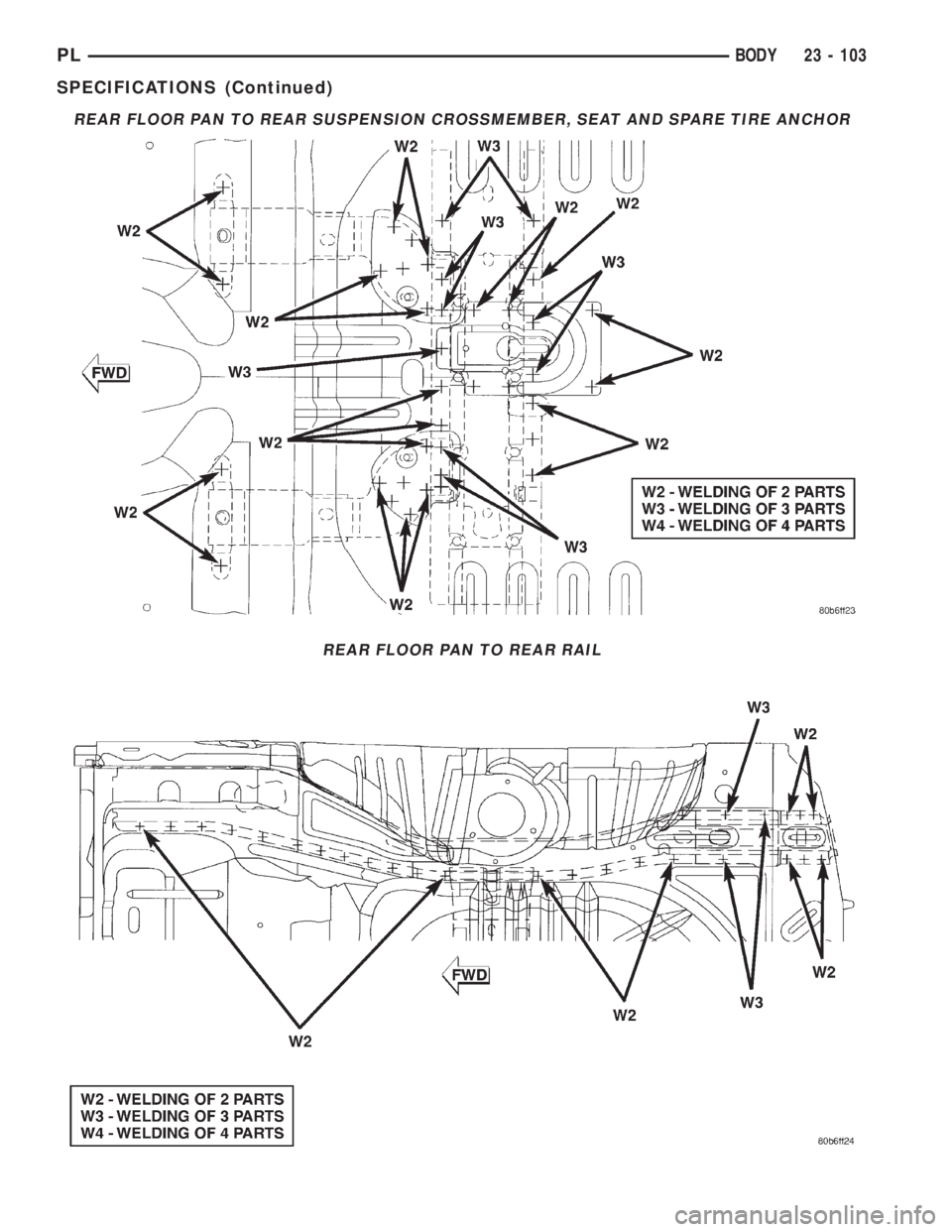

REAR FLOOR PAN TO REAR SUSPENSION CROSSMEMBER, SEAT AND SPARE TIRE ANCHOR

REAR FLOOR PAN TO REAR RAIL

PLBODY 23 - 103

SPECIFICATIONS (Continued)

Page 1233 of 1285

GENERAL INFORMATION

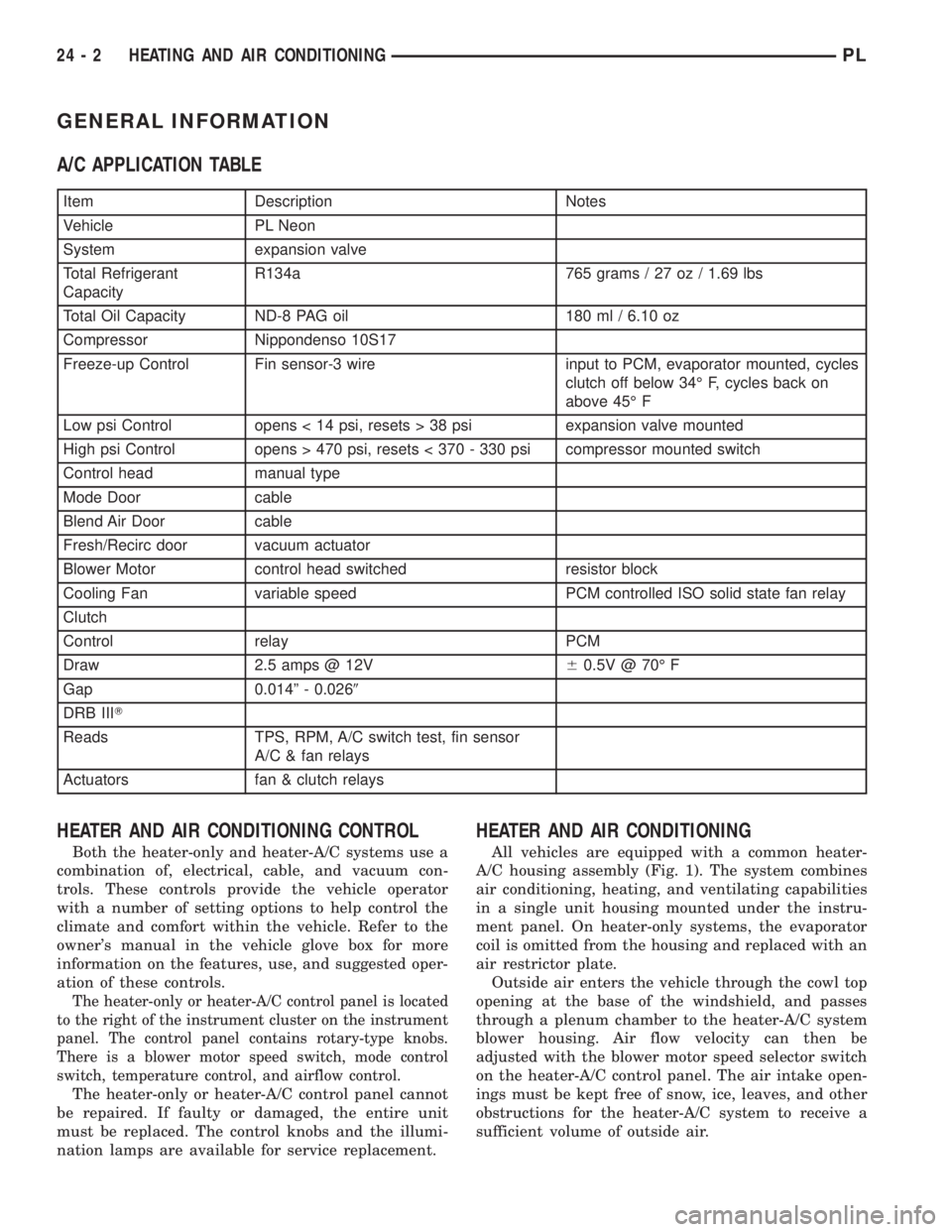

A/C APPLICATION TABLE

Item Description Notes

Vehicle PL Neon

System expansion valve

Total Refrigerant

CapacityR134a 765 grams / 27 oz / 1.69 lbs

Total Oil Capacity ND-8 PAG oil 180 ml / 6.10 oz

Compressor Nippondenso 10S17

Freeze-up Control Fin sensor-3 wire input to PCM, evaporator mounted, cycles

clutch off below 34É F, cycles back on

above 45É F

Low psi Control opens < 14 psi, resets > 38 psi expansion valve mounted

High psi Control opens > 470 psi, resets < 370 - 330 psi compressor mounted switch

Control head manual type

Mode Door cable

Blend Air Door cable

Fresh/Recirc door vacuum actuator

Blower Motor control head switched resistor block

Cooling Fan variable speed PCM controlled ISO solid state fan relay

Clutch

Control relay PCM

Draw 2.5 amps @ 12V60.5V @ 70É F

Gap 0.014º - 0.0269

DRB IIIT

Reads TPS, RPM, A/C switch test, fin sensor

A/C & fan relays

Actuators fan & clutch relays

HEATER AND AIR CONDITIONING CONTROL

Both the heater-only and heater-A/C systems use a

combination of, electrical, cable, and vacuum con-

trols. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or heater-A/C control panel is located

to the right of the instrument cluster on the instrument

panel. The control panel contains rotary-type knobs.

There is a blower motor speed switch, mode control

switch, temperature control, and airflow control.

The heater-only or heater-A/C control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The control knobs and the illumi-

nation lamps are available for service replacement.

HEATER AND AIR CONDITIONING

All vehicles are equipped with a common heater-

A/C housing assembly (Fig. 1). The system combines

air conditioning, heating, and ventilating capabilities

in a single unit housing mounted under the instru-

ment panel. On heater-only systems, the evaporator

coil is omitted from the housing and replaced with an

air restrictor plate.

Outside air enters the vehicle through the cowl top

opening at the base of the windshield, and passes

through a plenum chamber to the heater-A/C system

blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the heater-A/C control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the heater-A/C system to receive a

sufficient volume of outside air.

24 - 2 HEATING AND AIR CONDITIONINGPL

Page 1237 of 1285

COMPRESSOR FRONT SHAFT SEAL

The compressor front shaft seal is not serviceable.

If a leak is detected at the shaft seal, the compressor

must be replaced as a unit.

CONDENSATION DRAIN TUBE

Condensation that accumulates in the evaporator

housing is drained from a tube through the dash and

on to the ground. This tube must be kept open to

prevent condensate water from collecting in the bot-

tom of the housing.

The tapered end of the drain tube is designed to

keep contaminants from entering the heater A/C unit

housing. If the tube is pinched or blocked, condensate

cannot drain, causing water to back up and spill into

the passenger compartment. It is normal to see con-

densate drainage below the vehicle. If the tube is

damaged, it should be replaced.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain ample temperature levels from the

heating-A/C system, the cooling system must be in

proper working order. Refer to Group 0, Lubrication

and Maintenance or Group 7, Cooling System of this

manual.

The use of a bug screen is not recommended. Any

obstructions forward of the condenser can reduce the

effectiveness of the air conditioning system.

EVAPORATOR PROBE

The evaporator probe can be replaced without hav-

ing to remove the unit housing from the vehicle.

The evaporator probe is located in the unit housing

and placed in the evaporator fins. The probe prevents

evaporator freeze-up. This is done by cycling the com-

pressor clutch OFF when evaporator temperature

drops below freeze point. It cycles ON when the

evaporator temperature rises above freeze point. The

evaporator probe uses a thermistor probe in a capil-

lary tube. The tube is inserted between the evapora-

tor fins in the heater-A/C unit housing.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system.CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

A good rule for the flexible hose lines is to keep

the radius of all bends at least 10 times the diame-

ter of the hose. Sharper bends will reduce the flow

of refrigerant. The flexible hose lines should be

routed so they are at least 3 inches (80 mm) from

the exhaust manifold. Inspect all flexible hose lines

to make sure they are in good condition and prop-

erly routed.

The use of correct wrenches when making con-

nections is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain

stable as long as moisture-free refrigerant and

refrigerant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities.

When opening a refrigeration system, have every-

thing you will need to repair the system ready. This

will minimize the amount of time the system must

be opened. Cap or plug all lines and fittings as

soon as they are opened. This will help prevent the

entrance of dirt and moisture. All new lines and

components should be capped or sealed until they

are ready to be used.

All tools, including the refrigerant dispensing

manifold, the manifold gauge set, and test hoses

should be kept clean and dry.

HIGH PRESSURE CUT OUT SWITCH

The high pressure cut out switch is located on the

rear of the compressor (Fig. 7). It turns off the com-

pressor if the system pressure exceeds 3240 kPa (470

psi).

LOW PRESSURE CUT OFF SWITCH

The Low Pressure Cut Off Switch (Fig. 8) monitors

the refrigerant gas pressure on the suction side of

the system. The low pressure cut off switch is located

on the expansion valve. The low pressure cut off

switch turns off voltage to the compressor clutch coil

when refrigerant gas pressure drops to levels that

could damage the compressor. The low pressure cut

out switch is a sealed factory calibrated unit. It must

be replaced if defective.

24 - 6 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)