light DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 961 of 1285

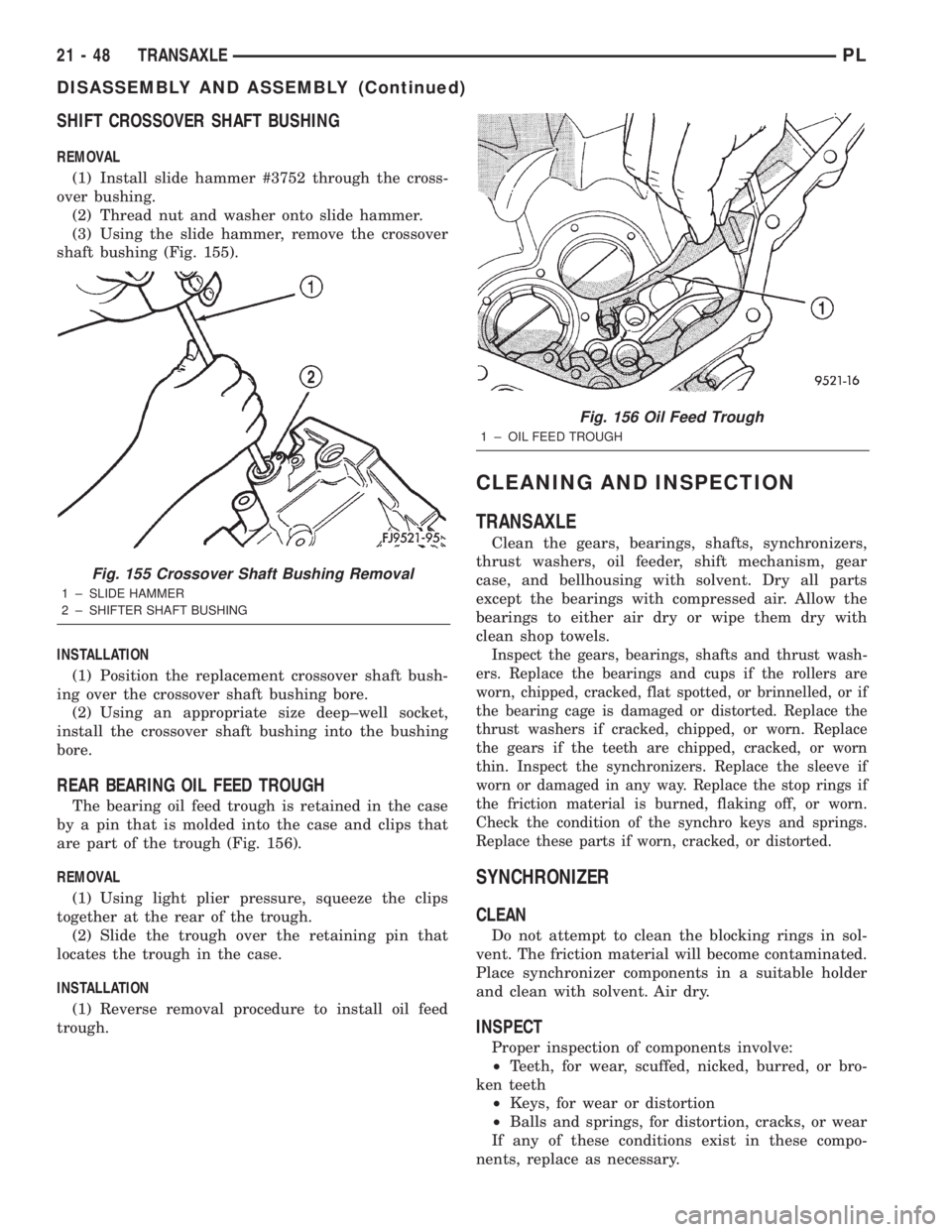

SHIFT CROSSOVER SHAFT BUSHING

REMOVAL

(1) Install slide hammer #3752 through the cross-

over bushing.

(2) Thread nut and washer onto slide hammer.

(3) Using the slide hammer, remove the crossover

shaft bushing (Fig. 155).

INSTALLATION

(1) Position the replacement crossover shaft bush-

ing over the crossover shaft bushing bore.

(2) Using an appropriate size deep±well socket,

install the crossover shaft bushing into the bushing

bore.

REAR BEARING OIL FEED TROUGH

The bearing oil feed trough is retained in the case

by a pin that is molded into the case and clips that

are part of the trough (Fig. 156).

REMOVAL

(1) Using light plier pressure, squeeze the clips

together at the rear of the trough.

(2) Slide the trough over the retaining pin that

locates the trough in the case.

INSTALLATION

(1) Reverse removal procedure to install oil feed

trough.

CLEANING AND INSPECTION

TRANSAXLE

Clean the gears, bearings, shafts, synchronizers,

thrust washers, oil feeder, shift mechanism, gear

case, and bellhousing with solvent. Dry all parts

except the bearings with compressed air. Allow the

bearings to either air dry or wipe them dry with

clean shop towels.

Inspect the gears, bearings, shafts and thrust wash-

ers. Replace the bearings and cups if the rollers are

worn, chipped, cracked, flat spotted, or brinnelled, or if

the bearing cage is damaged or distorted. Replace the

thrust washers if cracked, chipped, or worn. Replace

the gears if the teeth are chipped, cracked, or worn

thin. Inspect the synchronizers. Replace the sleeve if

worn or damaged in any way. Replace the stop rings if

the friction material is burned, flaking off, or worn.

Check the condition of the synchro keys and springs.

Replace these parts if worn, cracked, or distorted.

SYNCHRONIZER

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Keys, for wear or distortion

²Balls and springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

Fig. 155 Crossover Shaft Bushing Removal

1 ± SLIDE HAMMER

2 ± SHIFTER SHAFT BUSHING

Fig. 156 Oil Feed Trough

1 ± OIL FEED TROUGH

21 - 48 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1004 of 1285

ASSEMBLY

When rebuilding, reverse the above procedure.

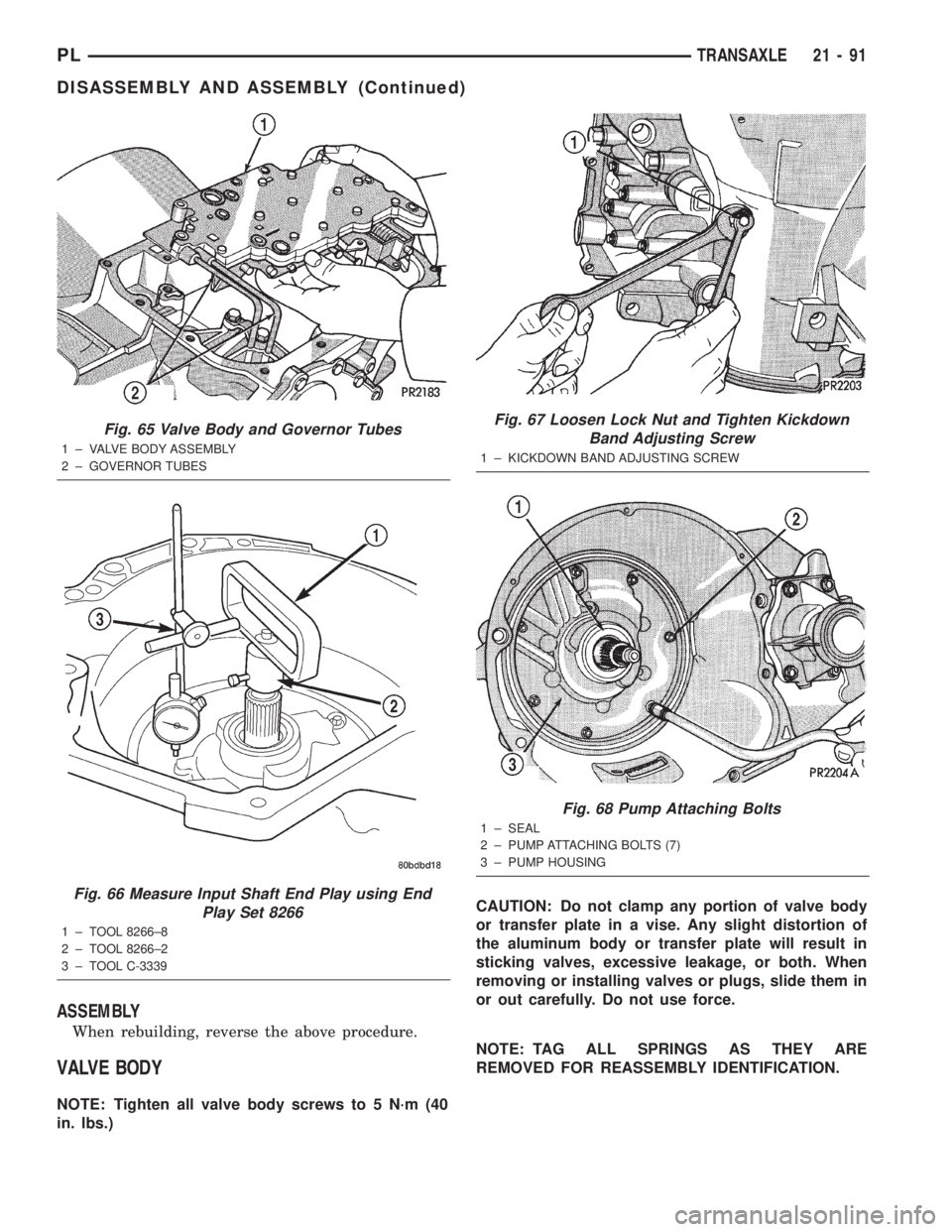

VALVE BODY

NOTE: Tighten all valve body screws to 5 N´m (40

in. lbs.)CAUTION: Do not clamp any portion of valve body

or transfer plate in a vise. Any slight distortion of

the aluminum body or transfer plate will result in

sticking valves, excessive leakage, or both. When

removing or installing valves or plugs, slide them in

or out carefully. Do not use force.

NOTE: TAG ALL SPRINGS AS THEY ARE

REMOVED FOR REASSEMBLY IDENTIFICATION.

Fig. 65 Valve Body and Governor Tubes

1 ± VALVE BODY ASSEMBLY

2 ± GOVERNOR TUBES

Fig. 66 Measure Input Shaft End Play using End

Play Set 8266

1 ± TOOL 8266±8

2 ± TOOL 8266±2

3 ± TOOL C-3339

Fig. 67 Loosen Lock Nut and Tighten Kickdown

Band Adjusting Screw

1 ± KICKDOWN BAND ADJUSTING SCREW

Fig. 68 Pump Attaching Bolts

1 ± SEAL

2 ± PUMP ATTACHING BOLTS (7)

3 ± PUMP HOUSING

PLTRANSAXLE 21 - 91

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1048 of 1285

CLEANING AND INSPECTION

VALVE BODY

Allow all parts to soak a few minutes in a suitable

clean solvent. Wash thoroughly and blow dry with

compressed air. Be sure all passages are clean and

free from obstructions.

Inspect manual and throttle valve operating levers

and shafts for being bent, worn or loose. If a lever is

loose on its shaft, it should be replaced. Do not

attempt to straighten bent levers.

Inspect all mating surfaces for burrs, nicks and

scratches. Minor blemishes may be removed with cro-

cus cloth, using only a very light pressure. Using a

straightedge, inspect all mating surfaces for warpage

or distortion. Slight distortion may be corrected,

using a surface plate. Be sure all metering holes in

steel plate are open. Using a penlight, inspect bores

in valve body for scores, scratches, pits, and irregu-

larities.

Inspect all valve springs for distortion and col-

lapsed coils. Inspect all valves and plugs for burrs,

nicks, and scores. Small nicks and scores may be

removed with crocus cloth, providing extreme care is

taken not to round off sharp edges. The sharpness of

these edges is vitally important. It prevents foreign

matter from lodging between valve and valve body.

This reduces the possibility of sticking. Inspect all

valves and plugs for freedom of operation in valve

body bores.

When bores, valves, and plugs are clean and dry,

the valves and plugs should fall freely in the bores.

The valve body bores do not change their dimensions

with use. Therefore, a valve body that was function-

ing properly when vehicle was new, will operate cor-

rectly if it is properly and thoroughly cleaned. There

is no need to replace a valve body unless it is dam-

aged in handling.

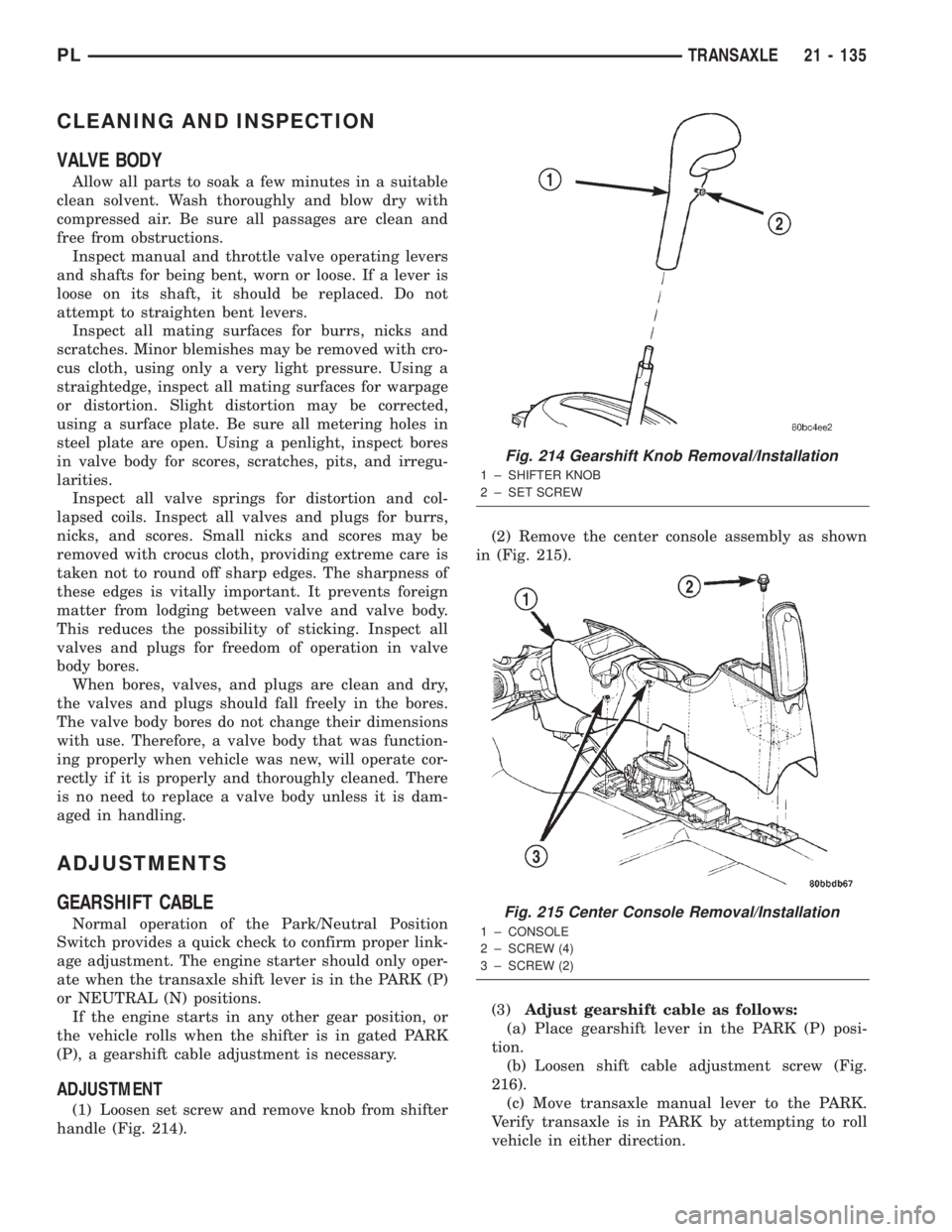

ADJUSTMENTS

GEARSHIFT CABLE

Normal operation of the Park/Neutral Position

Switch provides a quick check to confirm proper link-

age adjustment. The engine starter should only oper-

ate when the transaxle shift lever is in the PARK (P)

or NEUTRAL (N) positions.

If the engine starts in any other gear position, or

the vehicle rolls when the shifter is in gated PARK

(P), a gearshift cable adjustment is necessary.

ADJUSTMENT

(1) Loosen set screw and remove knob from shifter

handle (Fig. 214).(2) Remove the center console assembly as shown

in (Fig. 215).

(3)Adjust gearshift cable as follows:

(a) Place gearshift lever in the PARK (P) posi-

tion.

(b) Loosen shift cable adjustment screw (Fig.

216).

(c) Move transaxle manual lever to the PARK.

Verify transaxle is in PARK by attempting to roll

vehicle in either direction.

Fig. 214 Gearshift Knob Removal/Installation

1 ± SHIFTER KNOB

2 ± SET SCREW

Fig. 215 Center Console Removal/Installation

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

PLTRANSAXLE 21 - 135

Page 1085 of 1285

(3) When flange on retaining nut is past the 2

retaining tabs on the wheel cover, remove retaining

nut from wheel cover by pushing or pulling from hole

in wheel cover.

INSTALL

(1) Install retaining nut in hole of wheel cover

with retaining nut flange positioned under the large

retaining flange (Fig. 13).

(2) Push on hex of retaining nut forcing the retain-

ing nut flange past the 2 small retaining tabs in

wheel cover.

TIRE AND WHEEL ASSEMBLY

CAST WHEEL

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE section.

(2) Remove the wheel mounting nuts from the

studs.

(3) Remove the tire and wheel assembly from the

hub.

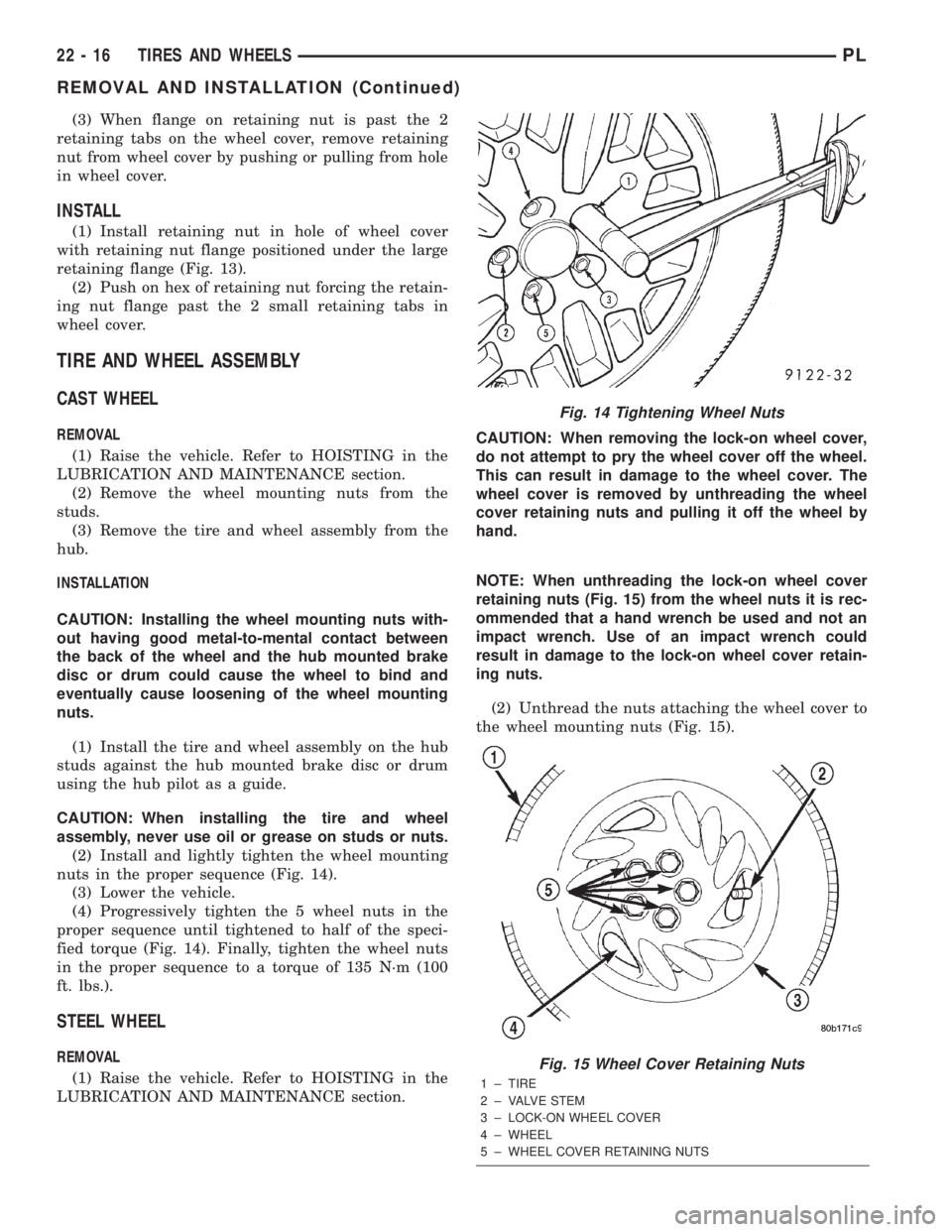

INSTALLATION

CAUTION: Installing the wheel mounting nuts with-

out having good metal-to-mental contact between

the back of the wheel and the hub mounted brake

disc or drum could cause the wheel to bind and

eventually cause loosening of the wheel mounting

nuts.

(1) Install the tire and wheel assembly on the hub

studs against the hub mounted brake disc or drum

using the hub pilot as a guide.

CAUTION: When installing the tire and wheel

assembly, never use oil or grease on studs or nuts.

(2) Install and lightly tighten the wheel mounting

nuts in the proper sequence (Fig. 14).

(3) Lower the vehicle.

(4) Progressively tighten the 5 wheel nuts in the

proper sequence until tightened to half of the speci-

fied torque (Fig. 14). Finally, tighten the wheel nuts

in the proper sequence to a torque of 135 N´m (100

ft. lbs.).

STEEL WHEEL

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE section.CAUTION: When removing the lock-on wheel cover,

do not attempt to pry the wheel cover off the wheel.

This can result in damage to the wheel cover. The

wheel cover is removed by unthreading the wheel

cover retaining nuts and pulling it off the wheel by

hand.

NOTE: When unthreading the lock-on wheel cover

retaining nuts (Fig. 15) from the wheel nuts it is rec-

ommended that a hand wrench be used and not an

impact wrench. Use of an impact wrench could

result in damage to the lock-on wheel cover retain-

ing nuts.

(2) Unthread the nuts attaching the wheel cover to

the wheel mounting nuts (Fig. 15).

Fig. 14 Tightening Wheel Nuts

Fig. 15 Wheel Cover Retaining Nuts

1 ± TIRE

2 ± VALVE STEM

3 ± LOCK-ON WHEEL COVER

4 ± WHEEL

5 ± WHEEL COVER RETAINING NUTS

22 - 16 TIRES AND WHEELSPL

REMOVAL AND INSTALLATION (Continued)

Page 1086 of 1285

(3) Grasp the wheel cover and pull straight out-

ward. This will remove the wheel cover from the

wheel.

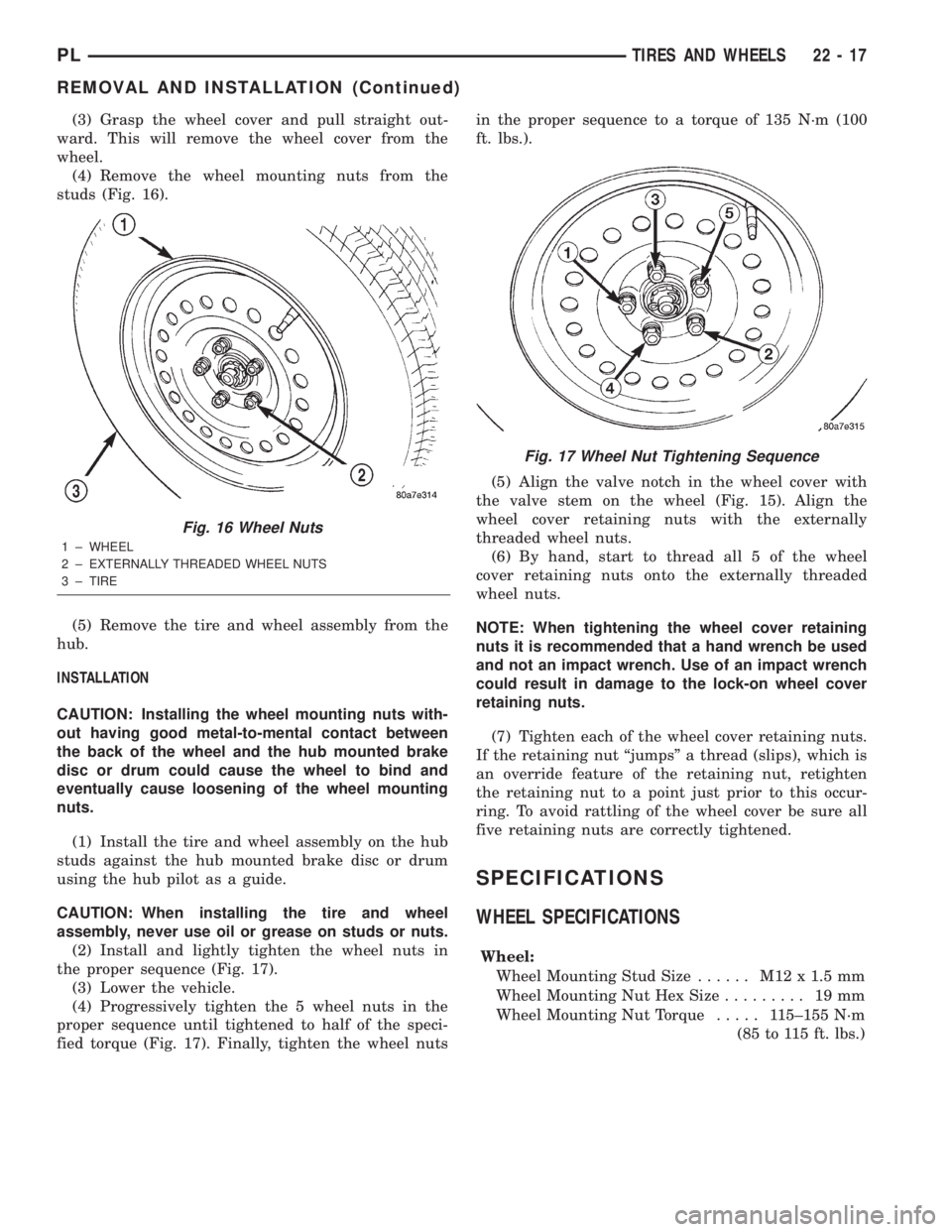

(4) Remove the wheel mounting nuts from the

studs (Fig. 16).

(5) Remove the tire and wheel assembly from the

hub.

INSTALLATION

CAUTION: Installing the wheel mounting nuts with-

out having good metal-to-mental contact between

the back of the wheel and the hub mounted brake

disc or drum could cause the wheel to bind and

eventually cause loosening of the wheel mounting

nuts.

(1) Install the tire and wheel assembly on the hub

studs against the hub mounted brake disc or drum

using the hub pilot as a guide.

CAUTION: When installing the tire and wheel

assembly, never use oil or grease on studs or nuts.

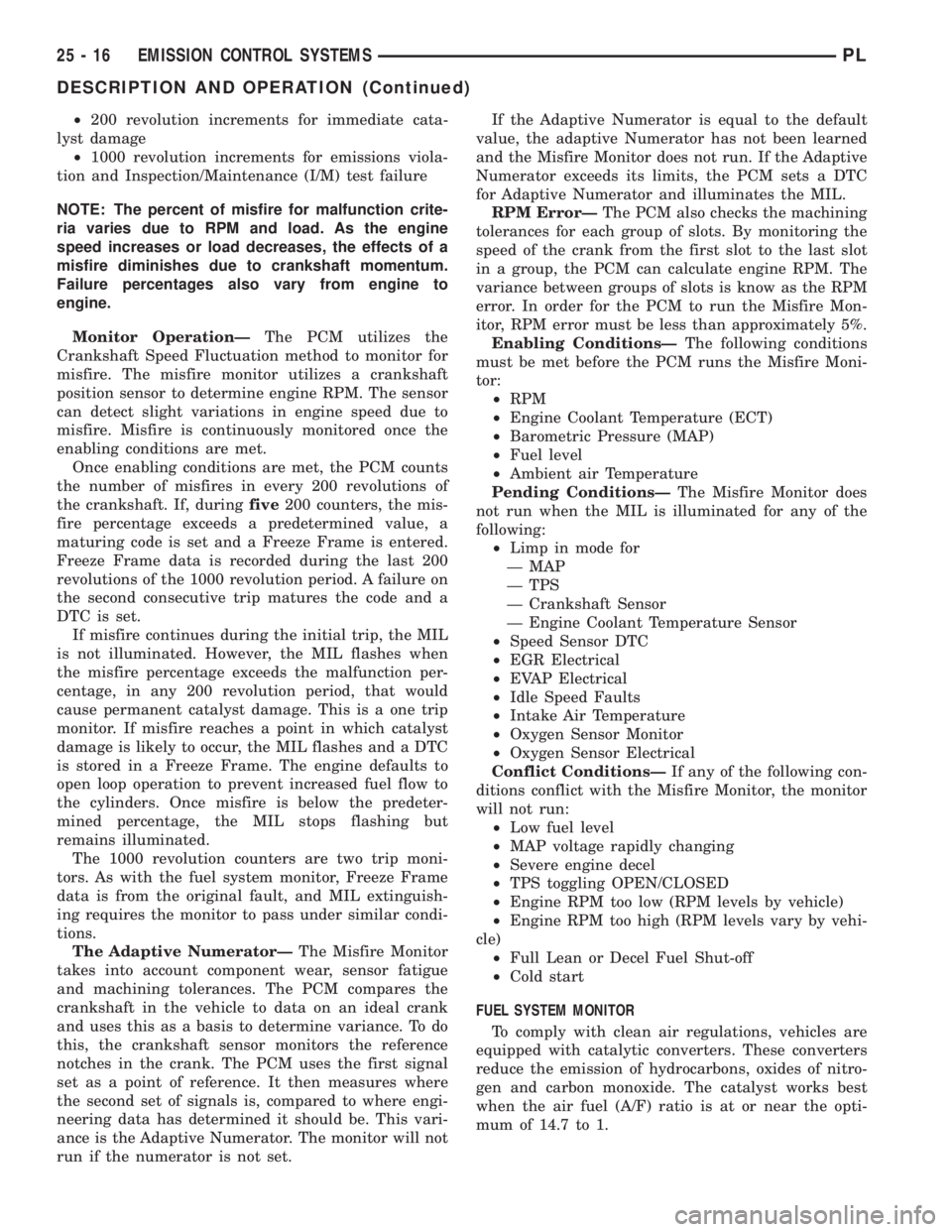

(2) Install and lightly tighten the wheel nuts in

the proper sequence (Fig. 17).

(3) Lower the vehicle.

(4) Progressively tighten the 5 wheel nuts in the

proper sequence until tightened to half of the speci-

fied torque (Fig. 17). Finally, tighten the wheel nutsin the proper sequence to a torque of 135 N´m (100

ft. lbs.).

(5) Align the valve notch in the wheel cover with

the valve stem on the wheel (Fig. 15). Align the

wheel cover retaining nuts with the externally

threaded wheel nuts.

(6) By hand, start to thread all 5 of the wheel

cover retaining nuts onto the externally threaded

wheel nuts.

NOTE: When tightening the wheel cover retaining

nuts it is recommended that a hand wrench be used

and not an impact wrench. Use of an impact wrench

could result in damage to the lock-on wheel cover

retaining nuts.

(7) Tighten each of the wheel cover retaining nuts.

If the retaining nut ªjumpsº a thread (slips), which is

an override feature of the retaining nut, retighten

the retaining nut to a point just prior to this occur-

ring. To avoid rattling of the wheel cover be sure all

five retaining nuts are correctly tightened.

SPECIFICATIONS

WHEEL SPECIFICATIONS

Wheel:

Wheel Mounting Stud Size...... M12x1.5mm

Wheel Mounting Nut Hex Size......... 19mm

Wheel Mounting Nut Torque..... 115±155 N´m

(85 to 115 ft. lbs.)

Fig. 16 Wheel Nuts

1 ± WHEEL

2 ± EXTERNALLY THREADED WHEEL NUTS

3 ± TIRE

Fig. 17 Wheel Nut Tightening Sequence

PLTIRES AND WHEELS 22 - 17

REMOVAL AND INSTALLATION (Continued)

Page 1103 of 1285

²200 revolution increments for immediate cata-

lyst damage

²1000 revolution increments for emissions viola-

tion and Inspection/Maintenance (I/M) test failure

NOTE: The percent of misfire for malfunction crite-

ria varies due to RPM and load. As the engine

speed increases or load decreases, the effects of a

misfire diminishes due to crankshaft momentum.

Failure percentages also vary from engine to

engine.

Monitor OperationÐThe PCM utilizes the

Crankshaft Speed Fluctuation method to monitor for

misfire. The misfire monitor utilizes a crankshaft

position sensor to determine engine RPM. The sensor

can detect slight variations in engine speed due to

misfire. Misfire is continuously monitored once the

enabling conditions are met.

Once enabling conditions are met, the PCM counts

the number of misfires in every 200 revolutions of

the crankshaft. If, duringfive200 counters, the mis-

fire percentage exceeds a predetermined value, a

maturing code is set and a Freeze Frame is entered.

Freeze Frame data is recorded during the last 200

revolutions of the 1000 revolution period. A failure on

the second consecutive trip matures the code and a

DTC is set.

If misfire continues during the initial trip, the MIL

is not illuminated. However, the MIL flashes when

the misfire percentage exceeds the malfunction per-

centage, in any 200 revolution period, that would

cause permanent catalyst damage. This is a one trip

monitor. If misfire reaches a point in which catalyst

damage is likely to occur, the MIL flashes and a DTC

is stored in a Freeze Frame. The engine defaults to

open loop operation to prevent increased fuel flow to

the cylinders. Once misfire is below the predeter-

mined percentage, the MIL stops flashing but

remains illuminated.

The 1000 revolution counters are two trip moni-

tors. As with the fuel system monitor, Freeze Frame

data is from the original fault, and MIL extinguish-

ing requires the monitor to pass under similar condi-

tions.

The Adaptive NumeratorÐThe Misfire Monitor

takes into account component wear, sensor fatigue

and machining tolerances. The PCM compares the

crankshaft in the vehicle to data on an ideal crank

and uses this as a basis to determine variance. To do

this, the crankshaft sensor monitors the reference

notches in the crank. The PCM uses the first signal

set as a point of reference. It then measures where

the second set of signals is, compared to where engi-

neering data has determined it should be. This vari-

ance is the Adaptive Numerator. The monitor will not

run if the numerator is not set.If the Adaptive Numerator is equal to the default

value, the adaptive Numerator has not been learned

and the Misfire Monitor does not run. If the Adaptive

Numerator exceeds its limits, the PCM sets a DTC

for Adaptive Numerator and illuminates the MIL.

RPM ErrorÐThe PCM also checks the machining

tolerances for each group of slots. By monitoring the

speed of the crank from the first slot to the last slot

in a group, the PCM can calculate engine RPM. The

variance between groups of slots is know as the RPM

error. In order for the PCM to run the Misfire Mon-

itor, RPM error must be less than approximately 5%.

Enabling ConditionsÐThe following conditions

must be met before the PCM runs the Misfire Moni-

tor:

²RPM

²Engine Coolant Temperature (ECT)

²Barometric Pressure (MAP)

²Fuel level

²Ambient air Temperature

Pending ConditionsÐThe Misfire Monitor does

not run when the MIL is illuminated for any of the

following:

²Limp in mode for

Ð MAP

Ð TPS

Ð Crankshaft Sensor

Ð Engine Coolant Temperature Sensor

²Speed Sensor DTC

²EGR Electrical

²EVAP Electrical

²Idle Speed Faults

²Intake Air Temperature

²Oxygen Sensor Monitor

²Oxygen Sensor Electrical

Conflict ConditionsÐIf any of the following con-

ditions conflict with the Misfire Monitor, the monitor

will not run:

²Low fuel level

²MAP voltage rapidly changing

²Severe engine decel

²TPS toggling OPEN/CLOSED

²Engine RPM too low (RPM levels by vehicle)

²Engine RPM too high (RPM levels vary by vehi-

cle)

²Full Lean or Decel Fuel Shut-off

²Cold start

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the air fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

25 - 16 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1118 of 1285

BODY

TABLE OF CONTENTS

page page

PAINT................................... 1

STATIONARY GLASS........................ 4

SEATS ................................... 8BODY COMPONENTS...................... 12

SPECIFICATIONS......................... 60

PAINT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

PAINT CODE.............................1

BASE COAT/CLEAR COAT FINISH.............1

WET SANDING, BUFFING, AND POLISHING.....1PAINTED SURFACE TOUCH-UP..............1

SPECIFICATIONS

AFTERMARKET PAINT REPAIR PRODUCTS.....2

DESCRIPTION AND OPERATION

PAINT CODE

A paint code is provided on the body code plate

located in the engine compartment. Refer to the

Introduction section at the front of this manual for

body code plate description. The paint and trim codes

are also included on the Vehicle Safety Label located

on the driver's door end frame.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two-part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultraviolet light and provides a dura-

ble high-gloss finish.

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning sol-

vents on painted surfaces. Damage to finish or

color can result.

WET SANDING, BUFFING, AND POLISHING

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light wet sanding, hand buffing, and polishing.

If the finish has been wet sanded in the past, itcannot be repeated. Wet sanding operation

should be performed by a trained automotive

paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

CAUTION: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

PLBODY 23 - 1

Page 1119 of 1285

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly wet sanded (1500 grit) and pol-

ished with rubbing compound.(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

CAUTION: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

SPECIFICATIONS

AFTERMARKET PAINT REPAIR PRODUCTS

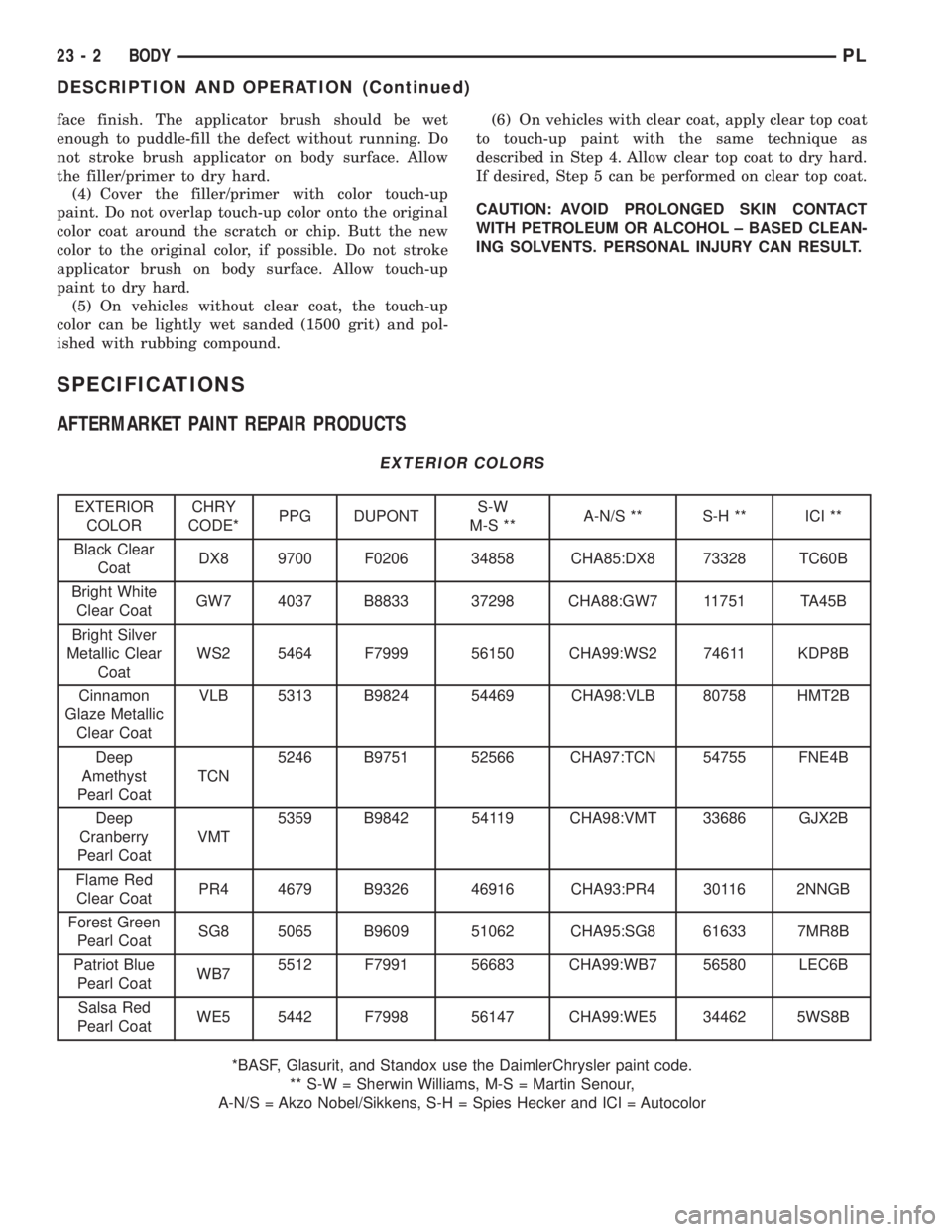

EXTERIOR COLORS

EXTERIOR

COLORCHRY

CODE*PPG DUPONTS-W

M-S **A-N/S ** S-H ** ICI **

Black Clear

CoatDX8 9700 F0206 34858 CHA85:DX8 73328 TC60B

Bright White

Clear CoatGW7 4037 B8833 37298 CHA88:GW7 11751 TA45B

Bright Silver

Metallic Clear

CoatWS2 5464 F7999 56150 CHA99:WS2 74611 KDP8B

Cinnamon

Glaze Metallic

Clear CoatVLB 5313 B9824 54469 CHA98:VLB 80758 HMT2B

Deep

Amethyst

Pearl CoatTCN5246 B9751 52566 CHA97:TCN 54755 FNE4B

Deep

Cranberry

Pearl CoatVMT5359 B9842 54119 CHA98:VMT 33686 GJX2B

Flame Red

Clear CoatPR4 4679 B9326 46916 CHA93:PR4 30116 2NNGB

Forest Green

Pearl CoatSG8 5065 B9609 51062 CHA95:SG8 61633 7MR8B

Patriot Blue

Pearl CoatWB75512 F7991 56683 CHA99:WB7 56580 LEC6B

Salsa Red

Pearl CoatWE5 5442 F7998 56147 CHA99:WE5 34462 5WS8B

*BASF, Glasurit, and Standox use the DaimlerChrysler paint code.

** S-W = Sherwin Williams, M-S = Martin Senour,

A-N/S = Akzo Nobel/Sikkens, S-H = Spies Hecker and ICI = Autocolor

23 - 2 BODYPL

DESCRIPTION AND OPERATION (Continued)

Page 1135 of 1285

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the lowest point of the water track or

drop. After leak point has been found, repair the leak

and water test to verify that the leak has stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 18 BODYPL

Page 1137 of 1285

SAFETY PRECAUTION AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING RTM AND SMC COMPONENTS.

PERSONAL INJURE CAN RESULT.

USE AN OSHA APPROVED BREATHING DEVICE

WHEN MIXING EPOXY, GRINDING RTM AND SMC,

AND SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

EPOXY RESIN, PETROLEUM, OR ALCOHOL BASED

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components and

electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds on

undamaged painted surfaces around repair areas.

Damage to finish can result.

PANEL SECTIONING

If it is required to section a large panel for an SMC

or RTM repair, it will be necessary to reinforce the

panel with epoxy structural adhesive (rigid repair

adhesive) (Fig. 2). To bond two plastic panels

together, a reinforcement must overlap both panels.

The panels must be ªV'dº at a 20 degree angle. The

area to be reinforced should be washed, then sanded.

Be sure to wipe off any excess soap and water when

finished. Lightly sand or abrade the plastic with an

abrasive pad or sandpaper. Blow off any dust with

compressed air or wipe with a clean dry rag.When bonding SMC or RTM panels, use a two-part

epoxy adhesive. Properly mix parts A and B, and

apply it to the panels being repaired. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.

After the parts have been bonded and have had

time to cure, rough sand the seam and apply the

final adhesive filler to the area being repaired.

Smooth the filler with a spatula, wooden tongue

depressor, or squeegee. For fine texturing, a small

amount of water can be applied to the filler surface

while smoothing. The cured filler can be sanded as

necessary and, as a final step, cleanup can be done

withy soapy water. Wipe the surface clean with a dry

cloth allowing time for the panel to dry before mov-

ing on with the repair.

PANEL REINFORCEMENT

Structural repair procedures for rigid panels such

as Sheet Molded compound (SMC) or Resin Transfer

Molded (RTM) with large cracks and holes will

require a reinforcement backing. Reinforcements can

be made with several applications of glass cloth sat-

urated with epoxy structural adhesive, semirigid or

flexible repair materials should be used for semirigid

or flexible part repairs (Fig. 3) and (Fig. 4). Open

meshed fiberglass dry wall tape can be used to form

a reinforcement. The dry wall tape allows the resin

to penetrate through and make a good bond between

the panel and the epoxy adhesive. Structurally, the

more dry wall tape used, the stronger the repair.

Another kind of repair that can be done to repair

large cracks and holes is to use a scrap piece of sim-

ilar plastic and bond with structural adhesive. The

reinforcement should cover the entire break and

should have a generous amount of overlap on either

side of the cracked or broken area.

When repairing plastic, the damaged area is first

ªV'dº out, or beveled. Large bonding areas are desir-

able when repairing plastic because small repairs are

less likely to hold permanently. Beveling the area

around a crack at a 20 degree angle will increase the

bonding surface for a repair (Fig. 5). It is recom-

mended that sharp edges be avoided because the

joint may show through after the panel is refinished.

²Panel repair for both flexible and rigid panels

are basically the same. The primary difference

between flexible panel repair and rigid panel repair

is in the adhesive materials used (Fig. 6).

²The technician should first decide what needs to

be done when working on any type of body panel.

One should determine if it is possible to return the

Fig. 2 Panel Sectioning

1 ± EXISTING PANEL

2 ± NEW PANEL

3 ± PANEL ADHESIVE

4 ± BONDING STRIP

23 - 20 BODYPL

SERVICE PROCEDURES (Continued)