tra DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 19 of 1285

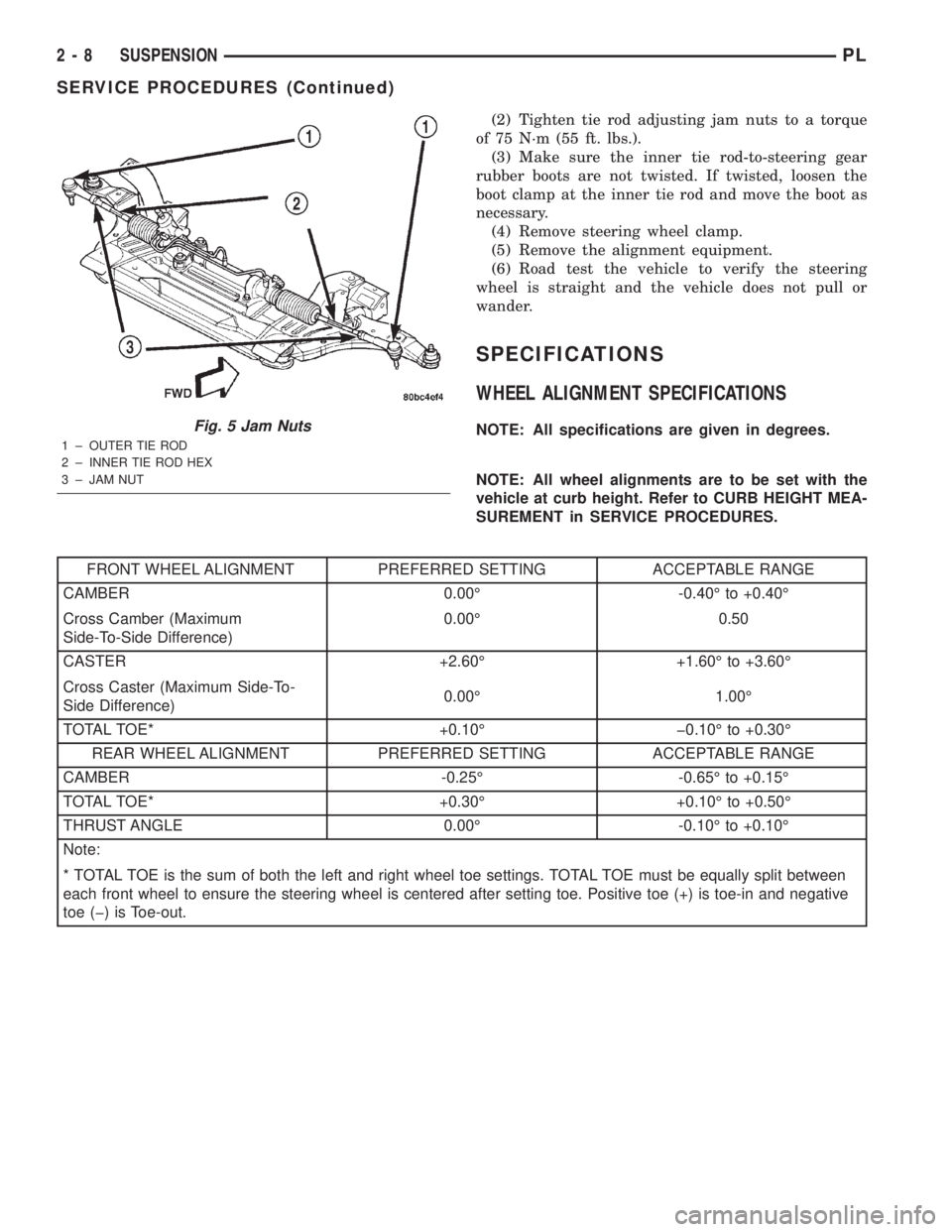

(2) Tighten tie rod adjusting jam nuts to a torque

of 75 N´m (55 ft. lbs.).

(3) Make sure the inner tie rod-to-steering gear

rubber boots are not twisted. If twisted, loosen the

boot clamp at the inner tie rod and move the boot as

necessary.

(4) Remove steering wheel clamp.

(5) Remove the alignment equipment.

(6) Road test the vehicle to verify the steering

wheel is straight and the vehicle does not pull or

wander.

SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS

NOTE: All specifications are given in degrees.

NOTE: All wheel alignments are to be set with the

vehicle at curb height. Refer to CURB HEIGHT MEA-

SUREMENT in SERVICE PROCEDURES.

FRONT WHEEL ALIGNMENT PREFERRED SETTING ACCEPTABLE RANGE

CAMBER 0.00É -0.40É to +0.40É

Cross Camber (Maximum

Side-To-Side Difference)0.00É 0.50

CASTER +2.60É +1.60É to +3.60É

Cross Caster (Maximum Side-To-

Side Difference)0.00É 1.00É

TOTAL TOE* +0.10É þ0.10É to +0.30É

REAR WHEEL ALIGNMENT PREFERRED SETTING ACCEPTABLE RANGE

CAMBER -0.25É -0.65É to +0.15É

TOTAL TOE* +0.30É +0.10É to +0.50É

THRUST ANGLE 0.00É -0.10É to +0.10É

Note:

* TOTAL TOE is the sum of both the left and right wheel toe settings. TOTAL TOE must be equally split between

each front wheel to ensure the steering wheel is centered after setting toe. Positive toe (+) is toe-in and negative

toe (þ) is Toe-out.

Fig. 5 Jam Nuts

1 ± OUTER TIE ROD

2 ± INNER TIE ROD HEX

3 ± JAM NUT

2 - 8 SUSPENSIONPL

SERVICE PROCEDURES (Continued)

Page 20 of 1285

FRONT SUSPENSION

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

FRONT SUSPENSION SYSTEM...............9

STRUT ASSEMBLY (FRONT)................11

STEERING KNUCKLE.....................11

LOWER CONTROL ARM...................11

STABILIZER BAR (FRONT).................12

DIAGNOSIS AND TESTING

STRUT ASSEMBLY (FRONT)................12

STEERING KNUCKLE.....................13

WHEEL BEARING AND HUB................13

LOWER CONTROL ARM...................13

BALL JOINT.............................13

STABILIZER BAR (FRONT).................14

SERVICE PROCEDURES

LUBRICATION...........................14

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........14STRUT ASSEMBLY (FRONT)................14

STEERING KNUCKLE.....................15

LOWER CONTROL ARM...................18

STABILIZER BAR (FRONT).................20

WHEEL MOUNTING STUD (FRONT)..........21

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (FRONT)................22

STEERING KNUCKLE (WHEEL BEARING AND

HUB).................................25

LOWER CONTROL ARM (BALL JOINT)........29

LOWER CONTROL ARM (REAR ISOLATOR

BUSHING).............................31

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

SPECIFICATIONS.......................33

SPECIAL TOOLS

FRONT SUSPENSION.....................33

DESCRIPTION AND OPERATION

FRONT SUSPENSION SYSTEM

The front suspension allows each front wheel on a

vehicle to adapt to different road surfaces and condi-

tions without greatly affecting the opposite wheel

and the ability to control the vehicle. Each side of the

front suspension is allowed to pivot so the vehicle can

be steered in the direction preferred.

This vehicle has a gas pressurized MacPherson

strut type front suspension design (Fig. 1).A strut assembly is used in place of the front sus-

pension upper control arm and upper ball joint.

When a vehicle strikes a bump, the force is trans-

ferred through the hub, bearing, and knuckle, into

the strut assembly to absorb the force and dampen it.

The top of the strut is mounted directly to the strut

tower of the vehicle. During steering maneuvers, the

strut assembly (through a pivot bearing in the upper

strut mount) and steering knuckle (through the lower

ball joint mounted on the lower control arm) turn as

an assembly.

PLSUSPENSION 2 - 9

Page 23 of 1285

BALL JOINT

The lower control arm connects to the steering

knuckle through a ball joint mounted at the outboard

end of the arm (Fig. 1). The ball joint is pressed into

the lower control arm and has a non-tapered stud

with a notch for steering knuckle pinch bolt clear-

ance. The ball joint stud is clamped and locked to the

steering knuckle lower leg using a pinch bolt.

The ball joint is lubricated for life during the man-

ufacturing process. Once lubricated for life, the

grease fitting head is snapped off by the manufac-

turer. This is done to eliminate the possibility of

lubrication later in the ball joints life thus damaging

the non-vented ball joint seal boot.

The ball joint used on this vehicle is replaceable

and, if found defective, can be serviced as a separate

component of the lower control arm.

STABILIZER BAR (FRONT)

The stabilizer bar helps control vehicle body roll.

Jounce and rebound movements affecting one wheel

are partially transmitted to the opposite wheel of the

vehicle to stabilize body roll.

The stabilizer bar interconnects both front lower

control arms of the vehicle and is attached to the

front suspension crossmember (Fig. 1).

Attachment of the stabilizer bar to the front sus-

pension crossmember is through 2 rubber-isolator

cushion and retainers (Fig. 1). The stabilizer bar

attachment to the lower control arm is done by uti-

lizing an isolated stabilizer bar link at each arm. All

components of the stabilizer bar are serviceable.

DIAGNOSIS AND TESTING

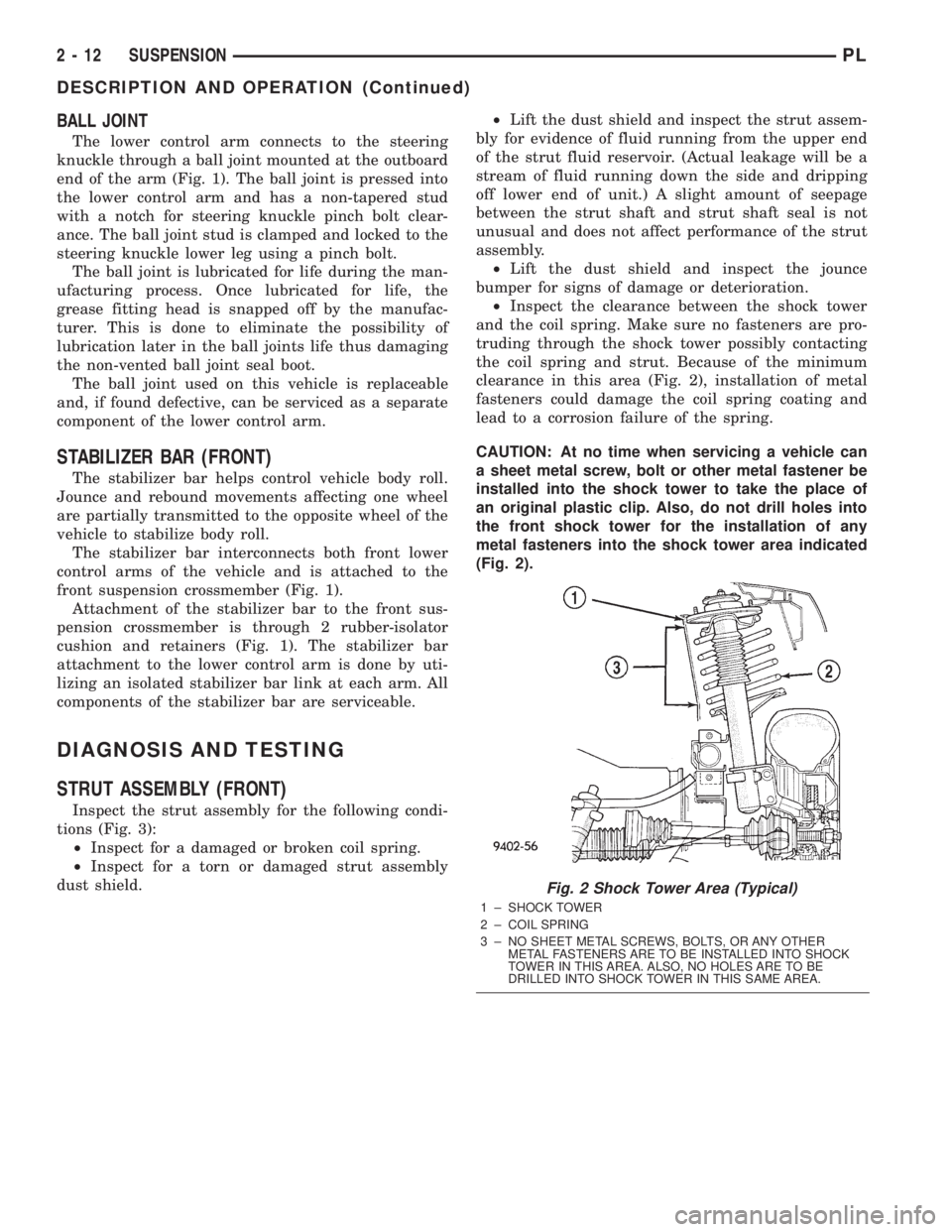

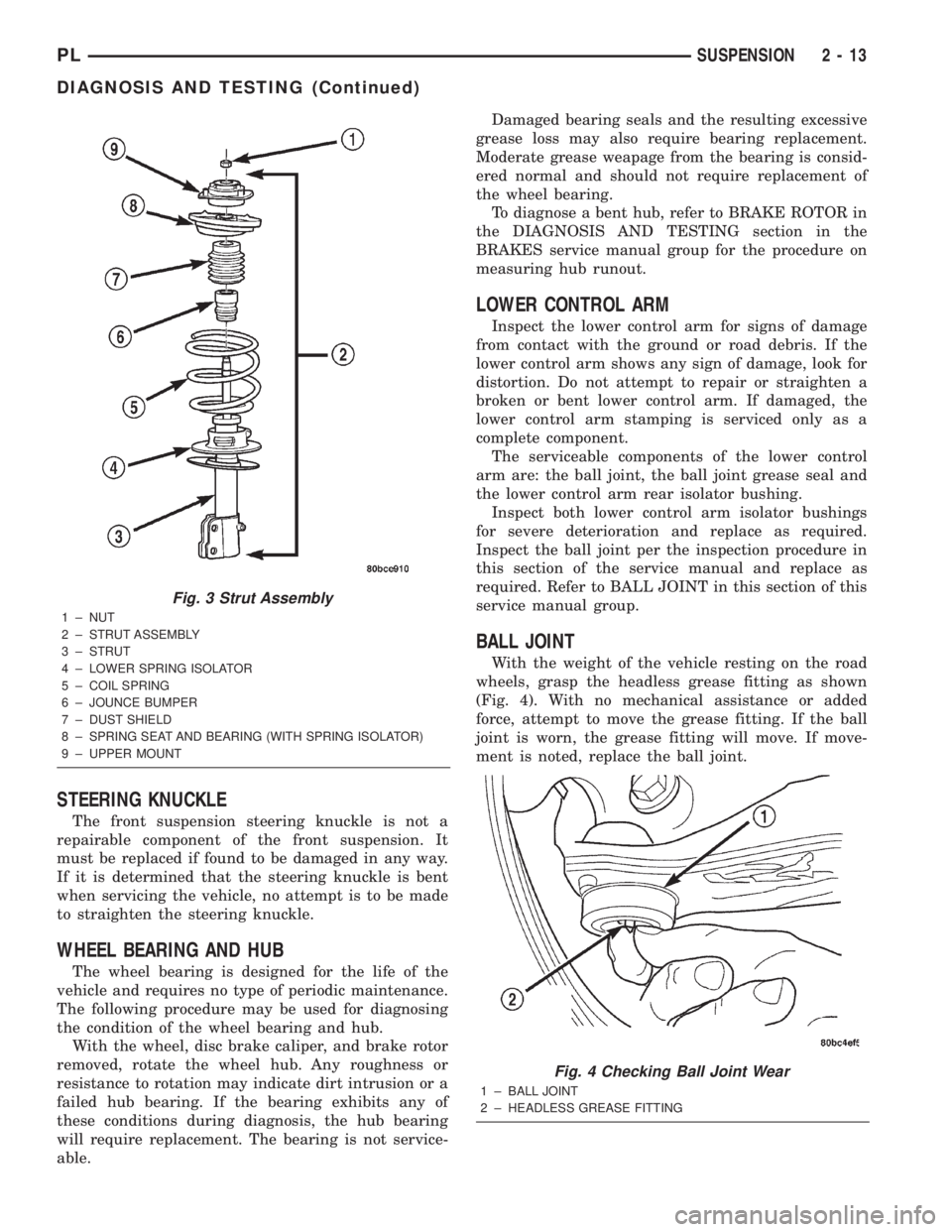

STRUT ASSEMBLY (FRONT)

Inspect the strut assembly for the following condi-

tions (Fig. 3):

²Inspect for a damaged or broken coil spring.

²Inspect for a torn or damaged strut assembly

dust shield.²Lift the dust shield and inspect the strut assem-

bly for evidence of fluid running from the upper end

of the strut fluid reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit.) A slight amount of seepage

between the strut shaft and strut shaft seal is not

unusual and does not affect performance of the strut

assembly.

²Lift the dust shield and inspect the jounce

bumper for signs of damage or deterioration.

²Inspect the clearance between the shock tower

and the coil spring. Make sure no fasteners are pro-

truding through the shock tower possibly contacting

the coil spring and strut. Because of the minimum

clearance in this area (Fig. 2), installation of metal

fasteners could damage the coil spring coating and

lead to a corrosion failure of the spring.

CAUTION: At no time when servicing a vehicle can

a sheet metal screw, bolt or other metal fastener be

installed into the shock tower to take the place of

an original plastic clip. Also, do not drill holes into

the front shock tower for the installation of any

metal fasteners into the shock tower area indicated

(Fig. 2).

Fig. 2 Shock Tower Area (Typical)

1 ± SHOCK TOWER

2 ± COIL SPRING

3 ± NO SHEET METAL SCREWS, BOLTS, OR ANY OTHER

METAL FASTENERS ARE TO BE INSTALLED INTO SHOCK

TOWER IN THIS AREA. ALSO, NO HOLES ARE TO BE

DRILLED INTO SHOCK TOWER IN THIS SAME AREA.

2 - 12 SUSPENSIONPL

DESCRIPTION AND OPERATION (Continued)

Page 24 of 1285

STEERING KNUCKLE

The front suspension steering knuckle is not a

repairable component of the front suspension. It

must be replaced if found to be damaged in any way.

If it is determined that the steering knuckle is bent

when servicing the vehicle, no attempt is to be made

to straighten the steering knuckle.

WHEEL BEARING AND HUB

The wheel bearing is designed for the life of the

vehicle and requires no type of periodic maintenance.

The following procedure may be used for diagnosing

the condition of the wheel bearing and hub.

With the wheel, disc brake caliper, and brake rotor

removed, rotate the wheel hub. Any roughness or

resistance to rotation may indicate dirt intrusion or a

failed hub bearing. If the bearing exhibits any of

these conditions during diagnosis, the hub bearing

will require replacement. The bearing is not service-

able.Damaged bearing seals and the resulting excessive

grease loss may also require bearing replacement.

Moderate grease weapage from the bearing is consid-

ered normal and should not require replacement of

the wheel bearing.

To diagnose a bent hub, refer to BRAKE ROTOR in

the DIAGNOSIS AND TESTING section in the

BRAKES service manual group for the procedure on

measuring hub runout.

LOWER CONTROL ARM

Inspect the lower control arm for signs of damage

from contact with the ground or road debris. If the

lower control arm shows any sign of damage, look for

distortion. Do not attempt to repair or straighten a

broken or bent lower control arm. If damaged, the

lower control arm stamping is serviced only as a

complete component.

The serviceable components of the lower control

arm are: the ball joint, the ball joint grease seal and

the lower control arm rear isolator bushing.

Inspect both lower control arm isolator bushings

for severe deterioration and replace as required.

Inspect the ball joint per the inspection procedure in

this section of the service manual and replace as

required. Refer to BALL JOINT in this section of this

service manual group.

BALL JOINT

With the weight of the vehicle resting on the road

wheels, grasp the headless grease fitting as shown

(Fig. 4). With no mechanical assistance or added

force, attempt to move the grease fitting. If the ball

joint is worn, the grease fitting will move. If move-

ment is noted, replace the ball joint.

Fig. 3 Strut Assembly

1 ± NUT

2 ± STRUT ASSEMBLY

3 ± STRUT

4 ± LOWER SPRING ISOLATOR

5 ± COIL SPRING

6 ± JOUNCE BUMPER

7 ± DUST SHIELD

8 ± SPRING SEAT AND BEARING (WITH SPRING ISOLATOR)

9 ± UPPER MOUNT

Fig. 4 Checking Ball Joint Wear

1 ± BALL JOINT

2 ± HEADLESS GREASE FITTING

PLSUSPENSION 2 - 13

DIAGNOSIS AND TESTING (Continued)

Page 25 of 1285

CAUTION: No attempt should be made to service

the headless grease fitting on the ball joint. It has

been purposely snapped off by the manufacturer to

avoid over-greasing.

STABILIZER BAR (FRONT)

Inspect for broken, cracked or distorted stabilizer

bar cushions and retainers. Inspect for worn or dam-

aged stabilizer bar links (Fig. 1).

SERVICE PROCEDURES

LUBRICATION

There are no serviceable lubrication points on the

front suspension. The front lower ball joints have

grease fittings which have had the head snapped off

by the manufacturer after they have been filled. This

has been done to eliminate the possibility of damag-

ing the non-vented seals. Grease will not leak from

the broken grease fittings. The ball joints are sealed

for life and require no maintenance.

CAUTION: No attempt should be made to replace

the ball joint grease fitting with a new fitting, then

filling the ball joint with grease. Damage to the

grease seal can result.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT WHILE STRUT ASSEMBLY IS INSTALLED IN

VEHICLE, OR BEFORE THE COIL SPRING IS COM-

PRESSED WITH A COMPRESSION TOOL. THE

SPRING IS HELD UNDER HIGH PRESSURE.

CAUTION: Only frame contact hoisting equipment

can be used on this vehicle. All vehicles have a

fully independent rear suspension. The vehicles

cannot be hoisted using equipment designed to lift

a vehicle by the rear axle. If this type of hoisting

equipment is used, damage to rear suspension

components will occur.

CAUTION: At no time when servicing a vehicle can

a sheet metal screw, bolt, or other metal fastener be

installed in the shock tower to take the place of an

original plastic clip. It may come into contact with

the strut or coil spring.CAUTION: Wheel bearing damage will result if after

loosening the hub nut, the vehicle is rolled on the

ground or the weight of the vehicle is allowed to be

supported by the tires for a length of time.

STRUT ASSEMBLY (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove tire and wheel assembly from location

on front of vehicle requiring strut removal.

(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

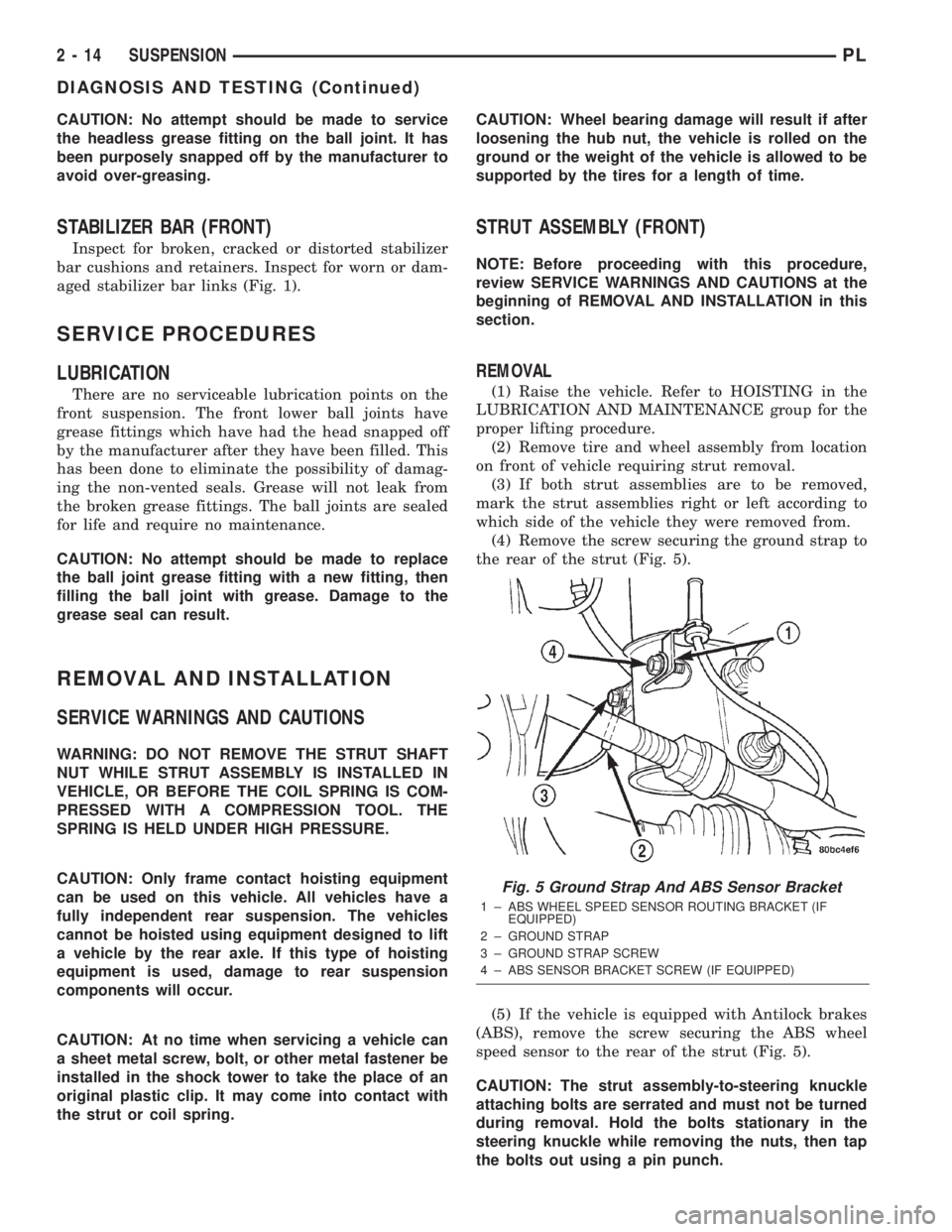

(4) Remove the screw securing the ground strap to

the rear of the strut (Fig. 5).

(5) If the vehicle is equipped with Antilock brakes

(ABS), remove the screw securing the ABS wheel

speed sensor to the rear of the strut (Fig. 5).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during removal. Hold the bolts stationary in the

steering knuckle while removing the nuts, then tap

the bolts out using a pin punch.

Fig. 5 Ground Strap And ABS Sensor Bracket

1 ± ABS WHEEL SPEED SENSOR ROUTING BRACKET (IF

EQUIPPED)

2 ± GROUND STRAP

3 ± GROUND STRAP SCREW

4 ± ABS SENSOR BRACKET SCREW (IF EQUIPPED)

2 - 14 SUSPENSIONPL

DIAGNOSIS AND TESTING (Continued)

Page 26 of 1285

(6) Remove the two bolts attaching the strut to the

steering knuckle (Fig. 1).

(7) Lower the vehicle just enough to open the

hood, but without letting the tires touch the floor.

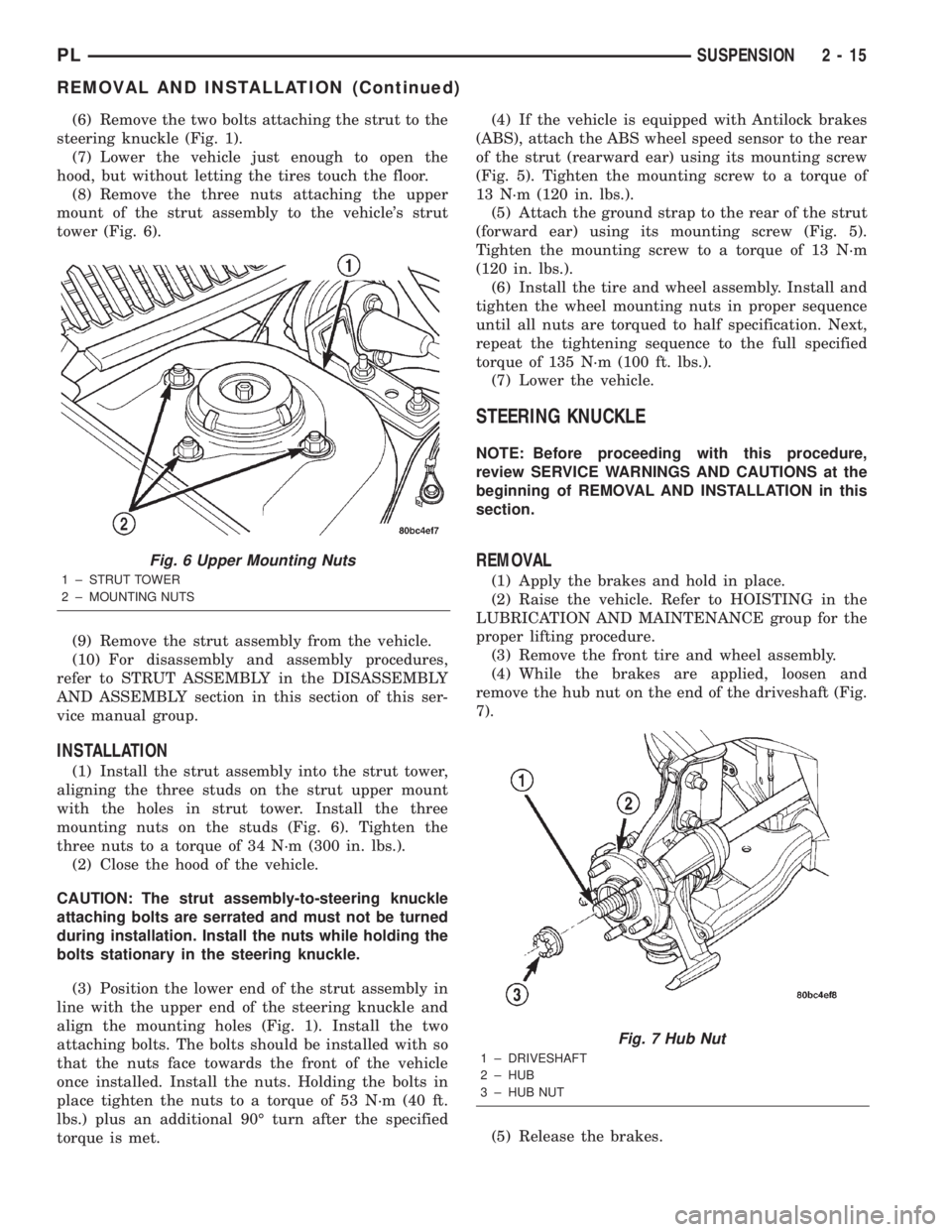

(8) Remove the three nuts attaching the upper

mount of the strut assembly to the vehicle's strut

tower (Fig. 6).

(9) Remove the strut assembly from the vehicle.

(10) For disassembly and assembly procedures,

refer to STRUT ASSEMBLY in the DISASSEMBLY

AND ASSEMBLY section in this section of this ser-

vice manual group.

INSTALLATION

(1) Install the strut assembly into the strut tower,

aligning the three studs on the strut upper mount

with the holes in strut tower. Install the three

mounting nuts on the studs (Fig. 6). Tighten the

three nuts to a torque of 34 N´m (300 in. lbs.).

(2) Close the hood of the vehicle.

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during installation. Install the nuts while holding the

bolts stationary in the steering knuckle.

(3) Position the lower end of the strut assembly in

line with the upper end of the steering knuckle and

align the mounting holes (Fig. 1). Install the two

attaching bolts. The bolts should be installed with so

that the nuts face towards the front of the vehicle

once installed. Install the nuts. Holding the bolts in

place tighten the nuts to a torque of 53 N´m (40 ft.

lbs.) plus an additional 90É turn after the specified

torque is met.(4) If the vehicle is equipped with Antilock brakes

(ABS), attach the ABS wheel speed sensor to the rear

of the strut (rearward ear) using its mounting screw

(Fig. 5). Tighten the mounting screw to a torque of

13 N´m (120 in. lbs.).

(5) Attach the ground strap to the rear of the strut

(forward ear) using its mounting screw (Fig. 5).

Tighten the mounting screw to a torque of 13 N´m

(120 in. lbs.).

(6) Install the tire and wheel assembly. Install and

tighten the wheel mounting nuts in proper sequence

until all nuts are torqued to half specification. Next,

repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

(7) Lower the vehicle.

STEERING KNUCKLE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Apply the brakes and hold in place.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(3) Remove the front tire and wheel assembly.

(4) While the brakes are applied, loosen and

remove the hub nut on the end of the driveshaft (Fig.

7).

(5) Release the brakes.

Fig. 6 Upper Mounting Nuts

1 ± STRUT TOWER

2 ± MOUNTING NUTS

Fig. 7 Hub Nut

1 ± DRIVESHAFT

2 ± HUB

3 ± HUB NUT

PLSUSPENSION 2 - 15

REMOVAL AND INSTALLATION (Continued)

Page 28 of 1285

(12) Remove the tie rod heat shield.

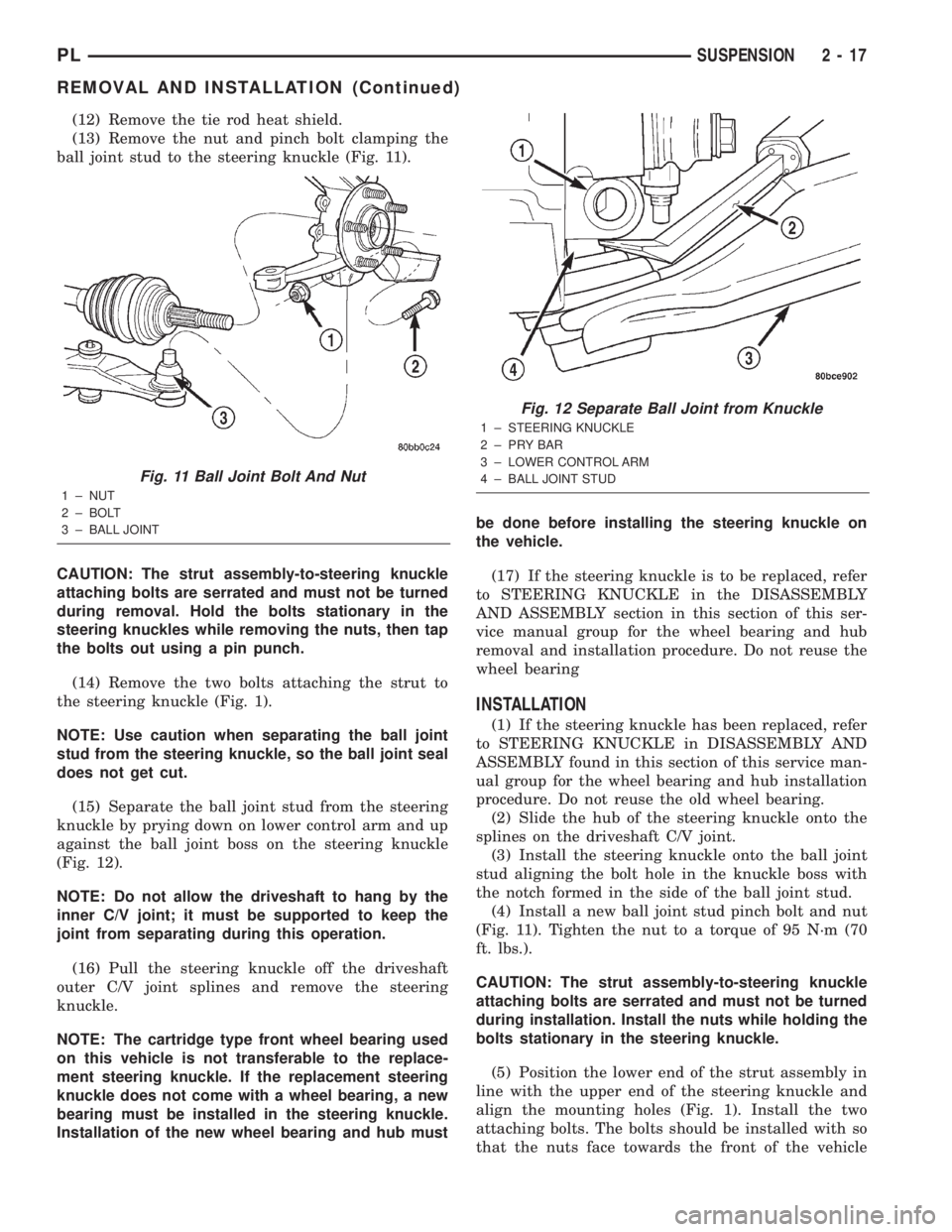

(13) Remove the nut and pinch bolt clamping the

ball joint stud to the steering knuckle (Fig. 11).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during removal. Hold the bolts stationary in the

steering knuckles while removing the nuts, then tap

the bolts out using a pin punch.

(14) Remove the two bolts attaching the strut to

the steering knuckle (Fig. 1).

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

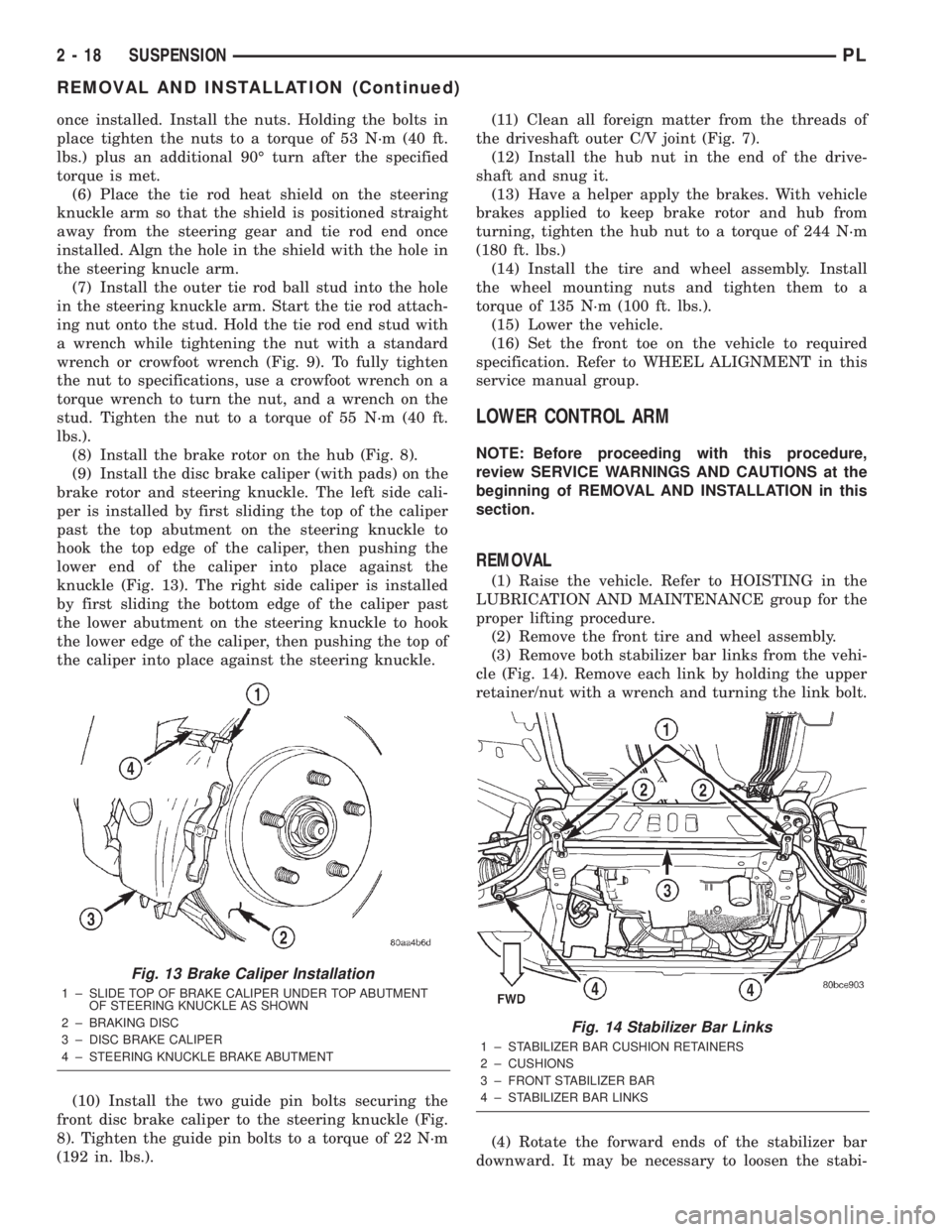

(15) Separate the ball joint stud from the steering

knuckle by prying down on lower control arm and up

against the ball joint boss on the steering knuckle

(Fig. 12).

NOTE: Do not allow the driveshaft to hang by the

inner C/V joint; it must be supported to keep the

joint from separating during this operation.

(16) Pull the steering knuckle off the driveshaft

outer C/V joint splines and remove the steering

knuckle.

NOTE: The cartridge type front wheel bearing used

on this vehicle is not transferable to the replace-

ment steering knuckle. If the replacement steering

knuckle does not come with a wheel bearing, a new

bearing must be installed in the steering knuckle.

Installation of the new wheel bearing and hub mustbe done before installing the steering knuckle on

the vehicle.

(17) If the steering knuckle is to be replaced, refer

to STEERING KNUCKLE in the DISASSEMBLY

AND ASSEMBLY section in this section of this ser-

vice manual group for the wheel bearing and hub

removal and installation procedure. Do not reuse the

wheel bearing

INSTALLATION

(1) If the steering knuckle has been replaced, refer

to STEERING KNUCKLE in DISASSEMBLY AND

ASSEMBLY found in this section of this service man-

ual group for the wheel bearing and hub installation

procedure. Do not reuse the old wheel bearing.

(2) Slide the hub of the steering knuckle onto the

splines on the driveshaft C/V joint.

(3) Install the steering knuckle onto the ball joint

stud aligning the bolt hole in the knuckle boss with

the notch formed in the side of the ball joint stud.

(4) Install a new ball joint stud pinch bolt and nut

(Fig. 11). Tighten the nut to a torque of 95 N´m (70

ft. lbs.).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during installation. Install the nuts while holding the

bolts stationary in the steering knuckle.

(5) Position the lower end of the strut assembly in

line with the upper end of the steering knuckle and

align the mounting holes (Fig. 1). Install the two

attaching bolts. The bolts should be installed with so

that the nuts face towards the front of the vehicle

Fig. 11 Ball Joint Bolt And Nut

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 12 Separate Ball Joint from Knuckle

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

PLSUSPENSION 2 - 17

REMOVAL AND INSTALLATION (Continued)

Page 29 of 1285

once installed. Install the nuts. Holding the bolts in

place tighten the nuts to a torque of 53 N´m (40 ft.

lbs.) plus an additional 90É turn after the specified

torque is met.

(6) Place the tie rod heat shield on the steering

knuckle arm so that the shield is positioned straight

away from the steering gear and tie rod end once

installed. Algn the hole in the shield with the hole in

the steering knucle arm.

(7) Install the outer tie rod ball stud into the hole

in the steering knuckle arm. Start the tie rod attach-

ing nut onto the stud. Hold the tie rod end stud with

a wrench while tightening the nut with a standard

wrench or crowfoot wrench (Fig. 9). To fully tighten

the nut to specifications, use a crowfoot wrench on a

torque wrench to turn the nut, and a wrench on the

stud. Tighten the nut to a torque of 55 N´m (40 ft.

lbs.).

(8) Install the brake rotor on the hub (Fig. 8).

(9) Install the disc brake caliper (with pads) on the

brake rotor and steering knuckle. The left side cali-

per is installed by first sliding the top of the caliper

past the top abutment on the steering knuckle to

hook the top edge of the caliper, then pushing the

lower end of the caliper into place against the

knuckle (Fig. 13). The right side caliper is installed

by first sliding the bottom edge of the caliper past

the lower abutment on the steering knuckle to hook

the lower edge of the caliper, then pushing the top of

the caliper into place against the steering knuckle.

(10) Install the two guide pin bolts securing the

front disc brake caliper to the steering knuckle (Fig.

8). Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).(11) Clean all foreign matter from the threads of

the driveshaft outer C/V joint (Fig. 7).

(12) Install the hub nut in the end of the drive-

shaft and snug it.

(13) Have a helper apply the brakes. With vehicle

brakes applied to keep brake rotor and hub from

turning, tighten the hub nut to a torque of 244 N´m

(180 ft. lbs.)

(14) Install the tire and wheel assembly. Install

the wheel mounting nuts and tighten them to a

torque of 135 N´m (100 ft. lbs.).

(15) Lower the vehicle.

(16) Set the front toe on the vehicle to required

specification. Refer to WHEEL ALIGNMENT in this

service manual group.

LOWER CONTROL ARM

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the front tire and wheel assembly.

(3) Remove both stabilizer bar links from the vehi-

cle (Fig. 14). Remove each link by holding the upper

retainer/nut with a wrench and turning the link bolt.

(4) Rotate the forward ends of the stabilizer bar

downward. It may be necessary to loosen the stabi-

Fig. 13 Brake Caliper Installation

1 ± SLIDE TOP OF BRAKE CALIPER UNDER TOP ABUTMENT

OF STEERING KNUCKLE AS SHOWN

2 ± BRAKING DISC

3 ± DISC BRAKE CALIPER

4 ± STEERING KNUCKLE BRAKE ABUTMENT

Fig. 14 Stabilizer Bar Links

1 ± STABILIZER BAR CUSHION RETAINERS

2 ± CUSHIONS

3 ± FRONT STABILIZER BAR

4 ± STABILIZER BAR LINKS

2 - 18 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 31 of 1285

with the notch formed in the side of the ball joint

stud.

(4) If the right lower control arm has been ser-

viced, install the engine torque strut (Fig. 16). Follow

the procedure described in the ENGINE service man-

ual group to properly align and tighten the torque

strut.

(5) Install a new ball joint stud pinch bolt and nut

(Fig. 15). Tighten the nut to a torque of 95 N´m (70

ft. lbs.).

(6) Rotate the forward ends of the stabilizer bar

into mounting position.

(7) Install both stabilizer bar links back on vehicle

(Fig. 14). Start each stabilizer bar link bolt with

bushing from the bottom, through the stabilizer bar,

inner link bushings, lower control arm, and into the

upper retainer/nut and bushing (Fig. 1). Do not fully

tighten the link assemblies at this time.

(8) Lower the vehicle to ground level.

NOTE: It may be necessary to put the vehicle on a

platform hoist or alignment rack to gain access to

the stabilizer bar mounting bolts with the vehicle at

curb height.

(9) Tighten each stabilizer bar link by holding the

upper retainer/nut with a wrench and turning the

link bolt. Tighten each link bolt to a torque of 23

N´m (200 in. lbs.).

(10) If previously loosened, tighten the stabilizer

bar cushion retainer bolts to a torque of 28 N´m (250

in. lbs.).

STABILIZER BAR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

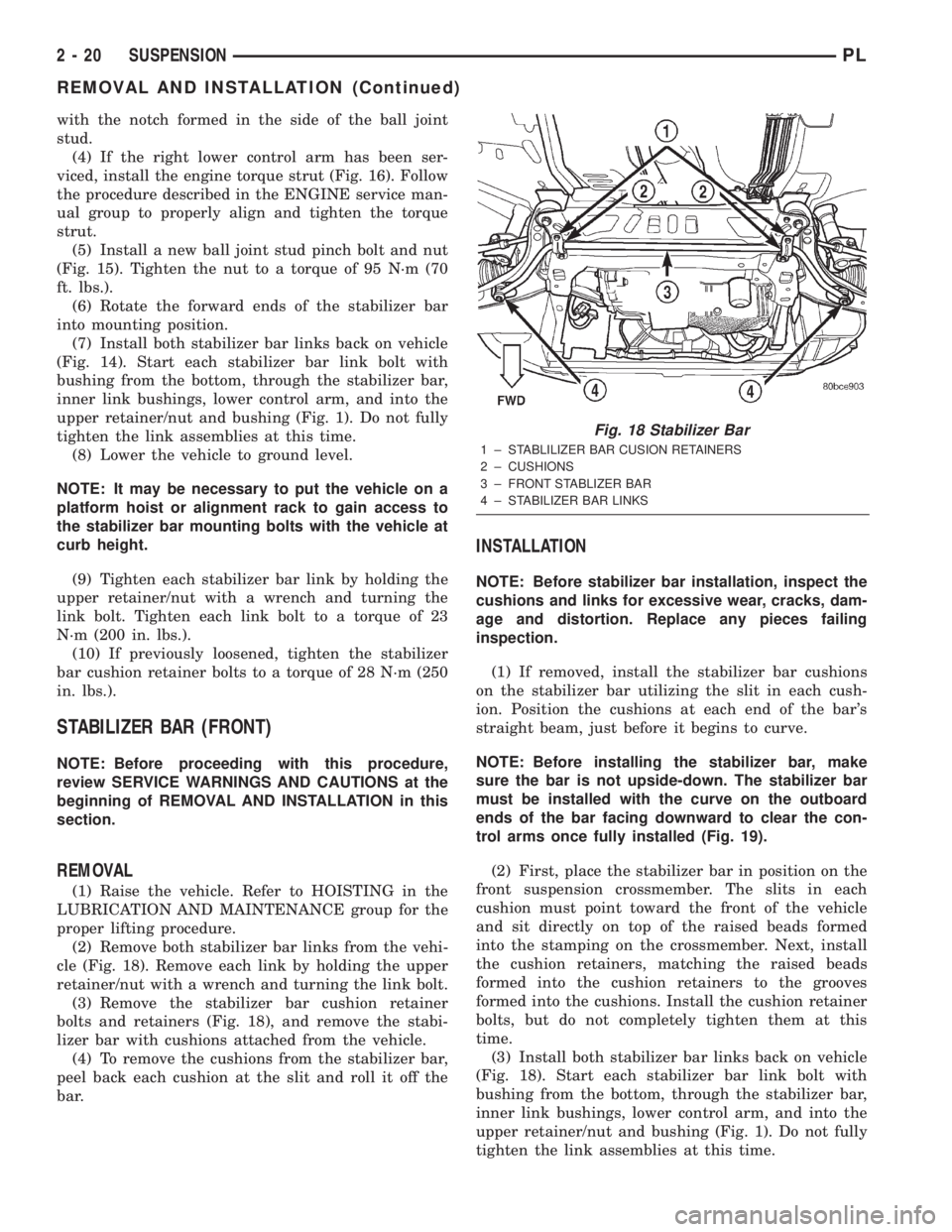

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove both stabilizer bar links from the vehi-

cle (Fig. 18). Remove each link by holding the upper

retainer/nut with a wrench and turning the link bolt.

(3) Remove the stabilizer bar cushion retainer

bolts and retainers (Fig. 18), and remove the stabi-

lizer bar with cushions attached from the vehicle.

(4) To remove the cushions from the stabilizer bar,

peel back each cushion at the slit and roll it off the

bar.

INSTALLATION

NOTE: Before stabilizer bar installation, inspect the

cushions and links for excessive wear, cracks, dam-

age and distortion. Replace any pieces failing

inspection.

(1) If removed, install the stabilizer bar cushions

on the stabilizer bar utilizing the slit in each cush-

ion. Position the cushions at each end of the bar's

straight beam, just before it begins to curve.

NOTE: Before installing the stabilizer bar, make

sure the bar is not upside-down. The stabilizer bar

must be installed with the curve on the outboard

ends of the bar facing downward to clear the con-

trol arms once fully installed (Fig. 19).

(2) First, place the stabilizer bar in position on the

front suspension crossmember. The slits in each

cushion must point toward the front of the vehicle

and sit directly on top of the raised beads formed

into the stamping on the crossmember. Next, install

the cushion retainers, matching the raised beads

formed into the cushion retainers to the grooves

formed into the cushions. Install the cushion retainer

bolts, but do not completely tighten them at this

time.

(3) Install both stabilizer bar links back on vehicle

(Fig. 18). Start each stabilizer bar link bolt with

bushing from the bottom, through the stabilizer bar,

inner link bushings, lower control arm, and into the

upper retainer/nut and bushing (Fig. 1). Do not fully

tighten the link assemblies at this time.

Fig. 18 Stabilizer Bar

1 ± STABLILIZER BAR CUSION RETAINERS

2 ± CUSHIONS

3 ± FRONT STABLIZER BAR

4 ± STABILIZER BAR LINKS

2 - 20 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 34 of 1285

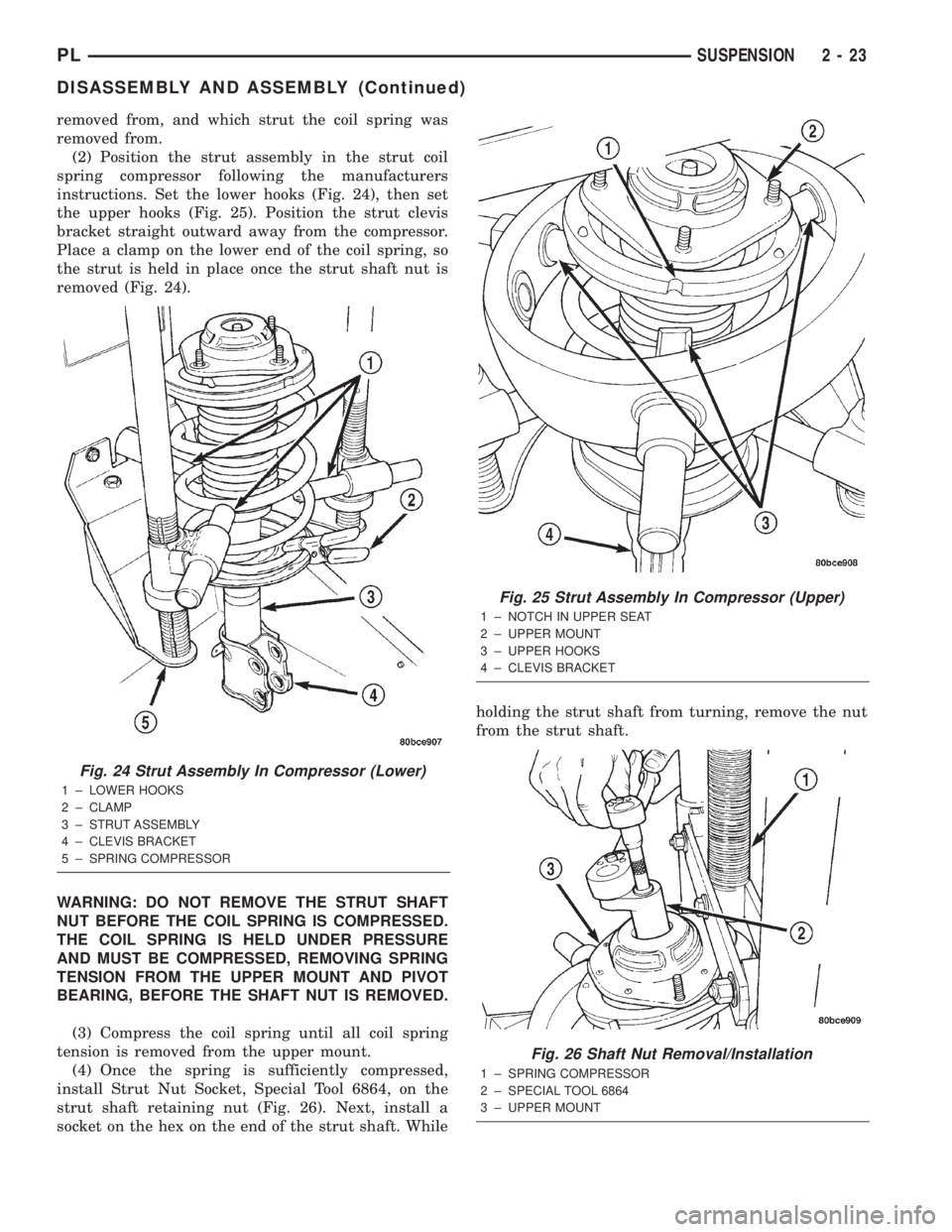

removed from, and which strut the coil spring was

removed from.

(2) Position the strut assembly in the strut coil

spring compressor following the manufacturers

instructions. Set the lower hooks (Fig. 24), then set

the upper hooks (Fig. 25). Position the strut clevis

bracket straight outward away from the compressor.

Place a clamp on the lower end of the coil spring, so

the strut is held in place once the strut shaft nut is

removed (Fig. 24).

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT BEFORE THE COIL SPRING IS COMPRESSED.

THE COIL SPRING IS HELD UNDER PRESSURE

AND MUST BE COMPRESSED, REMOVING SPRING

TENSION FROM THE UPPER MOUNT AND PIVOT

BEARING, BEFORE THE SHAFT NUT IS REMOVED.

(3) Compress the coil spring until all coil spring

tension is removed from the upper mount.

(4) Once the spring is sufficiently compressed,

install Strut Nut Socket, Special Tool 6864, on the

strut shaft retaining nut (Fig. 26). Next, install a

socket on the hex on the end of the strut shaft. Whileholding the strut shaft from turning, remove the nut

from the strut shaft.

Fig. 24 Strut Assembly In Compressor (Lower)

1 ± LOWER HOOKS

2 ± CLAMP

3 ± STRUT ASSEMBLY

4 ± CLEVIS BRACKET

5 ± SPRING COMPRESSOR

Fig. 25 Strut Assembly In Compressor (Upper)

1 ± NOTCH IN UPPER SEAT

2 ± UPPER MOUNT

3 ± UPPER HOOKS

4 ± CLEVIS BRACKET

Fig. 26 Shaft Nut Removal/Installation

1 ± SPRING COMPRESSOR

2 ± SPECIAL TOOL 6864

3 ± UPPER MOUNT

PLSUSPENSION 2 - 23

DISASSEMBLY AND ASSEMBLY (Continued)