oil capacity DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1238 of 1285

SIDE WINDOW DEMISTERS

The demisters direct air from the unit housing

through the outlets located on the top corners of the

instrument panel. The demisters operate when the

mode selector is anywhere between floor and defrost

settings. Some air may be noticeable from the demis-

ter outlets when the mode selector is in the bilevel to

floor positions.

SYSTEM AIRFLOW

The system pulls outside (ambient) air through the

cowl opening at the base of the windshield. Then it

goes into the plenum chamber above the unit hous-

ing. On air conditioned vehicles, the air passes

through the evaporator. Air flow can be directed

either through or around the heater core. This is

done by adjusting the blend-air door with the TEMP

control on the instrument panel. The air flow can

then be directed from the panel, floor and defrost

outlets in various combinations using the mode selec-

tor. There are 17 different mode selections possible.

Air flow velocity can be adjusted with the blower

speed selector switch on the instrument panel.

On A/C equipped vehicles the ambient air intake

can be controlled by opening and closing the recircu-

lating air door. When placed in RECIRC, air that is

inside vehicle is removed continuously and recircu-

lated through unit housing. Ambient air cannot be

controlled on vehicles without A/C. The system uses

outside air at all times.

The air conditioning compressor can be engaged by

turning the fan switch counterclockwise from the off

position. It can also be engaged by placing the mode

control in the mix to defrost positions. This will

remove heat and humidity from the air before it is

directed through or around the heater core.

SYSTEM OIL LEVEL

It is important to have the correct amount of oil in

the A/C system to ensure proper lubrication of the

compressor. Too little oil will result in damage to the

compressor. Too much oil will reduce the cooling

capacity of the system and consequently result in

higher discharge air temperatures.

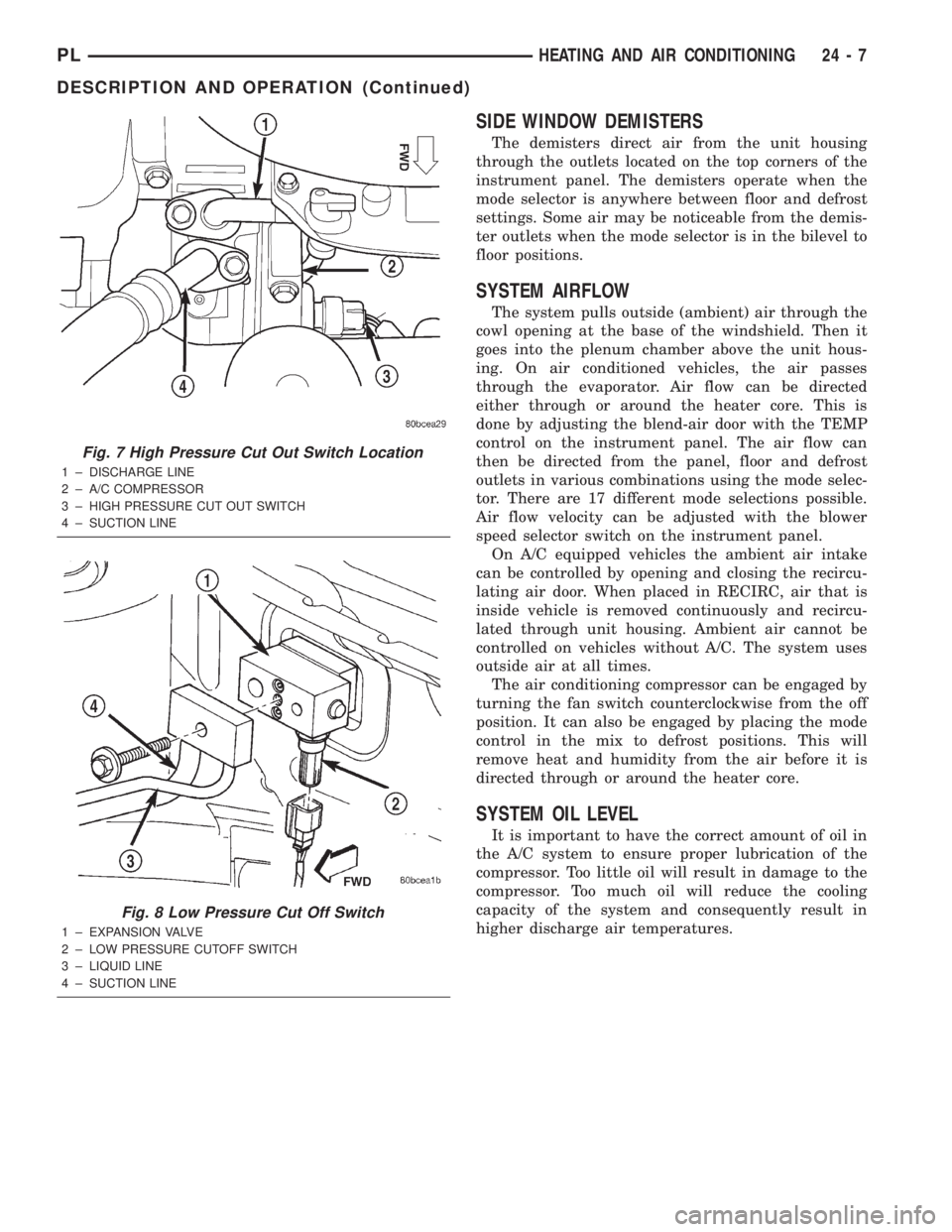

Fig. 7 High Pressure Cut Out Switch Location

1 ± DISCHARGE LINE

2 ± A/C COMPRESSOR

3 ± HIGH PRESSURE CUT OUT SWITCH

4 ± SUCTION LINE

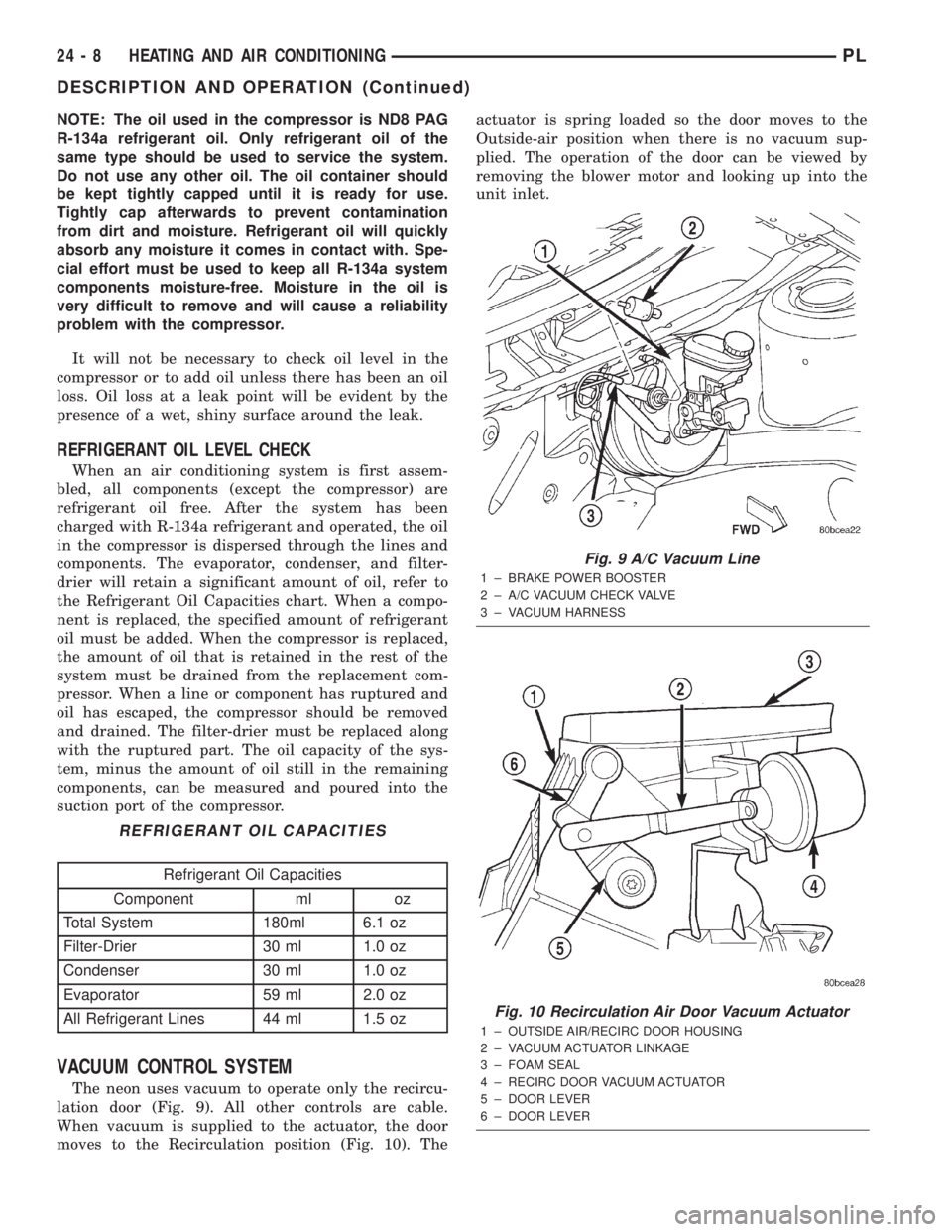

Fig. 8 Low Pressure Cut Off Switch

1 ± EXPANSION VALVE

2 ± LOW PRESSURE CUTOFF SWITCH

3 ± LIQUID LINE

4 ± SUCTION LINE

PLHEATING AND AIR CONDITIONING 24 - 7

DESCRIPTION AND OPERATION (Continued)

Page 1239 of 1285

NOTE: The oil used in the compressor is ND8 PAG

R-134a refrigerant oil. Only refrigerant oil of the

same type should be used to service the system.

Do not use any other oil. The oil container should

be kept tightly capped until it is ready for use.

Tightly cap afterwards to prevent contamination

from dirt and moisture. Refrigerant oil will quickly

absorb any moisture it comes in contact with. Spe-

cial effort must be used to keep all R-134a system

components moisture-free. Moisture in the oil is

very difficult to remove and will cause a reliability

problem with the compressor.

It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. Oil loss at a leak point will be evident by the

presence of a wet, shiny surface around the leak.

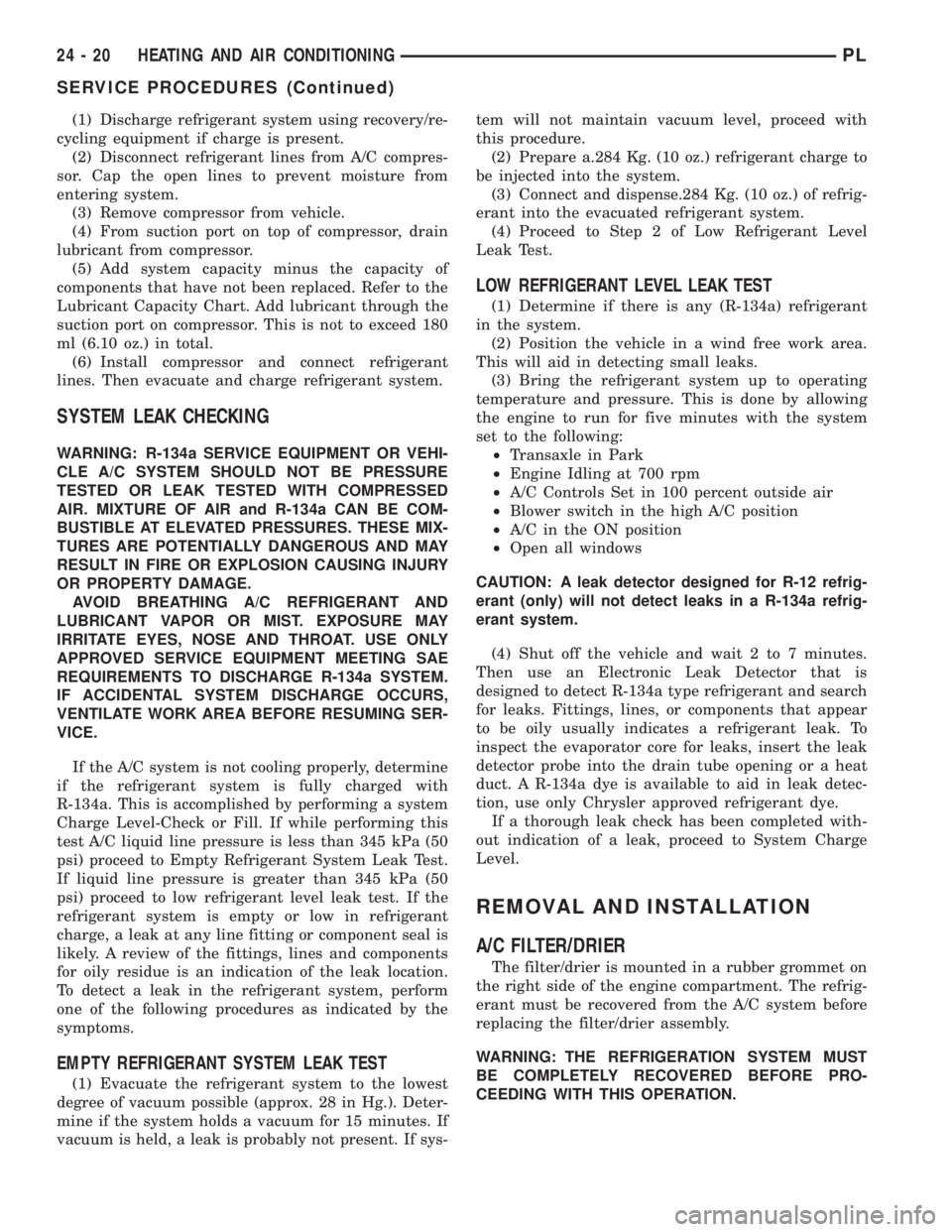

REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assem-

bled, all components (except the compressor) are

refrigerant oil free. After the system has been

charged with R-134a refrigerant and operated, the oil

in the compressor is dispersed through the lines and

components. The evaporator, condenser, and filter-

drier will retain a significant amount of oil, refer to

the Refrigerant Oil Capacities chart. When a compo-

nent is replaced, the specified amount of refrigerant

oil must be added. When the compressor is replaced,

the amount of oil that is retained in the rest of the

system must be drained from the replacement com-

pressor. When a line or component has ruptured and

oil has escaped, the compressor should be removed

and drained. The filter-drier must be replaced along

with the ruptured part. The oil capacity of the sys-

tem, minus the amount of oil still in the remaining

components, can be measured and poured into the

suction port of the compressor.

VACUUM CONTROL SYSTEM

The neon uses vacuum to operate only the recircu-

lation door (Fig. 9). All other controls are cable.

When vacuum is supplied to the actuator, the door

moves to the Recirculation position (Fig. 10). Theactuator is spring loaded so the door moves to the

Outside-air position when there is no vacuum sup-

plied. The operation of the door can be viewed by

removing the blower motor and looking up into the

unit inlet.

REFRIGERANT OIL CAPACITIES

Refrigerant Oil Capacities

Component ml oz

Total System 180ml 6.1 oz

Filter-Drier 30 ml 1.0 oz

Condenser 30 ml 1.0 oz

Evaporator 59 ml 2.0 oz

All Refrigerant Lines 44 ml 1.5 oz

Fig. 9 A/C Vacuum Line

1 ± BRAKE POWER BOOSTER

2 ± A/C VACUUM CHECK VALVE

3 ± VACUUM HARNESS

Fig. 10 Recirculation Air Door Vacuum Actuator

1 ± OUTSIDE AIR/RECIRC DOOR HOUSING

2 ± VACUUM ACTUATOR LINKAGE

3 ± FOAM SEAL

4 ± RECIRC DOOR VACUUM ACTUATOR

5 ± DOOR LEVER

6 ± DOOR LEVER

24 - 8 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1251 of 1285

(1) Discharge refrigerant system using recovery/re-

cycling equipment if charge is present.

(2) Disconnect refrigerant lines from A/C compres-

sor. Cap the open lines to prevent moisture from

entering system.

(3) Remove compressor from vehicle.

(4) From suction port on top of compressor, drain

lubricant from compressor.

(5) Add system capacity minus the capacity of

components that have not been replaced. Refer to the

Lubricant Capacity Chart. Add lubricant through the

suction port on compressor. This is not to exceed 180

ml (6.10 oz.) in total.

(6) Install compressor and connect refrigerant

lines. Then evacuate and charge refrigerant system.

SYSTEM LEAK CHECKING

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. MIXTURE OF AIR and R-134a CAN BE COM-

BUSTIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

AVOID BREATHING A/C REFRIGERANT AND

LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 345 kPa (50

psi) proceed to Empty Refrigerant System Leak Test.

If liquid line pressure is greater than 345 kPa (50

psi) proceed to low refrigerant level leak test. If the

refrigerant system is empty or low in refrigerant

charge, a leak at any line fitting or component seal is

likely. A review of the fittings, lines and components

for oily residue is an indication of the leak location.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

symptoms.

EMPTY REFRIGERANT SYSTEM LEAK TEST

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approx. 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-tem will not maintain vacuum level, proceed with

this procedure.

(2) Prepare a.284 Kg. (10 oz.) refrigerant charge to

be injected into the system.

(3) Connect and dispense.284 Kg. (10 oz.) of refrig-

erant into the evacuated refrigerant system.

(4) Proceed to Step 2 of Low Refrigerant Level

Leak Test.

LOW REFRIGERANT LEVEL LEAK TEST

(1) Determine if there is any (R-134a) refrigerant

in the system.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set in 100 percent outside air

²Blower switch in the high A/C position

²A/C in the ON position

²Open all windows

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only Chrysler approved refrigerant dye.

If a thorough leak check has been completed with-

out indication of a leak, proceed to System Charge

Level.

REMOVAL AND INSTALLATION

A/C FILTER/DRIER

The filter/drier is mounted in a rubber grommet on

the right side of the engine compartment. The refrig-

erant must be recovered from the A/C system before

replacing the filter/drier assembly.

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY RECOVERED BEFORE PRO-

CEEDING WITH THIS OPERATION.

24 - 20 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)