hood release DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 498 of 1285

MODULE ENTRY

KEYLESS

REMOTE

16 24

1

2

SWITCH CYLINDER

KEY

TRUNK

DECKLID

SOLENOID

2C302

G301 S311 S312

C3052

C30246

21

G71

20

VT/YL

G71

20

VT/YL

G71

20

VT/YL

Q2

16

LG/BK

Q2

16

LG/BK

Q2

16

LG/BK

Z1

18

BKZ1

18

BK

Z1

16

BK

Z1

18

BK

23

1

2

G103

C1032

S117

B2

SWITCH AJAR

HOOD

G70

20

BR/TN

G70

18

BR/TN

Z1

18

BK

DECKLID

RELEASE

RELAY

OUTPUTDECKLID

SECURITY

SWITCH

SENSEHOOD

AJAR

SWITCH

SENSE

2

1A2

A21

Z1

18

BK

Z1

18

BK

G304

Z1

12

BK

(8W-15-12)

(8W-15-13) (8W-15-12)

(8W-15-13) (8W-15-12)

(8W-15-13)

(8W-15-7) (8W-15-7) (8W-61-6)

(8W-61-6)

(8W-15-12)

(8W-15-13)

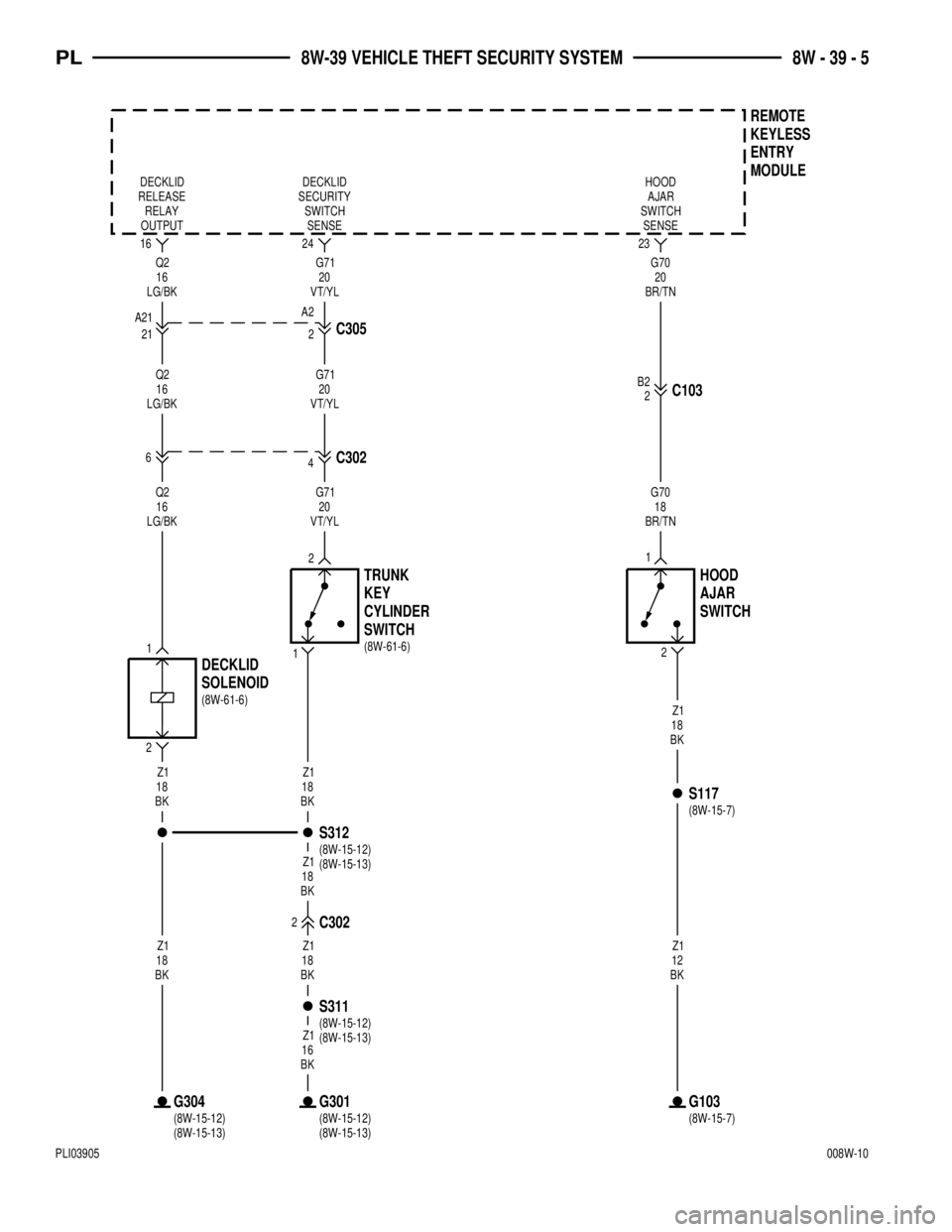

PL8W-39 VEHICLE THEFT SECURITY SYSTEM 8W - 39 - 5

PLI03905008W-10

Page 536 of 1285

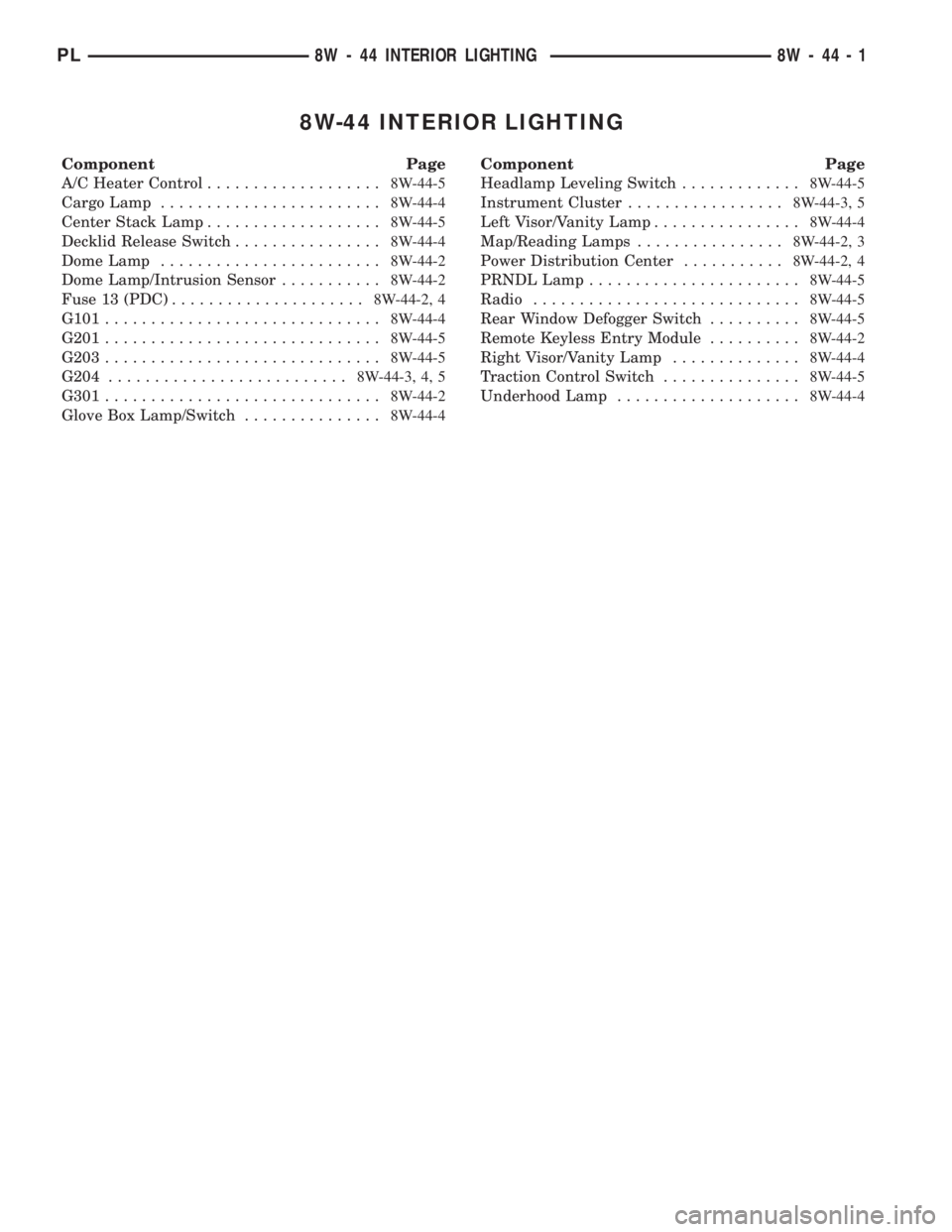

8W-44 INTERIOR LIGHTING

Component Page

A/C Heater Control...................8W-44-5

Cargo Lamp........................8W-44-4

Center Stack Lamp...................8W-44-5

Decklid Release Switch................8W-44-4

Dome Lamp........................8W-44-2

Dome Lamp/Intrusion Sensor...........8W-44-2

Fuse 13 (PDC).....................8W-44-2, 4

G101..............................8W-44-4

G201..............................8W-44-5

G203..............................8W-44-5

G204..........................8W-44-3, 4, 5

G301..............................8W-44-2

Glove Box Lamp/Switch...............8W-44-4Component Page

Headlamp Leveling Switch.............8W-44-5

Instrument Cluster.................8W-44-3, 5

Left Visor/Vanity Lamp................8W-44-4

Map/Reading Lamps................8W-44-2, 3

Power Distribution Center...........8W-44-2, 4

PRNDL Lamp.......................8W-44-5

Radio.............................8W-44-5

Rear Window Defogger Switch..........8W-44-5

Remote Keyless Entry Module..........8W-44-2

Right Visor/Vanity Lamp..............8W-44-4

Traction Control Switch...............8W-44-5

Underhood Lamp....................8W-44-4

PL8W - 44 INTERIOR LIGHTING 8W - 44 - 1

Page 539 of 1285

13

15A

FUSE

13

BATT A0

POWER

DISTRIBUTION

CENTER

1

2

G101

S112

C1071

UNDERHOOD

LAMP

21

SWITCH LAMP/

BOX

GLOVE

G204

S205

LAMP

VANITY

VISOR/

LEFT RIGHT

VISOR/

VANITY

LAMP

C204121

DECKLID

RELEASE CARGO

LAMP

C3023

S309

10C105

B5C1035

S201

M1

20

PK

M1

20

PK

M1

20

WT

M1

18

BK/PK

M1

18

BK/PKM1

18

BK/PK

M1

20

PKM1

20

PK

M1

20

PK

M1

20

PKM1

20

PK

M1

20

PK

Z1

20

BK

Z1

18

BK

Z3

20

BK/OR

Z3

14

BK/OR

S103

S251

G78

22

TN/BK

G78

18

TN/BK

SWITCH

2C107

BK20Z1

S133

S134

Z1

20

BK

M1

20

PK

(8W-10-12)(8W-10-7)

(8W-10-2)

(8W-10-3)

(8W-15-3) (8W-15-3)

(8W-15-11) (8W-15-11)(8W-10-12)

(8W-10-12)(8W-10-12)

(8W-10-12) (8W-10-12)

(8W-15-3)

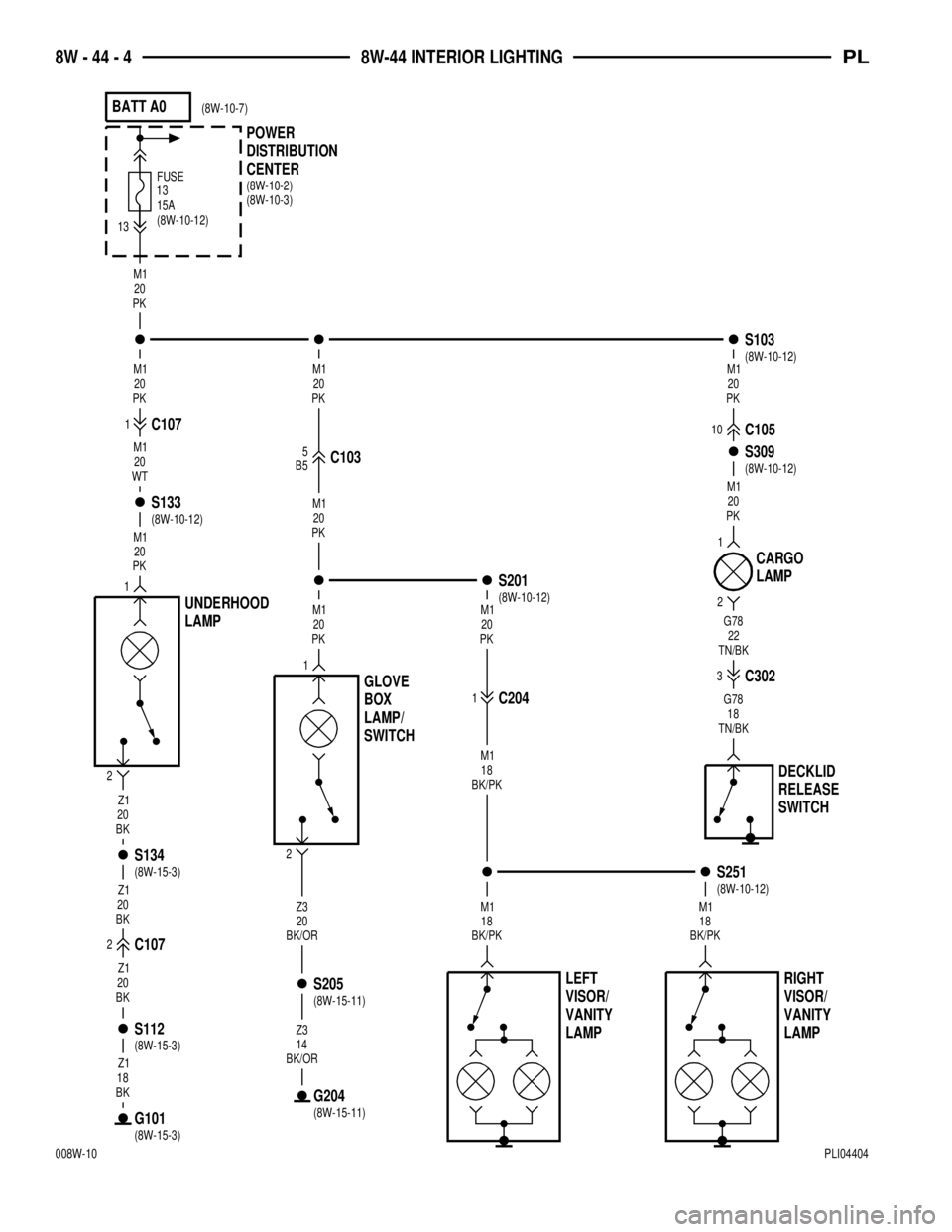

8W - 44 - 4 8W-44 INTERIOR LIGHTINGPL

008W-10PLI04404

Page 649 of 1285

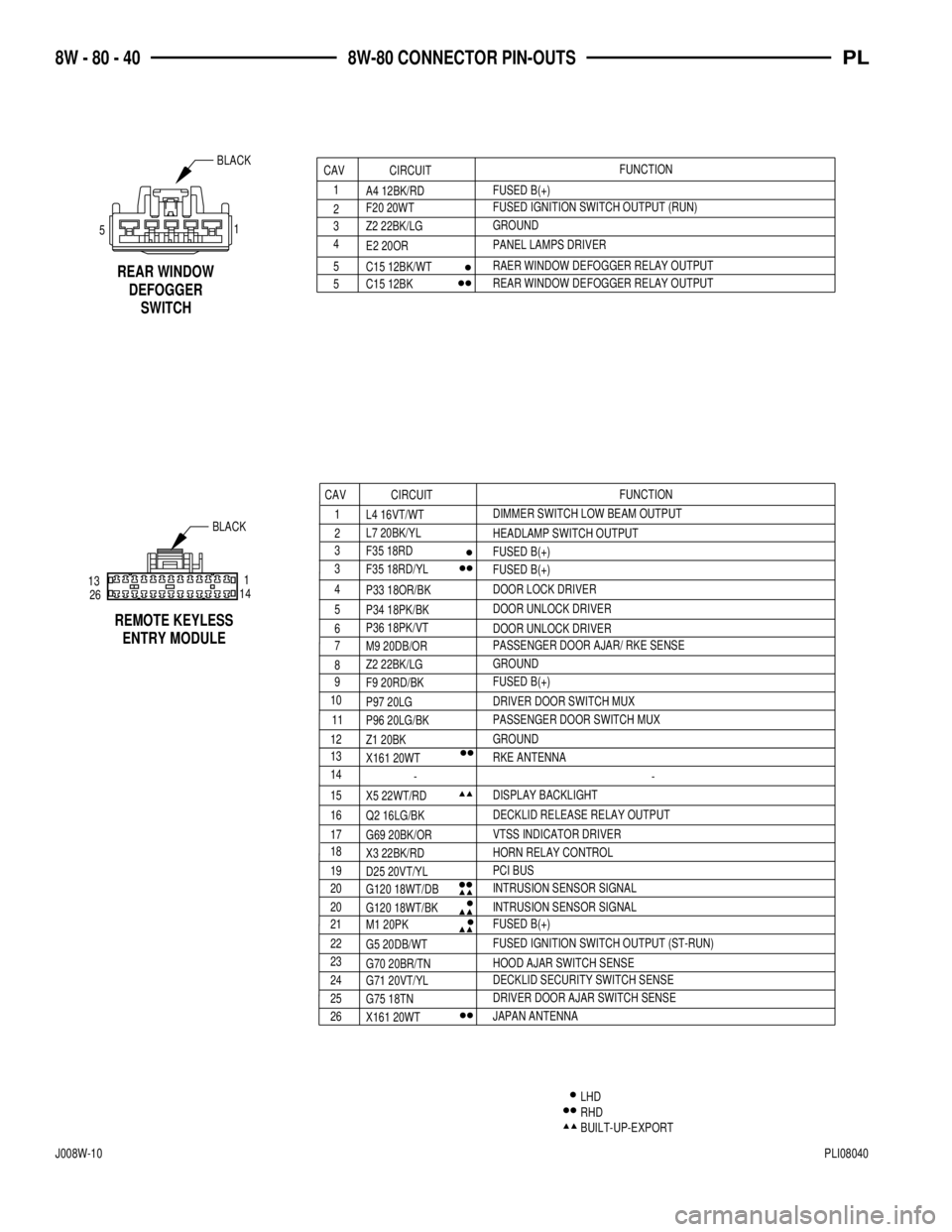

LHD

RHD

Z2 22BK/LGGROUND

F9 20RD/BKFUSED B(+)

PASSENGER DOOR SWITCH MUX

P96 20LG/BK

- -

L7 20BK/YLDIMMER SWITCH LOW BEAM OUTPUT

REMOTE KEYLESS

ENTRY MODULE

1411

12

13

9 5

6

8 7 3

4 2 1CIRCUIT CAV

10

21 15

18

19 17 16

20

24 23 22

25

26

F35 18RDHEADLAMP SWITCH OUTPUT

P33 18OR/BKFUSED B(+)

P34 18PK/BKDOOR LOCK DRIVER

P36 18PK/VTDOOR UNLOCK DRIVER

M9 20DB/ORDOOR UNLOCK DRIVER

PASSENGER DOOR AJAR/ RKE SENSE

P97 20LGDRIVER DOOR SWITCH MUX

Z1 20BKGROUND

X161 20WTRKE ANTENNA

X5 22WT/RDDISPLAY BACKLIGHT

Q2 16LG/BKDECKLID RELEASE RELAY OUTPUT

G69 20BK/ORVTSS INDICATOR DRIVER

X3 22BK/RDHORN RELAY CONTROL

D25 20VT/YLPCI BUS

G120 18WT/BKINTRUSION SENSOR SIGNAL

M1 20PKFUSED B(+)

G5 20DB/WTFUSED IGNITION SWITCH OUTPUT (ST-RUN)

G70 20BR/TNHOOD AJAR SWITCH SENSE

G71 20VT/YLDECKLID SECURITY SWITCH SENSE

G75 18TNDRIVER DOOR AJAR SWITCH SENSE

X161 20WTJAPAN ANTENNA L4 16VT/WT

BUILT-UP-EXPORT

1

13

14

26REAR WINDOW DEFOGGER RELAY OUTPUT

C15 12BKPANEL LAMPS DRIVER

E2 20OR Z2 22BK/LGGROUND F20 20WTFUSED IGNITION SWITCH OUTPUT (RUN) A4 12BK/RDFUSED B(+)

SWITCH

51

DEFOGGER REAR WINDOW

FUNCTION

CAV CIRCUIT

1

2

4 3

5

F35 18RD/YL

FUSED B(+) 3

5

C15 12BK/WTRAER WINDOW DEFOGGER RELAY OUTPUT

INTRUSION SENSOR SIGNAL

G120 18WT/DB20

BLACK

BLACK

FUNCTION

8W - 80 - 40 8W-80 CONNECTOR PIN-OUTSPL

J008W-10PLI08040

Page 1129 of 1285

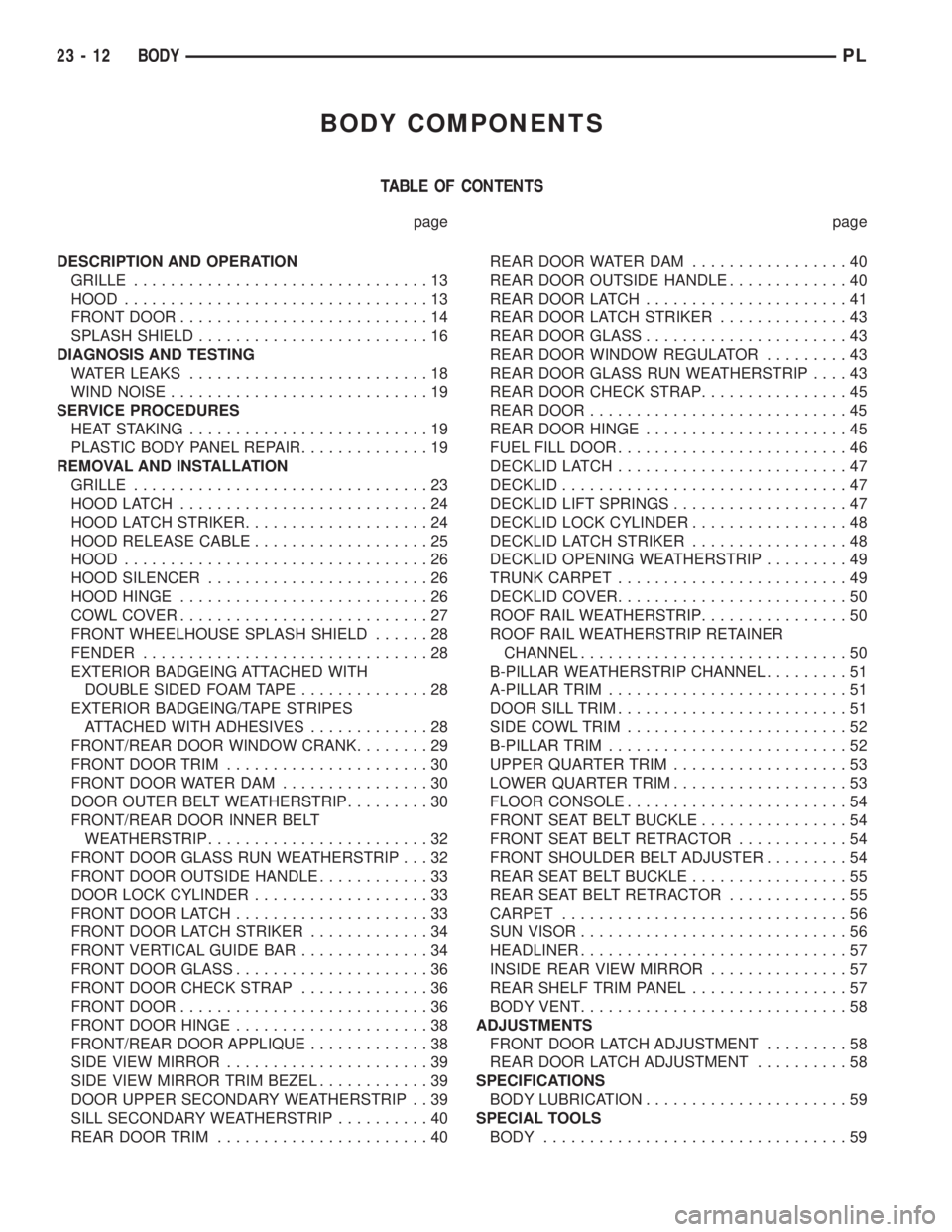

BODY COMPONENTS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

GRILLE................................13

HOOD.................................13

FRONT DOOR...........................14

SPLASH SHIELD.........................16

DIAGNOSIS AND TESTING

WATER LEAKS..........................18

WIND NOISE............................19

SERVICE PROCEDURES

HEAT STAKING..........................19

PLASTIC BODY PANEL REPAIR..............19

REMOVAL AND INSTALLATION

GRILLE................................23

HOOD LATCH...........................24

HOOD LATCH STRIKER....................24

HOOD RELEASE CABLE...................25

HOOD.................................26

HOOD SILENCER........................26

HOOD HINGE...........................26

COWL COVER...........................27

FRONT WHEELHOUSE SPLASH SHIELD......28

FENDER...............................28

EXTERIOR BADGEING ATTACHED WITH

DOUBLE SIDED FOAM TAPE..............28

EXTERIOR BADGEING/TAPE STRIPES

ATTACHED WITH ADHESIVES.............28

FRONT/REAR DOOR WINDOW CRANK........29

FRONT DOOR TRIM......................30

FRONT DOOR WATER DAM................30

DOOR OUTER BELT WEATHERSTRIP.........30

FRONT/REAR DOOR INNER BELT

WEATHERSTRIP........................32

FRONT DOOR GLASS RUN WEATHERSTRIP . . . 32

FRONT DOOR OUTSIDE HANDLE............33

DOOR LOCK CYLINDER...................33

FRONT DOOR LATCH.....................33

FRONT DOOR LATCH STRIKER.............34

FRONT VERTICAL GUIDE BAR..............34

FRONT DOOR GLASS.....................36

FRONT DOOR CHECK STRAP..............36

FRONT DOOR...........................36

FRONT DOOR HINGE.....................38

FRONT/REAR DOOR APPLIQUE.............38

SIDE VIEW MIRROR......................39

SIDE VIEW MIRROR TRIM BEZEL............39

DOOR UPPER SECONDARY WEATHERSTRIP . . 39

SILL SECONDARY WEATHERSTRIP..........40

REAR DOOR TRIM.......................40REAR DOOR WATER DAM.................40

REAR DOOR OUTSIDE HANDLE.............40

REAR DOOR LATCH......................41

REAR DOOR LATCH STRIKER..............43

REAR DOOR GLASS......................43

REAR DOOR WINDOW REGULATOR.........43

REAR DOOR GLASS RUN WEATHERSTRIP....43

REAR DOOR CHECK STRAP................45

REAR DOOR............................45

REAR DOOR HINGE......................45

FUEL FILL DOOR.........................46

DECKLID LATCH.........................47

DECKLID...............................47

DECKLID LIFT SPRINGS...................47

DECKLID LOCK CYLINDER.................48

DECKLID LATCH STRIKER.................48

DECKLID OPENING WEATHERSTRIP.........49

TRUNK CARPET.........................49

DECKLID COVER.........................50

ROOF RAIL WEATHERSTRIP................50

ROOF RAIL WEATHERSTRIP RETAINER

CHANNEL.............................50

B-PILLAR WEATHERSTRIP CHANNEL.........51

A-PILLAR TRIM..........................51

DOOR SILL TRIM.........................51

SIDE COWL TRIM........................52

B-PILLAR TRIM..........................52

UPPER QUARTER TRIM...................53

LOWER QUARTER TRIM...................53

FLOOR CONSOLE........................54

FRONT SEAT BELT BUCKLE................54

FRONT SEAT BELT RETRACTOR............54

FRONT SHOULDER BELT ADJUSTER.........54

REAR SEAT BELT BUCKLE.................55

REAR SEAT BELT RETRACTOR.............55

CARPET...............................56

SUN VISOR.............................56

HEADLINER.............................57

INSIDE REAR VIEW MIRROR...............57

REAR SHELF TRIM PANEL.................57

BODY VENT.............................58

ADJUSTMENTS

FRONT DOOR LATCH ADJUSTMENT.........58

REAR DOOR LATCH ADJUSTMENT..........58

SPECIFICATIONS

BODY LUBRICATION......................59

SPECIAL TOOLS

BODY.................................59

23 - 12 BODYPL

Page 1130 of 1285

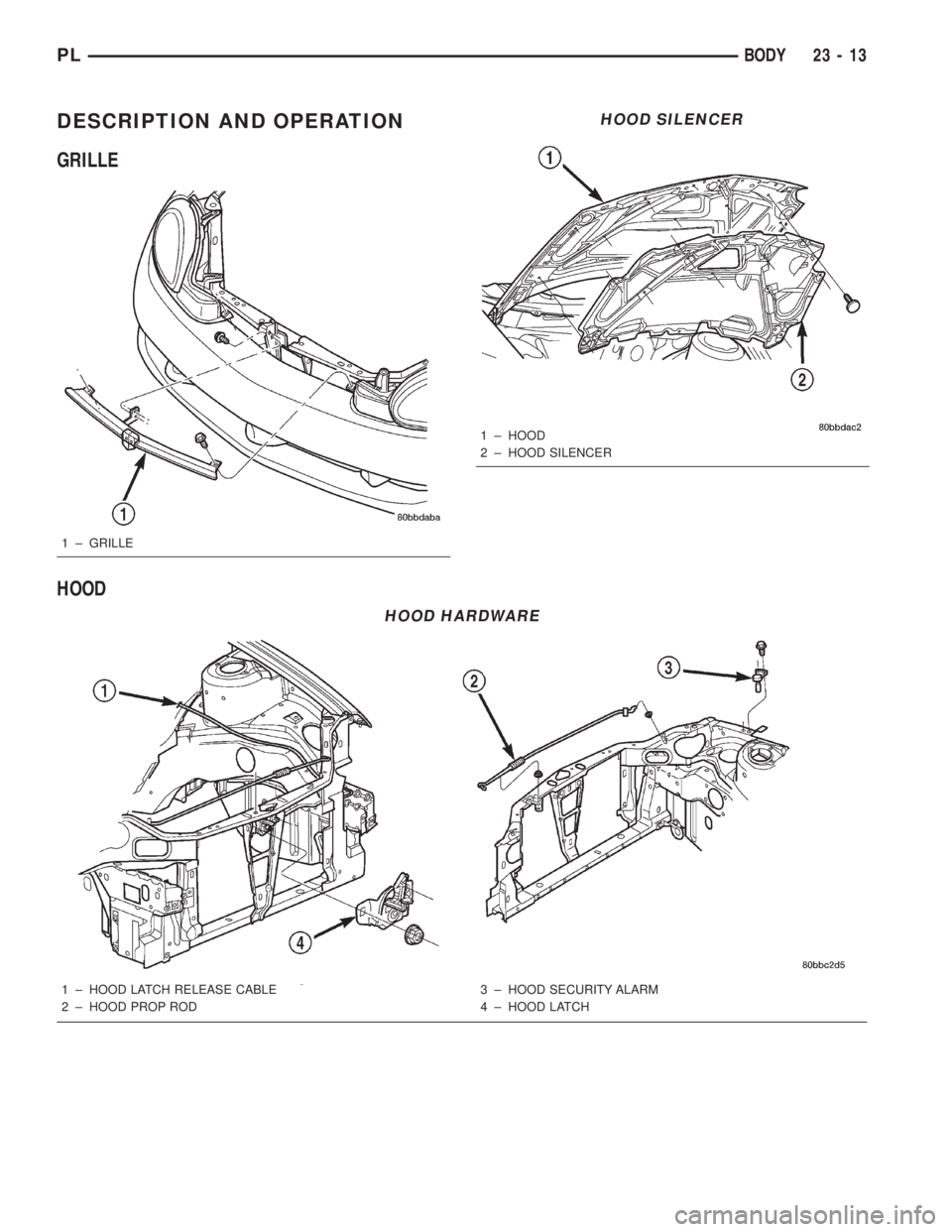

DESCRIPTION AND OPERATION

GRILLE

HOOD

1 ± GRILLE

HOOD HARDWARE

1 ± HOOD LATCH RELEASE CABLE

2 ± HOOD PROP ROD3 ± HOOD SECURITY ALARM

4 ± HOOD LATCH

HOOD SILENCER

1 ± HOOD

2 ± HOOD SILENCER

PLBODY 23 - 13

Page 1140 of 1285

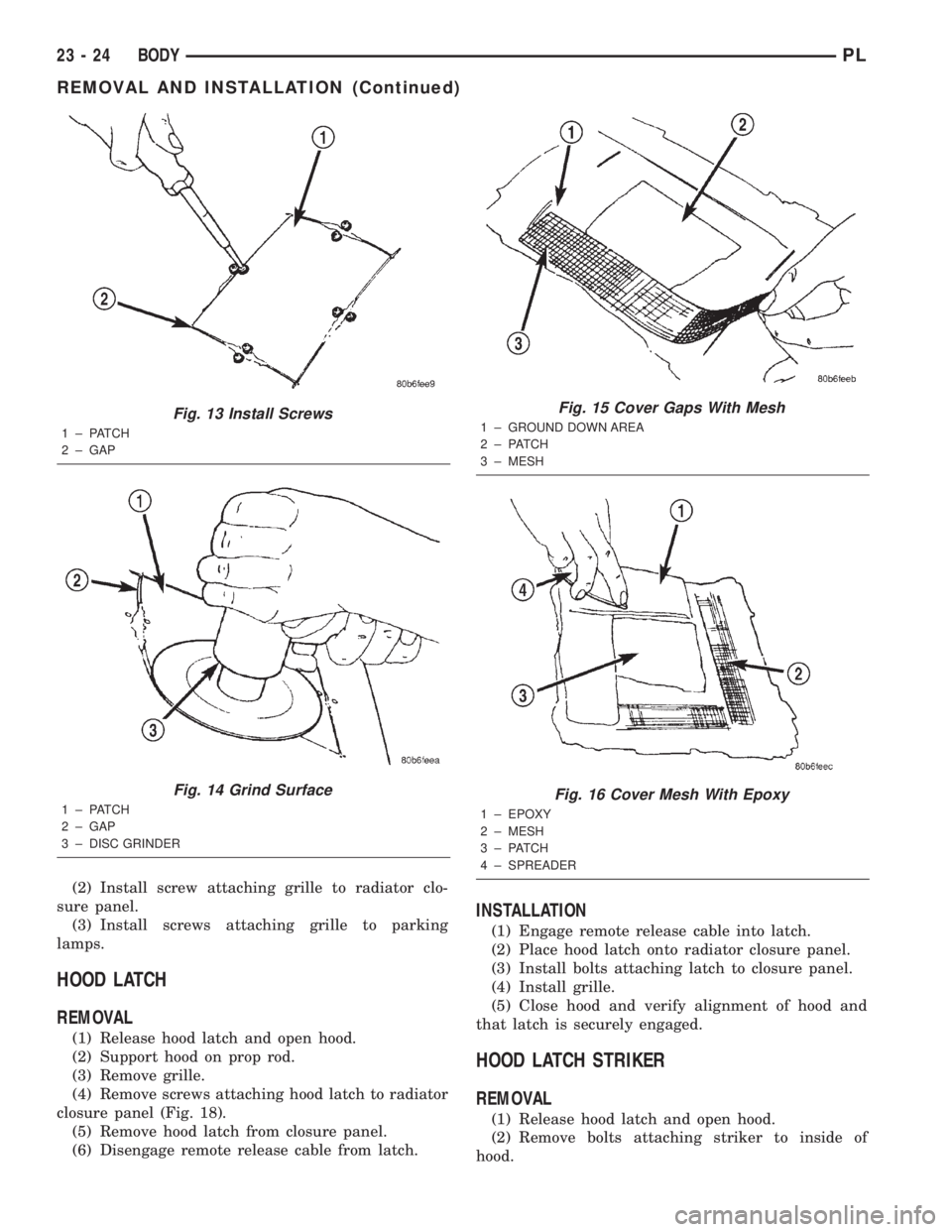

(12) Position patch in cutout against support

squares and adjust patch until the gap is equal along

all sides (Fig. 11).

(13) Drill 3 mm (0.125 in.) holes in the support

squares through the pre-drilled holes in the patch.

(14) Apply a coat of epoxy to the exposed ends of

the support squares (Fig. 12).

(15) Install screws to hold the patch to support

squares (Fig. 13). Tighten screws until patch surface

is flush with panel surface.

(16) Allow epoxy to cure, and remove all screws.

(17) Using a 125 mm (5 in.) 24 grit disc grinder,

grind a 50 mm (2 in.) to 75 mm (3 in.) wide and 2

mm (0.080 in.) deep path across the gaps around the

patch (Fig. 14). With compressed air, blow dust from

around patch.

(18) Apply adhesive backed nylon mesh (dry wall

tape) over gaps around patch (Fig. 15).

(19) Mix enough epoxy to cover the entire patch

area.

(20) Apply epoxy over the mesh around patch, and

smooth epoxy with a wide spreader to reduce finish

grinding. Use two to three layers of mesh and epoxy

to create a stronger repair (Fig. 16).

PATCHED PANEL SURFACING

After patch panel is installed, the patch area can

be finished using the same methods as finishing

other types of body panels. If mesh material is

exposed in the patched area, grind surface down, and

apply a coat of high quality rigid plastic body filler.

Prime, block sand, and paint as required.

REMOVAL AND INSTALLATION

GRILLE

REMOVAL

(1) Release hood latch, open and support hood on

prop rod.

(2) Remove screws attaching grille to parking

lamps (Fig. 17).

(3) Remove screw attaching grille to radiator clo-

sure panel.

(4) Remove grille from vehicle.

INSTALLATION

(1) Place grille into position on vehicle.

Fig. 10 Secure Support Squares To Body Panel

1 ± SUPPORT SQUARES

2 ± SCREWS

3 ± DAMAGED BODY PANEL

Fig. 11 Position Patch In Cutout And Align

1 ± CUTOUT

2 ± SUPPORT SQUARES

Fig. 12 Apply Epoxy To Support Squares

1 ± APPLICATOR

2 ± SUPPORT SQUARES

3 ± EPOXY

PLBODY 23 - 23

SERVICE PROCEDURES (Continued)

Page 1141 of 1285

(2) Install screw attaching grille to radiator clo-

sure panel.

(3) Install screws attaching grille to parking

lamps.

HOOD LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Support hood on prop rod.

(3) Remove grille.

(4) Remove screws attaching hood latch to radiator

closure panel (Fig. 18).

(5) Remove hood latch from closure panel.

(6) Disengage remote release cable from latch.

INSTALLATION

(1) Engage remote release cable into latch.

(2) Place hood latch onto radiator closure panel.

(3) Install bolts attaching latch to closure panel.

(4) Install grille.

(5) Close hood and verify alignment of hood and

that latch is securely engaged.

HOOD LATCH STRIKER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching striker to inside of

hood.

Fig. 13 Install Screws

1 ± PATCH

2 ± GAP

Fig. 14 Grind Surface

1 ± PATCH

2 ± GAP

3 ± DISC GRINDER

Fig. 15 Cover Gaps With Mesh

1 ± GROUND DOWN AREA

2 ± PATCH

3 ± MESH

Fig. 16 Cover Mesh With Epoxy

1 ± EPOXY

2 ± MESH

3 ± PATCH

4 ± SPREADER

23 - 24 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1142 of 1285

(3) Remove hood latch striker from vehicle.

INSTALLATION

(1) Position hood latch striker on vehicle.

(2) Install bolts attaching hood latch striker to

hood. Tighten bolts to 13.5 N´m (10 ft. lbs.) torque.

(3) Align hood latch striker to engage smoothly

into hood latch.(4) Verify hood operation and alignment. Adjust as

necessary.

(5) Tighten attaching bolts to 13.5 N´m (10 ft. lbs.)

torque.

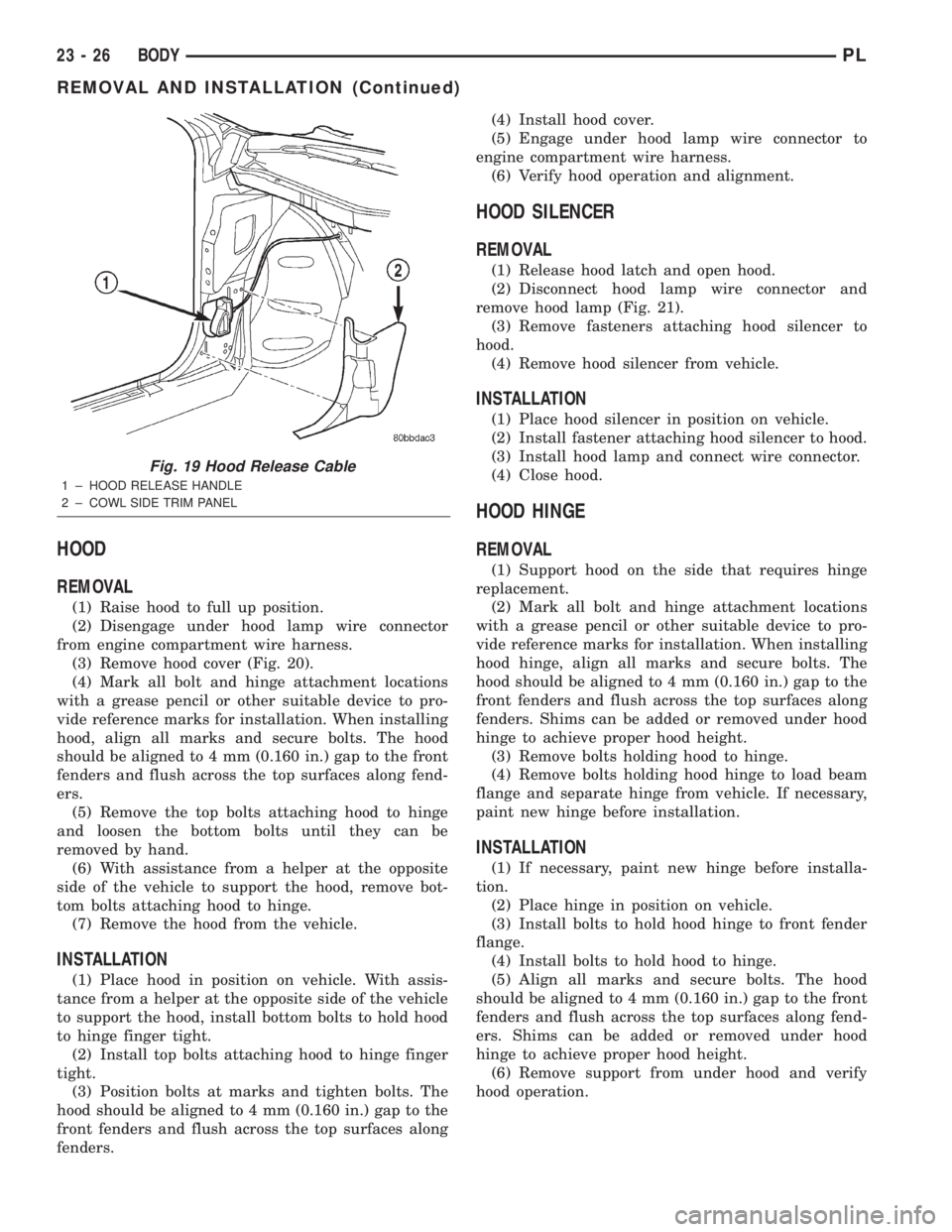

HOOD RELEASE CABLE

REMOVAL

(1) Disconnect remote hood release cable from

hood latch.

(2) Remove left front cowl trim panel.

(3) Remove screws attaching hood release handle

to cowl panel (Fig. 19).

(4) Disconnect rubber grommet from dash panel

behind instrument panel.

(5) Pull release cable through hole in dash panel.

(6) Remove cable and handle from vehicle.

INSTALLATION

(1) Assemble cable and handle onto vehicle.

(2) Push release cable through hole in dash panel.

(3) Connect rubber grommet into dash panel.

(4) Install screws attaching hood release handle to

cowl panel.

(5) Install left front cowl trim panel.

(6) Connect remote hood release cable to hood

latch.

(7) Close hood and verify operation.

Fig. 18 Hood Latch

1 ± HOOD LATCH RELEASE CABLE

2 ± HOOD PROP ROD3 ± HOOD SECURITY ALARM

4 ± HOOD LATCH

Fig. 17 Grille

1 ± GRILLE

PLBODY 23 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1143 of 1285

HOOD

REMOVAL

(1) Raise hood to full up position.

(2) Disengage under hood lamp wire connector

from engine compartment wire harness.

(3) Remove hood cover (Fig. 20).

(4) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.

(5) Remove the top bolts attaching hood to hinge

and loosen the bottom bolts until they can be

removed by hand.

(6) With assistance from a helper at the opposite

side of the vehicle to support the hood, remove bot-

tom bolts attaching hood to hinge.

(7) Remove the hood from the vehicle.

INSTALLATION

(1) Place hood in position on vehicle. With assis-

tance from a helper at the opposite side of the vehicle

to support the hood, install bottom bolts to hold hood

to hinge finger tight.

(2) Install top bolts attaching hood to hinge finger

tight.

(3) Position bolts at marks and tighten bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders.(4) Install hood cover.

(5) Engage under hood lamp wire connector to

engine compartment wire harness.

(6) Verify hood operation and alignment.

HOOD SILENCER

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect hood lamp wire connector and

remove hood lamp (Fig. 21).

(3) Remove fasteners attaching hood silencer to

hood.

(4) Remove hood silencer from vehicle.

INSTALLATION

(1) Place hood silencer in position on vehicle.

(2) Install fastener attaching hood silencer to hood.

(3) Install hood lamp and connect wire connector.

(4) Close hood.

HOOD HINGE

REMOVAL

(1) Support hood on the side that requires hinge

replacement.

(2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height.

(3) Remove bolts holding hood to hinge.

(4) Remove bolts holding hood hinge to load beam

flange and separate hinge from vehicle. If necessary,

paint new hinge before installation.

INSTALLATION

(1) If necessary, paint new hinge before installa-

tion.

(2) Place hinge in position on vehicle.

(3) Install bolts to hold hood hinge to front fender

flange.

(4) Install bolts to hold hood to hinge.

(5) Align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. Shims can be added or removed under hood

hinge to achieve proper hood height.

(6) Remove support from under hood and verify

hood operation.

Fig. 19 Hood Release Cable

1 ± HOOD RELEASE HANDLE

2 ± COWL SIDE TRIM PANEL

23 - 26 BODYPL

REMOVAL AND INSTALLATION (Continued)