oil viscosity DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 2 of 1285

LUBRICATION AND MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICANTS............................. 1

MAINTENANCE SCHEDULES................. 3JUMP STARTING, TOWING, AND HOISTING..... 7

LUBRICANTS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

PARTS AND LUBRICANT

RECOMMENDATIONS....................1

CLASSIFICATION OF LUBRICANTS............1

INTERNATIONAL SYMBOLS.................2FLUID CHECK/FILL POINTS AND

LUBRICATION LOCATIONS.................2

LUBRICATION POINT LOCATIONS............2

SPECIFICATIONS

FLUID CAPACITIES........................2

DESCRIPTION AND OPERATION

PARTS AND LUBRICANT RECOMMENDATIONS

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopar provides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

CLASSIFICATION OF LUBRICANTS

DESCRIPTION

Only lubricants bearing designations defined by

the following organization should be used to service a

DaimlerChrysler Corporation vehicle.

²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API) (Fig. 1)

²National Lubricating Grease Institute (NLGI)

(Fig. 2)

SAE VISCOSITY RATING

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. These are specified with a dual

SAE viscosity grade which indicates the cold-to-hot

temperature viscosity range. Example SAE 5W-30 =

multiple grade engine oil.DaimlerChrysler Corporation only recommends

multiple grade engine oils.

API QUALITY CLASSIFICATION

This symbol (Fig. 1) on the front of an oil container

means that the oil has been certified by the Ameri-

can Petroleum Institute (API) to meet all the lubri-

cation requirements specified by DaimlerChrysler

Corporation.

Refer to Group 9, Engine for gasoline engine oil

specification.

GEAR LUBRICANTS

SAE ratings also apply to multiple grade gear

lubricants. In addition, API classification defines the

lubricants usage. Such as API GL-5 and SAE 80W-90.

Fig. 1 API Symbol

PLLUBRICATION AND MAINTENANCE 0 - 1

Page 730 of 1285

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conforms to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only, engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

SAE 5W-30 engine oil is preferred. Select an engine

oil that is best suited to your particular temperature

range and variation (Fig. 9).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of the engine oil

container.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 10).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Group 0, Lubrication and Mainte-

nance.TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

Refer to Group 0, Lubrication and Maintenance for

Hoisting and Jacking Recommendations.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

Fig. 9 Temperature/Engine Oil Viscosity

Fig. 10 Engine Oil Container Standard Notations

PLENGINE 9 - 7

GENERAL INFORMATION (Continued)

Page 735 of 1285

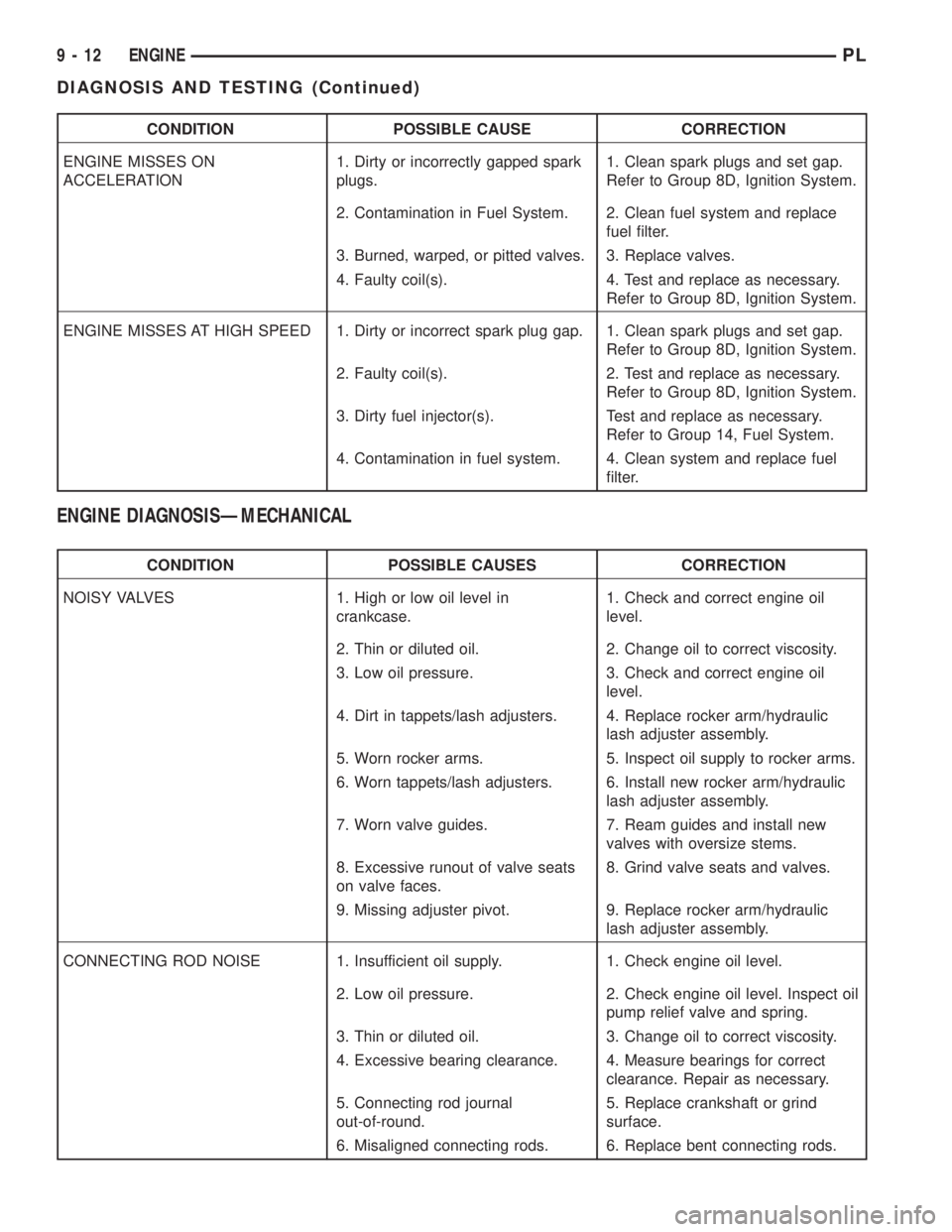

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE MISSES ON

ACCELERATION1. Dirty or incorrectly gapped spark

plugs.1. Clean spark plugs and set gap.

Refer to Group 8D, Ignition System.

2. Contamination in Fuel System. 2. Clean fuel system and replace

fuel filter.

3. Burned, warped, or pitted valves. 3. Replace valves.

4. Faulty coil(s). 4. Test and replace as necessary.

Refer to Group 8D, Ignition System.

ENGINE MISSES AT HIGH SPEED 1. Dirty or incorrect spark plug gap. 1. Clean spark plugs and set gap.

Refer to Group 8D, Ignition System.

2. Faulty coil(s). 2. Test and replace as necessary.

Refer to Group 8D, Ignition System.

3. Dirty fuel injector(s). Test and replace as necessary.

Refer to Group 14, Fuel System.

4. Contamination in fuel system. 4. Clean system and replace fuel

filter.

ENGINE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Low oil pressure. 3. Check and correct engine oil

level.

4. Dirt in tappets/lash adjusters. 4. Replace rocker arm/hydraulic

lash adjuster assembly.

5. Worn rocker arms. 5. Inspect oil supply to rocker arms.

6. Worn tappets/lash adjusters. 6. Install new rocker arm/hydraulic

lash adjuster assembly.

7. Worn valve guides. 7. Ream guides and install new

valves with oversize stems.

8. Excessive runout of valve seats

on valve faces.8. Grind valve seats and valves.

9. Missing adjuster pivot. 9. Replace rocker arm/hydraulic

lash adjuster assembly.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Connecting rod journal

out-of-round.5. Replace crankshaft or grind

surface.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

9 - 12 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 736 of 1285

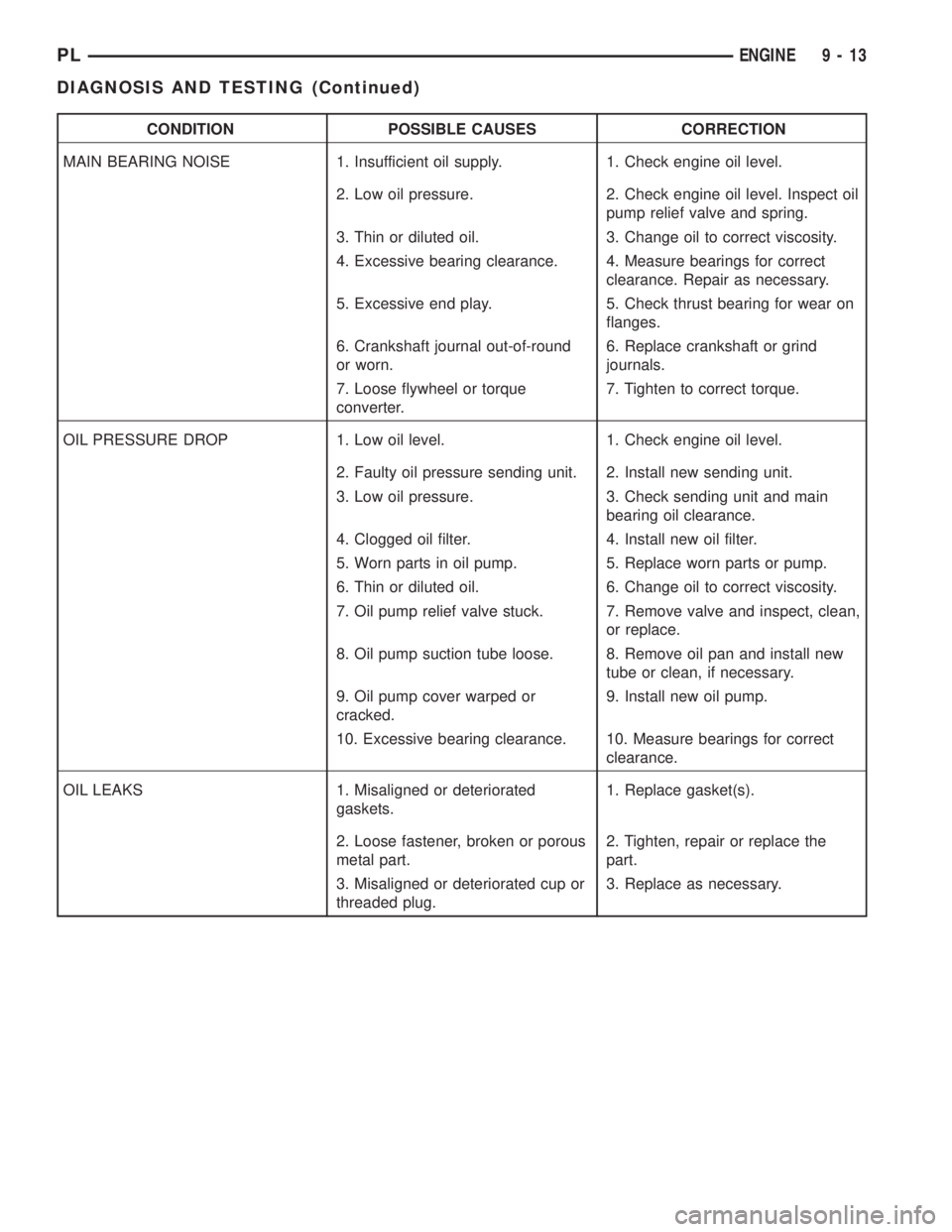

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on

flanges.

6. Crankshaft journal out-of-round

or worn.6. Replace crankshaft or grind

journals.

7. Loose flywheel or torque

converter.7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main

bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

PLENGINE 9 - 13

DIAGNOSIS AND TESTING (Continued)