tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 270 of 1285

AUDIO SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION...............1

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES......1

TESTING................................1

BENCH TEST FOR ANTENNA MALFUNCTION...7REMOVAL AND INSTALLATION

CD CHANGER............................7

FRONT DOOR SPEAKER....................8

INSTRUMENT PANEL SPEAKER(S)...........8

MAST and ANTENNA ASSEMBLY.............8

RADIO..................................9

REAR SHELF SPEAKER(S).................10

GENERAL INFORMATION

INTRODUCTION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with the vehicle.

The vehicles are equipped with an Interior (Igni-

tion Off Draw) fuse in the Power Distribution Center

located in the engine compartment. After the Interior

(IOD) fuse or battery has been disconnected the clock

will require resetting. The radio station presets have

a nonvolatile memory and will retain the preset sta-

tions after a battery disconnect.

The available radio options are:

²AM/FM Stereo Cassette w/Clock

²AM/FM/CD

²AM/FM Cassette w/CD Changer Controls and

Display

²CD/4 Disc Changer - In-Dash (used w/Radio CD

Changer Controls)

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION

The radio utilizes a ground wire plugged on to a

blade terminal and is bolted to the radio chassis.

Both connector and terminal should be securely

attached. The engine has two separate ground straps

to suppress ignition noise which may interfere with

radio reception.

²Left engine mount clip on strap

²Engine to shock tower reinforcement

Inductive type spark plug cables in the high ten-

sion circuit of the ignition system complete the inter-

ference suppression. Faulty or deteriorated spark

plug wires should be replaced.

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES

CAUTION: The CD player will only operate between

approximate temperatures of -23ÉC and +65ÉC (-10ÉF

and +145ÉF).

Whenever a radio malfunction occurs;

(1) First check FUSES:

(a) Power Distribution Center (PDC), Interior

lamp fuse, M1 - Radio Memory Feed

(b) Fuse Block:

(I) Fuse 12, Illumination in the fuse block

(II) Fuse 16, Ignition feed in the fuse block

NOTE: The vehicles are shipped with the INTERIOR

LAMP fuse disconnected.

(2) Verify, the radio wire harness are properly con-

nected before starting normal diagnosis and repair

procedures. Refer to Audio Diagnostic Charts and/or

Group 8W, Wiring Diagrams, Radio Section.

TESTING

The antenna has a short cable which connects into

the instrument panel harness. The connection is

made on the right side of the instrument panel.

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows:

(1) Continuity should be present between the

antenna mast and radio end pin of antenna cable

plug (Fig. 1).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

PLAUDIO SYSTEM 8F - 1

Page 280 of 1285

HORNS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

HORN..................................2

HORN RELAY............................2

HORN SWITCH...........................2HORN SYSTEM TEST......................2

REMOVAL AND INSTALLATION

HORN..................................4

HORN RELAY............................4

HORN SWITCH...........................5

DESCRIPTION AND OPERATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, PASSIVE RESTRAINT SYS-

TEMS FOR STEERING WHEEL REMOVAL.

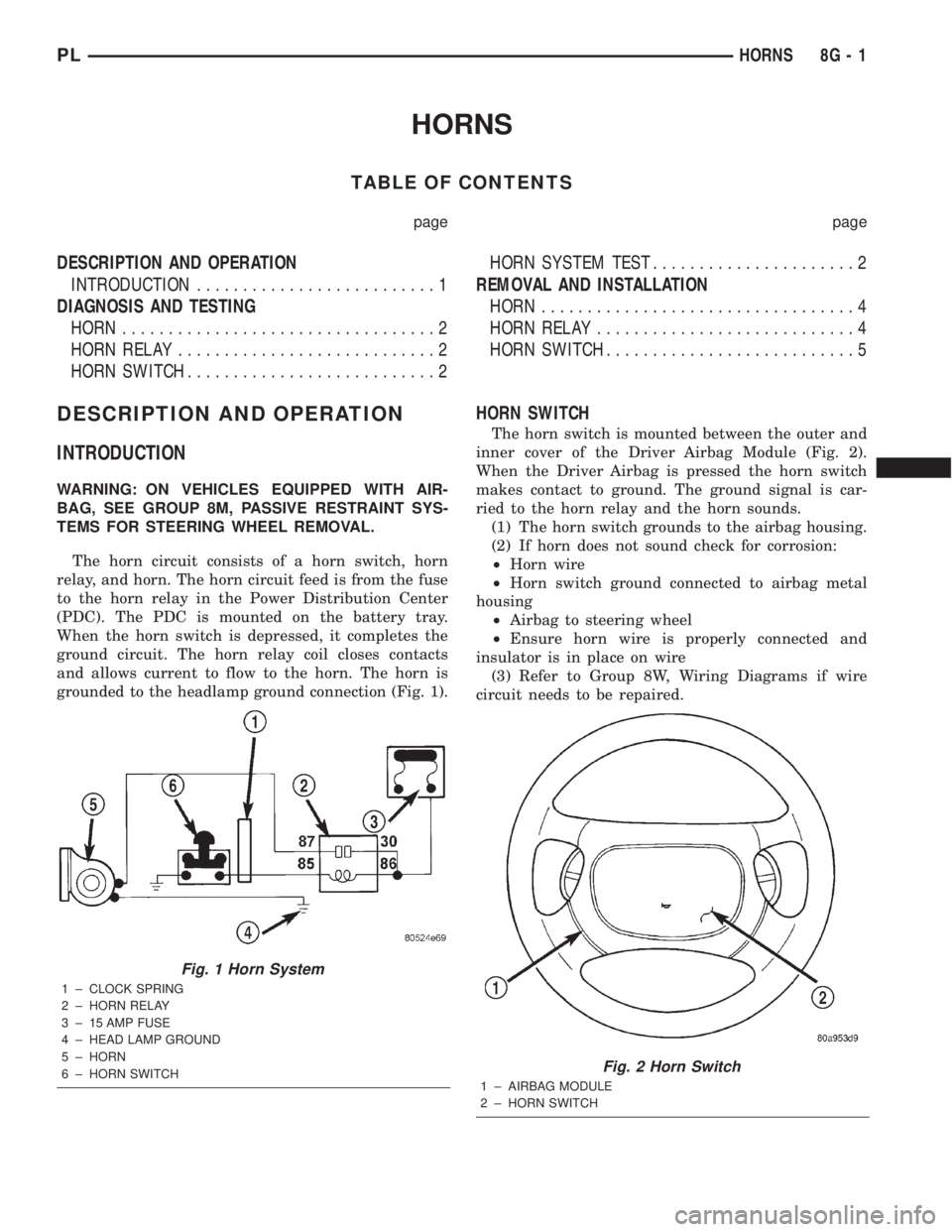

The horn circuit consists of a horn switch, horn

relay, and horn. The horn circuit feed is from the fuse

to the horn relay in the Power Distribution Center

(PDC). The PDC is mounted on the battery tray.

When the horn switch is depressed, it completes the

ground circuit. The horn relay coil closes contacts

and allows current to flow to the horn. The horn is

grounded to the headlamp ground connection (Fig. 1).

HORN SWITCH

The horn switch is mounted between the outer and

inner cover of the Driver Airbag Module (Fig. 2).

When the Driver Airbag is pressed the horn switch

makes contact to ground. The ground signal is car-

ried to the horn relay and the horn sounds.

(1) The horn switch grounds to the airbag housing.

(2) If horn does not sound check for corrosion:

²Horn wire

²Horn switch ground connected to airbag metal

housing

²Airbag to steering wheel

²Ensure horn wire is properly connected and

insulator is in place on wire

(3) Refer to Group 8W, Wiring Diagrams if wire

circuit needs to be repaired.

Fig. 1 Horn System

1 ± CLOCK SPRING

2 ± HORN RELAY

3 ± 15 AMP FUSE

4 ± HEAD LAMP GROUND

5 ± HORN

6 ± HORN SWITCH

Fig. 2 Horn Switch

1 ± AIRBAG MODULE

2 ± HORN SWITCH

PLHORNS 8G - 1

Page 284 of 1285

HORN SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 5).

(2) Remove the Driver Airbag Module. Refer to

Group 8M Passive Restraint Systems, Driver Airbag

Module Removal and Installation.

(3) Clip off strap tie holding the horn switch wire

to the airbag module.

(4) Unclip horn switch wire connector from airbag

module.(5) Remove four torx screws from top side of air-

bag module.

(6) Fold airbag module cover down to expose the

horn switch.

(7) Lift the horn switch off indexing tabs and

remove from vehicle.

INSTALLATION

For installation, reverse the above procedures.

PLHORNS 8G - 5

REMOVAL AND INSTALLATION (Continued)

Page 286 of 1285

VEHICLE SPEED CONTROL SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

SPEED CONTROL SYSTEM.................1

SPEED CONTROL SERVO-PCM OUTPUT.......2

SPEED CONTROL SWITCHESÐPCM INPUT....2

STOP LAMP SWITCH......................3

SERVO CABLE...........................3

VACUUM RESERVOIR.....................3VEHICLE SPEED SENSOR..................3

REMOVAL AND INSTALLATION

SPEED CONTROL SERVO...................3

SPEED CONTROL SWITCH..................4

SPEED CONTROL SERVO CABLE.............4

VACUUM RESERVOIR.....................5

DESCRIPTION AND OPERATION

SPEED CONTROL SYSTEM

OPERATION

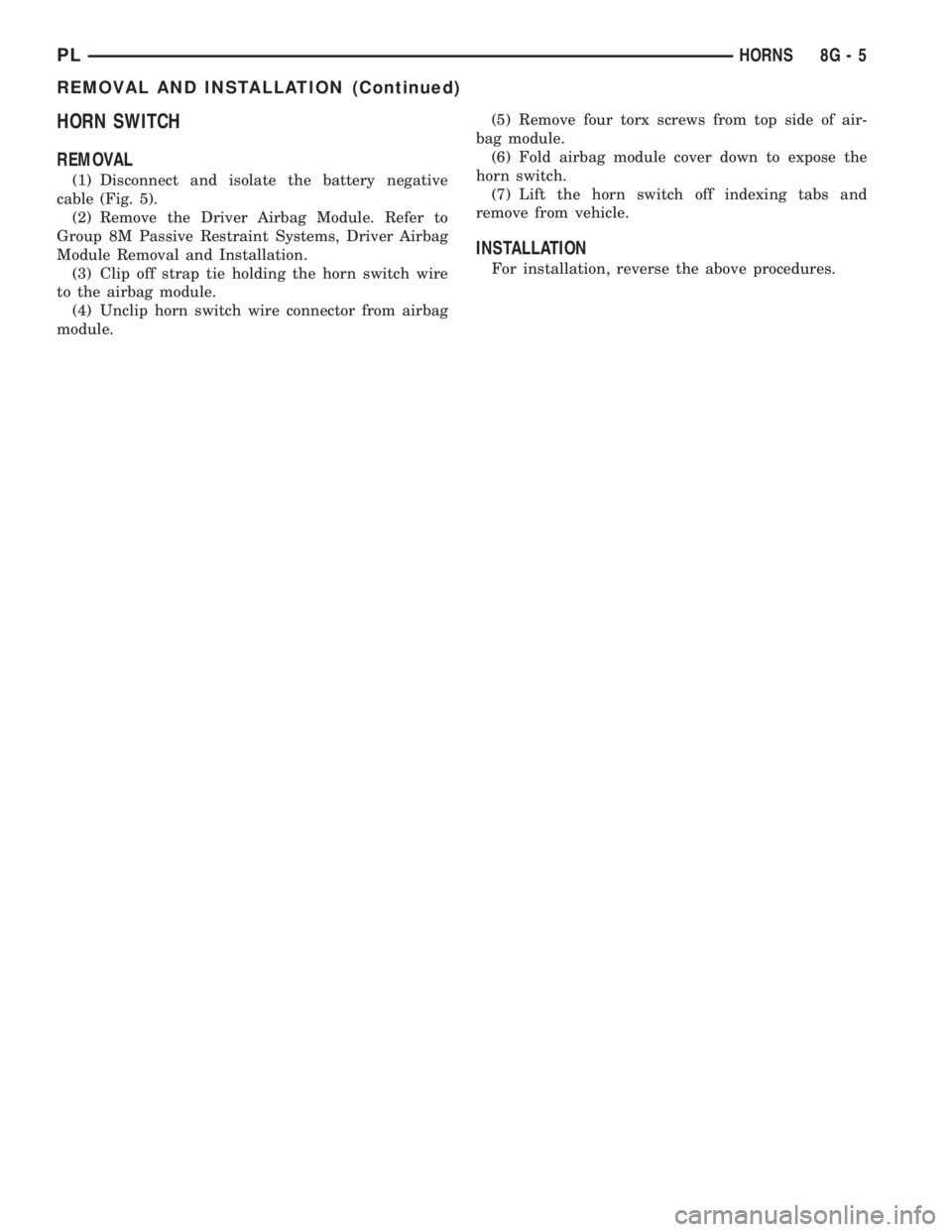

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the Powertrain Control Module

which is located in the engine compartment. The con-

trols are located on the steering wheel and consist of

five switches. The ON, OFF and SET buttons are

located on the left side of the airbag module. The

RESUME, ACCEL, COAST and CANCEL buttons

are located on the right side of the airbag module

(Fig. 1).

The system is designed to operate at speeds above

25 mph (40 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

The speed control can be disengaged also by any of

the following conditions:

²An indication of Park or Neutral

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²Depressing the clutch pedal.

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)²The VSS signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is not within 20 mph of the

set speed

The previous disengagement conditions are pro-

grammed for added safety.

Fig. 1 Speed Control Switch

1 ± SPEED CONTROL SWITCHES

2 ± RES ACCEL

3 ± CANCEL

4 ± COAST

5 ± SET

6 ± ON/OFF

PLVEHICLE SPEED CONTROL SYSTEM 8H - 1

Page 287 of 1285

SPEED CONTROL SERVO-PCM OUTPUT

DESCRIPTION

The servo unit consists of a solenoid valve body,

and a vacuum chamber. The solenoid valve body con-

tains three solenoids:

²Vacuum

²Vent

²Dump

The vacuum chamber contains a diaphragm with a

cable attached to control the throttle linkage.

OPERATION

The PCM controls the solenoid valve body. The

solenoid valve body controls the application and

release of vacuum to the diaphragm of the vacuum

servo. The servo unit cannot be repaired and is ser-

viced only as a complete assembly.

Power is supplied to the servo's by the PCM

through the brake switch. The PCM controls the

ground path for the vacuum and vent solenoids.

The dump solenoid is energized anytime it receives

power. If power to the dump solenoid is interrupted,

the solenoid dumps vacuum in the servo. This pro-

vides a safety backup to the vent and vacuum sole-

noids.

The vacuum and vent solenoids must be grounded

at the PCM to operate. When the PCM grounds the

vacuum servo solenoid, the solenoid allows vacuum

to enter the servo and pull open the throttle plate

using the cable. When the PCM breaks the ground,

the solenoid closes and no more vacuum is allowed to

enter the servo. The PCM also operates the vent sole-

noid via ground. The vent solenoid opens and closes a

passage to bleed or hold vacuum in the servo as

required.

The PCM duty cycles the vacuum and vent sole-

noids to maintain the set speed, or to accelerate and

decelerate the vehicle. To increase throttle opening,

the PCM grounds the vacuum and vent solenoids. To

decrease throttle opening, the PCM removes the

grounds from the vacuum and vent solenoids. When

the brake is released, if vehicle speed exceeds 25

mph to resume, 30 mph to set, and the RES/ACCEL

switch has been depressed, ground for the vent and

vacuum circuits is restored.

SPEED CONTROL SWITCHESÐPCM INPUT

Description

There are two separate switch pods that operate

the speed control system. The steering-wheel-

mounted switches use multiplexed circuits to provide

inputs to the PCM for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer tothe owner's manual for more information on speed

control switch functions and setting procedures.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

Operation

When speed control is selected by depressing the

ON, OFF switch, the PCM allows a set speed to be

stored in RAM for speed control. To store a set speed,

depress the SET switch while the vehicle is moving

at a speed between 25 and 85 mph. In order for the

speed control to engage, the brakes cannot be

applied, nor can the gear selector be indicating the

transmission is in Park or Neutral.

Once the speed control has been disengaged,

depressing the ACCEL switch restores the vehicle to

the target speed that was stored in the PCM's RAM.

NOTE: Depressing the OFF switch will erase the

set speed stored in the PCM's RAM.

If, while the speed control is engaged, the driver

wishes to increase vehicle speed, the PCM is pro-

grammed for an acceleration feature. With the

ACCEL switch held closed, the vehicle accelerates

slowly to the desired speed. The new target speed is

stored in the RAM when the ACCEL switch is

released. The PCM also has a ªtap-upº feature in

which vehicle speed increases at a rate of approxi-

mately 2 mph for each momentary switch activation

of the ACCEL switch.

The PCM also provides a means to decelerate with-

out disengaging speed control. To decelerate from an

existing recorded target speed, depress and hold the

COAST switch until the desired speed is reached.

Then release the switch. The ON, OFF switch oper-

ates two components: the PCM's ON, OFF input, and

the battery voltage to the brake switch, which powers

the speed control servo.

Multiplexing

The PCM sends out 5 volts through a fixed resistor

and monitors the voltage change between the fixed

resistor and the switches. If none of the switches are

depressed, the PCM will measure 5 volts at the sen-

sor point (open circuit). If a switch with no resistor is

closed, the PCM will measure 0 volts (grounded cir-

cuit). Now, if a resistor is added to a switch, then the

PCM will measure some voltage proportional to the

size of the resistor. By adding a different resistor to

each switch, the PCM will see a different voltage

depending on which switch is pushed.

8H - 2 VEHICLE SPEED CONTROL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 288 of 1285

On most vehicles another resistor has been added

to the at rest circuit causing the PCM to never see 5

volts. This was done for diagnostic purposes. If the

switch circuit should open (bad connection) then the

PCM will see the 5 volts and know the circuit is bad.

The PCM will then set an open circuit fault.

STOP LAMP SWITCH

DESCRIPTION

The switch is mounted on the brake pedal mount-

ing bracket under the instrument panel.

OPERATION

Vehicles equipped with the speed control option use

a dual function stop lamp switch. The PCM monitors

the state of the dual function stop lamp switch. Refer

to the Brake section for more information on stop

lamp switch service and adjustment procedures.

The brake switch is equipped with three sets of

contacts, one normally open and the other two nor-

mally closed (brakes disengaged). The PCM sends a

12 volt signal to one of the normally closed contacts

in the brake switch, which is connected to a ground.

With the contacts closed, the 12 volt signal is pulled

to ground causing the signal to go low. The low volt-

age signal, monitored by the PCM, indicates that the

brakes are not applied. When the brakes are applied,

the contacts open, causing the PCM's output voltage

to go high, disengaging the speed control also

grounding the dump solenoid.

The second set of normally closed contacts is sup-

plied battery voltage any time speed control is

selected. From the brake switch, current is routed to

the speed control servo solenoids. The speed control

solenoids (vacuum, vent and dump) are provided this

current any time the speed control is ON and the

brakes are disengaged. When the driver applies the

brakes, the contacts open and current is interrupted

to the solenoids. The normally open contacts are fed

battery voltage. When the brakes are applied, battery

voltage is supplied to the stop lamps.

SERVO CABLE

DESCRIPTION

The speed control servo cable is connected between

the speed control vacuum servo diaphragm and the

throttle body control linkage.

OPERATION

This cable causes the throttle control linkage to

open or close the throttle valve in response to move-

ment of the vacuum servo diaphragm.

VACUUM RESERVOIR

OPERATION

The reservoir stores engine vacuum in the reser-

voir. When engine vacuum drops, as in climbing a

grade while driving, the reservoir supplies the vac-

uum needed to maintain proper speed control opera-

tion. The vacuum reservoir cannot be repaired and

must be replaced if faulty.

VEHICLE SPEED SENSOR

The Vehicle Speed Sensor (VSS) is a pulse genera-

tor mounted to an adapter near the transmission out-

put shaft. The sensor is driven through the adapter

by a speedometer pinion gear. The VSS pulse signal

to the speedometer/odometer is monitored by the

PCM speed control circuitry to determine vehicle

speed and to maintain speed control set speed.

REMOVAL AND INSTALLATION

SPEED CONTROL SERVO

REMOVAL

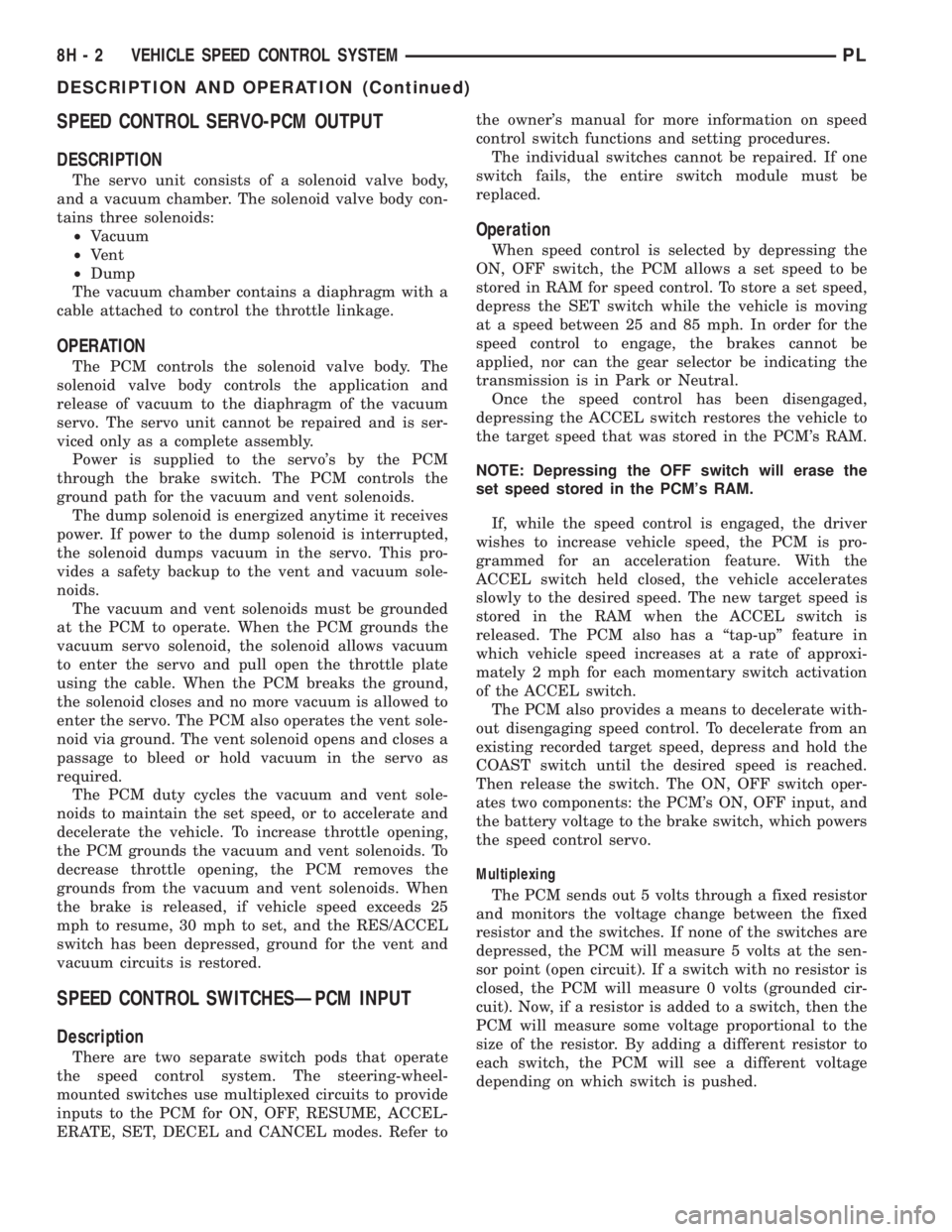

(1) Disconnect electrical connector from servo (Fig.

2).

(2) Disconnect vacuum hose from servo

(3) Remove 2 nuts retaining cable to servo.

(4) Remove retaining clip pin holding cable to

servo.

Fig. 2 Speed Control Servo

PLVEHICLE SPEED CONTROL SYSTEM 8H - 3

DESCRIPTION AND OPERATION (Continued)

Page 289 of 1285

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(3) Connect electrical connector to servo.

(4) Connect vacuum hose to servo

SPEED CONTROL SWITCH

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module (Fig. 1).

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS.

REMOVAL

(1) Turn off ignition.

(2) Remove two screws from side of each switch.

(3) Rock switch away from airbag and steering

wheel.

(4) Disconnect two-way electrical connector.

(5) Repeat for the other switch.

INSTALLATION

(1) Install switches.

(2) Connect two-way electrical connector.

(3) Install two screws to the side of each switch.

(4) Install airbag, refer to the Restraint Systems

SPEED CONTROL SERVO CABLE

REMOVAL

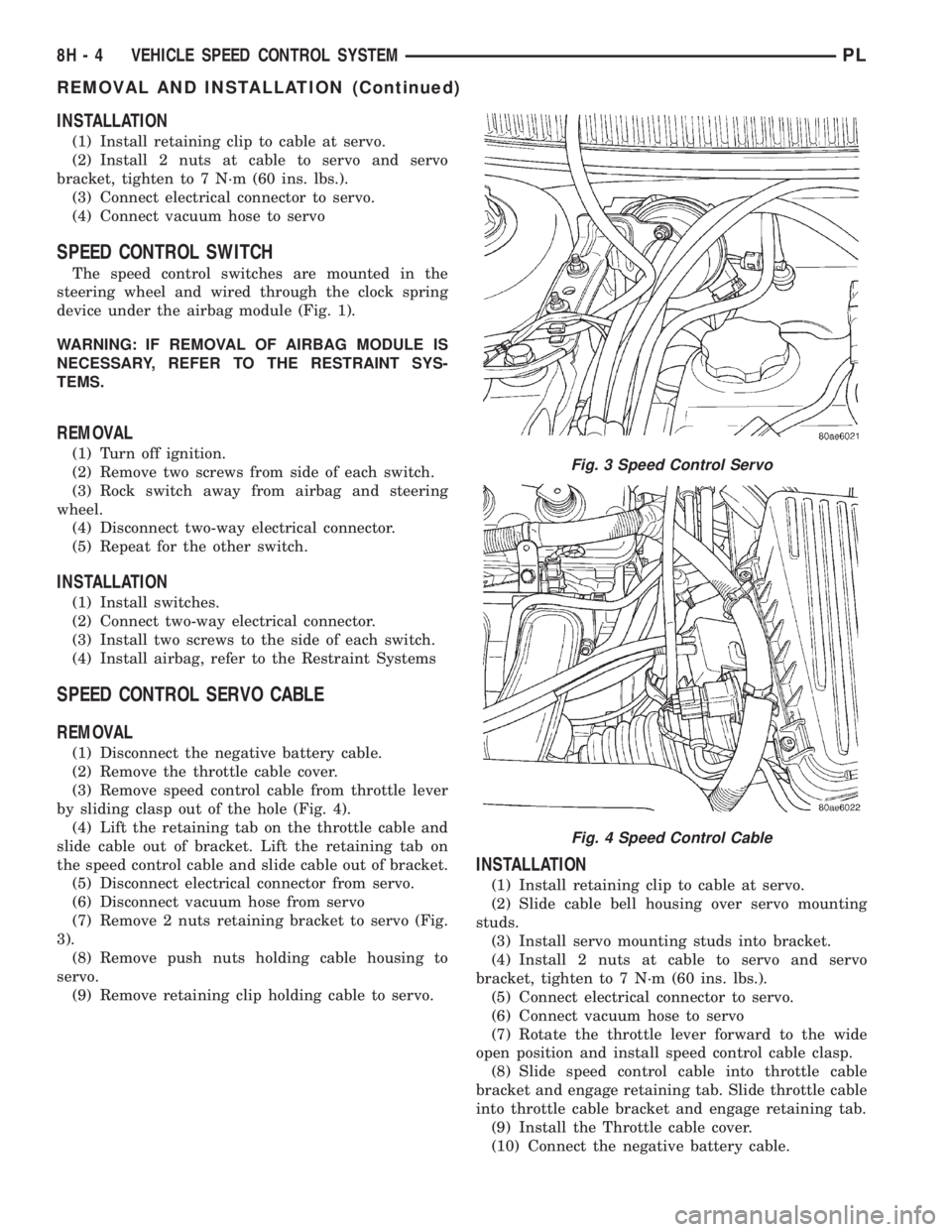

(1) Disconnect the negative battery cable.

(2) Remove the throttle cable cover.

(3) Remove speed control cable from throttle lever

by sliding clasp out of the hole (Fig. 4).

(4) Lift the retaining tab on the throttle cable and

slide cable out of bracket. Lift the retaining tab on

the speed control cable and slide cable out of bracket.

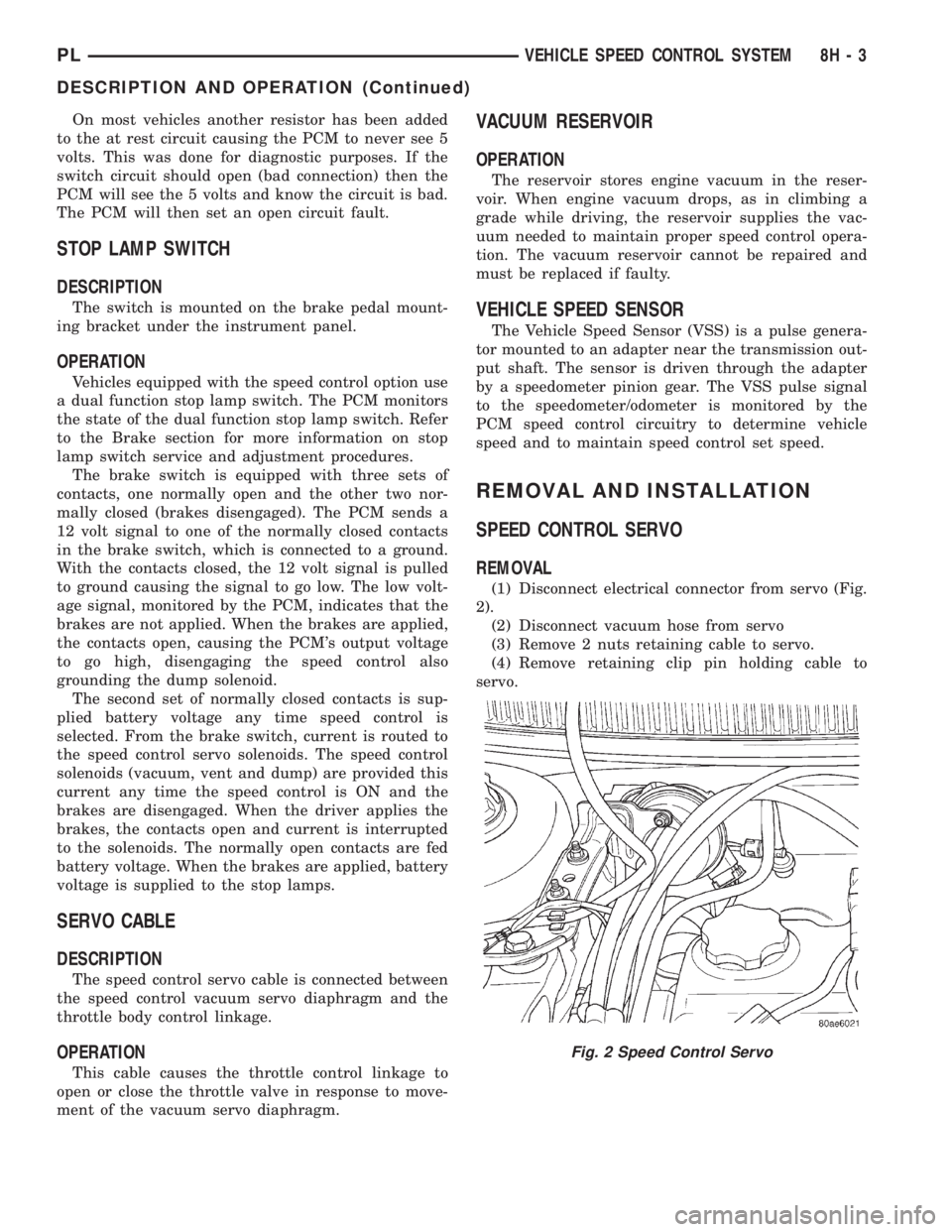

(5) Disconnect electrical connector from servo.

(6) Disconnect vacuum hose from servo

(7) Remove 2 nuts retaining bracket to servo (Fig.

3).

(8) Remove push nuts holding cable housing to

servo.

(9) Remove retaining clip holding cable to servo.

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Slide cable bell housing over servo mounting

studs.

(3) Install servo mounting studs into bracket.

(4) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(5) Connect electrical connector to servo.

(6) Connect vacuum hose to servo

(7) Rotate the throttle lever forward to the wide

open position and install speed control cable clasp.

(8) Slide speed control cable into throttle cable

bracket and engage retaining tab. Slide throttle cable

into throttle cable bracket and engage retaining tab.

(9) Install the Throttle cable cover.

(10) Connect the negative battery cable.

Fig. 3 Speed Control Servo

Fig. 4 Speed Control Cable

8H - 4 VEHICLE SPEED CONTROL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 292 of 1285

TURN SIGNAL and HAZARD WARNING SYSTEMS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

HAZARD WARNING SYSTEM................2

HEADLAMP SWITCH......................2

COMBINATION FLASHER...................2DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH.................3

REMOVAL AND INSTALLATION

COMBINATION FLASHER...................5

MULTI-FUNCTION SWITCH.................5

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, PASSIVE RESTRAINT SYS-

TEMS FOR AIRBAG REMOVAL.

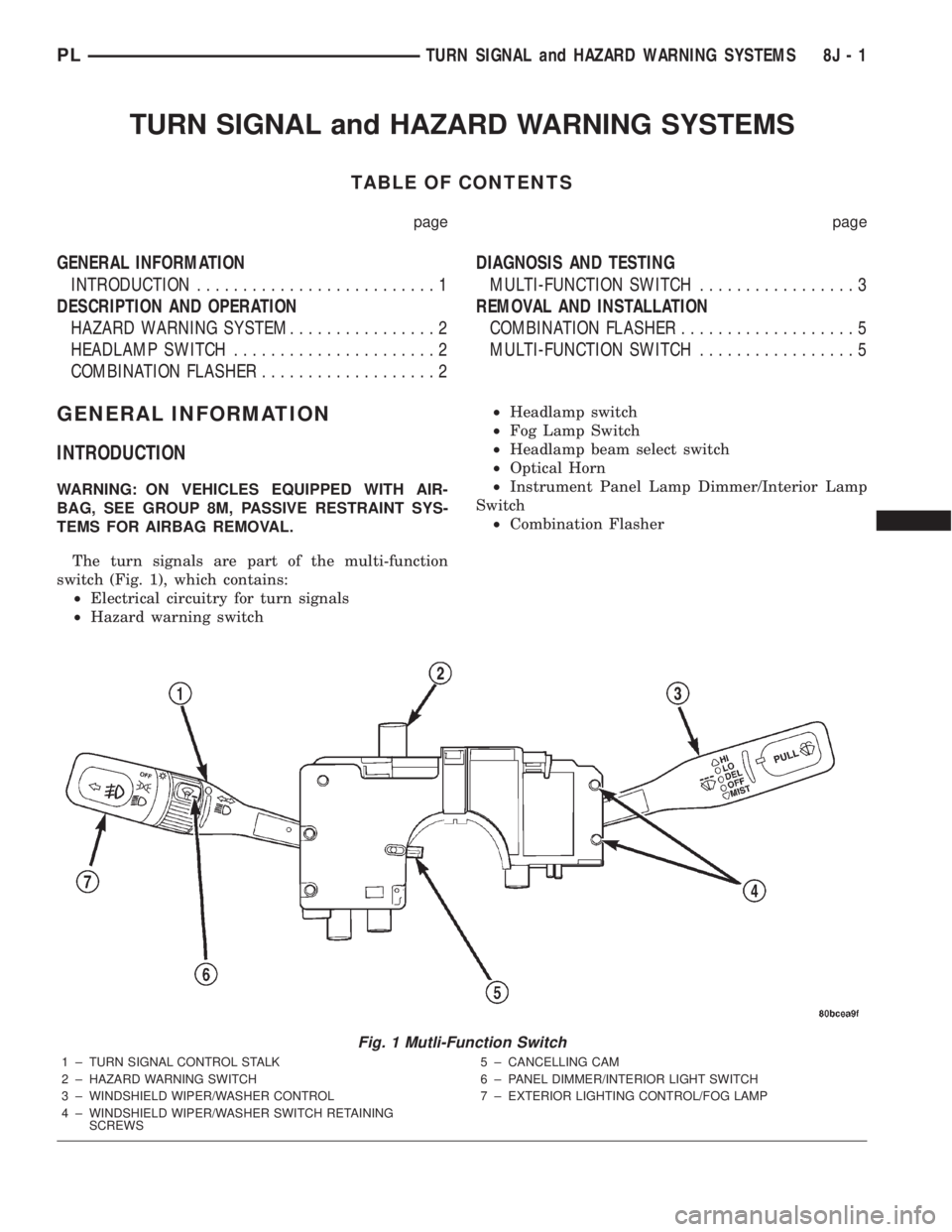

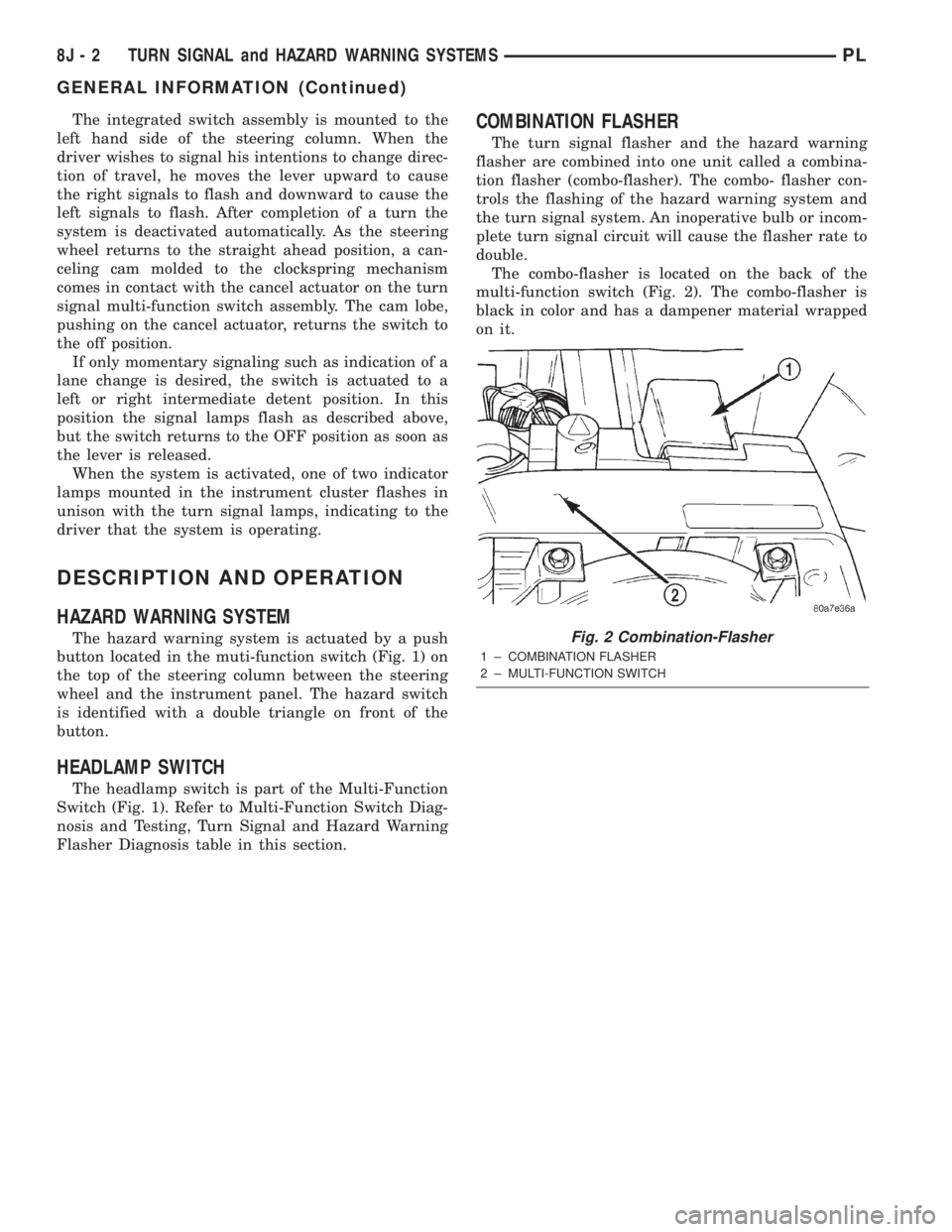

The turn signals are part of the multi-function

switch (Fig. 1), which contains:

²Electrical circuitry for turn signals

²Hazard warning switch²Headlamp switch

²Fog Lamp Switch

²Headlamp beam select switch

²Optical Horn

²Instrument Panel Lamp Dimmer/Interior Lamp

Switch

²Combination Flasher

Fig. 1 Mutli-Function Switch

1 ± TURN SIGNAL CONTROL STALK

2 ± HAZARD WARNING SWITCH

3 ± WINDSHIELD WIPER/WASHER CONTROL

4 ± WINDSHIELD WIPER/WASHER SWITCH RETAINING

SCREWS5 ± CANCELLING CAM

6 ± PANEL DIMMER/INTERIOR LIGHT SWITCH

7 ± EXTERIOR LIGHTING CONTROL/FOG LAMP

PLTURN SIGNAL and HAZARD WARNING SYSTEMS 8J - 1

Page 293 of 1285

The integrated switch assembly is mounted to the

left hand side of the steering column. When the

driver wishes to signal his intentions to change direc-

tion of travel, he moves the lever upward to cause

the right signals to flash and downward to cause the

left signals to flash. After completion of a turn the

system is deactivated automatically. As the steering

wheel returns to the straight ahead position, a can-

celing cam molded to the clockspring mechanism

comes in contact with the cancel actuator on the turn

signal multi-function switch assembly. The cam lobe,

pushing on the cancel actuator, returns the switch to

the off position.

If only momentary signaling such as indication of a

lane change is desired, the switch is actuated to a

left or right intermediate detent position. In this

position the signal lamps flash as described above,

but the switch returns to the OFF position as soon as

the lever is released.

When the system is activated, one of two indicator

lamps mounted in the instrument cluster flashes in

unison with the turn signal lamps, indicating to the

driver that the system is operating.

DESCRIPTION AND OPERATION

HAZARD WARNING SYSTEM

The hazard warning system is actuated by a push

button located in the muti-function switch (Fig. 1) on

the top of the steering column between the steering

wheel and the instrument panel. The hazard switch

is identified with a double triangle on front of the

button.

HEADLAMP SWITCH

The headlamp switch is part of the Multi-Function

Switch (Fig. 1). Refer to Multi-Function Switch Diag-

nosis and Testing, Turn Signal and Hazard Warning

Flasher Diagnosis table in this section.

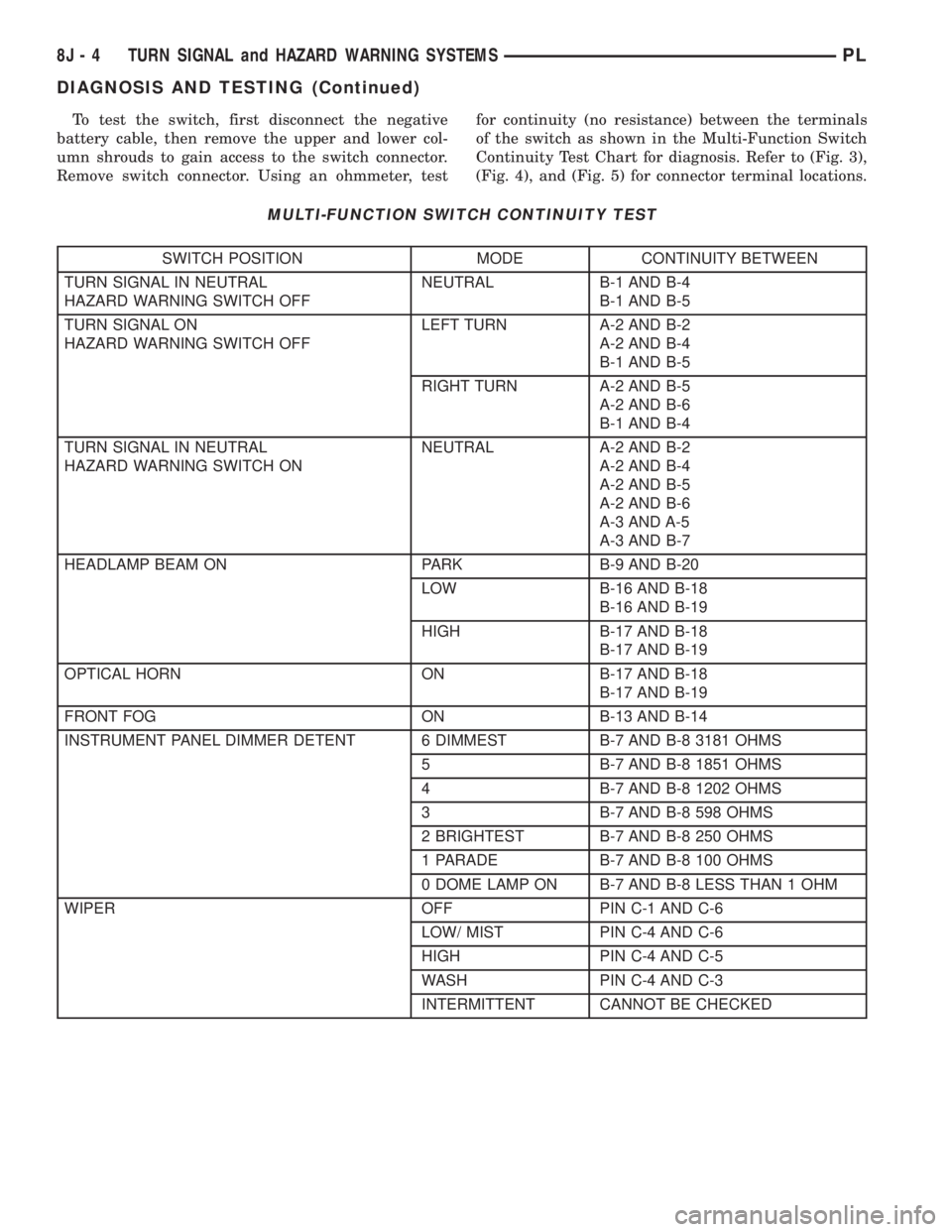

COMBINATION FLASHER

The turn signal flasher and the hazard warning

flasher are combined into one unit called a combina-

tion flasher (combo-flasher). The combo- flasher con-

trols the flashing of the hazard warning system and

the turn signal system. An inoperative bulb or incom-

plete turn signal circuit will cause the flasher rate to

double.

The combo-flasher is located on the back of the

multi-function switch (Fig. 2). The combo-flasher is

black in color and has a dampener material wrapped

on it.

Fig. 2 Combination-Flasher

1 ± COMBINATION FLASHER

2 ± MULTI-FUNCTION SWITCH

8J - 2 TURN SIGNAL and HAZARD WARNING SYSTEMSPL

GENERAL INFORMATION (Continued)

Page 295 of 1285

To test the switch, first disconnect the negative

battery cable, then remove the upper and lower col-

umn shrouds to gain access to the switch connector.

Remove switch connector. Using an ohmmeter, testfor continuity (no resistance) between the terminals

of the switch as shown in the Multi-Function Switch

Continuity Test Chart for diagnosis. Refer to (Fig. 3),

(Fig. 4), and (Fig. 5) for connector terminal locations.

MULTI-FUNCTION SWITCH CONTINUITY TEST

SWITCH POSITION MODE CONTINUITY BETWEEN

TURN SIGNAL IN NEUTRAL

HAZARD WARNING SWITCH OFFNEUTRAL B-1 AND B-4

B-1 AND B-5

TURN SIGNAL ON

HAZARD WARNING SWITCH OFFLEFT TURN A-2 AND B-2

A-2 AND B-4

B-1 AND B-5

RIGHT TURN A-2 AND B-5

A-2 AND B-6

B-1 AND B-4

TURN SIGNAL IN NEUTRAL

HAZARD WARNING SWITCH ONNEUTRAL A-2 AND B-2

A-2 AND B-4

A-2 AND B-5

A-2 AND B-6

A-3 AND A-5

A-3 AND B-7

HEADLAMP BEAM ON PARK B-9 AND B-20

LOW B-16 AND B-18

B-16 AND B-19

HIGH B-17 AND B-18

B-17 AND B-19

OPTICAL HORN ON B-17 AND B-18

B-17 AND B-19

FRONT FOG ON B-13 AND B-14

INSTRUMENT PANEL DIMMER DETENT 6 DIMMEST B-7 AND B-8 3181 OHMS

5 B-7 AND B-8 1851 OHMS

4 B-7 AND B-8 1202 OHMS

3 B-7 AND B-8 598 OHMS

2 BRIGHTEST B-7 AND B-8 250 OHMS

1 PARADE B-7 AND B-8 100 OHMS

0 DOME LAMP ON B-7 AND B-8 LESS THAN 1 OHM

WIPER OFF PIN C-1 AND C-6

LOW/ MIST PIN C-4 AND C-6

HIGH PIN C-4 AND C-5

WASH PIN C-4 AND C-3

INTERMITTENT CANNOT BE CHECKED

8J - 4 TURN SIGNAL and HAZARD WARNING SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)