light DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 610 of 1285

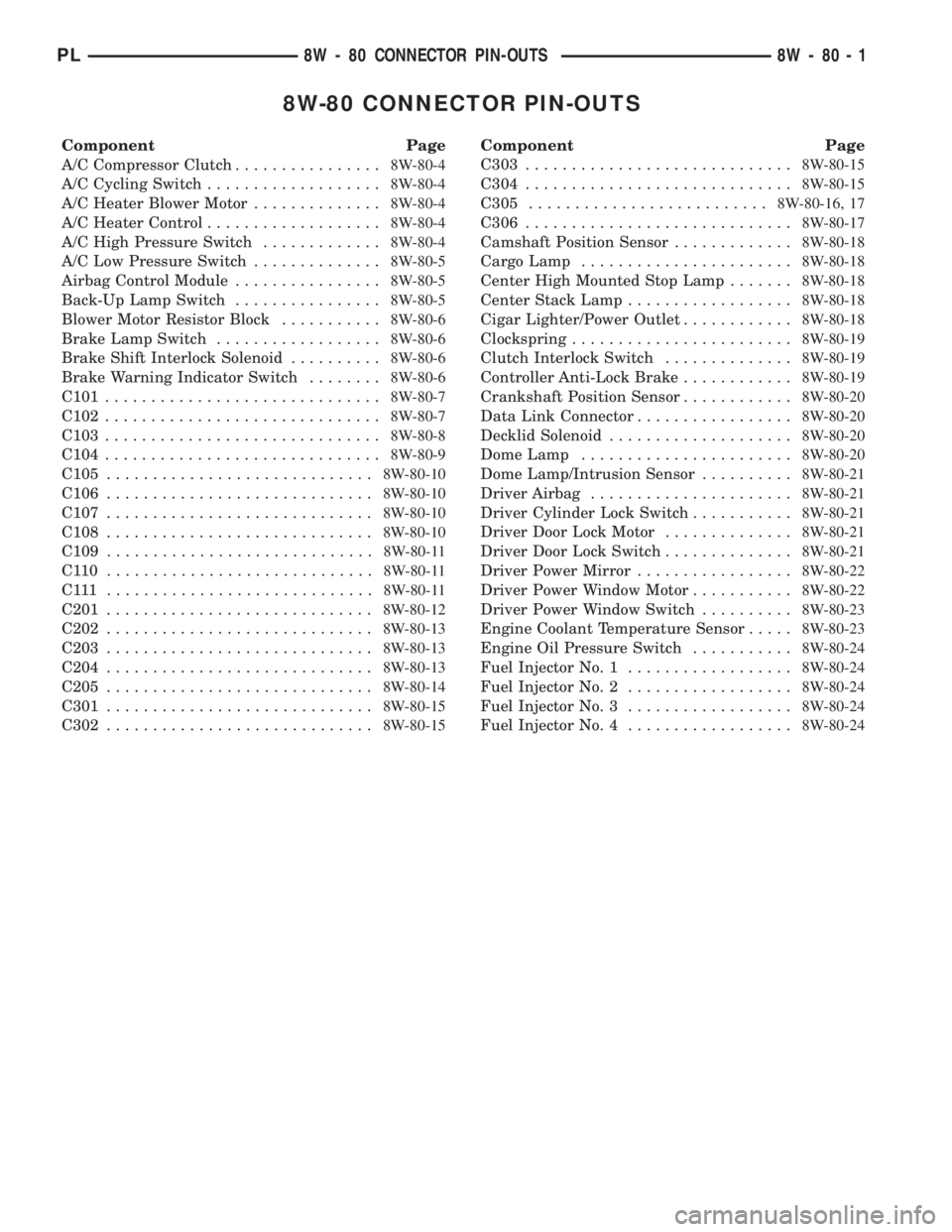

8W-80 CONNECTOR PIN-OUTS

Component Page

A/C Compressor Clutch................8W-80-4

A/C Cycling Switch...................8W-80-4

A/C Heater Blower Motor..............8W-80-4

A/C Heater Control...................8W-80-4

A/C High Pressure Switch.............8W-80-4

A/C Low Pressure Switch..............8W-80-5

Airbag Control Module................8W-80-5

Back-Up Lamp Switch................8W-80-5

Blower Motor Resistor Block...........8W-80-6

Brake Lamp Switch..................8W-80-6

Brake Shift Interlock Solenoid..........8W-80-6

Brake Warning Indicator Switch........8W-80-6

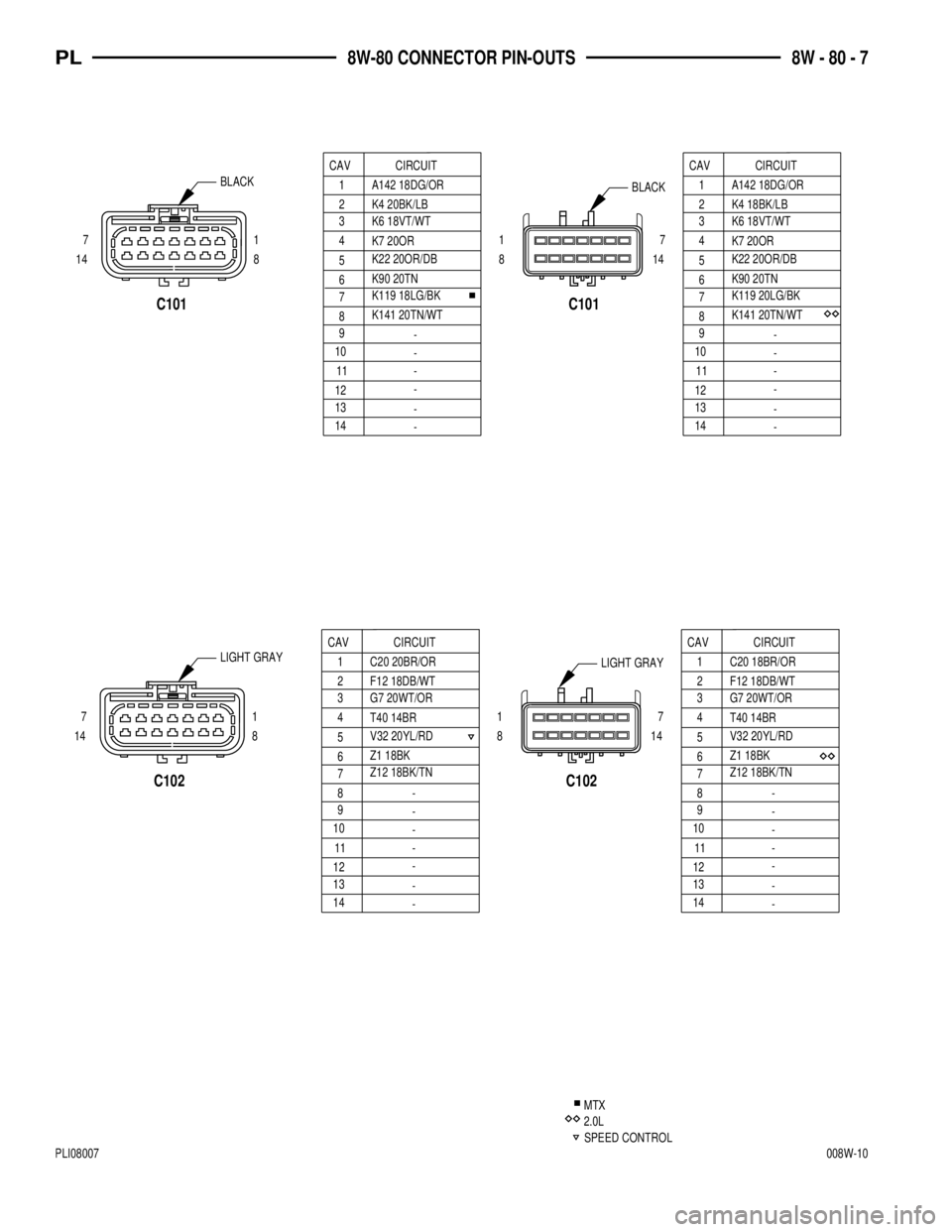

C101..............................8W-80-7

C102..............................8W-80-7

C103..............................8W-80-8

C104..............................8W-80-9

C105.............................8W-80-10

C106.............................8W-80-10

C107.............................8W-80-10

C108.............................8W-80-10

C109.............................8W-80-11

C110 .............................8W-80-11

C111 .............................8W-80-11

C201.............................8W-80-12

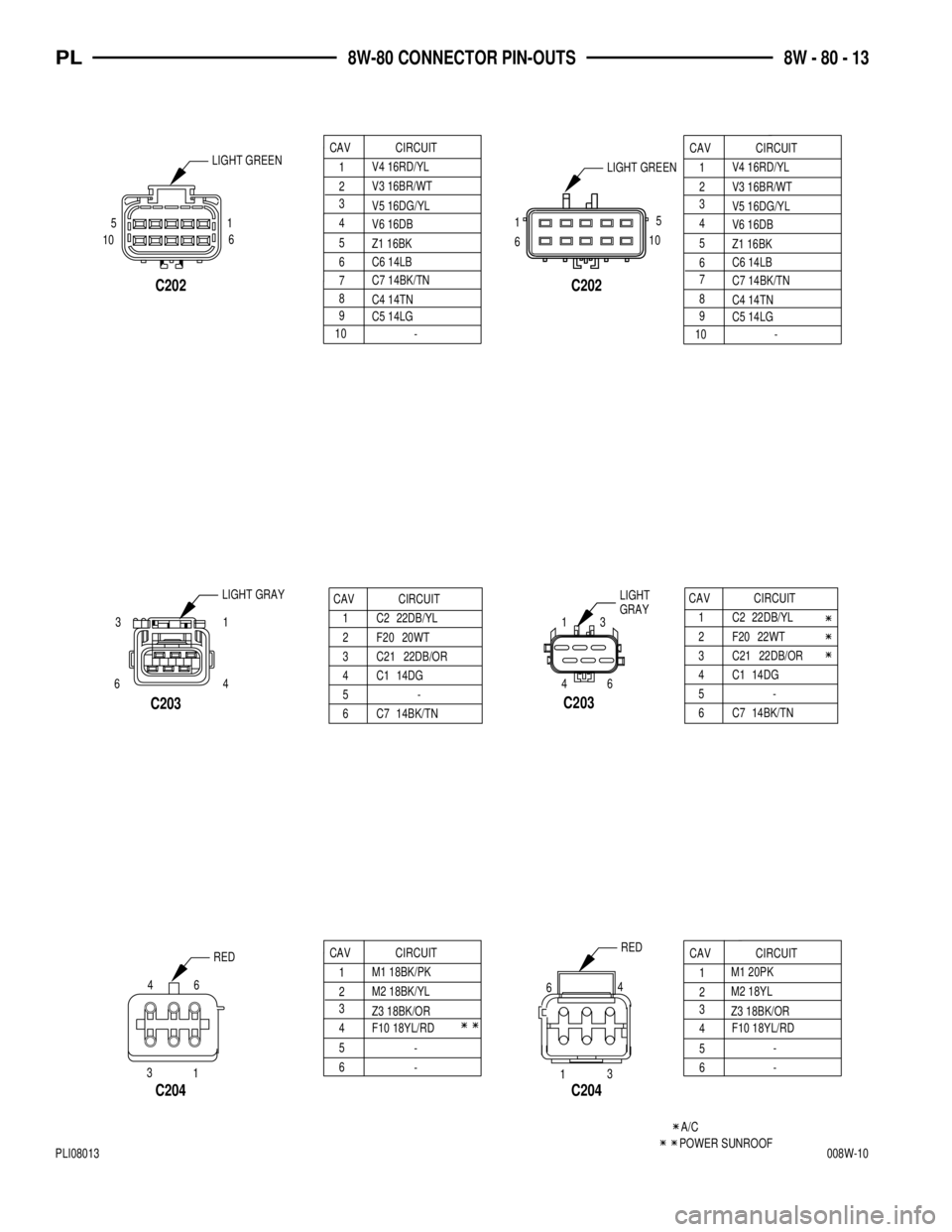

C202.............................8W-80-13

C203.............................8W-80-13

C204.............................8W-80-13

C205.............................8W-80-14

C301.............................8W-80-15

C302.............................8W-80-15Component Page

C303.............................8W-80-15

C304.............................8W-80-15

C305..........................8W-80-16, 17

C306.............................8W-80-17

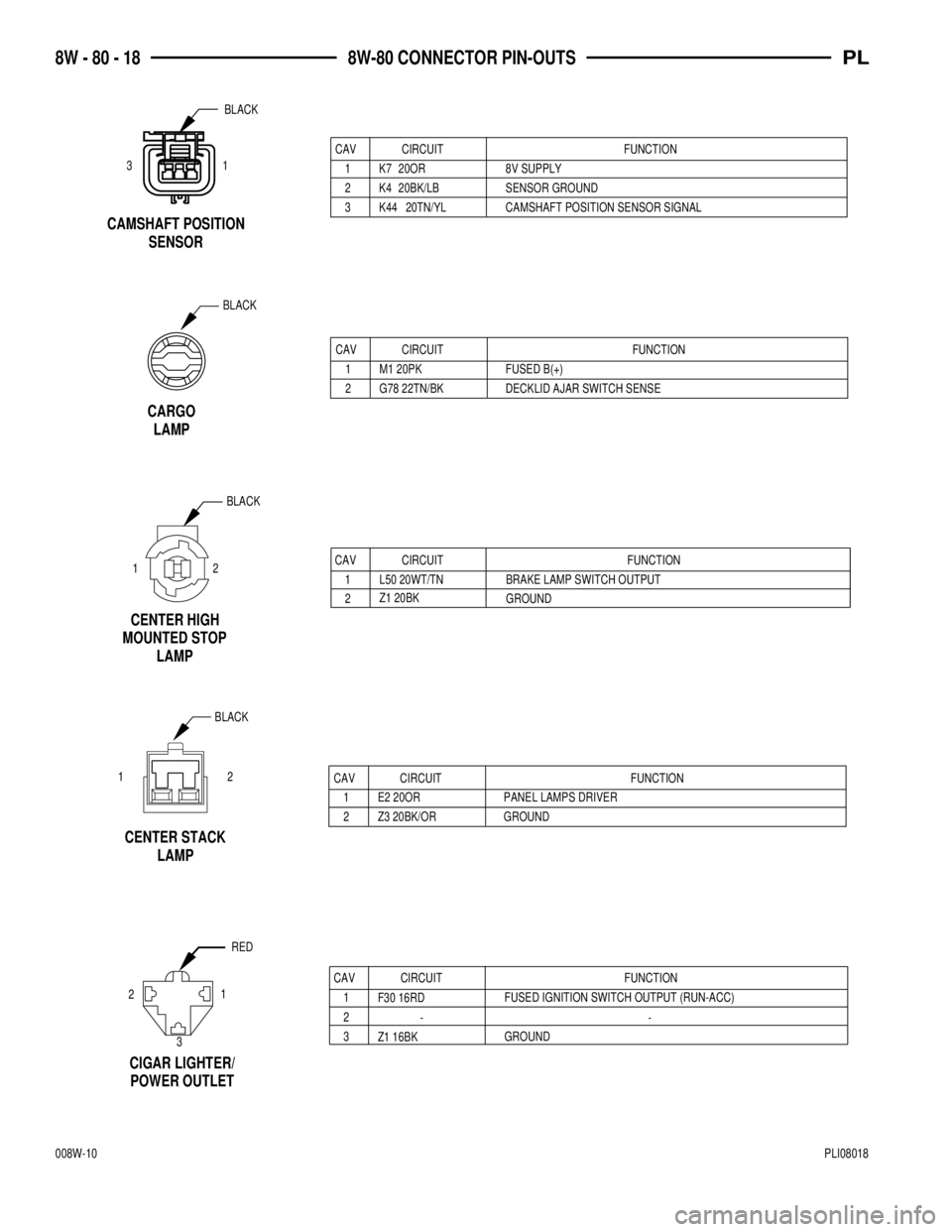

Camshaft Position Sensor.............8W-80-18

Cargo Lamp.......................8W-80-18

Center High Mounted Stop Lamp.......8W-80-18

Center Stack Lamp..................8W-80-18

Cigar Lighter/Power Outlet............8W-80-18

Clockspring........................8W-80-19

Clutch Interlock Switch..............8W-80-19

Controller Anti-Lock Brake............8W-80-19

Crankshaft Position Sensor............8W-80-20

Data Link Connector.................8W-80-20

Decklid Solenoid....................8W-80-20

Dome Lamp.......................8W-80-20

Dome Lamp/Intrusion Sensor..........8W-80-21

Driver Airbag......................8W-80-21

Driver Cylinder Lock Switch...........8W-80-21

Driver Door Lock Motor..............8W-80-21

Driver Door Lock Switch..............8W-80-21

Driver Power Mirror.................8W-80-22

Driver Power Window Motor...........8W-80-22

Driver Power Window Switch..........8W-80-23

Engine Coolant Temperature Sensor.....8W-80-23

Engine Oil Pressure Switch...........8W-80-24

Fuel Injector No. 1..................8W-80-24

Fuel Injector No. 2..................8W-80-24

Fuel Injector No. 3..................8W-80-24

Fuel Injector No. 4..................8W-80-24

PL8W - 80 CONNECTOR PIN-OUTS 8W - 80 - 1

Page 616 of 1285

- - -

- - - V32 20YL/RD

Z1 18BK

Z12 18BK/TN G7 20WT/OR

T40 14BR F12 18DB/WT

1411

12

13

9C20 20BR/OR

5

6

8 7 3

4 2 1CIRCUIT CAV

10 7

14 81

C102C102

10

CAV CIRCUIT

1

2

4 3

7

8 6 5

9

13 1211

14-

-

- -

-

- 147 1

8

-

SPEED CONTROL

C20 18BR/OR

F12 18DB/WT

T40 14BR G7 20WT/OR

Z12 18BK/TN V32 20YL/RD

- - - -

- - - K22 20OR/DB

K90 20TN

K141 20TN/WT K119 18LG/BK K6 18VT/WT

K7 20OR K4 20BK/LB

1411

12

13

9A142 18DG/OR

5

6

8 7 3

4 2 1CIRCUIT CAV

10 7

14 81

C101C101

10

CAV CIRCUIT

1

2

4 3

7

8 6 5A142 18DG/OR

9

13 1211

14K4 18BK/LB

K7 20OR K6 18VT/WT

K119 20LG/BK

K141 20TN/WT K90 20TN K22 20OR/DB

-

-

- -

-

- 147 1

8

2.0L

MTX

BLACKBLACK

LIGHT GRAYLIGHT GRAY

Z1 18BK

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 7

PLI08007008W-10

Page 622 of 1285

C203

C203

LIGHT

3 1

6 4LIGHT GRAY

14BK/TN C7 6- 5

14DG C1 4

22DB/OR C21 3

22WT F20 2

22DB/YL C2 1

CIRCUIT CAV

14BK/TN C7 6- 5

14DG C1 4

22DB/OR C21 3

20WT F20 2

22DB/YL C2 1

CIRCUIT CAVGRAY

A/C

64

3

1

Z3 18BK/OR M2 18YL

M1 20PK

-

-

- -

4

6

3

1M1 18BK/PK

M2 18BK/YL

Z3 18BK/ORCAV CIRCUIT

1

2

4 3

6 5

C204

5

6 3

4 2 1CIRCUIT CAV

C204C202

10 CAV CIRCUIT

1

2

4 3

7

8 6 5

9-

C5 14LG

C202

1 5

6

10

9 5

6

8 7 3

4 2 1CIRCUIT CAV

10 105

1

6

C4 14TN C7 14BK/TN C6 14LB

Z1 16BK V6 16DB V5 16DG/YL V3 16BR/WT

V4 16RD/YL

V4 16RD/YL

V3 16BR/WT

V5 16DG/YL

V6 16DB

Z1 16BK

C6 14LB

C7 14BK/TN

C4 14TN

C5 14LG

-

4 1

63

POWER SUNROOF

F10 18YL/RD F10 18YL/RD

REDRED

LIGHT GREENLIGHT GREEN

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 13

PLI08013008W-10

Page 627 of 1285

CAV CIRCUIT FUNCTION

1 L50 20WT/TN BRAKE LAMP SWITCH OUTPUT

BLACK

1 2

3 CAV

2 1

CIRCUIT

GROUND FUSED IGNITION SWITCH OUTPUT (RUN-ACC)FUNCTION

--

2

3

1REDF30 16RD

Z1 16BK

LAMP MOUNTED STOPCENTER HIGH

CIGAR LIGHTER/

POWER OUTLET

BLACK

CAV CIRCUIT FUNCTION

1 M1 20PK FUSED B(+)

2 G78 22TN/BK DECKLID AJAR SWITCH SENSE

CARGO

LAMP

GROUND 2Z1 20BK

SENSOR CAMSHAFT POSITION

BLACK

1 3

CAMSHAFT POSITION SENSOR SIGNAL 20TN/YL K44 3SENSOR GROUND 20BK/LB K4 2

8V SUPPLY 20OR K7 1

FUNCTION CIRCUIT CAV

LAMP CENTER STACK

GROUND Z3 20BK/OR 2PANEL LAMPS DRIVER E2 20OR 1

FUNCTION CIRCUIT CAV1 2BLACK

8W - 80 - 18 8W-80 CONNECTOR PIN-OUTSPL

008W-10PLI08018

Page 649 of 1285

LHD

RHD

Z2 22BK/LGGROUND

F9 20RD/BKFUSED B(+)

PASSENGER DOOR SWITCH MUX

P96 20LG/BK

- -

L7 20BK/YLDIMMER SWITCH LOW BEAM OUTPUT

REMOTE KEYLESS

ENTRY MODULE

1411

12

13

9 5

6

8 7 3

4 2 1CIRCUIT CAV

10

21 15

18

19 17 16

20

24 23 22

25

26

F35 18RDHEADLAMP SWITCH OUTPUT

P33 18OR/BKFUSED B(+)

P34 18PK/BKDOOR LOCK DRIVER

P36 18PK/VTDOOR UNLOCK DRIVER

M9 20DB/ORDOOR UNLOCK DRIVER

PASSENGER DOOR AJAR/ RKE SENSE

P97 20LGDRIVER DOOR SWITCH MUX

Z1 20BKGROUND

X161 20WTRKE ANTENNA

X5 22WT/RDDISPLAY BACKLIGHT

Q2 16LG/BKDECKLID RELEASE RELAY OUTPUT

G69 20BK/ORVTSS INDICATOR DRIVER

X3 22BK/RDHORN RELAY CONTROL

D25 20VT/YLPCI BUS

G120 18WT/BKINTRUSION SENSOR SIGNAL

M1 20PKFUSED B(+)

G5 20DB/WTFUSED IGNITION SWITCH OUTPUT (ST-RUN)

G70 20BR/TNHOOD AJAR SWITCH SENSE

G71 20VT/YLDECKLID SECURITY SWITCH SENSE

G75 18TNDRIVER DOOR AJAR SWITCH SENSE

X161 20WTJAPAN ANTENNA L4 16VT/WT

BUILT-UP-EXPORT

1

13

14

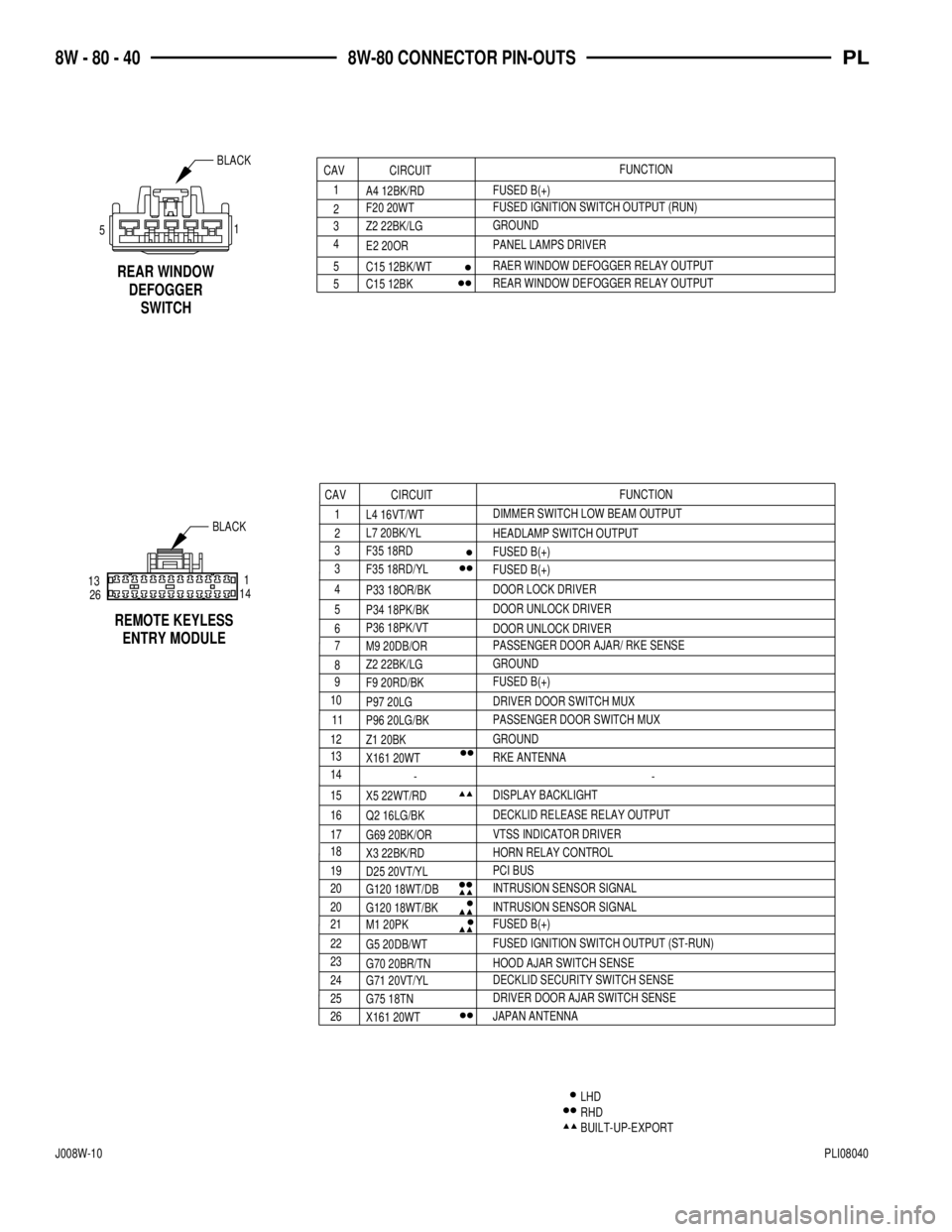

26REAR WINDOW DEFOGGER RELAY OUTPUT

C15 12BKPANEL LAMPS DRIVER

E2 20OR Z2 22BK/LGGROUND F20 20WTFUSED IGNITION SWITCH OUTPUT (RUN) A4 12BK/RDFUSED B(+)

SWITCH

51

DEFOGGER REAR WINDOW

FUNCTION

CAV CIRCUIT

1

2

4 3

5

F35 18RD/YL

FUSED B(+) 3

5

C15 12BK/WTRAER WINDOW DEFOGGER RELAY OUTPUT

INTRUSION SENSOR SIGNAL

G120 18WT/DB20

BLACK

BLACK

FUNCTION

8W - 80 - 40 8W-80 CONNECTOR PIN-OUTSPL

J008W-10PLI08040

Page 654 of 1285

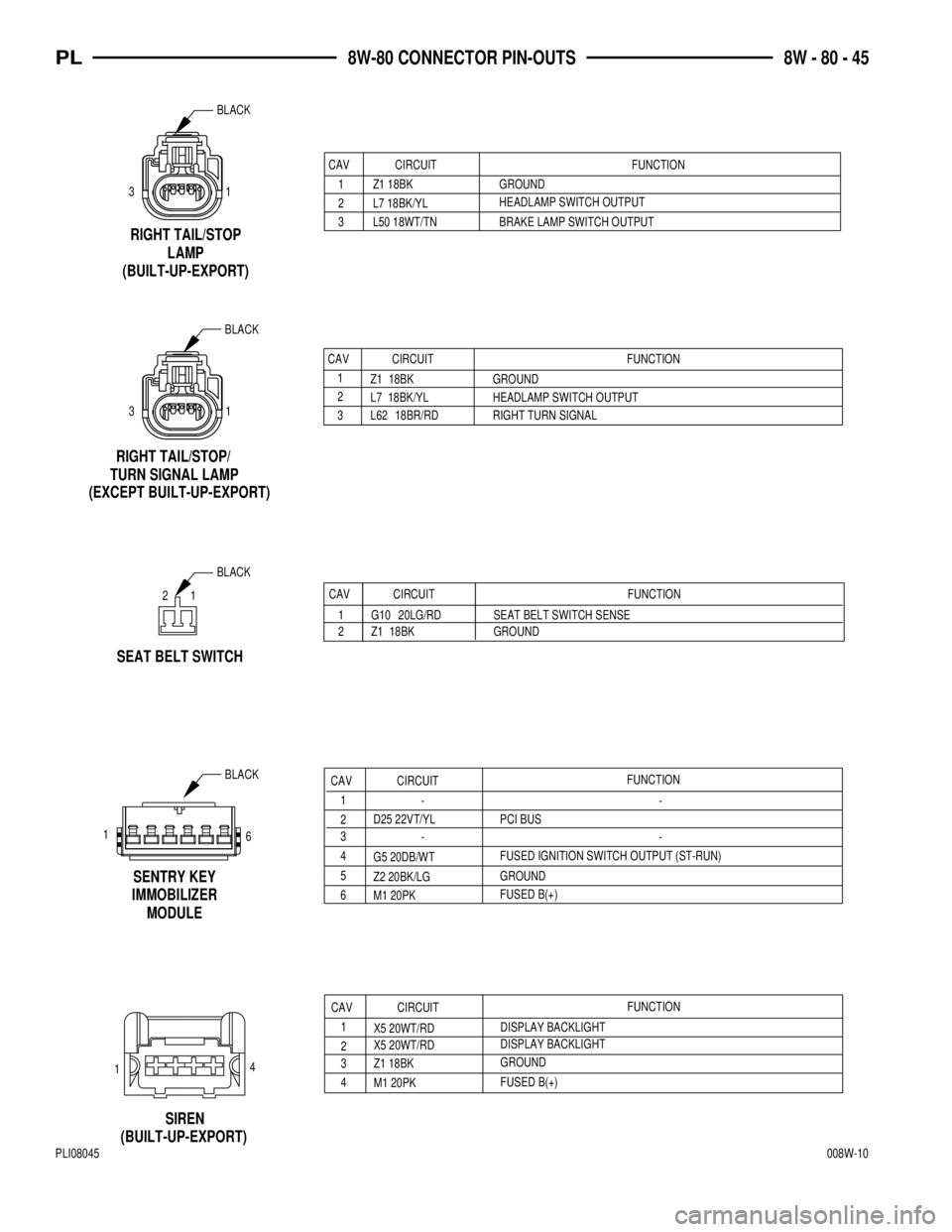

CAV CIRCUIT FUNCTION

1

Z1 18BK GROUND

2

L7 18BK/YL HEADLAMP SWITCH OUTPUT

3 L62 18BR/RD RIGHT TURN SIGNAL

RIGHT TAIL/STOP/

TURN SIGNAL LAMP

SEAT BELT SWITCH

1 2

BLACK

SEAT BELT SWITCH SENSE 20LG/RD G10 1

GROUND 18BK Z1 2

FUNCTION CIRCUIT CAV

(EXCEPT BUILT-UP-EXPORT)

M1 20PKFUSED B(+) GROUND

Z1 18BK X5 20WT/RDDISPLAY BACKLIGHT

4

1

SIREN

DISPLAY BACKLIGHT

X5 20WT/RDFUNCTION

CAV CIRCUIT

1

2

4 3

MODULE IMMOBILIZER

- -- -

FUSED B(+)

M1 20PKGROUND

Z2 20BK/LGFUSED IGNITION SWITCH OUTPUT (ST-RUN)

G5 20DB/WTPCI BUS D25 22VT/YL1

6

SENTRY KEY

FUNCTION

CAV CIRCUIT

1

2

4 3

6 5

RIGHT TAIL/STOP

LAMP

(BUILT-UP-EXPORT)

1 3

HEADLAMP SWITCH OUTPUTGROUND Z1 18BK

3

CAV CIRCUIT FUNCTION

1

L50 18WT/TN BRAKE LAMP SWITCH OUTPUT 2 L7 18BK/YL

(BUILT-UP-EXPORT)

31

BLACK

BLACK

BLACK

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 45

PLI08045008W-10

Page 659 of 1285

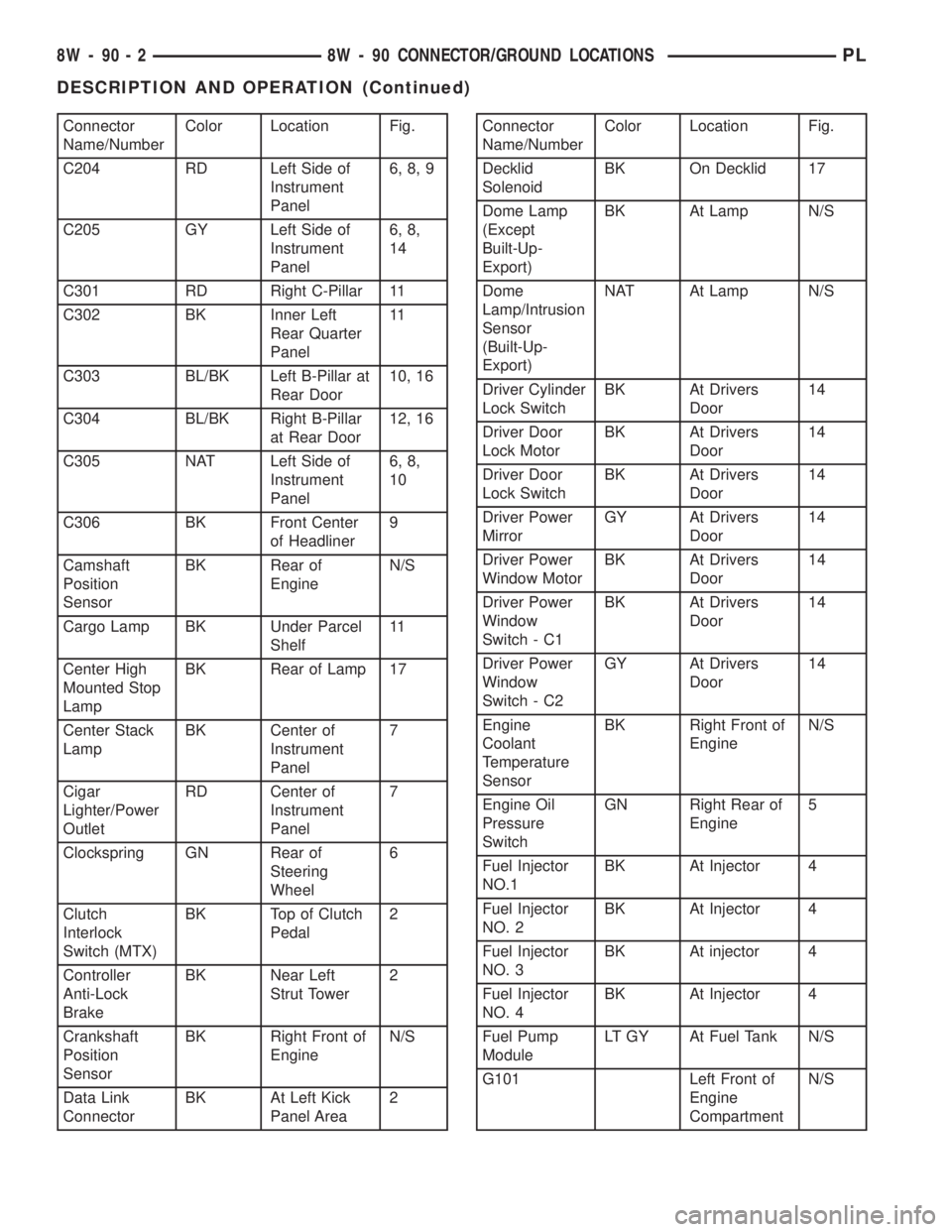

Connector

Name/NumberColor Location Fig.

C204 RD Left Side of

Instrument

Panel6, 8, 9

C205 GY Left Side of

Instrument

Panel6, 8,

14

C301 RD Right C-Pillar 11

C302 BK Inner Left

Rear Quarter

Panel11

C303 BL/BK Left B-Pillar at

Rear Door10, 16

C304 BL/BK Right B-Pillar

at Rear Door12, 16

C305 NAT Left Side of

Instrument

Panel6, 8,

10

C306 BK Front Center

of Headliner9

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf11

Center High

Mounted Stop

LampBK Rear of Lamp 17

Center Stack

LampBK Center of

Instrument

Panel7

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel7

Clockspring GN Rear of

Steering

Wheel6

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal2

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower2

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK At Left Kick

Panel Area2Connector

Name/NumberColor Location Fig.

Decklid

SolenoidBK On Decklid 17

Dome Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Dome

Lamp/Intrusion

Sensor

(Built-Up-

Export)NAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door14

Driver Door

Lock MotorBK At Drivers

Door14

Driver Door

Lock SwitchBK At Drivers

Door14

Driver Power

MirrorGY At Drivers

Door14

Driver Power

Window MotorBK At Drivers

Door14

Driver Power

Window

Switch - C1BK At Drivers

Door14

Driver Power

Window

Switch - C2GY At Drivers

Door14

Engine

Coolant

Temperature

SensorBK Right Front of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine5

Fuel Injector

NO.1BK At Injector 4

Fuel Injector

NO. 2BK At Injector 4

Fuel Injector

NO. 3BK At injector 4

Fuel Injector

NO. 4BK At Injector 4

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

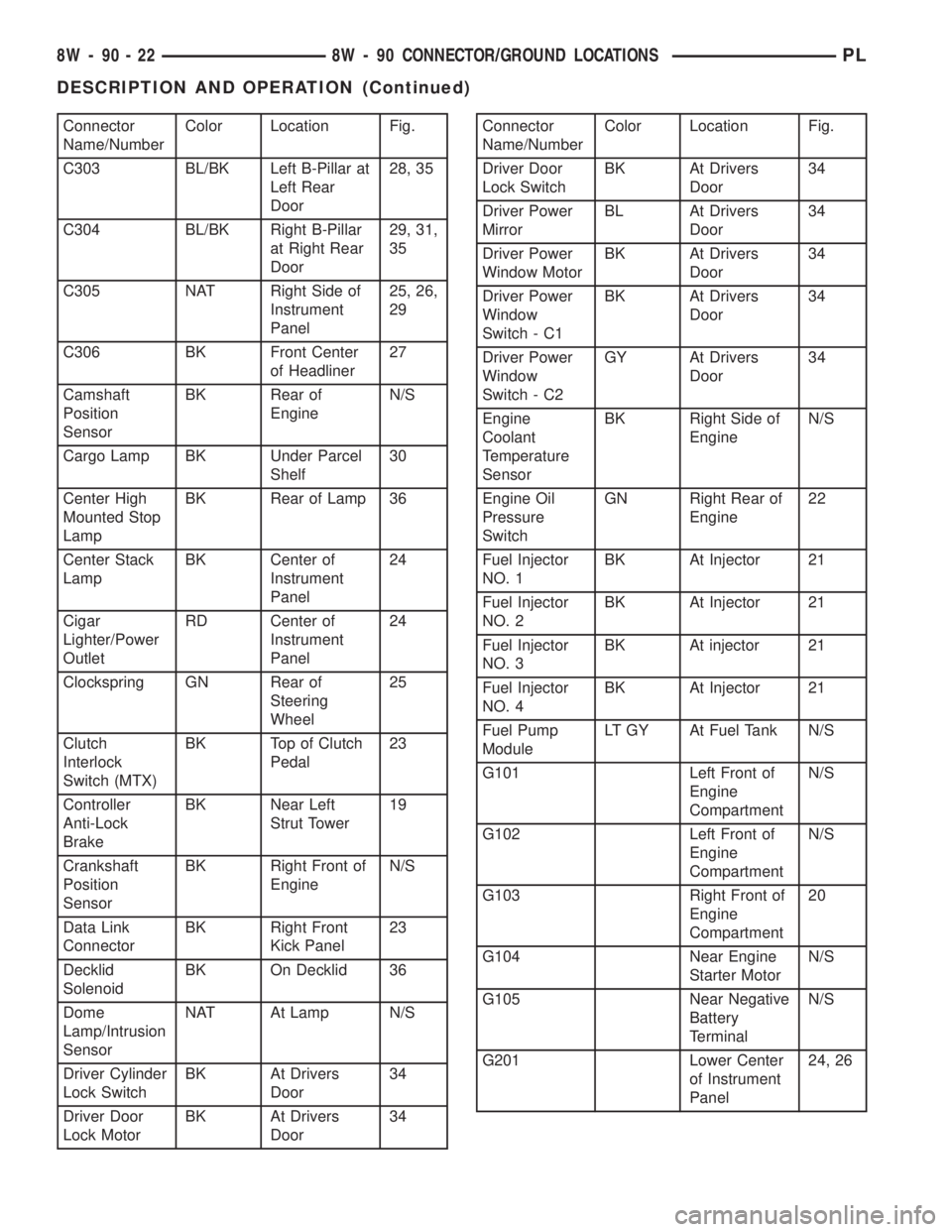

Page 679 of 1285

Connector

Name/NumberColor Location Fig.

C303 BL/BK Left B-Pillar at

Left Rear

Door28, 35

C304 BL/BK Right B-Pillar

at Right Rear

Door29, 31,

35

C305 NAT Right Side of

Instrument

Panel25, 26,

29

C306 BK Front Center

of Headliner27

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf30

Center High

Mounted Stop

LampBK Rear of Lamp 36

Center Stack

LampBK Center of

Instrument

Panel24

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel24

Clockspring GN Rear of

Steering

Wheel25

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal23

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower19

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK Right Front

Kick Panel23

Decklid

SolenoidBK On Decklid 36

Dome

Lamp/Intrusion

SensorNAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door34

Driver Door

Lock MotorBK At Drivers

Door34Connector

Name/NumberColor Location Fig.

Driver Door

Lock SwitchBK At Drivers

Door34

Driver Power

MirrorBL At Drivers

Door34

Driver Power

Window MotorBK At Drivers

Door34

Driver Power

Window

Switch - C1BK At Drivers

Door34

Driver Power

Window

Switch - C2GY At Drivers

Door34

Engine

Coolant

Temperature

SensorBK Right Side of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine22

Fuel Injector

NO. 1BK At Injector 21

Fuel Injector

NO. 2BK At Injector 21

Fuel Injector

NO. 3BK At injector 21

Fuel Injector

NO. 4BK At Injector 21

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

G102 Left Front of

Engine

CompartmentN/S

G103 Right Front of

Engine

Compartment20

G104 Near Engine

Starter MotorN/S

G105 Near Negative

Battery

TerminalN/S

G201 Lower Center

of Instrument

Panel24, 26

8W - 90 - 22 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 726 of 1285

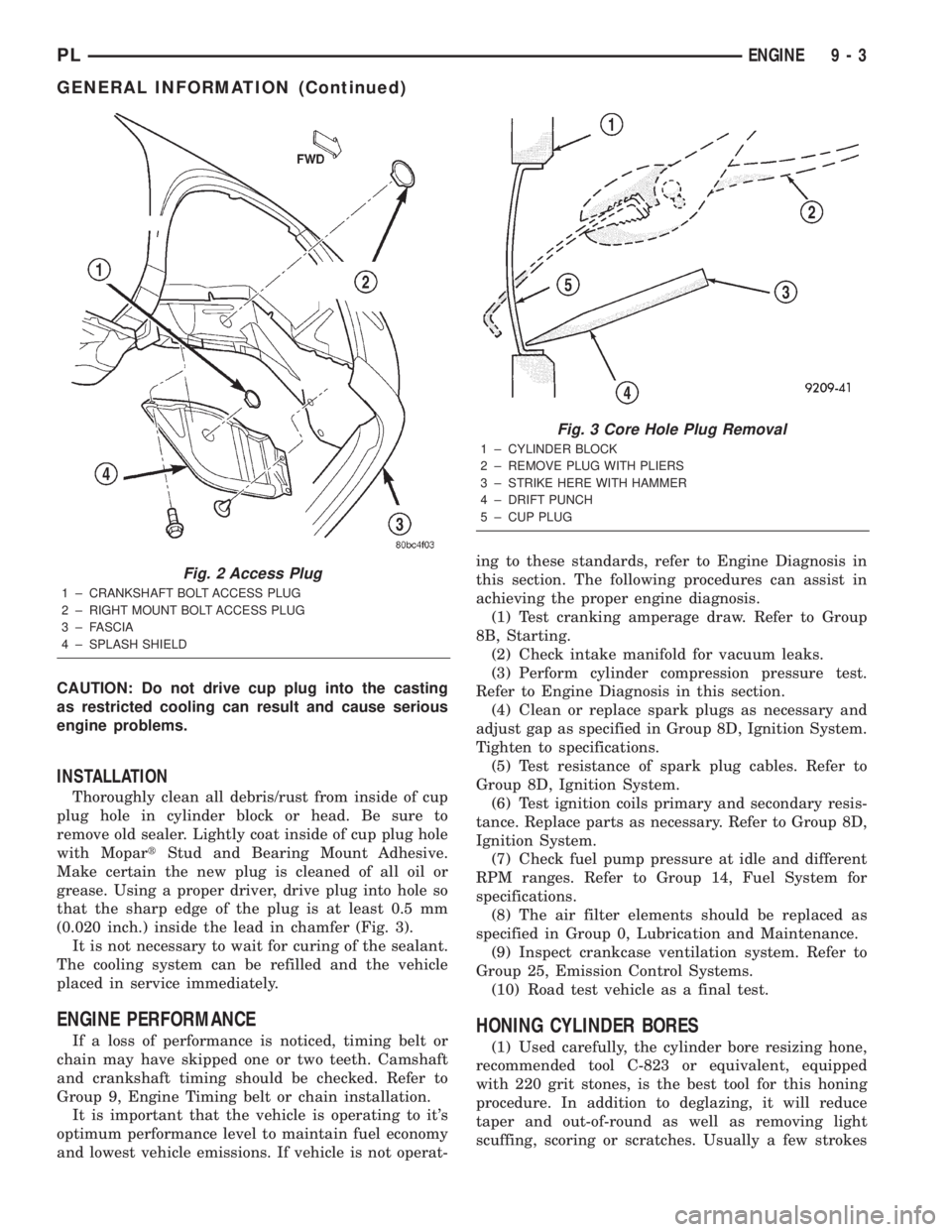

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly clean all debris/rust from inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with MopartStud and Bearing Mount Adhesive.

Make certain the new plug is cleaned of all oil or

grease. Using a proper driver, drive plug into hole so

that the sharp edge of the plug is at least 0.5 mm

(0.020 inch.) inside the lead in chamfer (Fig. 3).

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to it's

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-ing to these standards, refer to Engine Diagnosis in

this section. The following procedures can assist in

achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system. Refer to

Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.HONING CYLINDER BORES

(1) Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped

with 220 grit stones, is the best tool for this honing

procedure. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

Fig. 2 Access Plug

1 ± CRANKSHAFT BOLT ACCESS PLUG

2 ± RIGHT MOUNT BOLT ACCESS PLUG

3 ± FASCIA

4 ± SPLASH SHIELD

Fig. 3 Core Hole Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

PLENGINE 9 - 3

GENERAL INFORMATION (Continued)

Page 727 of 1285

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, recommended tool

C-3501 or equivalent, equipped with 280 grit stones,

if the cylinder bore is straight and round. 20±60

strokes depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Inspect cyl-

inder walls after each 20 strokes, using a light

honing oil.Do not use engine or transmission oil,

mineral spirits or kerosene.

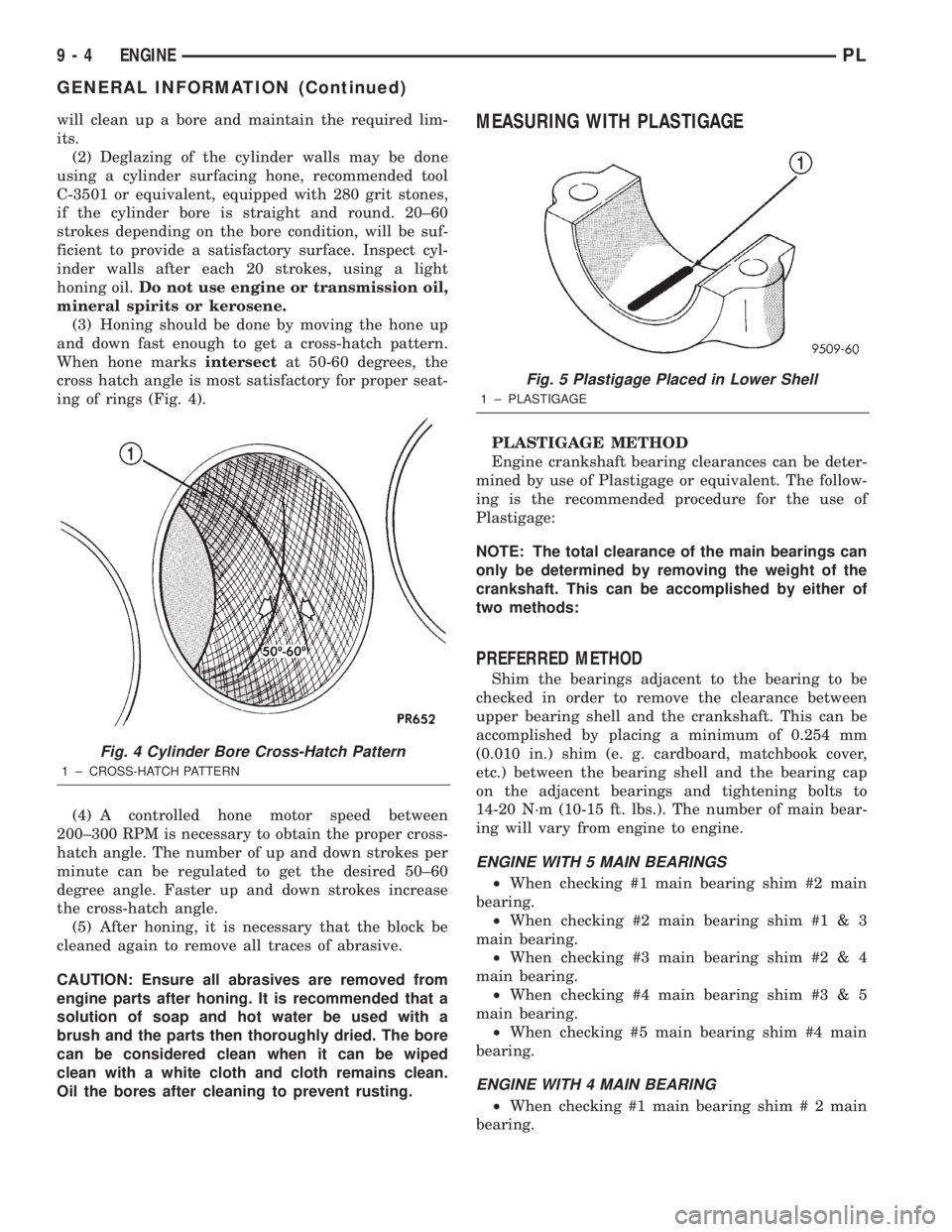

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 50-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 4).

(4) A controlled hone motor speed between

200±300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50±60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.MEASURING WITH PLASTIGAGE

PLASTIGAGE METHOD

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

NOTE: The total clearance of the main bearings can

only be determined by removing the weight of the

crankshaft. This can be accomplished by either of

two methods:

PREFERRED METHOD

Shim the bearings adjacent to the bearing to be

checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14-20 N´m (10-15 ft. lbs.). The number of main bear-

ing will vary from engine to engine.

ENGINE WITH 5 MAIN BEARINGS

²When checking #1 main bearing shim #2 main

bearing.

²When checking #2 main bearing shim #1 & 3

main bearing.

²When checking #3 main bearing shim #2 & 4

main bearing.

²When checking #4 main bearing shim #3 & 5

main bearing.

²When checking #5 main bearing shim #4 main

bearing.

ENGINE WITH 4 MAIN BEARING

²When checking #1 main bearing shim # 2 main

bearing.

Fig. 4 Cylinder Bore Cross-Hatch Pattern

1 ± CROSS-HATCH PATTERN

Fig. 5 Plastigage Placed in Lower Shell

1 ± PLASTIGAGE

9 - 4 ENGINEPL

GENERAL INFORMATION (Continued)