ignition switch DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 769 of 1285

(10) Install right engine mount to engine mount

bracket through bolt.

(11) Remove jack from under engine.

(12) Install upper torque strut.

(13) Install power steering pump assembly.

(14) Raise vehicle and install lower torque strut.

(15) Install crankshaft damper using M12-1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (100 ft. lbs.) (Fig. 77).

(16) Install accessory drive belts. Refer to Group 7,

Cooling System for procedures.

(17) Install right inner splash shield.

(18) Lower vehicle and perform camshaft and

crankshaft timing relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

TIMING BELT TENSIONER

REMOVAL

(1) Remove timing belt. Refer to procedure in this

section.

(2) Remove tensioner assembly attaching bolts

(Fig. 78).

(3) Remove tensioner assembly.

CAUTION: The timing belt tensioner is serviced as

an assembly. To prevent premature timing belt fail-

ure, DO NOT separate the tensioner pulley from

mounting bracket.

INSTALLATION

(1) Install timing belt tensioner assembly. Tighten

attaching bolts to 31 N´m (275 in. lbs.).

(2) Install timing belt. Refer to procedure in this

section.

CAMSHAFT OIL SEAL

REMOVAL

CAUTION: Do Not Rotate the camshaft or crank-

shaft when timing belt is removed damage to the

engine may occur.

(1) Remove crankshaft damper, front timing belt

cover, timing belt and tensioner assembly. Refer to

procedures in this section.

(2) Hold camshaft sprocket with Special Tools

C-4687 and modified C-4687-1 as shown in (Fig. 79),

while removing attaching bolt.

(3) Remove sprocket from camshaft.

(4) Remove rear timing belt cover.

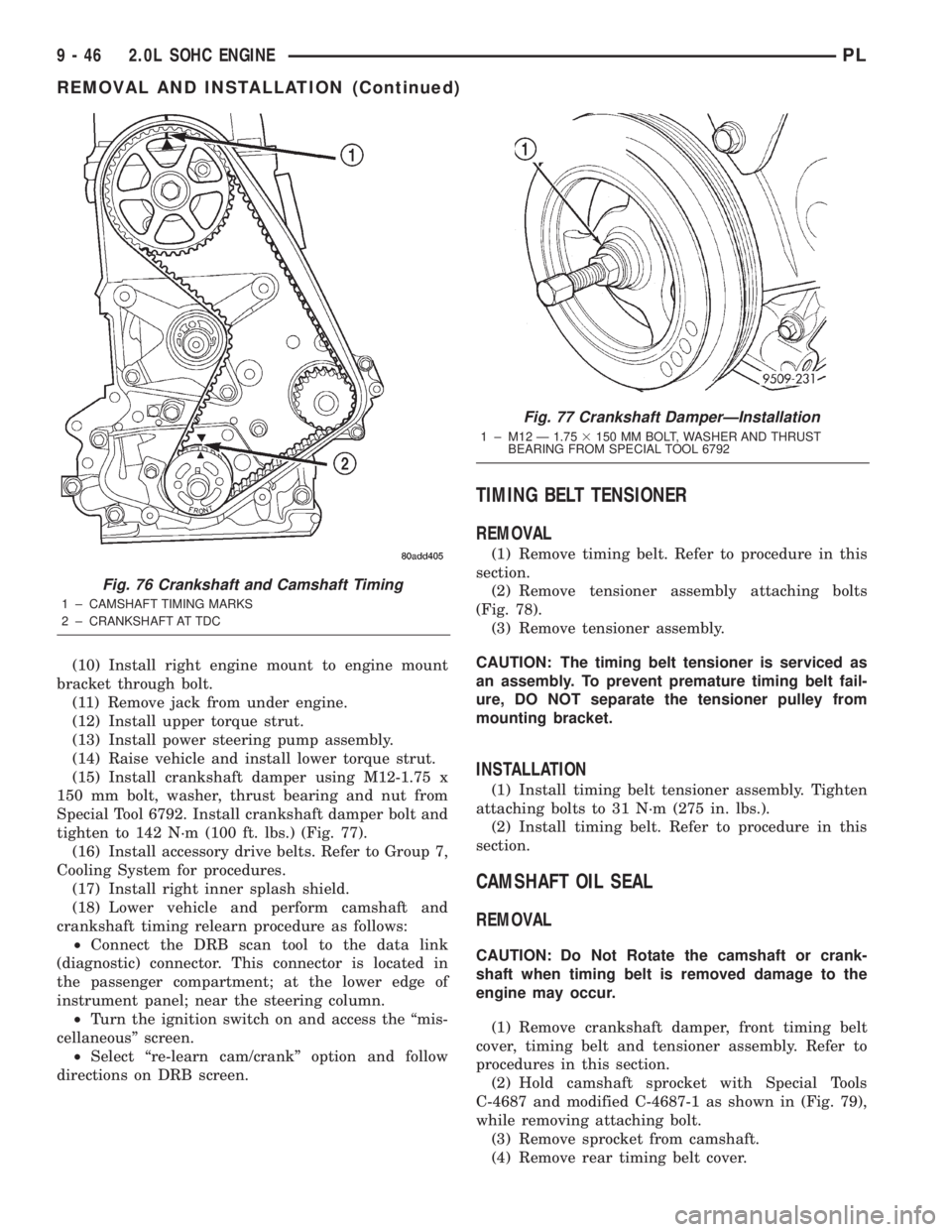

Fig. 76 Crankshaft and Camshaft Timing

1 ± CAMSHAFT TIMING MARKS

2 ± CRANKSHAFT AT TDC

Fig. 77 Crankshaft DamperÐInstallation

1 ± M12 Ð 1.753150 MM BOLT, WASHER AND THRUST

BEARING FROM SPECIAL TOOL 6792

9 - 46 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 778 of 1285

(17) Install rear timing belt cover and camshaft

sprocket.

(18) Install crankshaft sprocket, timing belt ten-

sioner, timing belt, and cover.

(19) Install front engine mount bracket.

(20) Remove engine from repair stand and position

on Special Tools 6135 and 6710 Engine Dolly and

Cradle. Install safety straps around the engine to

cradle and tighten and lock them into position.

(21) Install crankshaft rear oil seal. Refer to proce-

dure in this section.

(22) Install drive plate/flywheel. Apply Mopart

Lock & Seal Adhesive to bolt threads and tighten to

95 N´m (70 ft. lbs.).

(23) Install transaxle to engine.

(24) Install structural collar. Refer to procedure in

this section.

(25) Install engine assembly. Refer to procedure in

this section.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

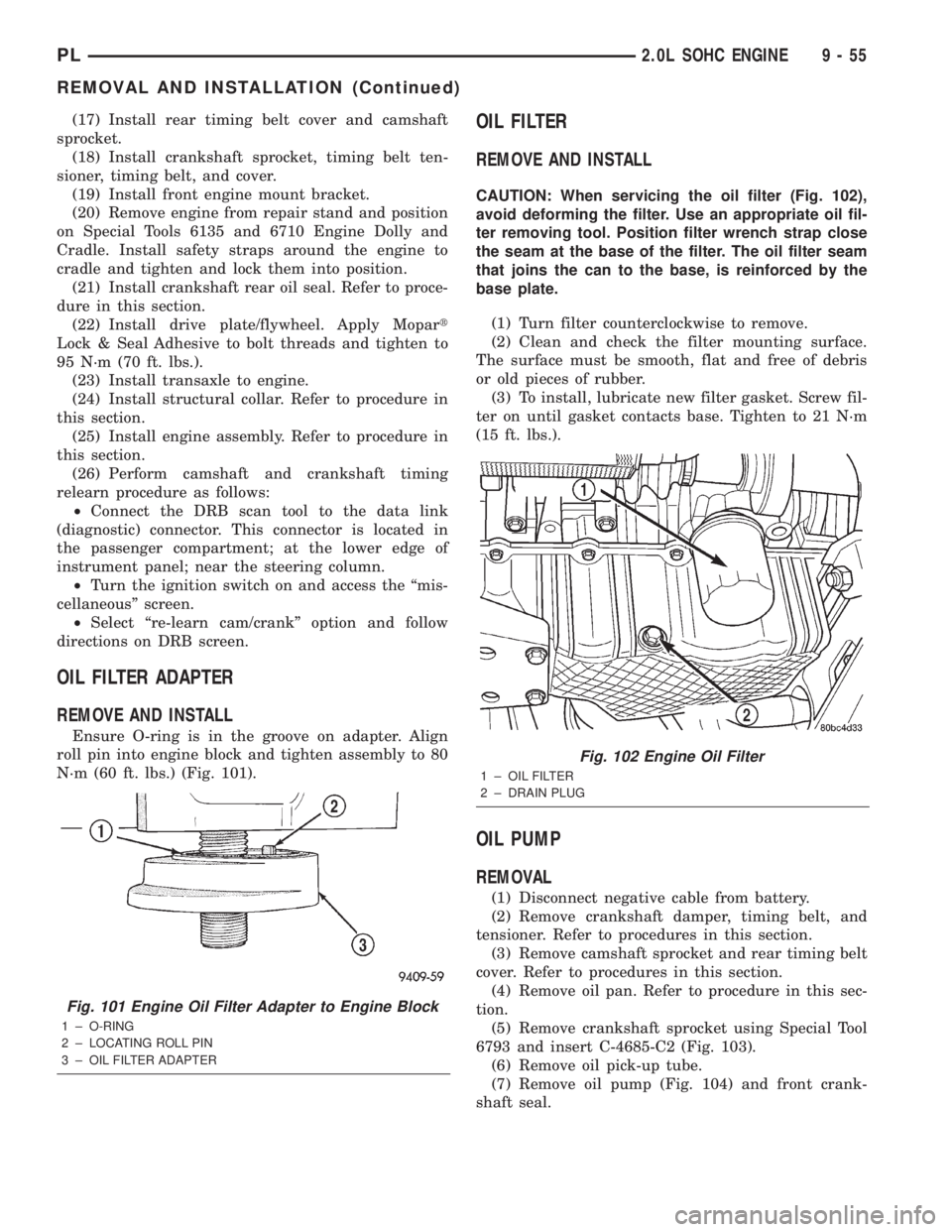

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 101).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 102),

avoid deforming the filter. Use an appropriate oil fil-

ter removing tool. Position filter wrench strap close

the seam at the base of the filter. The oil filter seam

that joins the can to the base, is reinforced by the

base plate.

(1) Turn filter counterclockwise to remove.

(2) Clean and check the filter mounting surface.

The surface must be smooth, flat and free of debris

or old pieces of rubber.

(3) To install, lubricate new filter gasket. Screw fil-

ter on until gasket contacts base. Tighten to 21 N´m

(15 ft. lbs.).

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(3) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(4) Remove oil pan. Refer to procedure in this sec-

tion.

(5) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 103).

(6) Remove oil pick-up tube.

(7) Remove oil pump (Fig. 104) and front crank-

shaft seal.

Fig. 101 Engine Oil Filter Adapter to Engine Block

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 102 Engine Oil Filter

1 ± OIL FILTER

2 ± DRAIN PLUG

PL2.0L SOHC ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 831 of 1285

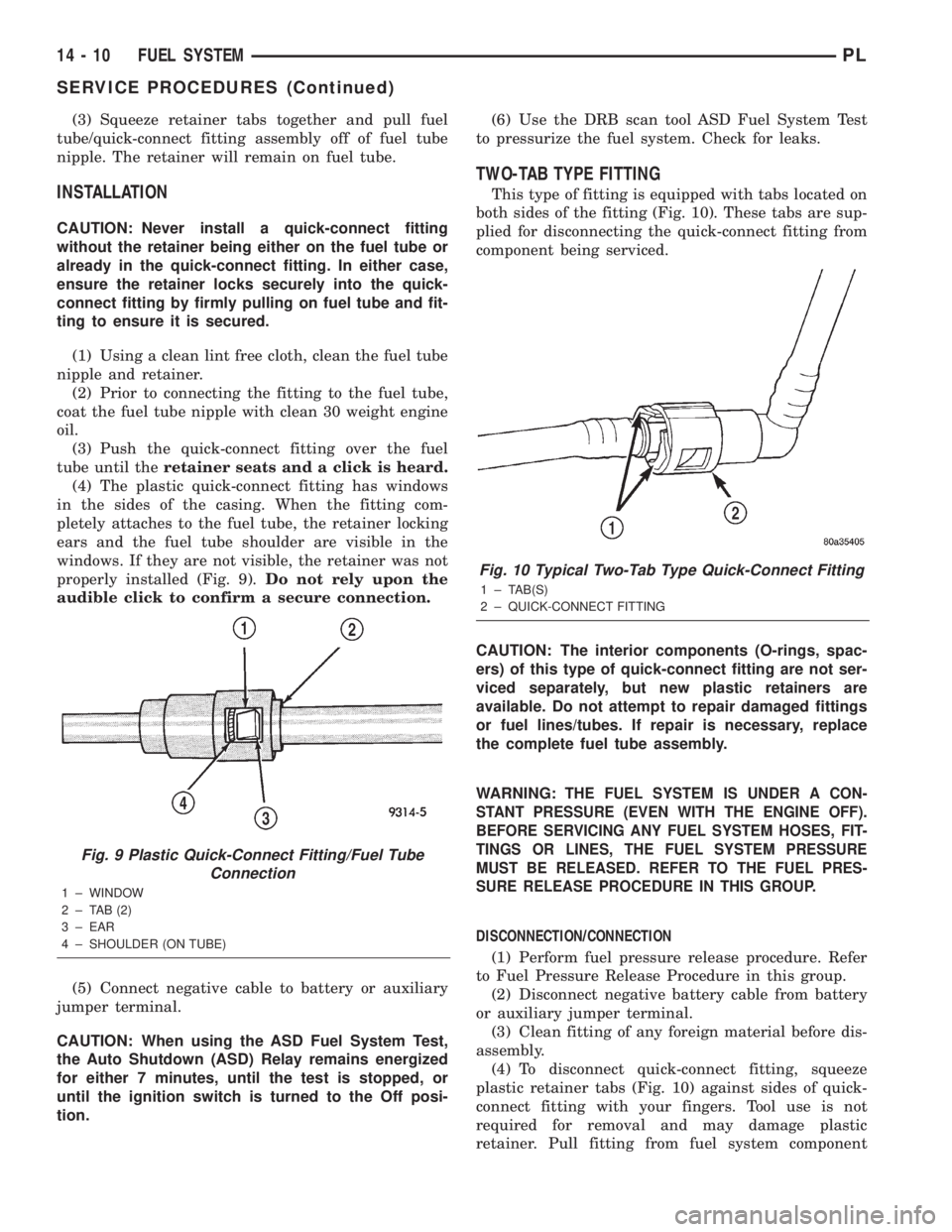

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 9).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 10). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

WARNING:

THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES, FIT-

TINGS OR LINES, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL PRES-

SURE RELEASE PROCEDURE IN THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 10) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

Fig. 9 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 ± WINDOW

2 ± TAB (2)

3 ± EAR

4 ± SHOULDER (ON TUBE)

Fig. 10 Typical Two-Tab Type Quick-Connect Fitting

1 ± TAB(S)

2 ± QUICK-CONNECT FITTING

14 - 10 FUEL SYSTEMPL

SERVICE PROCEDURES (Continued)

Page 838 of 1285

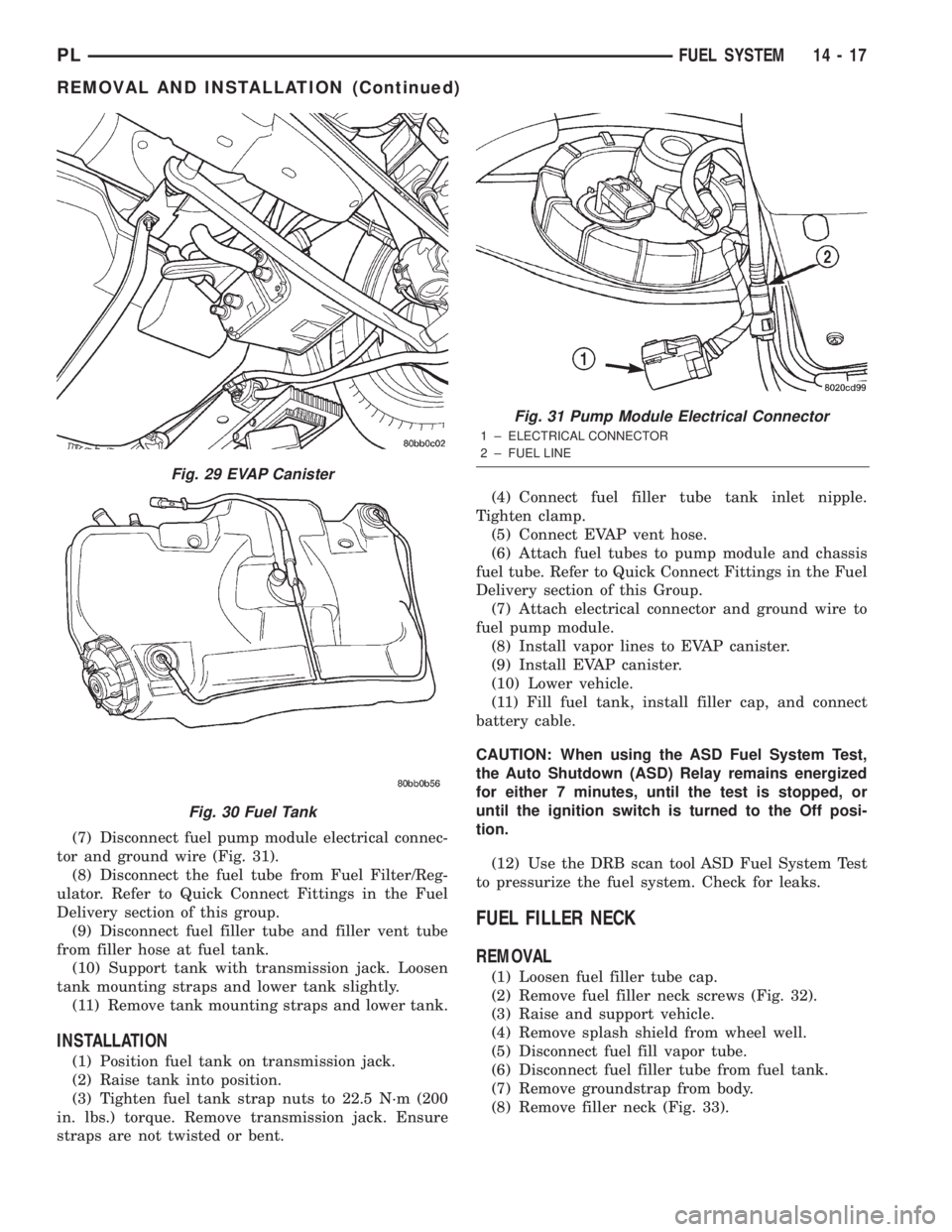

(7) Disconnect fuel pump module electrical connec-

tor and ground wire (Fig. 31).

(8) Disconnect the fuel tube from Fuel Filter/Reg-

ulator. Refer to Quick Connect Fittings in the Fuel

Delivery section of this group.

(9) Disconnect fuel filler tube and filler vent tube

from filler hose at fuel tank.

(10) Support tank with transmission jack. Loosen

tank mounting straps and lower tank slightly.

(11) Remove tank mounting straps and lower tank.

INSTALLATION

(1) Position fuel tank on transmission jack.

(2) Raise tank into position.

(3) Tighten fuel tank strap nuts to 22.5 N´m (200

in. lbs.) torque. Remove transmission jack. Ensure

straps are not twisted or bent.(4) Connect fuel filler tube tank inlet nipple.

Tighten clamp.

(5) Connect EVAP vent hose.

(6) Attach fuel tubes to pump module and chassis

fuel tube. Refer to Quick Connect Fittings in the Fuel

Delivery section of this Group.

(7) Attach electrical connector and ground wire to

fuel pump module.

(8) Install vapor lines to EVAP canister.

(9) Install EVAP canister.

(10) Lower vehicle.

(11) Fill fuel tank, install filler cap, and connect

battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(12) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL FILLER NECK

REMOVAL

(1) Loosen fuel filler tube cap.

(2) Remove fuel filler neck screws (Fig. 32).

(3) Raise and support vehicle.

(4) Remove splash shield from wheel well.

(5) Disconnect fuel fill vapor tube.

(6) Disconnect fuel filler tube from fuel tank.

(7) Remove groundstrap from body.

(8) Remove filler neck (Fig. 33).

Fig. 29 EVAP Canister

Fig. 30 Fuel Tank

Fig. 31 Pump Module Electrical Connector

1 ± ELECTRICAL CONNECTOR

2 ± FUEL LINE

PLFUEL SYSTEM 14 - 17

REMOVAL AND INSTALLATION (Continued)

Page 842 of 1285

FUEL INJECTION SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INJECTION SYSTEM......................22

MODES OF OPERATION...................22

SYSTEM DIAGNOSIS......................24

POWER DISTRIBUTION CENTER............24

POWERTRAIN CONTROL MODULE...........24

PCM GROUND...........................26

5 VOLT SUPPLYÐPCM OUTPUT.............26

8-VOLT SUPPLYÐPCM OUTPUT.............26

FUEL CORRECTION or ADAPTIVE MEMORIES . . 26

PROGRAMMABLE COMMUNICATIONS

INTERFACE (PCI) BUS...................27

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUT..............27

AUTOMATIC SHUTDOWN (ASD) SENSEÐ

PCM INPUT...........................27

BATTERY VOLTAGEÐPCM INPUT............28

BRAKE SWITCHÐPCM INPUT...............28

CAMSHAFT POSITION SENSORÐPCM INPUT . . 28

CLUTCH INTERLOCK/UPSTOP SWITCH.......29

CRANKSHAFT POSITION SENSORÐPCM

INPUT................................30

ENGINE COOLANT TEMPERATURE

SENSORÐPCM INPUT...................30

FUEL LEVEL SENSORÐPCM INPUT..........31

HEATED OXYGEN SENSOR (O2 SENSOR)Ð

PCM INPUT...........................32

IGNITION CIRCUIT SENSEÐPCM INPUT......34

INLET AIR TEMPERATURE SENSORÐPCM

INPUT................................34

KNOCK SENSORÐPCM INPUT..............34

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT...................35

POWER STEERING PRESSURE SWITCHÐ

PCM INPUT...........................35

SENSOR RETURNÐPCM INPUT.............35

SPEED CONTROLÐPCM INPUT.............36

SCI RECEIVEÐPCM INPUT.................36

PARK/NEUTRAL POSITION SWITCHÐPCM

INPUT................................36

THROTTLE POSITION SENSORÐPCM INPUT . . 36VEHICLE SPEED SIGNAL (VSS)ÐPCM INPUT . . 37

AIR CONDITIONING CLUTCH RELAYÐPCM

OUTPUT..............................38

AUTOMATIC SHUTDOWN RELAYÐPCM

OUTPUT..............................38

CHARGING SYSTEM INDICATOR LAMPÐPCM

OUTPUT..............................38

FUEL PUMP RELAYÐPCM OUTPUT..........38

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT..............................39

GENERATOR FIELDÐPCM OUTPUT..........39

IDLE AIR CONTROL MOTORÐPCM OUTPUT . . . 39

DATA LINK CONNECTOR...................40

FUEL INJECTORSÐPCM OUTPUT...........40

IGNITION COILÐPCM OUTPUT..............40

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT...................41

SPEED CONTROLÐPCM INPUT.............41

SCI RECEIVEÐPCM OUTPUT...............41

TACHOMETERÐPCM OUTPUT..............42

TORQUE CONVERTOR CLUTCH SOLENOIDÐ

PCM OUTPUT..........................42

REMOVAL AND INSTALLATION

THROTTLE BODY........................42

THROTTLE POSITION SENSOR.............43

IDLE AIR CONTROL MOTOR................43

MAP SENSOR...........................44

POWERTRAIN CONTROL MODULE (PCM).....44

UPSTREAM HEATED OXYGEN SENSOR......45

DOWNSTREAM HEATED OXYGEN SENSOR

1/2 ..................................46

AIR CLEANER BOX.......................46

AIR CLEANER ELEMENT...................47

ENGINE COOLANT TEMPERATURE SENSOR . . . 47

VEHICLE SPEED SENSOR.................47

KNOCK SENSOR.........................48

SPECIFICATIONS

VECI LABEL.............................49

TORQUE...............................49

SPECIAL TOOLS

FUEL..................................49

PLFUEL SYSTEM 14 - 21

Page 843 of 1285

DESCRIPTION AND OPERATION

INJECTION SYSTEM

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygensensor diagnostics (they are checked for shorted con-

ditions at all times).

During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35É the PCM will wait 44

seconds.

²If the coolant is over 50ÉF the PCM will wait 38

seconds.

²If the coolant is over 167ÉF the PCM will wait

11 seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than 0.745

volts or less than 0.1 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

14 - 22 FUEL SYSTEMPL

Page 844 of 1285

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

ENGINE START-UP MODE

This is an OPEN LOOP mode. If the vehicle is in

park or neutral (automatic transaxles) or the clutch

pedal is depressed (manual transaxles) the ignition

switch energizes the starter relay. The following

actions occur when the starter motor is engaged.

²If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the Auto Shutdown (ASD) relay and fuel pump relay.

If the PCM does not receive both signals within

approximately one second, it will not energize the

ASD relay and fuel pump relay. The ASD and fuel

pump relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil and heated oxygen sen-

sors.

²The PCM energizes the injectors (on the 69É

degree falling edge) for a calculated pulse width until

it determines crankshaft position from the camshaft

position sensor and crankshaft position sensor sig-

nals. The PCM determines crankshaft position within

1 engine revolution.

²After determining crankshaft position, the PCM

begins energizing the injectors in sequence. It adjusts

injector pulse width and controls injector synchroni-

zation by turning the individual ground paths to the

injectors On and Off.

²When the engine idles within664 RPM of its

target RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode. If

the PCM does not detect a minimum difference

between the two values, it sets a MAP diagnostic

trouble code into memory.

Once the ASD and fuel pump relays have been

energized, the PCM determines injector pulse width

based on the following:

²Battery voltage

²Engine coolant temperature

²Engine RPM

²Intake air temperature (IAT)

²Throttle position

²The number of engine revolutions since cranking

was initiated.

During Start-up the PCM maintains ignition tim-

ing at 9É BTDC.

ENGINE WARM-UP MODE

This is an OPEN LOOP mode. The following inputs

are received by the PCM:

²Engine coolant temperature

²Manifold Absolute Pressure (MAP)

²Intake air temperature (IAT)²Crankshaft position (engine speed)

²Camshaft position

²Knock sensor

²Throttle position

²A/C switch

²Battery voltage

²Power steering pressure switch

²Vehicle speed

²Speed control

²O2 sensors

²All diagnostics

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising or idle

the following inputs are received by the PCM:

²Intake air temperature

²Engine coolant temperature

²Manifold absolute pressure

²Crankshaft position (engine speed)

²Camshaft position

²Knock sensor

²Throttle position

²Exhaust gas oxygen content

²A/C control positions

²Power steering pressure switch

²Battery voltage

²Vehicle speed

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas (measured

by the upstream and downstream heated oxygen sen-

sor).

The PCM monitors for engine misfire. During

active misfire and depending on the severity, the

PCM either continuously illuminates or flashes the

malfunction indicator lamp (Check Engine light on

instrument panel). Also, the PCM stores an engine

misfire DTC in memory.

The PCM performs several diagnostic routines.

They include:

²Oxygen sensor monitor

²Downstream heated oxygen sensor diagnostics

during open loop operation (except for shorted)

²Fuel system monitor

²EGR monitor

²Purge system monitor

PLFUEL SYSTEM 14 - 23

DESCRIPTION AND OPERATION (Continued)

Page 845 of 1285

²All inputs monitored for proper voltage range.

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic

convertor efficiency. If the catalyst efficiency drops

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in response to MAP

sensor feedback.

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

SYSTEM DIAGNOSIS

OPERATION

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information see On-Board Diagnostics.

POWER DISTRIBUTION CENTER

The Power Distribution Center (PDC) is located

next to the battery (Fig. 1). The PDC contains the

starter relay, radiator fan relay, A/C compressor

clutch relay, auto shutdown relay, fuel pump relay

and several fuses.

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various

engine and vehicle operations through devices that

are referred to as PCM Outputs.

PCM Inputs:

14 - 24 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 846 of 1285

²Air Conditioning Controls

²Battery Voltage

²Inlet Air/Battery Temperature Sensor

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Engine Coolant Temperature Sensor

²Fuel Level Sensor

²Ignition Switch

²Inlet Air/Intake Air Temperature Sensor

²Knock Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensors

²Power Steering Pressure Switch²SCI Receive

²Speed Control Switches

²Throttle Position Sensor

²Transmission Park/Neutral Switch (automatic

transmission)

²Vehicle Speed Sensor

PCM Outputs:

²Air Conditioning WOT Relay

²Auto Shutdown (ASD) Relay

²Charging Indicator Lamp

²Data Link Connector

²Proportional Purge Solenoid

²EGR Solenoid

²Fuel Injectors

²Fuel Pump Relay

²Generator Field

²Idle Air Control Motor

²Ignition Coils

²Malfunction Indicator (Check Engine) Lamp

²Radiator Fan Relay

²Speed Control Solenoids

²Tachometer

²Torque Convertor Clutch Solenoid

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark

advance, ignition coil dwell and EVAP canister purge

operation. The PCM regulates the cooling fan, air

conditioning and speed control systems. The PCM

changes generator charge rate by adjusting the gen-

erator field. The PCM also performs diagnostics.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery voltage

²Coolant temperature

²Inlet Air/Intake air temperature

²Exhaust gas content (oxygen sensor)

²Engine speed (crankshaft position sensor)

²Manifold absolute pressure

²Throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Coolant temperature

²Inlet Air/Intake air temperature

²Engine speed (crankshaft position sensor)

²Knock sensor

²Manifold absolute pressure

²Throttle position

²Transmission gear selection (park/neutral

switch)

The PCM also adjusts engine idle speed through

the idle air control motor based on the following

inputs.

²Air conditioning sense

²Battery voltage

²Battery temperature

²Brake switch

Fig. 1 Power Distribution Center (PDC)

Fig. 2 Powertrain Control Module (PCM)

1 ± PCM

PLFUEL SYSTEM 14 - 25

DESCRIPTION AND OPERATION (Continued)

Page 847 of 1285

²Coolant temperature

²Engine speed (crankshaft position sensor)

²Engine run time

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²Transmission gear selection (park/neutral

switch)

²Vehicle distance (speed)

The Auto Shutdown (ASD) and fuel pump relays

are mounted externally, but turned on and off by the

PCM.

The crankshaft position sensor signal is sent to the

PCM. If the PCM does not receive the signal within

approximately one second of engine cranking, it deac-

tivates the ASD relay and fuel pump relay. When

these relays deactivate, power is shut off from the

fuel injectors, ignition coils, heating element in the

oxygen sensors and the fuel pump.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8 volts direct

current to power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5 volt direct current supply for

the manifold absolute pressure sensor and throttle

position sensor.

PCM GROUND

OPERATION

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as three different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side of any relay, solenoid, ignition coil or injector.

The signal ground is used for any input that uses

sensor return for ground, and the ground side of any

internal processing component.

The SBEC III case is shielded to prevent RFI and

EMI. The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the case is also

grounded separately from the ground pins.

5 VOLT SUPPLYÐPCM OUTPUT

OPERATION

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Engine coolant temperature sensor

²Manifold absolute pressure sensor

²Throttle position sensor

²Linear EGR solenoid

8-VOLT SUPPLYÐPCM OUTPUT

OPERATION

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

FUEL CORRECTION or ADAPTIVE MEMORIES

DESCRIPTION

In Open Loop, the PCM changes pulse width with-

out feedback from the O2 Sensors. Once the engine

warms up to approximately 30 to 35É F, the PCM

goes into closed loopShort Term Correctionand

utilitzes feedback from the O2 Sensors. Closed loop

Long Term Adaptive Memoryis maintained above

170É to 190É F unless the PCM senses wide open

throttle. At that time the PCM returns to Open Loop

operation.

OPERATION

Short Term

The first fuel correction program that begins func-

tioning is the short term fuel correction. This system

corrects fuel delivery in direct proportion to the read-

ings from the Upstream O2 Sensor.

The PCM monitors the air/fuel ratio by using the

input voltage from the O2 Sensor. When the voltage

reaches its preset high or low limit, the PCM begins

to add or remove fuel until the sensor reaches its

switch point. The short term corrections then begin.

The PCM makes a series of quick changes in the

injector pulse-width until the O2 Sensor reaches its

opposite preset limit or switch point. The process

then repeats itself in the opposite direction.

Short term fuel correction will keep increasing or

decreasing injector pulse-width based upon the

upstream O2 Sensor input. The maximum range of

authority for short term memory is 25% (+/-) of base

pulse-width.

Long Term

The second fuel correction program is the long

term adaptive memory. In order to maintain correct

emission throughout all operating ranges of the

engine, a cell structure based on engine rpm and load

(MAP) is used.

There are up to 16 cells. Two cells are used only

during idle, based upon TPS and Park/Neutral

switch inputs. There may be two other cells used for

deceleration, based on TPS, engine rpm, and vehicle

speed. The other twelve cells represent a manifold

pressure and an rpm range. Six of the cells are high

rpm and the other six are low rpm. Each of these

cells is a specific MAP voltage range.

14 - 26 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)