check engine DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1251 of 1285

(1) Discharge refrigerant system using recovery/re-

cycling equipment if charge is present.

(2) Disconnect refrigerant lines from A/C compres-

sor. Cap the open lines to prevent moisture from

entering system.

(3) Remove compressor from vehicle.

(4) From suction port on top of compressor, drain

lubricant from compressor.

(5) Add system capacity minus the capacity of

components that have not been replaced. Refer to the

Lubricant Capacity Chart. Add lubricant through the

suction port on compressor. This is not to exceed 180

ml (6.10 oz.) in total.

(6) Install compressor and connect refrigerant

lines. Then evacuate and charge refrigerant system.

SYSTEM LEAK CHECKING

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. MIXTURE OF AIR and R-134a CAN BE COM-

BUSTIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

AVOID BREATHING A/C REFRIGERANT AND

LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 345 kPa (50

psi) proceed to Empty Refrigerant System Leak Test.

If liquid line pressure is greater than 345 kPa (50

psi) proceed to low refrigerant level leak test. If the

refrigerant system is empty or low in refrigerant

charge, a leak at any line fitting or component seal is

likely. A review of the fittings, lines and components

for oily residue is an indication of the leak location.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

symptoms.

EMPTY REFRIGERANT SYSTEM LEAK TEST

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approx. 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-tem will not maintain vacuum level, proceed with

this procedure.

(2) Prepare a.284 Kg. (10 oz.) refrigerant charge to

be injected into the system.

(3) Connect and dispense.284 Kg. (10 oz.) of refrig-

erant into the evacuated refrigerant system.

(4) Proceed to Step 2 of Low Refrigerant Level

Leak Test.

LOW REFRIGERANT LEVEL LEAK TEST

(1) Determine if there is any (R-134a) refrigerant

in the system.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set in 100 percent outside air

²Blower switch in the high A/C position

²A/C in the ON position

²Open all windows

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only Chrysler approved refrigerant dye.

If a thorough leak check has been completed with-

out indication of a leak, proceed to System Charge

Level.

REMOVAL AND INSTALLATION

A/C FILTER/DRIER

The filter/drier is mounted in a rubber grommet on

the right side of the engine compartment. The refrig-

erant must be recovered from the A/C system before

replacing the filter/drier assembly.

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY RECOVERED BEFORE PRO-

CEEDING WITH THIS OPERATION.

24 - 20 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)

Page 1256 of 1285

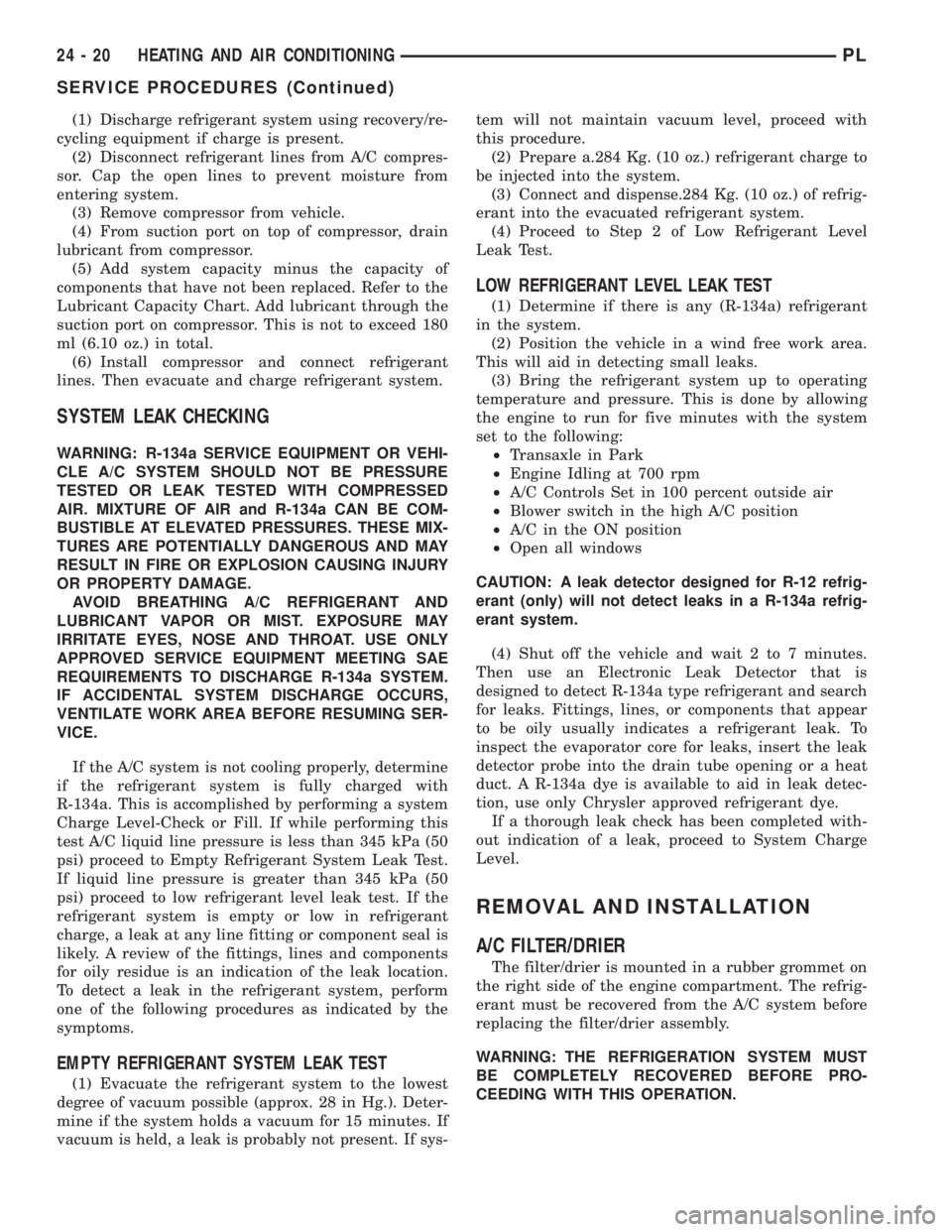

obtained, add or subtract shims until desired read-

ing is obtained.

(8) Install compressor shaft bolt. Tighten to 17.56

2 N´m (155620 in. lbs.) torque.

NOTE: Shims may compress after tightening shaft

nut. Check air gap in four or more places to verify if

air gap is still correct. Spin pulley for final check.

CLUTCH BREAK-IN

After new clutch installation, cycle the A/C clutch

20 times (5 seconds on and 5 seconds off). During

this procedure, set the system to the A/C mode,

engine rpm at 1500 - 2000, and high blower speed.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher clutch torque

capability.

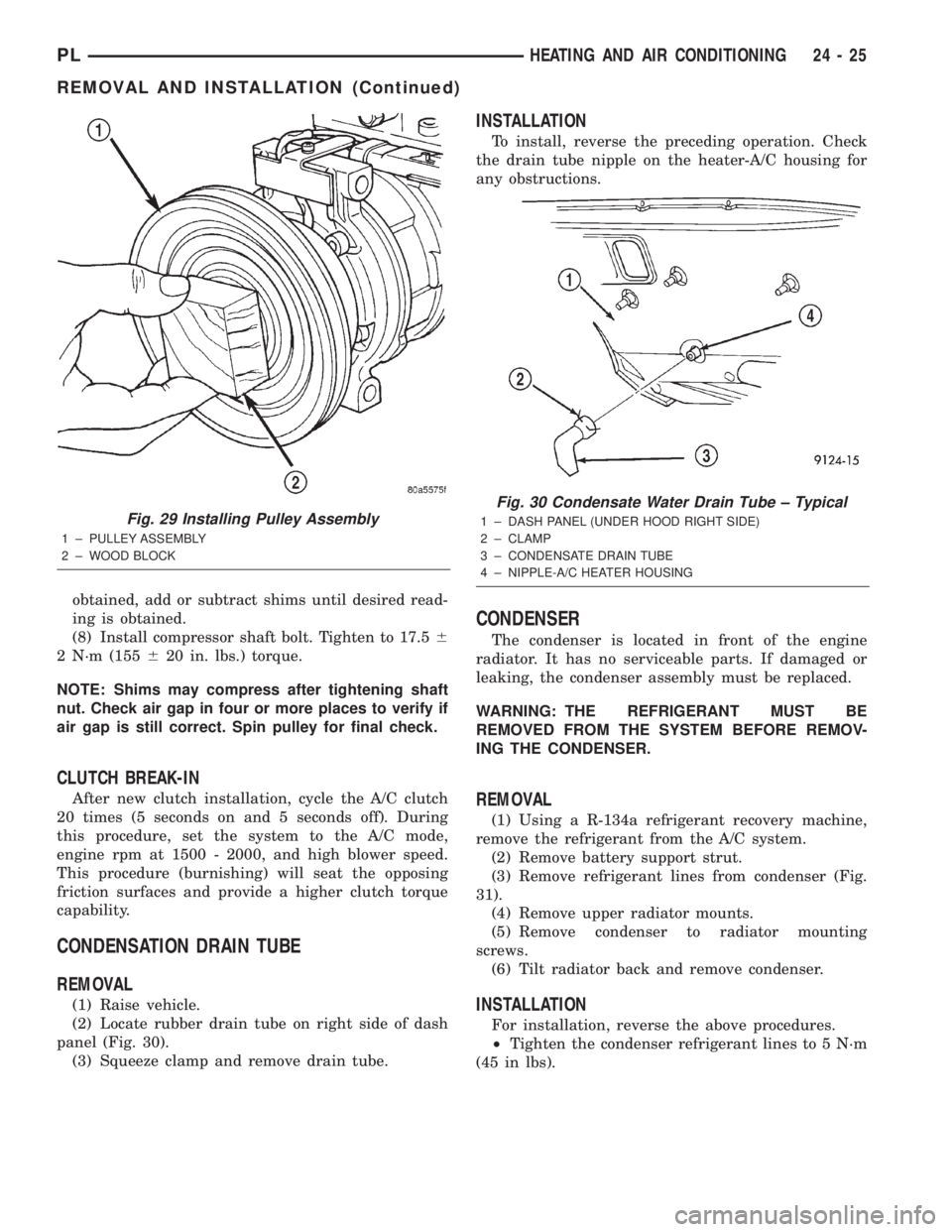

CONDENSATION DRAIN TUBE

REMOVAL

(1) Raise vehicle.

(2) Locate rubber drain tube on right side of dash

panel (Fig. 30).

(3) Squeeze clamp and remove drain tube.

INSTALLATION

To install, reverse the preceding operation. Check

the drain tube nipple on the heater-A/C housing for

any obstructions.

CONDENSER

The condenser is located in front of the engine

radiator. It has no serviceable parts. If damaged or

leaking, the condenser assembly must be replaced.

WARNING: THE REFRIGERANT MUST BE

REMOVED FROM THE SYSTEM BEFORE REMOV-

ING THE CONDENSER.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from the A/C system.

(2) Remove battery support strut.

(3) Remove refrigerant lines from condenser (Fig.

31).

(4) Remove upper radiator mounts.

(5) Remove condenser to radiator mounting

screws.

(6) Tilt radiator back and remove condenser.

INSTALLATION

For installation, reverse the above procedures.

²Tighten the condenser refrigerant lines to 5 N´m

(45 in lbs).

Fig. 29 Installing Pulley Assembly

1 ± PULLEY ASSEMBLY

2 ± WOOD BLOCK

Fig. 30 Condensate Water Drain Tube ± Typical

1 ± DASH PANEL (UNDER HOOD RIGHT SIDE)

2 ± CLAMP

3 ± CONDENSATE DRAIN TUBE

4 ± NIPPLE-A/C HEATER HOUSING

PLHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1259 of 1285

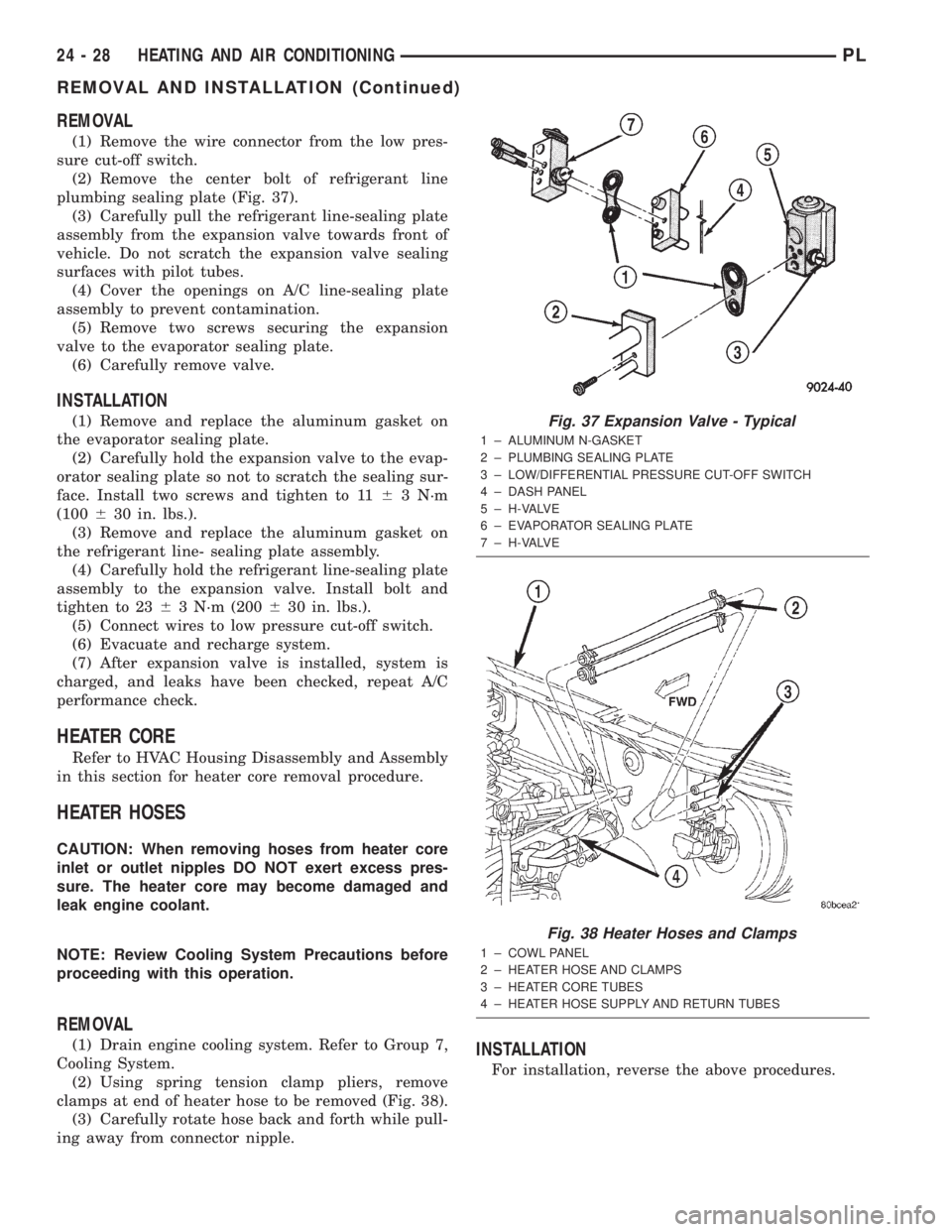

REMOVAL

(1) Remove the wire connector from the low pres-

sure cut-off switch.

(2) Remove the center bolt of refrigerant line

plumbing sealing plate (Fig. 37).

(3) Carefully pull the refrigerant line-sealing plate

assembly from the expansion valve towards front of

vehicle. Do not scratch the expansion valve sealing

surfaces with pilot tubes.

(4) Cover the openings on A/C line-sealing plate

assembly to prevent contamination.

(5) Remove two screws securing the expansion

valve to the evaporator sealing plate.

(6) Carefully remove valve.

INSTALLATION

(1) Remove and replace the aluminum gasket on

the evaporator sealing plate.

(2) Carefully hold the expansion valve to the evap-

orator sealing plate so not to scratch the sealing sur-

face. Install two screws and tighten to 1163 N´m

(100630 in. lbs.).

(3) Remove and replace the aluminum gasket on

the refrigerant line- sealing plate assembly.

(4) Carefully hold the refrigerant line-sealing plate

assembly to the expansion valve. Install bolt and

tighten to 2363 N´m (200630 in. lbs.).

(5) Connect wires to low pressure cut-off switch.

(6) Evacuate and recharge system.

(7) After expansion valve is installed, system is

charged, and leaks have been checked, repeat A/C

performance check.

HEATER CORE

Refer to HVAC Housing Disassembly and Assembly

in this section for heater core removal procedure.

HEATER HOSES

CAUTION: When removing hoses from heater core

inlet or outlet nipples DO NOT exert excess pres-

sure. The heater core may become damaged and

leak engine coolant.

NOTE: Review Cooling System Precautions before

proceeding with this operation.

REMOVAL

(1) Drain engine cooling system. Refer to Group 7,

Cooling System.

(2) Using spring tension clamp pliers, remove

clamps at end of heater hose to be removed (Fig. 38).

(3) Carefully rotate hose back and forth while pull-

ing away from connector nipple.INSTALLATION

For installation, reverse the above procedures.

Fig. 37 Expansion Valve - Typical

1 ± ALUMINUM N-GASKET

2 ± PLUMBING SEALING PLATE

3 ± LOW/DIFFERENTIAL PRESSURE CUT-OFF SWITCH

4 ± DASH PANEL

5 ± H-VALVE

6 ± EVAPORATOR SEALING PLATE

7 ± H-VALVE

Fig. 38 Heater Hoses and Clamps

1 ± COWL PANEL

2 ± HEATER HOSE AND CLAMPS

3 ± HEATER CORE TUBES

4 ± HEATER HOSE SUPPLY AND RETURN TUBES

24 - 28 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1264 of 1285

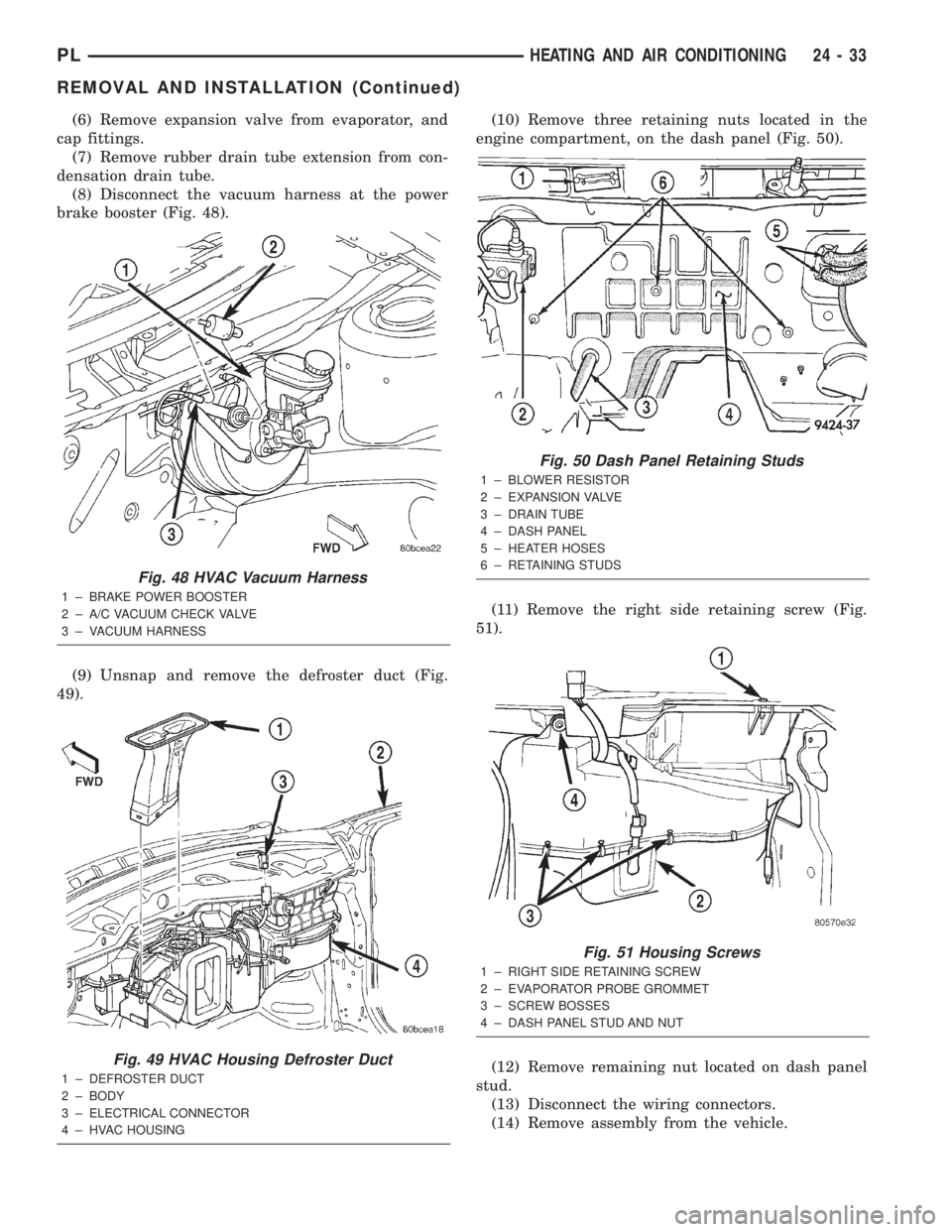

(6) Remove expansion valve from evaporator, and

cap fittings.

(7) Remove rubber drain tube extension from con-

densation drain tube.

(8) Disconnect the vacuum harness at the power

brake booster (Fig. 48).

(9) Unsnap and remove the defroster duct (Fig.

49).(10) Remove three retaining nuts located in the

engine compartment, on the dash panel (Fig. 50).

(11) Remove the right side retaining screw (Fig.

51).

(12) Remove remaining nut located on dash panel

stud.

(13) Disconnect the wiring connectors.

(14) Remove assembly from the vehicle.

Fig. 48 HVAC Vacuum Harness

1 ± BRAKE POWER BOOSTER

2 ± A/C VACUUM CHECK VALVE

3 ± VACUUM HARNESS

Fig. 49 HVAC Housing Defroster Duct

1 ± DEFROSTER DUCT

2 ± BODY

3 ± ELECTRICAL CONNECTOR

4 ± HVAC HOUSING

Fig. 50 Dash Panel Retaining Studs

1 ± BLOWER RESISTOR

2 ± EXPANSION VALVE

3 ± DRAIN TUBE

4 ± DASH PANEL

5 ± HEATER HOSES

6 ± RETAINING STUDS

Fig. 51 Housing Screws

1 ± RIGHT SIDE RETAINING SCREW

2 ± EVAPORATOR PROBE GROMMET

3 ± SCREW BOSSES

4 ± DASH PANEL STUD AND NUT

PLHEATING AND AIR CONDITIONING 24 - 33

REMOVAL AND INSTALLATION (Continued)

Page 1275 of 1285

VIN CODE DECODING

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 1 = United states

2 MakeB = Dodge

P = Plymouth

3 Vehicle Type 3 = Passenger Car

4 Pass. Safety E = Restraint System, Active Driver & Passenger Airbags

5 Car Line S = Neon

6 Series2 = Low Line

4 = High Line

7 Body Style6 = 4 Door Sedan

8 Engine C = 2.0 L 4 Cyl. 16V

9 Check Digit See explanation in this section.

10 Model Year Y = 2000

11 Assembly Plant D = Belvidere

12 Thru 17 Vehicle Build Sequence 6 digit number assigned by assembly plant.

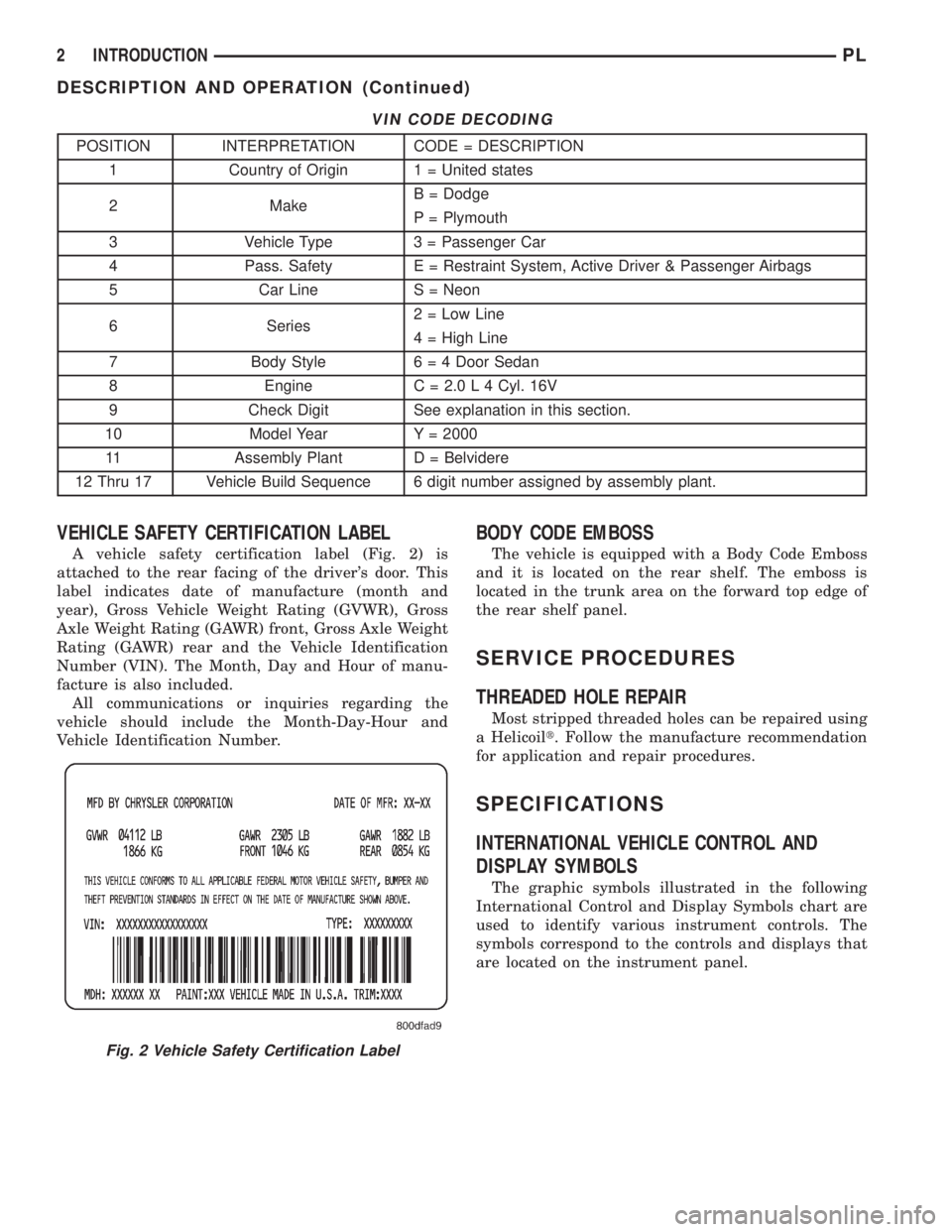

VEHICLE SAFETY CERTIFICATION LABEL

A vehicle safety certification label (Fig. 2) is

attached to the rear facing of the driver's door. This

label indicates date of manufacture (month and

year), Gross Vehicle Weight Rating (GVWR), Gross

Axle Weight Rating (GAWR) front, Gross Axle Weight

Rating (GAWR) rear and the Vehicle Identification

Number (VIN). The Month, Day and Hour of manu-

facture is also included.

All communications or inquiries regarding the

vehicle should include the Month-Day-Hour and

Vehicle Identification Number.

BODY CODE EMBOSS

The vehicle is equipped with a Body Code Emboss

and it is located on the rear shelf. The emboss is

located in the trunk area on the forward top edge of

the rear shelf panel.

SERVICE PROCEDURES

THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the manufacture recommendation

for application and repair procedures.

SPECIFICATIONS

INTERNATIONAL VEHICLE CONTROL AND

DISPLAY SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

Fig. 2 Vehicle Safety Certification Label

2 INTRODUCTIONPL

DESCRIPTION AND OPERATION (Continued)

Page 1283 of 1285

VIN DECODING INFORMATION

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of origin 1 = United States

2 Make C = Chrysler

3 Vehicle Type 3 = Passenger Car

4 Passenger Safety E = Active Restraints, Driver and Passenger Airbags

5 Car Line S = Neon BUX L. H. D.

V = Neon BUX R. H. D.

6 Series M = DD5 5-Speed Manual Transmission

A = 3-Speed Automatic Transmission

7 Body Style7 = 4 Door Pillared Hardtop

8 Engine C = 2.0L 4 Cyl. 16V SOHC

A = 1.8L 4 Cyl. 16V SOHC

9 Check Digit See explanation in this section.

10 Model Year Y = 2000

11 Assembly Plant D = Belvedere Assembly

12 Thru 17 Build Sequence 6 Digit number assigned by assembly plant

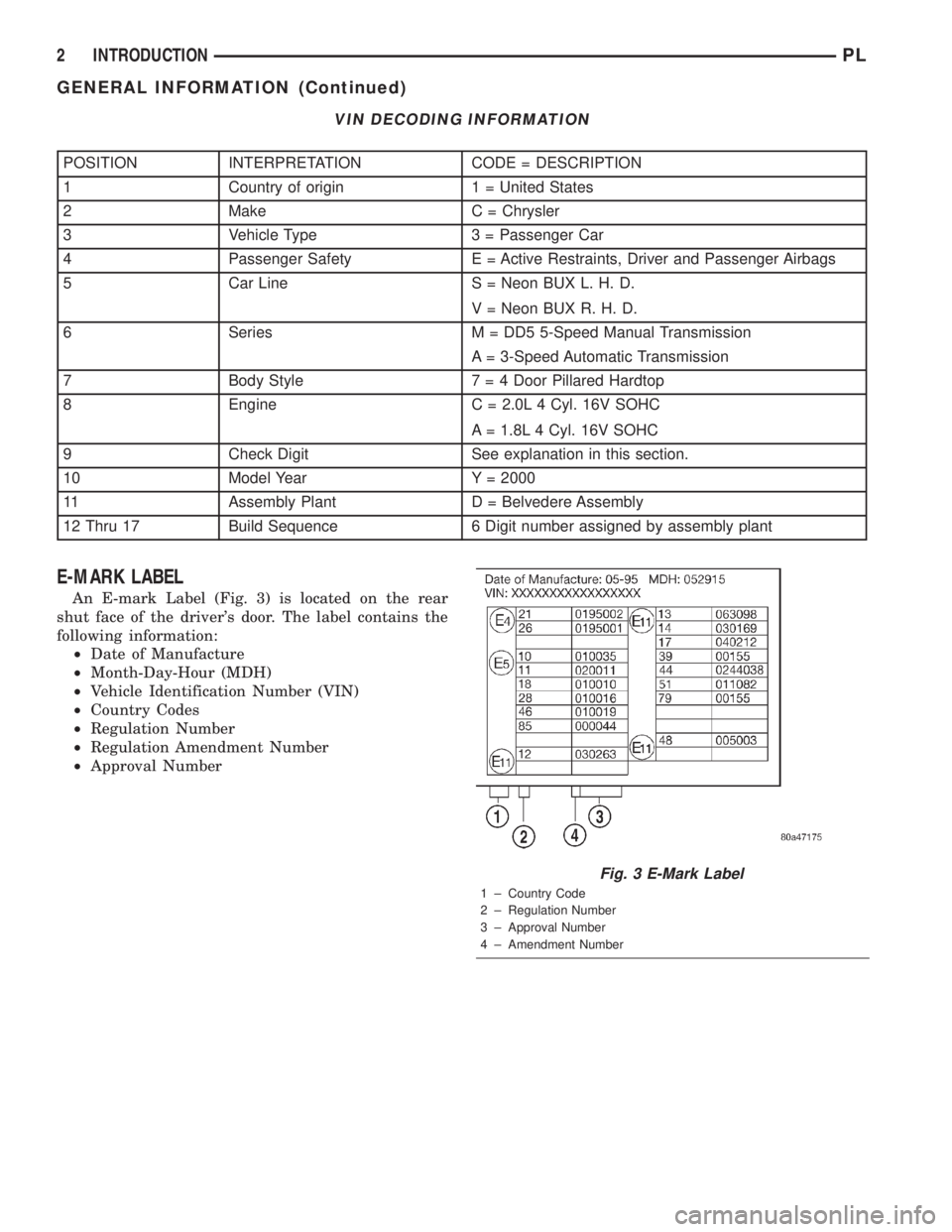

E-MARK LABEL

An E-mark Label (Fig. 3) is located on the rear

shut face of the driver's door. The label contains the

following information:

²Date of Manufacture

²Month-Day-Hour (MDH)

²Vehicle Identification Number (VIN)

²Country Codes

²Regulation Number

²Regulation Amendment Number

²Approval Number

Fig. 3 E-Mark Label

1 ± Country Code

2 ± Regulation Number

3 ± Approval Number

4 ± Amendment Number

2 INTRODUCTIONPL

GENERAL INFORMATION (Continued)