water pump DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 198 of 1285

COOLING SYSTEMÐDRAINING

NOTE: Drain, flush, and fill the cooling system at

the mileage or time intervals specified in Group 0,

Lubrication and Maintenance. If the solution is dirty,

rusty, or contains a considerable amount of sedi-

ment; clean and flush with a reliable cooling system

cleaner. Care should be taken in disposing of the

used engine coolant from your vehicle. Check gov-

ernmental regulations for disposal of used engine

coolant.

Without removing radiator pressure cap and

with system not under pressure:

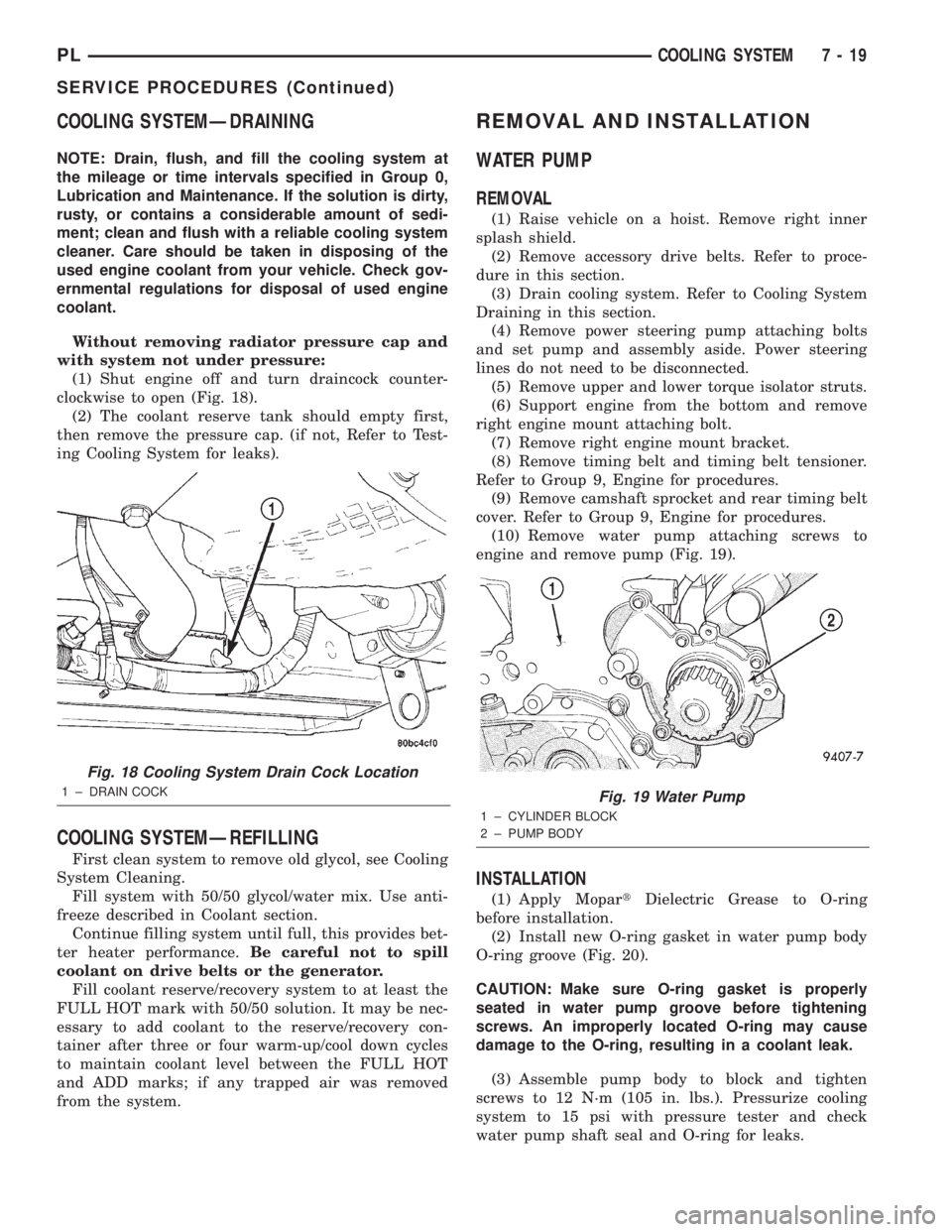

(1) Shut engine off and turn draincock counter-

clockwise to open (Fig. 18).

(2) The coolant reserve tank should empty first,

then remove the pressure cap. (if not, Refer to Test-

ing Cooling System for leaks).

COOLING SYSTEMÐREFILLING

First clean system to remove old glycol, see Cooling

System Cleaning.

Fill system with 50/50 glycol/water mix. Use anti-

freeze described in Coolant section.

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve/recovery system to at least the

FULL HOT mark with 50/50 solution. It may be nec-

essary to add coolant to the reserve/recovery con-

tainer after three or four warm-up/cool down cycles

to maintain coolant level between the FULL HOT

and ADD marks; if any trapped air was removed

from the system.

REMOVAL AND INSTALLATION

WATER PUMP

REMOVAL

(1) Raise vehicle on a hoist. Remove right inner

splash shield.

(2) Remove accessory drive belts. Refer to proce-

dure in this section.

(3) Drain cooling system. Refer to Cooling System

Draining in this section.

(4) Remove power steering pump attaching bolts

and set pump and assembly aside. Power steering

lines do not need to be disconnected.

(5) Remove upper and lower torque isolator struts.

(6) Support engine from the bottom and remove

right engine mount attaching bolt.

(7) Remove right engine mount bracket.

(8) Remove timing belt and timing belt tensioner.

Refer to Group 9, Engine for procedures.

(9) Remove camshaft sprocket and rear timing belt

cover. Refer to Group 9, Engine for procedures.

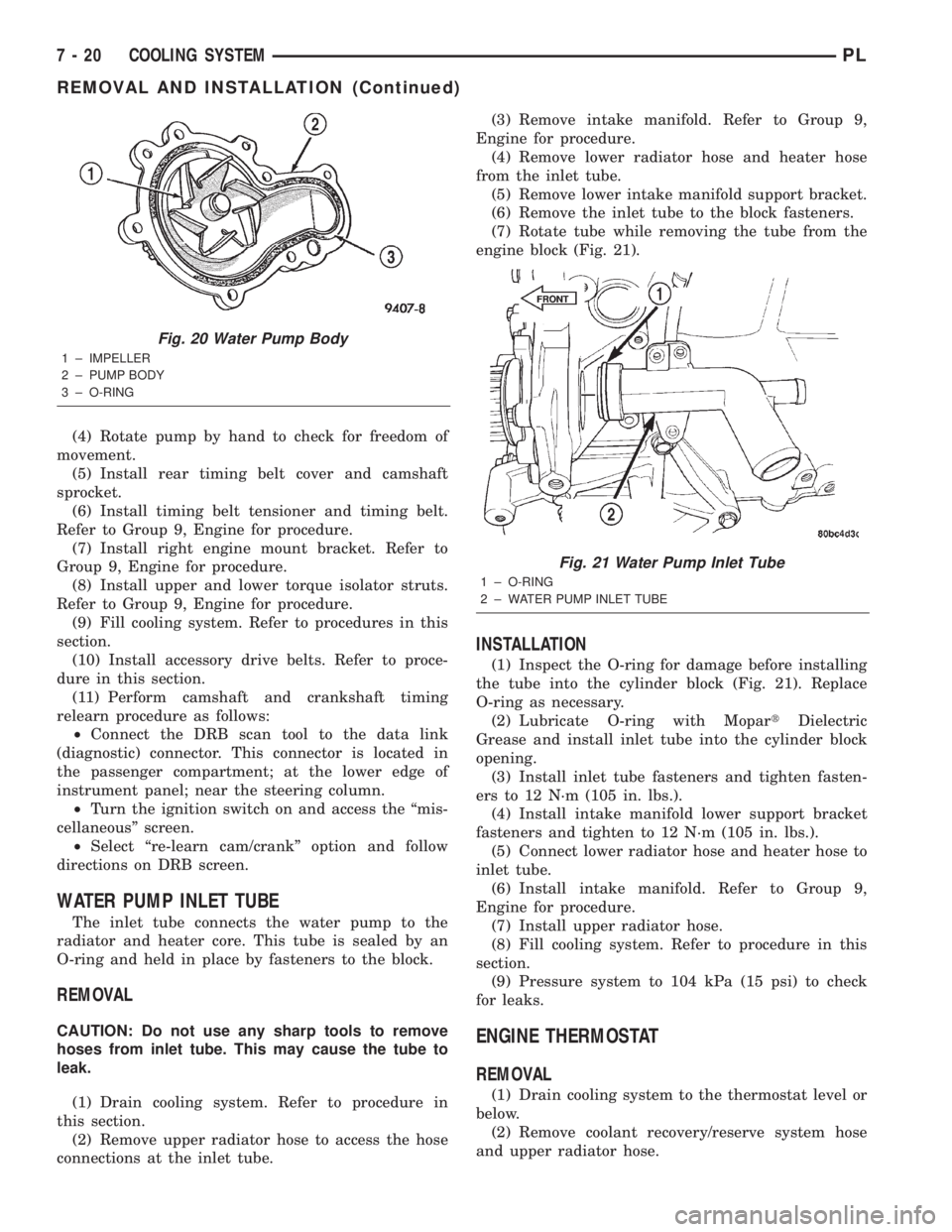

(10) Remove water pump attaching screws to

engine and remove pump (Fig. 19).

INSTALLATION

(1) Apply MopartDielectric Grease to O-ring

before installation.

(2) Install new O-ring gasket in water pump body

O-ring groove (Fig. 20).

CAUTION: Make sure O-ring gasket is properly

seated in water pump groove before tightening

screws. An improperly located O-ring may cause

damage to the O-ring, resulting in a coolant leak.

(3) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 15 psi with pressure tester and check

water pump shaft seal and O-ring for leaks.

Fig. 18 Cooling System Drain Cock Location

1 ± DRAIN COCKFig. 19 Water Pump

1 ± CYLINDER BLOCK

2 ± PUMP BODY

PLCOOLING SYSTEM 7 - 19

SERVICE PROCEDURES (Continued)

Page 199 of 1285

(4) Rotate pump by hand to check for freedom of

movement.

(5) Install rear timing belt cover and camshaft

sprocket.

(6) Install timing belt tensioner and timing belt.

Refer to Group 9, Engine for procedure.

(7) Install right engine mount bracket. Refer to

Group 9, Engine for procedure.

(8) Install upper and lower torque isolator struts.

Refer to Group 9, Engine for procedure.

(9) Fill cooling system. Refer to procedures in this

section.

(10) Install accessory drive belts. Refer to proce-

dure in this section.

(11) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

WATER PUMP INLET TUBE

The inlet tube connects the water pump to the

radiator and heater core. This tube is sealed by an

O-ring and held in place by fasteners to the block.

REMOVAL

CAUTION: Do not use any sharp tools to remove

hoses from inlet tube. This may cause the tube to

leak.

(1) Drain cooling system. Refer to procedure in

this section.

(2) Remove upper radiator hose to access the hose

connections at the inlet tube.(3) Remove intake manifold. Refer to Group 9,

Engine for procedure.

(4) Remove lower radiator hose and heater hose

from the inlet tube.

(5) Remove lower intake manifold support bracket.

(6) Remove the inlet tube to the block fasteners.

(7) Rotate tube while removing the tube from the

engine block (Fig. 21).

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 21). Replace

O-ring as necessary.

(2) Lubricate O-ring with MopartDielectric

Grease and install inlet tube into the cylinder block

opening.

(3) Install inlet tube fasteners and tighten fasten-

ers to 12 N´m (105 in. lbs.).

(4) Install intake manifold lower support bracket

fasteners and tighten to 12 N´m (105 in. lbs.).

(5) Connect lower radiator hose and heater hose to

inlet tube.

(6) Install intake manifold. Refer to Group 9,

Engine for procedure.

(7) Install upper radiator hose.

(8) Fill cooling system. Refer to procedure in this

section.

(9) Pressure system to 104 kPa (15 psi) to check

for leaks.

ENGINE THERMOSTAT

REMOVAL

(1) Drain cooling system to the thermostat level or

below.

(2) Remove coolant recovery/reserve system hose

and upper radiator hose.

Fig. 20 Water Pump Body

1 ± IMPELLER

2 ± PUMP BODY

3 ± O-RING

Fig. 21 Water Pump Inlet Tube

1 ± O-RING

2 ± WATER PUMP INLET TUBE

FRONT

7 - 20 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 203 of 1285

(2) Connect recovery hose to water outlet connec-

tor/thermostat housing (Fig. 29).

(3) Fill container to proper level. Refer to Cooling

System Refilling in this section.

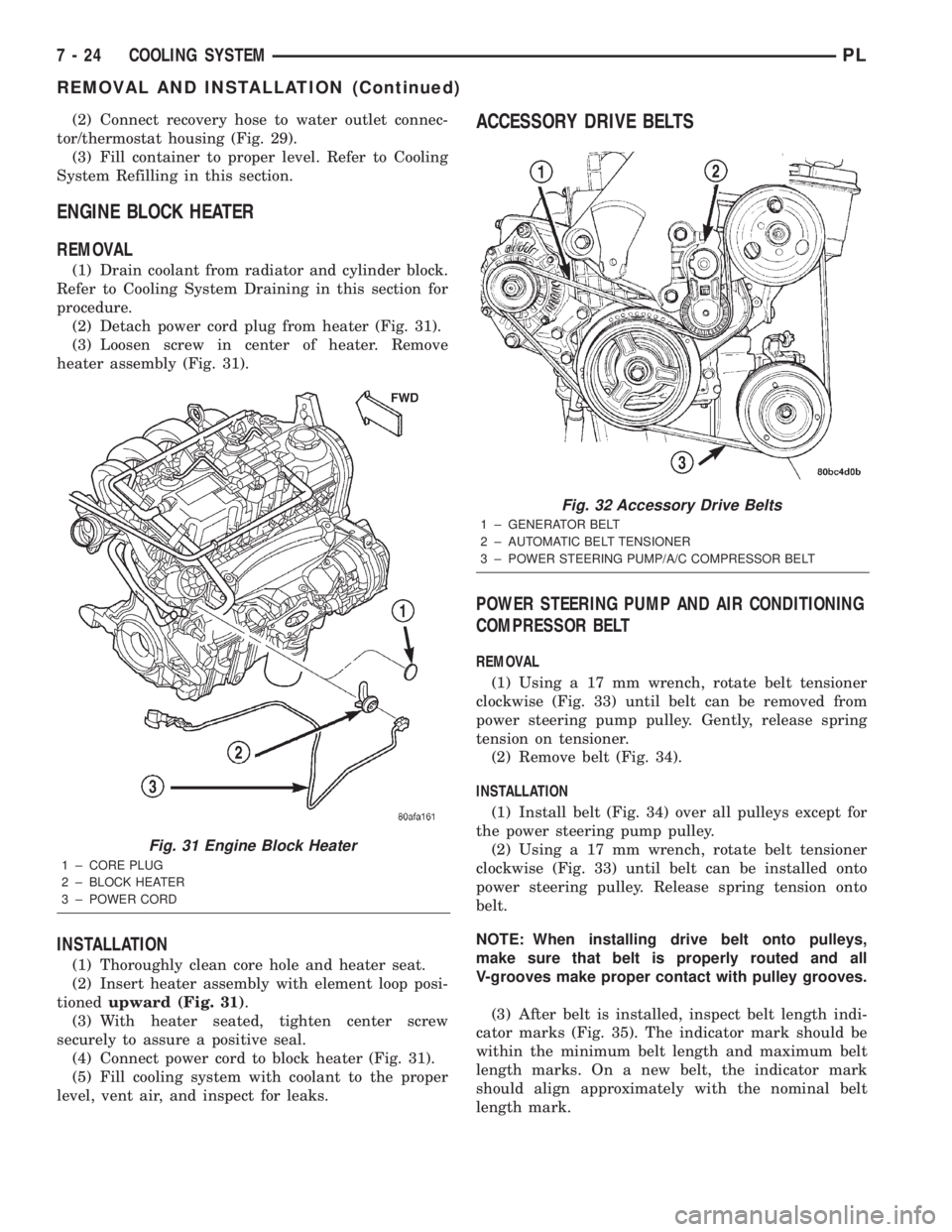

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Draining in this section for

procedure.

(2) Detach power cord plug from heater (Fig. 31).

(3) Loosen screw in center of heater. Remove

heater assembly (Fig. 31).

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward (Fig. 31).

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Connect power cord to block heater (Fig. 31).

(5) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks.

ACCESSORY DRIVE BELTS

POWER STEERING PUMP AND AIR CONDITIONING

COMPRESSOR BELT

REMOVAL

(1) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be removed from

power steering pump pulley. Gently, release spring

tension on tensioner.

(2) Remove belt (Fig. 34).

INSTALLATION

(1) Install belt (Fig. 34) over all pulleys except for

the power steering pump pulley.

(2) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be installed onto

power steering pulley. Release spring tension onto

belt.

NOTE: When installing drive belt onto pulleys,

make sure that belt is properly routed and all

V-grooves make proper contact with pulley grooves.

(3) After belt is installed, inspect belt length indi-

cator marks (Fig. 35). The indicator mark should be

within the minimum belt length and maximum belt

length marks. On a new belt, the indicator mark

should align approximately with the nominal belt

length mark.

Fig. 31 Engine Block Heater

1 ± CORE PLUG

2 ± BLOCK HEATER

3 ± POWER CORD

Fig. 32 Accessory Drive Belts

1 ± GENERATOR BELT

2 ± AUTOMATIC BELT TENSIONER

3 ± POWER STEERING PUMP/A/C COMPRESSOR BELT

7 - 24 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 207 of 1285

SHROUD

REMOVAL

(1) Remove cooling fan module. Refer to procedure

in this section.

(2) Remove fan and fan motor as previously

described.

INSTALLATION

(1) Install fan motor and fan as previously

described.

(2) Install cooling fan module. Refer to procedure

in this section.

CLEANING AND INSPECTION

WATER PUMP

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

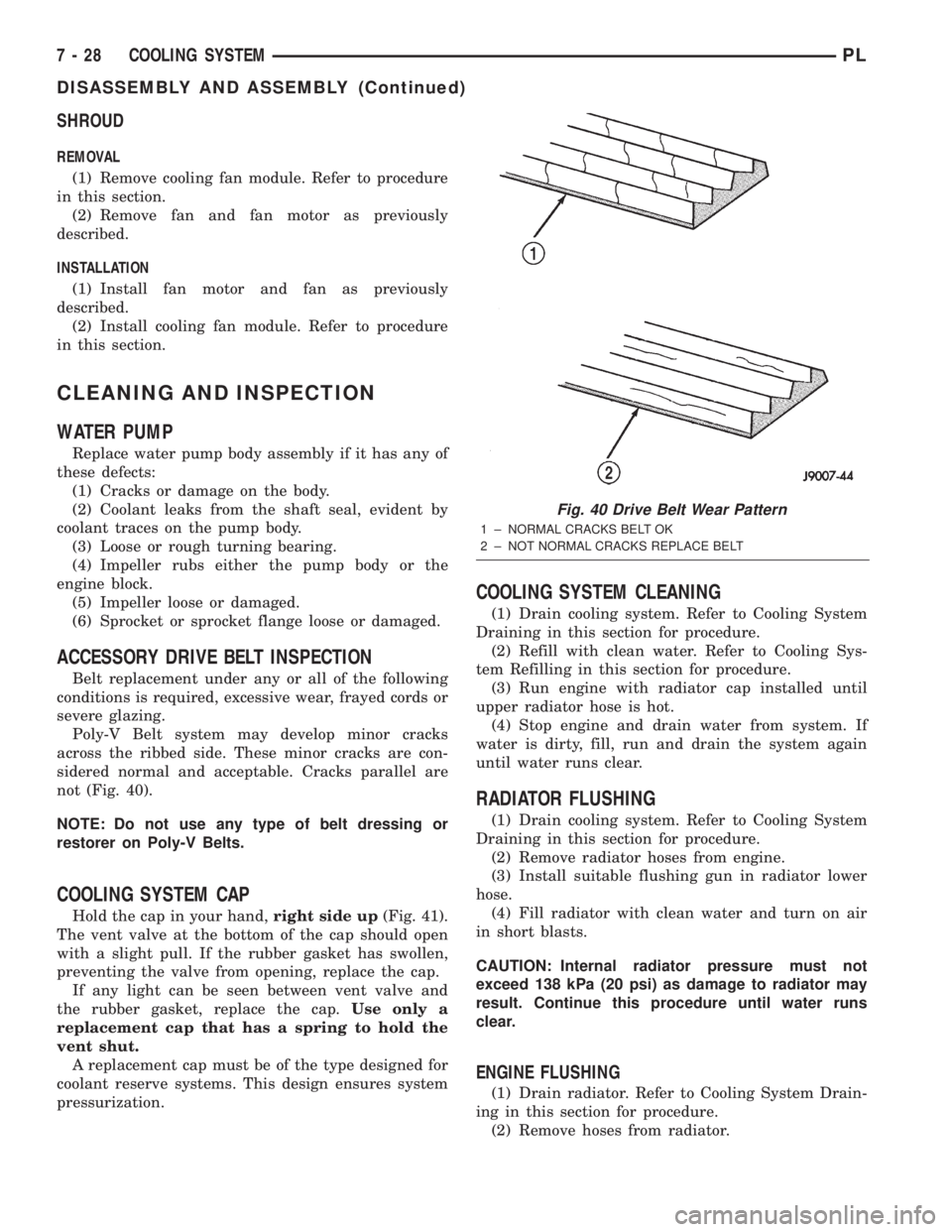

ACCESSORY DRIVE BELT INSPECTION

Belt replacement under any or all of the following

conditions is required, excessive wear, frayed cords or

severe glazing.

Poly-V Belt system may develop minor cracks

across the ribbed side. These minor cracks are con-

sidered normal and acceptable. Cracks parallel are

not (Fig. 40).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V Belts.

COOLING SYSTEM CAP

Hold the cap in your hand,right side up(Fig. 41).

The vent valve at the bottom of the cap should open

with a slight pull. If the rubber gasket has swollen,

preventing the valve from opening, replace the cap.

If any light can be seen between vent valve and

the rubber gasket, replace the cap.Use only a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures system

pressurization.

COOLING SYSTEM CLEANING

(1) Drain cooling system. Refer to Cooling System

Draining in this section for procedure.

(2) Refill with clean water. Refer to Cooling Sys-

tem Refilling in this section for procedure.

(3) Run engine with radiator cap installed until

upper radiator hose is hot.

(4) Stop engine and drain water from system. If

water is dirty, fill, run and drain the system again

until water runs clear.

RADIATOR FLUSHING

(1) Drain cooling system. Refer to Cooling System

Draining in this section for procedure.

(2) Remove radiator hoses from engine.

(3) Install suitable flushing gun in radiator lower

hose.

(4) Fill radiator with clean water and turn on air

in short blasts.

CAUTION: Internal radiator pressure must not

exceed 138 kPa (20 psi) as damage to radiator may

result. Continue this procedure until water runs

clear.

ENGINE FLUSHING

(1) Drain radiator. Refer to Cooling System Drain-

ing in this section for procedure.

(2) Remove hoses from radiator.

Fig. 40 Drive Belt Wear Pattern

1 ± NORMAL CRACKS BELT OK

2 ± NOT NORMAL CRACKS REPLACE BELT

7 - 28 COOLING SYSTEMPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 209 of 1285

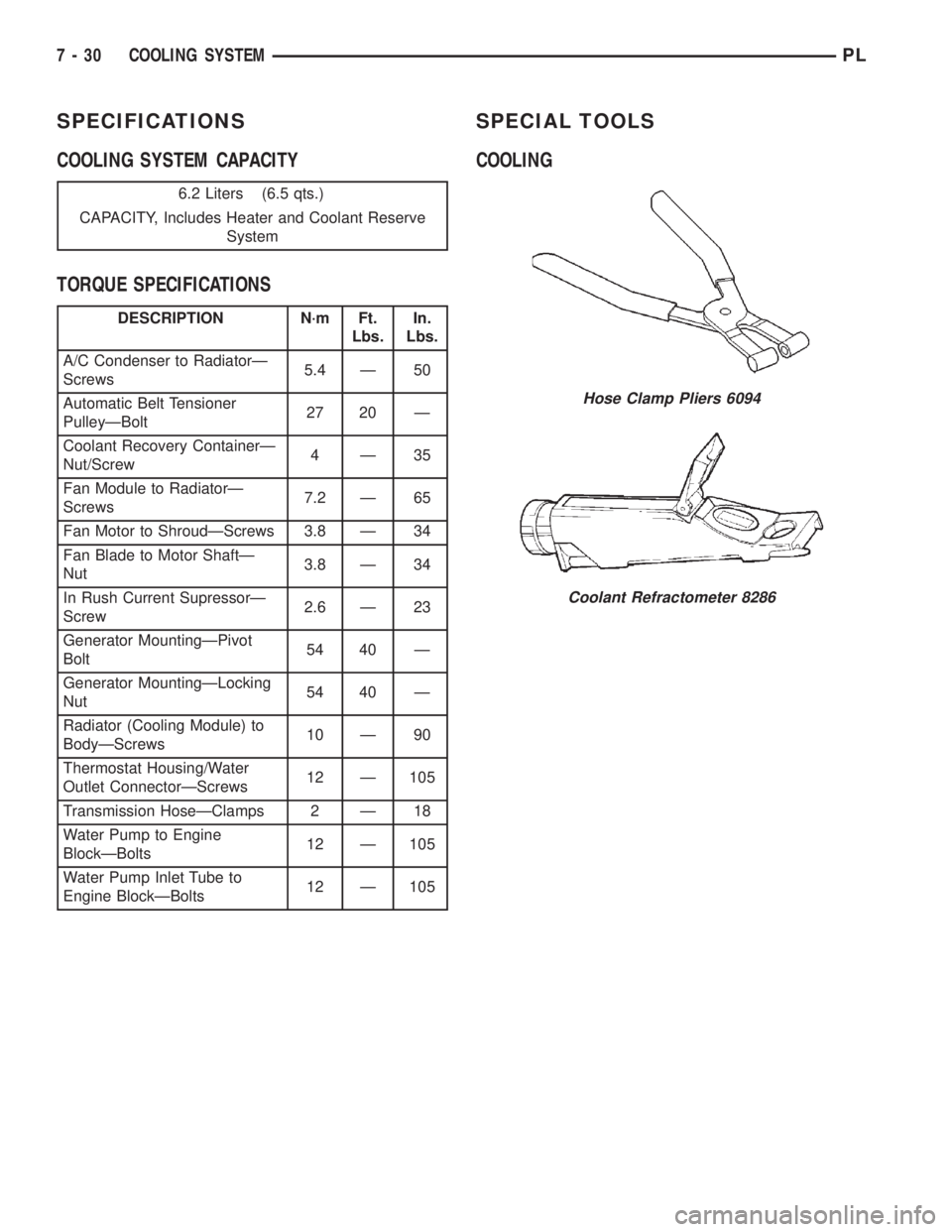

SPECIFICATIONS

COOLING SYSTEM CAPACITY

TORQUE SPECIFICATIONSSPECIAL TOOLS

COOLING

6.2 Liters (6.5 qts.)

CAPACITY, Includes Heater and Coolant Reserve

System

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

A/C Condenser to RadiatorÐ

Screws5.4 Ð 50

Automatic Belt Tensioner

PulleyÐBolt27 20 Ð

Coolant Recovery ContainerÐ

Nut/Screw4Ð35

Fan Module to RadiatorÐ

Screws7.2 Ð 65

Fan Motor to ShroudÐScrews 3.8 Ð 34

Fan Blade to Motor ShaftÐ

Nut3.8 Ð 34

In Rush Current SupressorÐ

Screw2.6 Ð 23

Generator MountingÐPivot

Bolt54 40 Ð

Generator MountingÐLocking

Nut54 40 Ð

Radiator (Cooling Module) to

BodyÐScrews10 Ð 90

Thermostat Housing/Water

Outlet ConnectorÐScrews12 Ð 105

Transmission HoseÐClamps 2 Ð 18

Water Pump to Engine

BlockÐBolts12 Ð 105

Water Pump Inlet Tube to

Engine BlockÐBolts12 Ð 105

Hose Clamp Pliers 6094

Coolant Refractometer 8286

7 - 30 COOLING SYSTEMPL

Page 732 of 1285

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

PLENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 738 of 1285

2.0L SOHC ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION..................15

ENGINE COMPONENTS...................15

ENGINE LUBRICATION SYSTEM.............17

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE..........18

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING........18

FITTING PISTON RINGS...................19

FITTING CONNECTING RODS...............19

FITTING CRANKSHAFT BEARINGS...........19

CRANKSHAFT END PLAY..................20

REMOVAL AND INSTALLATION

TORQUE STRUTS........................20

ENGINE MOUNTÐLEFT...................21

ENGINE MOUNTÐRIGHT..................23

ENGINE MOUNT BRACKETÐRIGHT..........24

STRUCTURAL COLLAR....................25

ENGINE ASSEMBLY.......................25

INTAKE MANIFOLD.......................28

EXHAUST MANIFOLD.....................30

CYLINDER HEAD COVER..................31

SPARK PLUG TUBE SEALS.................32

SPARK PLUG TUBE.......................33

CAMSHAFT.............................33

ROCKER ARM/HYDRAULIC LASH ADJUSTER . . . 34

VALVE SEALS AND SPRINGSÐIN VEHICLE....36

CYLINDER HEAD.........................37

CRANKSHAFT DAMPER...................40

TIMING BELT COVERS....................41TIMING BELT............................43

TIMING BELT TENSIONER..................46

CAMSHAFT OIL SEAL.....................46

OILPAN................................47

CRANKSHAFT OIL SEALÐFRONT............48

CRANKSHAFT OIL SEALÐREAR.............50

DRIVE PLATE...........................51

CRANKSHAFT...........................52

OIL FILTER ADAPTER.....................55

OILFILTER .............................55

OIL PUMP..............................55

PISTON AND CONNECTING ROD............57

DISASSEMBLY AND ASSEMBLY

OIL PUMP..............................60

VALVE SERVICE WITH THE CYLINDER HEAD

REMOVED............................60

CLEANING AND INSPECTION

INTAKE MANIFOLD.......................63

EXHAUST MANIFOLD.....................63

CYLINDER HEAD AND CAMSHAFT

JOURNALS............................63

OIL PUMP..............................64

CYLINDER BLOCK AND BORE..............65

ADJUSTMENTS

ENGINE TORQUE STRUT ADJUSTMENT......66

SPECIFICATIONS

2.0L SOHC ENGINE.......................68

TORQUE...............................71

SPECIAL TOOLS

2.0L SOHC ENGINE.......................72

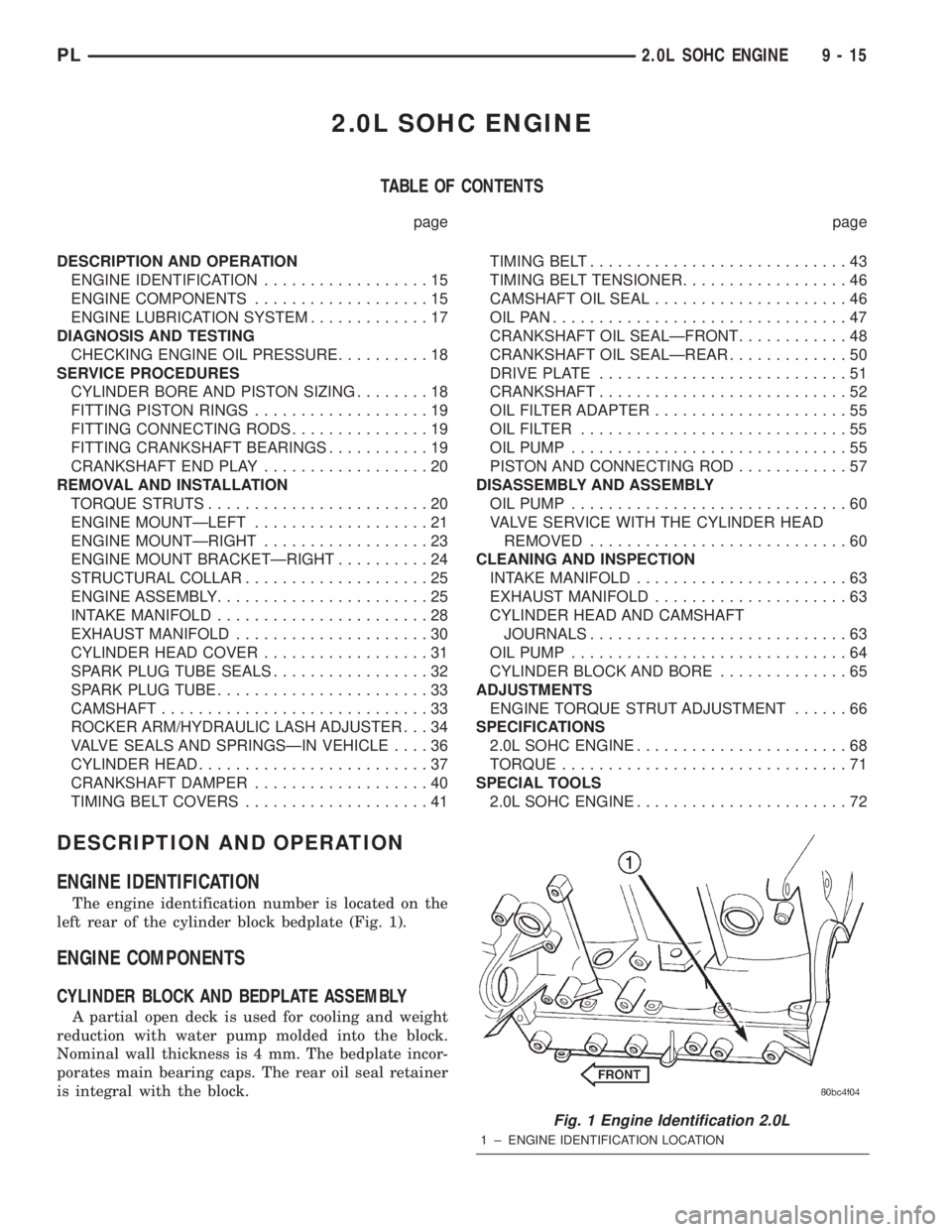

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION

The engine identification number is located on the

left rear of the cylinder block bedplate (Fig. 1).

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEMBLY

A partial open deck is used for cooling and weight

reduction with water pump molded into the block.

Nominal wall thickness is 4 mm. The bedplate incor-

porates main bearing caps. The rear oil seal retainer

is integral with the block.

Fig. 1 Engine Identification 2.0L

1 ± ENGINE IDENTIFICATION LOCATION

PL2.0L SOHC ENGINE 9 - 15

Page 739 of 1285

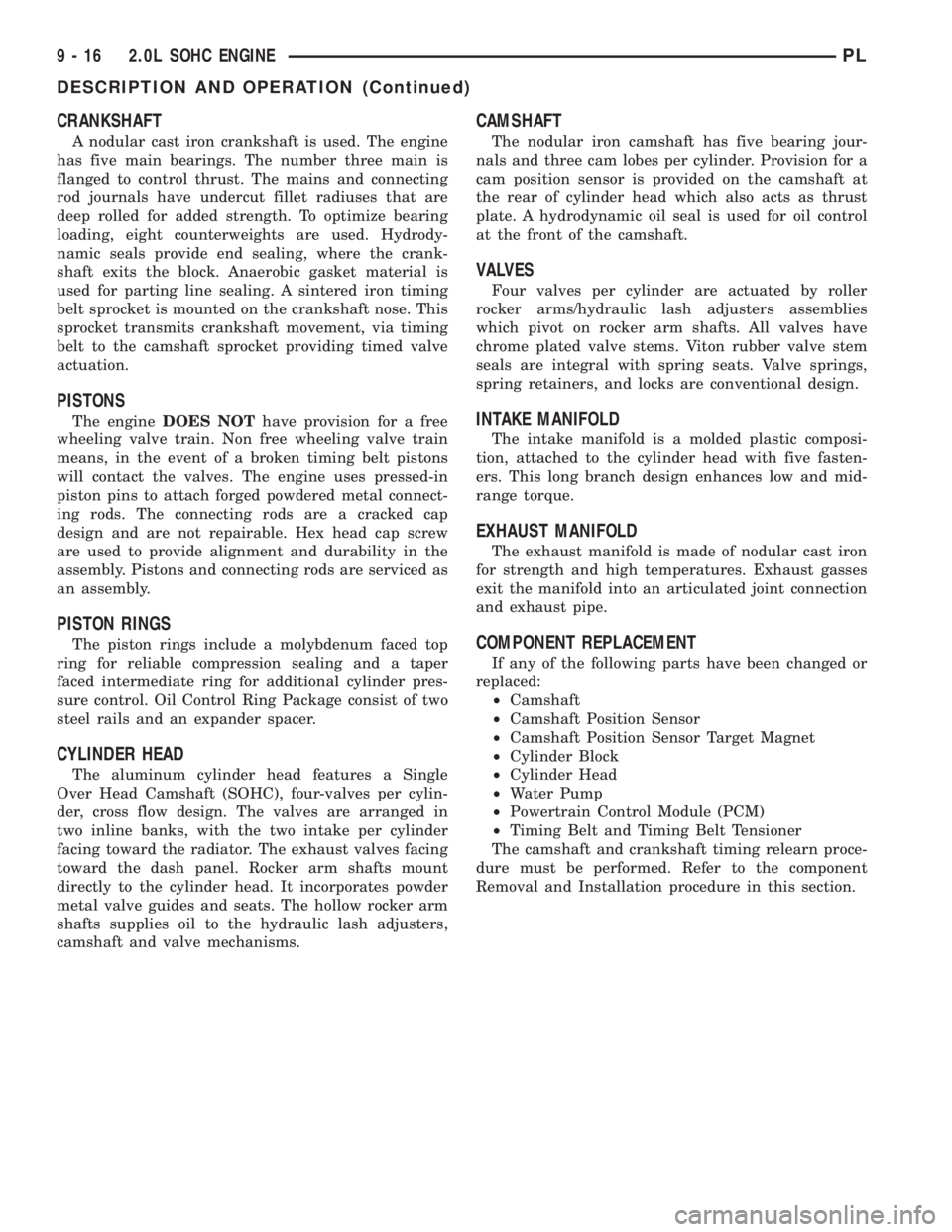

CRANKSHAFT

A nodular cast iron crankshaft is used. The engine

has five main bearings. The number three main is

flanged to control thrust. The mains and connecting

rod journals have undercut fillet radiuses that are

deep rolled for added strength. To optimize bearing

loading, eight counterweights are used. Hydrody-

namic seals provide end sealing, where the crank-

shaft exits the block. Anaerobic gasket material is

used for parting line sealing. A sintered iron timing

belt sprocket is mounted on the crankshaft nose. This

sprocket transmits crankshaft movement, via timing

belt to the camshaft sprocket providing timed valve

actuation.

PISTONS

The engineDOES NOThave provision for a free

wheeling valve train. Non free wheeling valve train

means, in the event of a broken timing belt pistons

will contact the valves. The engine uses pressed-in

piston pins to attach forged powdered metal connect-

ing rods. The connecting rods are a cracked cap

design and are not repairable. Hex head cap screw

are used to provide alignment and durability in the

assembly. Pistons and connecting rods are serviced as

an assembly.

PISTON RINGS

The piston rings include a molybdenum faced top

ring for reliable compression sealing and a taper

faced intermediate ring for additional cylinder pres-

sure control. Oil Control Ring Package consist of two

steel rails and an expander spacer.

CYLINDER HEAD

The aluminum cylinder head features a Single

Over Head Camshaft (SOHC), four-valves per cylin-

der, cross flow design. The valves are arranged in

two inline banks, with the two intake per cylinder

facing toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFT

The nodular iron camshaft has five bearing jour-

nals and three cam lobes per cylinder. Provision for a

cam position sensor is provided on the camshaft at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVES

Four valves per cylinder are actuated by roller

rocker arms/hydraulic lash adjusters assemblies

which pivot on rocker arm shafts. All valves have

chrome plated valve stems. Viton rubber valve stem

seals are integral with spring seats. Valve springs,

spring retainers, and locks are conventional design.

INTAKE MANIFOLD

The intake manifold is a molded plastic composi-

tion, attached to the cylinder head with five fasten-

ers. This long branch design enhances low and mid-

range torque.

EXHAUST MANIFOLD

The exhaust manifold is made of nodular cast iron

for strength and high temperatures. Exhaust gasses

exit the manifold into an articulated joint connection

and exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure in this section.

9 - 16 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 766 of 1285

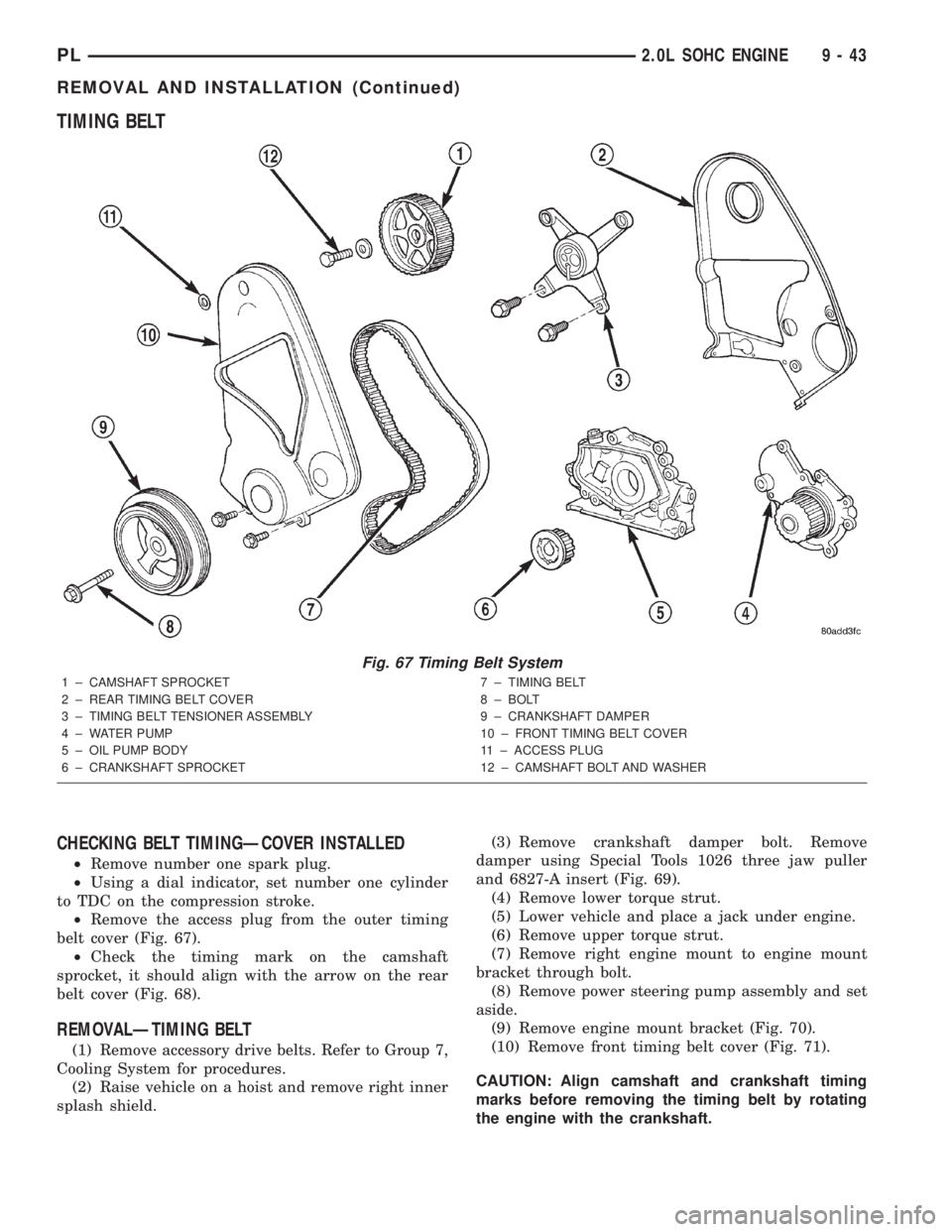

TIMING BELT

CHECKING BELT TIMINGÐCOVER INSTALLED

²Remove number one spark plug.

²Using a dial indicator, set number one cylinder

to TDC on the compression stroke.

²Remove the access plug from the outer timing

belt cover (Fig. 67).

²Check the timing mark on the camshaft

sprocket, it should align with the arrow on the rear

belt cover (Fig. 68).

REMOVALÐTIMING BELT

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedures.

(2) Raise vehicle on a hoist and remove right inner

splash shield.(3) Remove crankshaft damper bolt. Remove

damper using Special Tools 1026 three jaw puller

and 6827-A insert (Fig. 69).

(4) Remove lower torque strut.

(5) Lower vehicle and place a jack under engine.

(6) Remove upper torque strut.

(7) Remove right engine mount to engine mount

bracket through bolt.

(8) Remove power steering pump assembly and set

aside.

(9) Remove engine mount bracket (Fig. 70).

(10) Remove front timing belt cover (Fig. 71).

CAUTION: Align camshaft and crankshaft timing

marks before removing the timing belt by rotating

the engine with the crankshaft.

Fig. 67 Timing Belt System

1 ± CAMSHAFT SPROCKET

2 ± REAR TIMING BELT COVER

3 ± TIMING BELT TENSIONER ASSEMBLY

4 ± WATER PUMP

5 ± OIL PUMP BODY

6 ± CRANKSHAFT SPROCKET7 ± TIMING BELT

8 ± BOLT

9 ± CRANKSHAFT DAMPER

10 ± FRONT TIMING BELT COVER

11 ± ACCESS PLUG

12 ± CAMSHAFT BOLT AND WASHER

PL2.0L SOHC ENGINE 9 - 43

REMOVAL AND INSTALLATION (Continued)

Page 768 of 1285

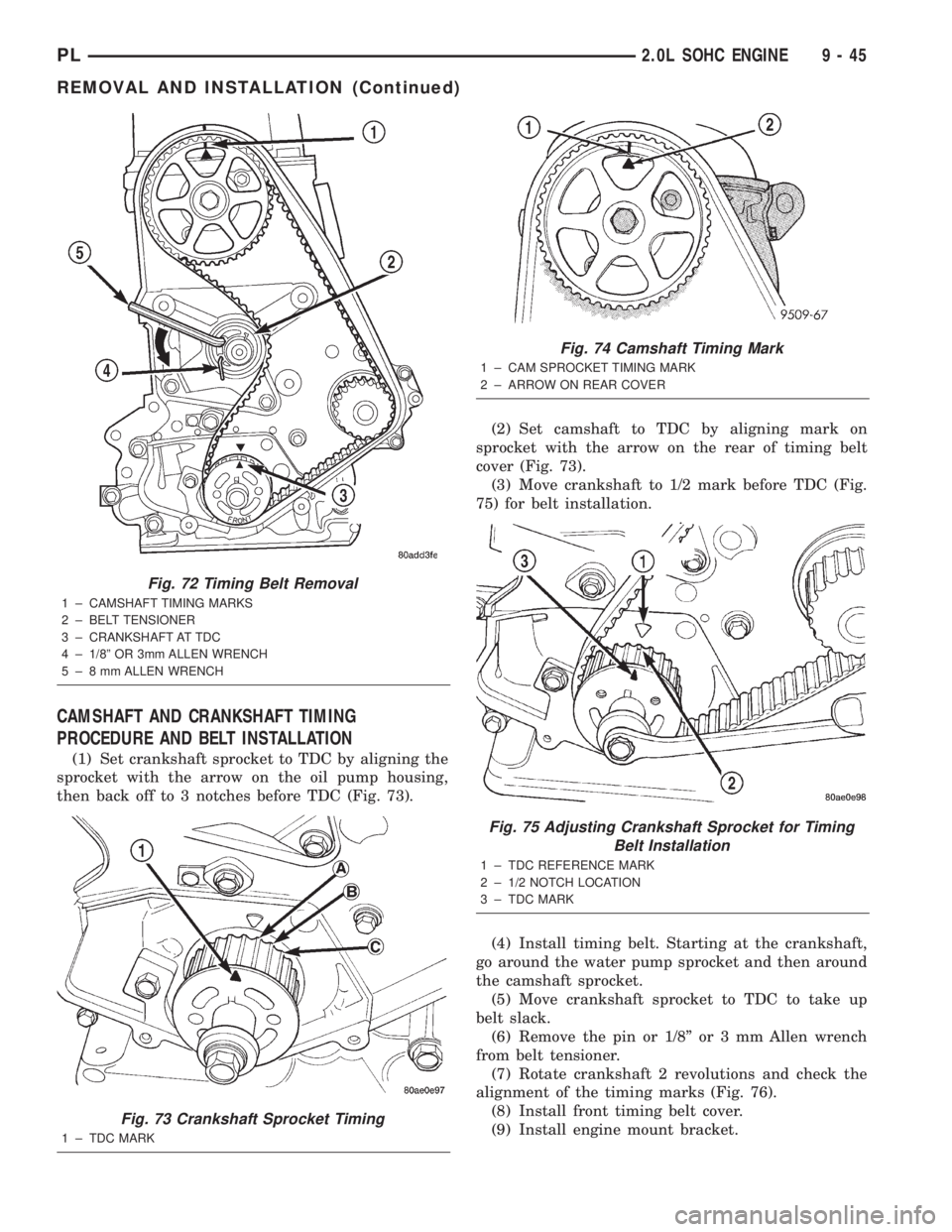

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE AND BELT INSTALLATION

(1) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing,

then back off to 3 notches before TDC (Fig. 73).(2) Set camshaft to TDC by aligning mark on

sprocket with the arrow on the rear of timing belt

cover (Fig. 73).

(3) Move crankshaft to 1/2 mark before TDC (Fig.

75) for belt installation.

(4) Install timing belt. Starting at the crankshaft,

go around the water pump sprocket and then around

the camshaft sprocket.

(5) Move crankshaft sprocket to TDC to take up

belt slack.

(6) Remove the pin or 1/8º or 3 mm Allen wrench

from belt tensioner.

(7) Rotate crankshaft 2 revolutions and check the

alignment of the timing marks (Fig. 76).

(8) Install front timing belt cover.

(9) Install engine mount bracket.

Fig. 72 Timing Belt Removal

1 ± CAMSHAFT TIMING MARKS

2 ± BELT TENSIONER

3 ± CRANKSHAFT AT TDC

4 ± 1/8º OR 3mm ALLEN WRENCH

5 ± 8 mm ALLEN WRENCH

Fig. 73 Crankshaft Sprocket Timing

1 ± TDC MARK

Fig. 74 Camshaft Timing Mark

1 ± CAM SPROCKET TIMING MARK

2 ± ARROW ON REAR COVER

Fig. 75 Adjusting Crankshaft Sprocket for Timing

Belt Installation

1 ± TDC REFERENCE MARK

2 ± 1/2 NOTCH LOCATION

3 ± TDC MARK

PL2.0L SOHC ENGINE 9 - 45

REMOVAL AND INSTALLATION (Continued)