water pump DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 157 of 1285

NOTE: It is not necessary to bleed the entire

hydraulic system after replacing just the master cyl-

inder unless the brake system has been open to air

for an excessive amount of time or air is present in

the lines. Only the master cylinder must be bled

and filled.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

Review this entire section prior to performing any

mechanical work on a vehicle equipped with ABS.

This section contains information on precautions per-

taining to potential component damage, vehicle dam-

age and personal injury which could result when

servicing an ABS equipped vehicle.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash off with water immediately.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.

CAUTION: If welding work is to be performed on

the vehicle, using an electric arc welder, the CAB

connector should be disconnected during the weld-

ing operation.

CAUTION: The CAB 25-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

Many components of the ABS System are not ser-

viceable and must be replaced as an assembly. Do not

disassemble any component which is not designed to

be serviced.

MASTER CYLINDER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal while the engine is not running until a

firm brake pedal is achieved.

(1) With the engine not running, pump the brake

pedal 4-5 strokes until the pedal feel is firm.

(2) Disconnect the negative (ground) cable from

the battery and isolate the cable.

(3) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(4) Disconnect the wiring harness connector from

the brake fluid level switch on the master cylinder

reservoir (Fig. 12).

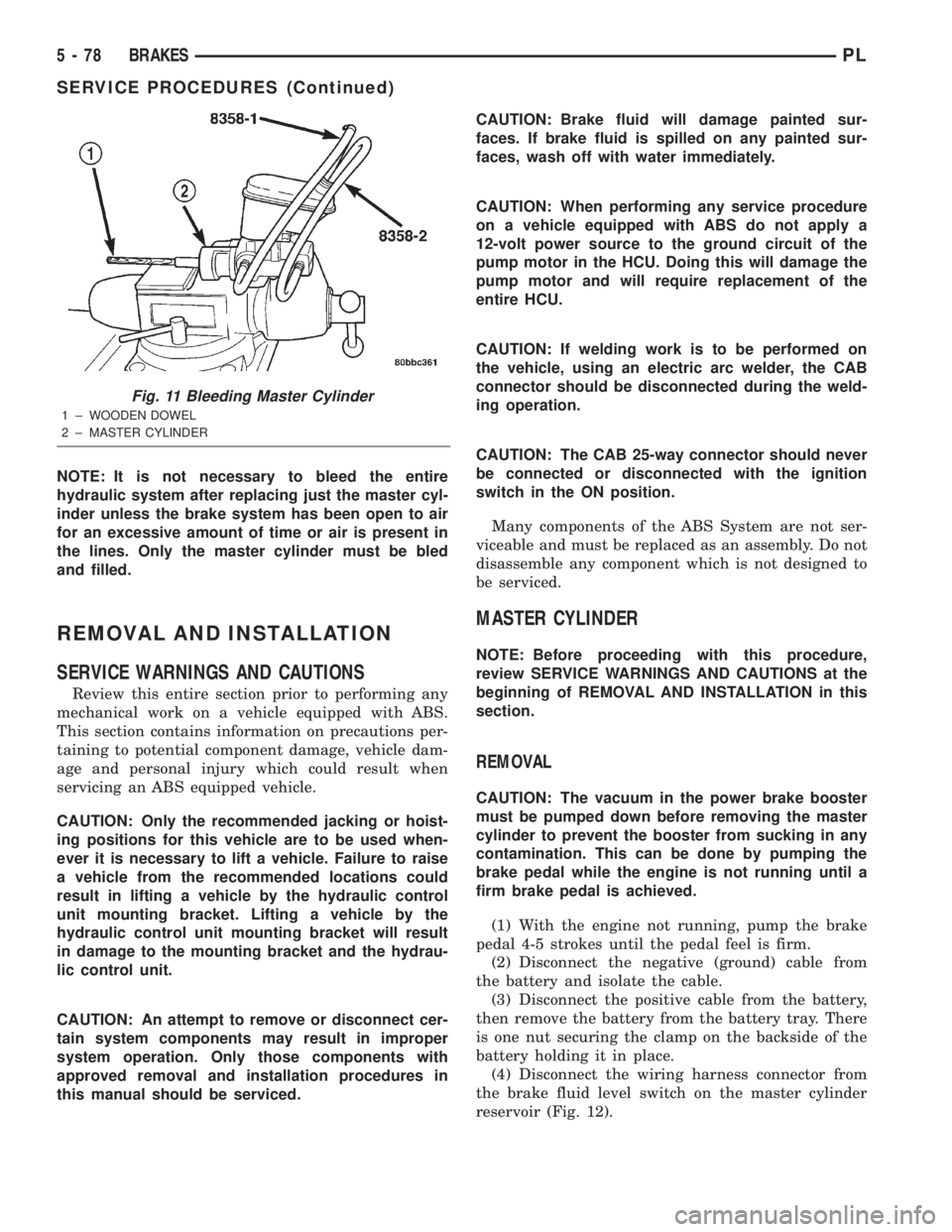

Fig. 11 Bleeding Master Cylinder

1 ± WOODEN DOWEL

2 ± MASTER CYLINDER

5 - 78 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 180 of 1285

COOLING SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

COOLING SYSTEM........................1

COOLANT...............................2

COOLANT PERFORMANCE..................2

COOLANT RECOVERY SYSTEM..............3

ENGINE THERMOSTAT.....................3

RADIATOR..............................3

RADIATOR COOLING FAN MODULE...........3

COOLING SYSTEM PRESSURE CAP..........4

RADIATOR HOSES AND CLAMPS............5

WATER PUMP...........................5

AUTOMATIC TRANSMISSION OIL COOLER.....6

ACCESSORY DRIVE BELTS.................6

ENGINE BLOCK HEATER...................6

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS..............7

ENGINE THERMOSTAT TESTING............14

ACCESSORY DRIVE BELT DIAGNOSIS........14

WATER PUMP DIAGNOSIS................15

COOLING SYSTEM FLOW CHECK...........15

ELECTRIC FAN MOTOR TEST...............15

COOLANT CONCENTRATION TESTING........15

TESTING COOLING SYSTEM FOR LEAKS.....15

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK...............16

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP.......................16

LOW COOLANT LEVEL AERATION...........17

DEAERATION...........................17

TEMPERATURE GAUGE INDICATION.........17

ENGINE BLOCK HEATER..................17

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE.........17COOLANTÐADDING ADDITIONAL...........18

COOLANT LEVELÐSERVICING.............18

COOLING SYSTEMÐDRAINING.............19

COOLING SYSTEMÐREFILLING............19

REMOVAL AND INSTALLATION

WATER PUMP..........................19

WATER PUMP INLET TUBE................20

ENGINE THERMOSTAT....................20

RADIATOR.............................21

RADIATOR DRAINCOCK...................22

COOLING FAN MODULE...................22

COOLANT RECOVERY CONTAINER..........23

ENGINE BLOCK HEATER..................24

ACCESSORY DRIVE BELTS................24

AUTOMATIC BELT TENSIONER & PULLEY....26

DISASSEMBLY AND ASSEMBLY

COOLING FAN MODULE...................26

CLEANING AND INSPECTION

WATER PUMP..........................28

ACCESSORY DRIVE BELT INSPECTION.......28

COOLING SYSTEM CAP...................28

COOLING SYSTEM CLEANING..............28

RADIATOR FLUSHING....................28

REVERSE FLUSHING.....................29

CHEMICAL CLEANING....................29

ADJUSTMENTS

BELT TENSION..........................29

SPECIFICATIONS

COOLING SYSTEM CAPACITY..............30

TORQUE SPECIFICATIONS.................30

SPECIAL TOOLS

COOLING..............................30

DESCRIPTION AND OPERATION

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, and a water pump to

circulate the coolant. The engine cooling module may

consist of a radiator, electric fan motor, fan, shroud,

coolant reserve system, transmission oil cooler, hoses,clamps, air conditioning condenser and transmission

oil lines.

²When the Engine is cold: The thermostat is

closed and the cooling system has no flow through

the radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open

and the cooling system has flow through the radiator,

engine, heater system, and bypass.

PLCOOLING SYSTEM 7 - 1

Page 181 of 1285

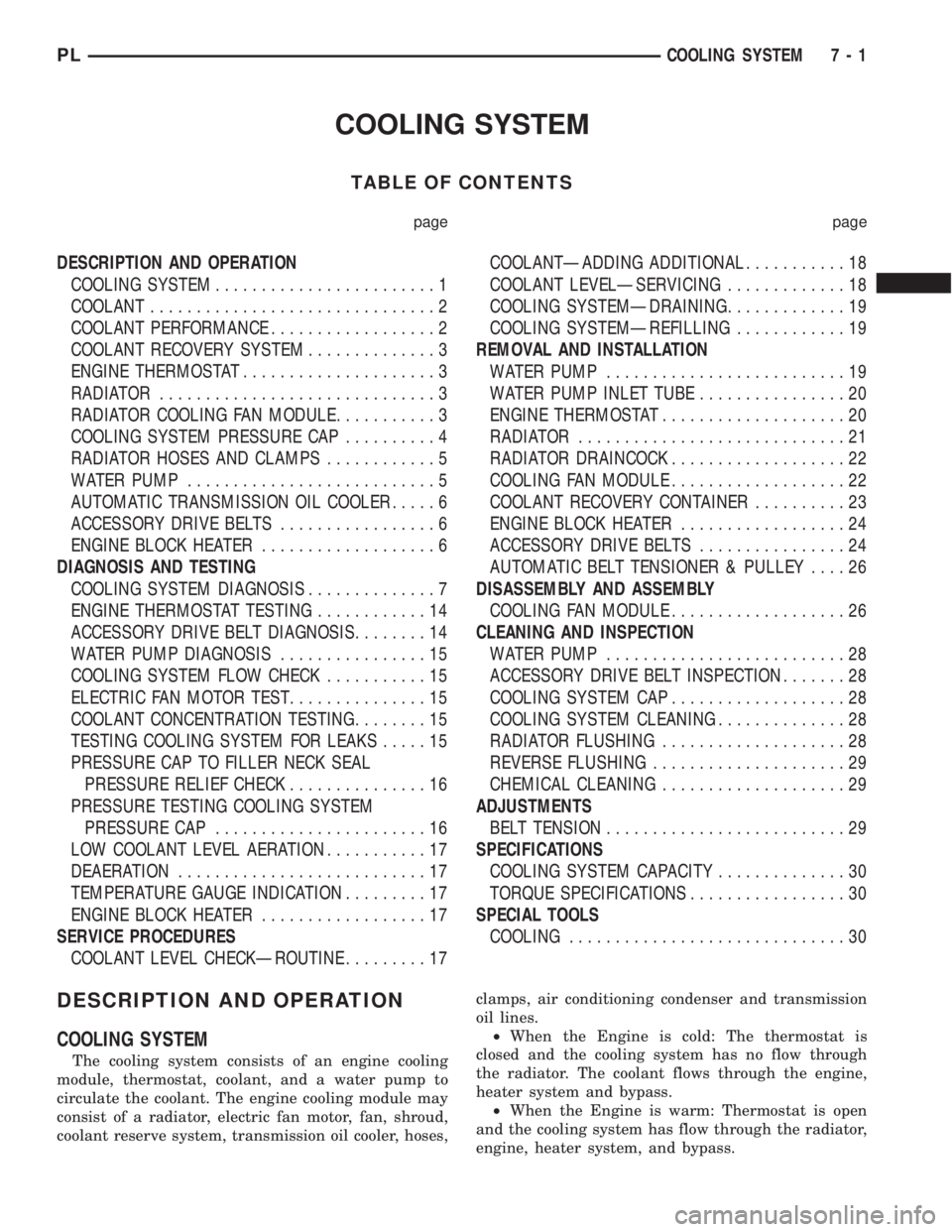

Coolant flow circuit for the 2.0L engine is shown in

(Fig. 1).

During any reassembly procedures all pipe fittings

in water jacket, and water box require cleaning and

application of thread sealant for entire length of

threads.

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine block

metal and in the cylinder head area near the exhaust

valves. Then coolant carries this heat to the radiator

where the tube/fin assemblies can give off the heat to

the air.

MopartAntifreeze or the equivalent is recom-

mended for optimum cooling performance and corro-

sion protection when mixed to a freeze point of -37É C

(-35É F).

COOLANT REPLACEMENT

Refer to Group 0, Lubrication and Maintenance for

schedule.

COOLANT PERFORMANCE

Performance is measurable. For heat transfer pure

water excels (Formula = 1 btu per minute for eachdegree of temperature rise for each pound of water).

This formula is altered when necessary additives to

control boiling, freezing, and corrosion are added as

follows:

²Pure Water (1 btu) boils at 100ÉC (212ÉF) and

freezes at 0ÉC (32ÉF).

²100 Percent Glycol (.7 btu) can cause a hot

engine and detonation and will raise the freeze point

to 22ÉC (-8ÉF).

²50/50 Glycol and Water (0.82 btu) is the recom-

mended combination that provides a freeze point of

-37ÉC (-35ÉF). The radiator, water pump, engine

water jacket, radiator pressure cap, thermostat, tem-

perature gauge, sending unit and heater are all

designed for 50/50 glycol.

Where required, a 56 percent glycol and 44 percent

water mixture will provide a freeze point of -59ÉC

(-50ÉF).

CAUTION: Richer mixtures cannot be measured

with field equipment which can lead to problems

associated with 100 percent glycol.SELECTION AND ADDITIVES

The use of aluminum cylinder heads, intake mani-

folds, and water pumps requires special corrosion

Fig. 1 Cooling System Operation

1 ± HEATER

2 ± HEAT UP

3 ± COOL DOWN

4 ± PRESSURE CAP

5 ± THERMOSTAT HOUSING6 ± WATER PUMP

7 ± ENGINE

8 ± COOLANT RECOVERY SYSTEM TANK

9 ± RADIATOR

7 - 2 COOLING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 184 of 1285

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE WORKING ON VEHI-

CLE. RELIEVE PRESSURE BY PLACING A SHOP

TOWEL OVER THE CAP AND WITHOUT PUSHING

DOWN ROTATE IT COUNTERCLOCKWISE TO THE

FIRST STOP. ALLOW FLUIDS TO ESCAPE

THROUGH THE OVERFLOW TUBE AND WHEN THE

SYSTEM STOPS PUSHING OUT COOLANT AND

STEAM AND THE PRESSURE DROPS CONTINUE

SERVICE.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

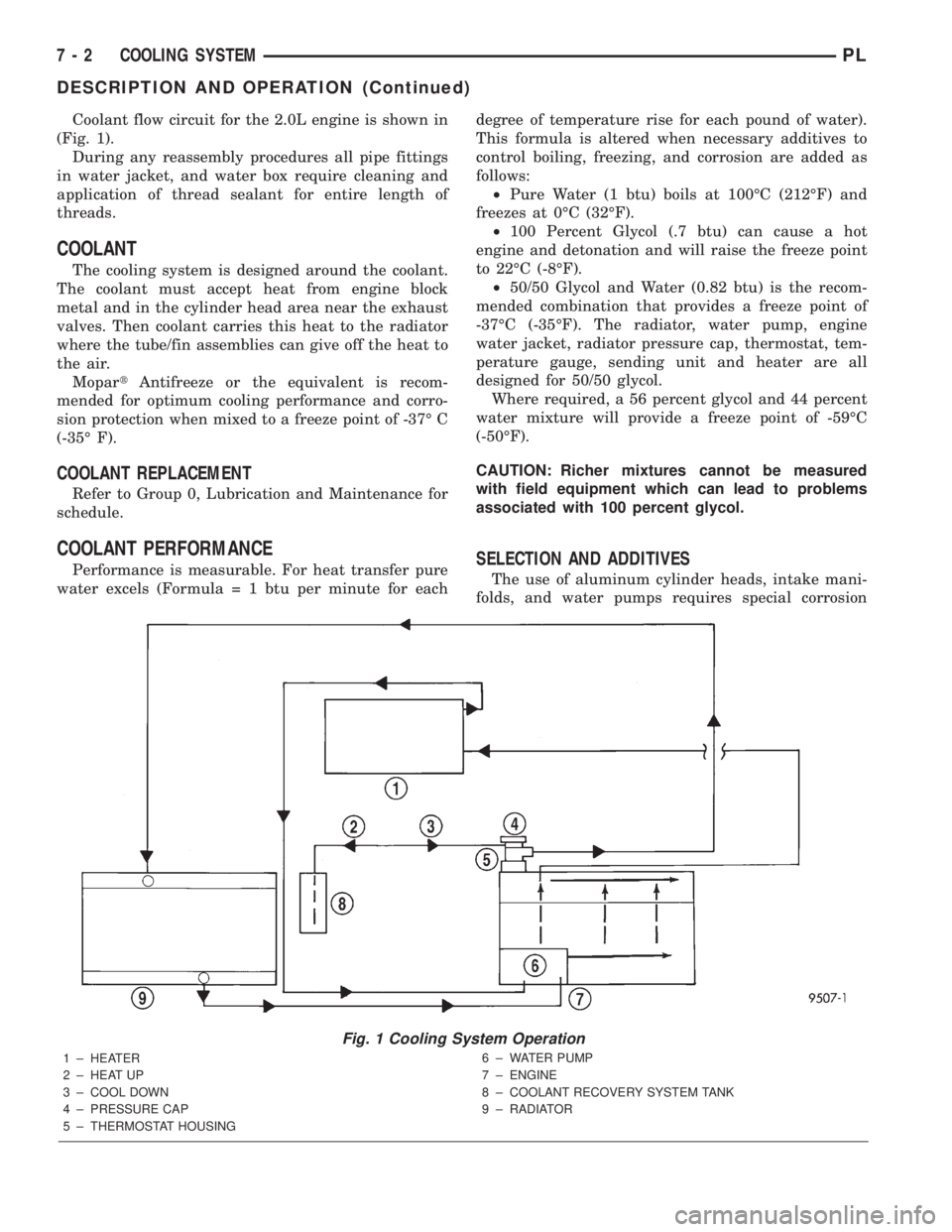

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 6).

The hose clamps are removed by using Special Tool

6094 or equivalent constant tension clamp pliers

(Fig. 7) to compress the hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Care should be taken not to dam-

age radiator inlet and outlet when removing hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.Make sure hoses and connectors are clean and dry

before installation. Do not lubricate hoses when

installing.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary, replace with the

original Mopartequipment spring type clamp.

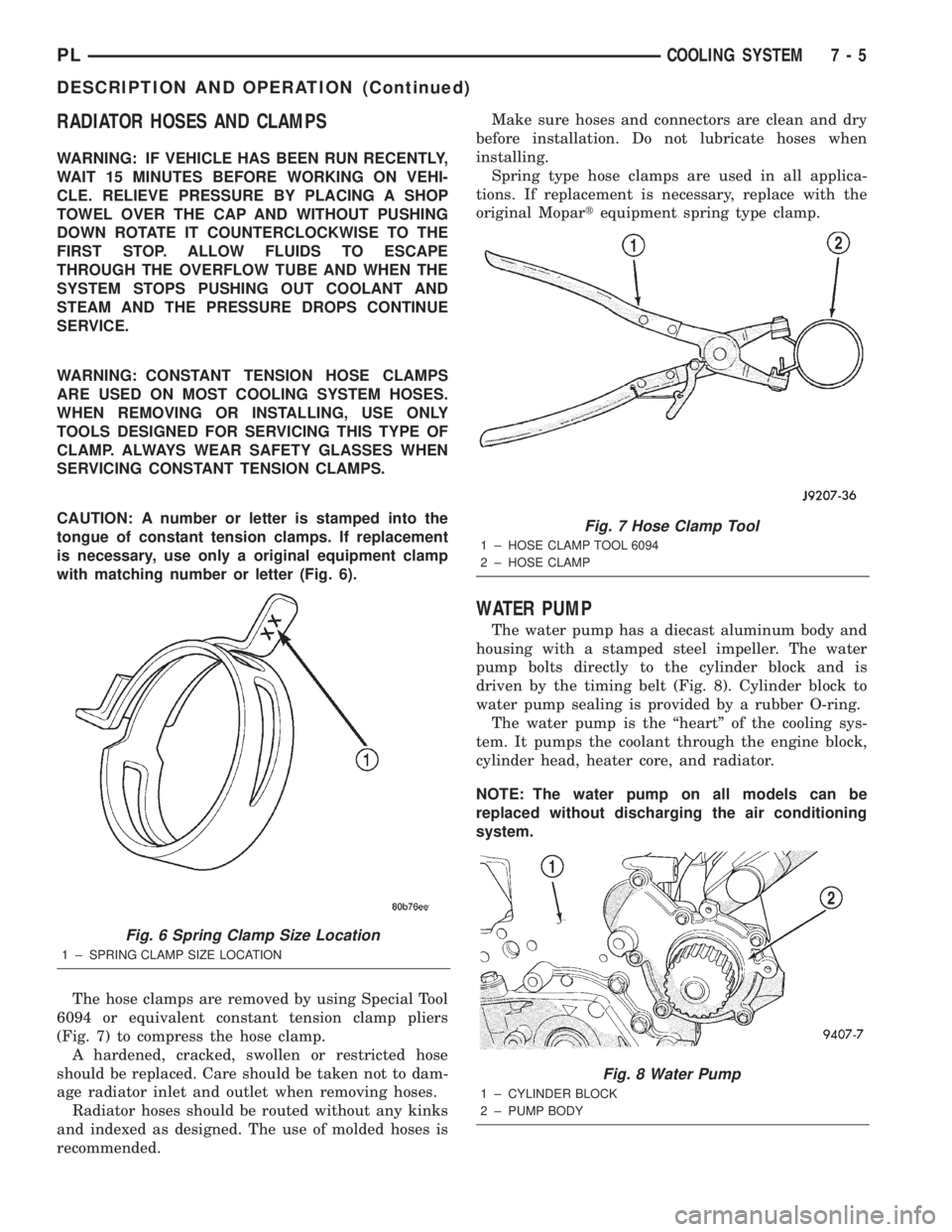

WATER PUMP

The water pump has a diecast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the cylinder block and is

driven by the timing belt (Fig. 8). Cylinder block to

water pump sealing is provided by a rubber O-ring.

The water pump is the ªheartº of the cooling sys-

tem. It pumps the coolant through the engine block,

cylinder head, heater core, and radiator.

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

Fig. 6 Spring Clamp Size Location

1 ± SPRING CLAMP SIZE LOCATION

Fig. 7 Hose Clamp Tool

1 ± HOSE CLAMP TOOL 6094

2 ± HOSE CLAMP

Fig. 8 Water Pump

1 ± CYLINDER BLOCK

2 ± PUMP BODY

PLCOOLING SYSTEM 7 - 5

DESCRIPTION AND OPERATION (Continued)

Page 188 of 1285

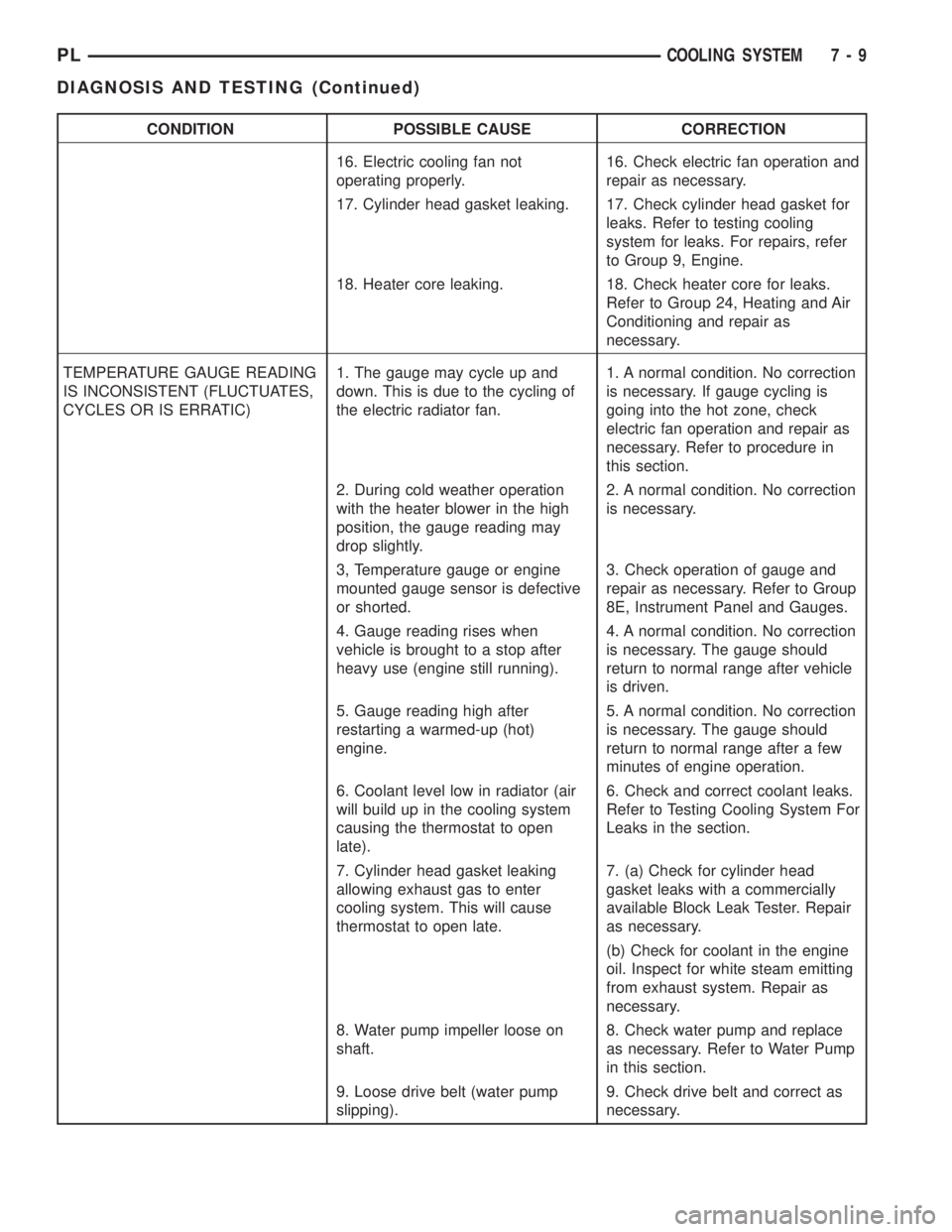

CONDITION POSSIBLE CAUSE CORRECTION

16. Electric cooling fan not

operating properly.16. Check electric fan operation and

repair as necessary.

17. Cylinder head gasket leaking. 17. Check cylinder head gasket for

leaks. Refer to testing cooling

system for leaks. For repairs, refer

to Group 9, Engine.

18. Heater core leaking. 18. Check heater core for leaks.

Refer to Group 24, Heating and Air

Conditioning and repair as

necessary.

TEMPERATURE GAUGE READING

IS INCONSISTENT (FLUCTUATES,

CYCLES OR IS ERRATIC)1. The gauge may cycle up and

down. This is due to the cycling of

the electric radiator fan.1. A normal condition. No correction

is necessary. If gauge cycling is

going into the hot zone, check

electric fan operation and repair as

necessary. Refer to procedure in

this section.

2. During cold weather operation

with the heater blower in the high

position, the gauge reading may

drop slightly.2. A normal condition. No correction

is necessary.

3, Temperature gauge or engine

mounted gauge sensor is defective

or shorted.3. Check operation of gauge and

repair as necessary. Refer to Group

8E, Instrument Panel and Gauges.

4. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running).4. A normal condition. No correction

is necessary. The gauge should

return to normal range after vehicle

is driven.

5. Gauge reading high after

restarting a warmed-up (hot)

engine.5. A normal condition. No correction

is necessary. The gauge should

return to normal range after a few

minutes of engine operation.

6. Coolant level low in radiator (air

will build up in the cooling system

causing the thermostat to open

late).6. Check and correct coolant leaks.

Refer to Testing Cooling System For

Leaks in the section.

7. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system. This will cause

thermostat to open late.7. (a) Check for cylinder head

gasket leaks with a commercially

available Block Leak Tester. Repair

as necessary.

(b) Check for coolant in the engine

oil. Inspect for white steam emitting

from exhaust system. Repair as

necessary.

8. Water pump impeller loose on

shaft.8. Check water pump and replace

as necessary. Refer to Water Pump

in this section.

9. Loose drive belt (water pump

slipping).9. Check drive belt and correct as

necessary.

PLCOOLING SYSTEM 7 - 9

DIAGNOSIS AND TESTING (Continued)

Page 189 of 1285

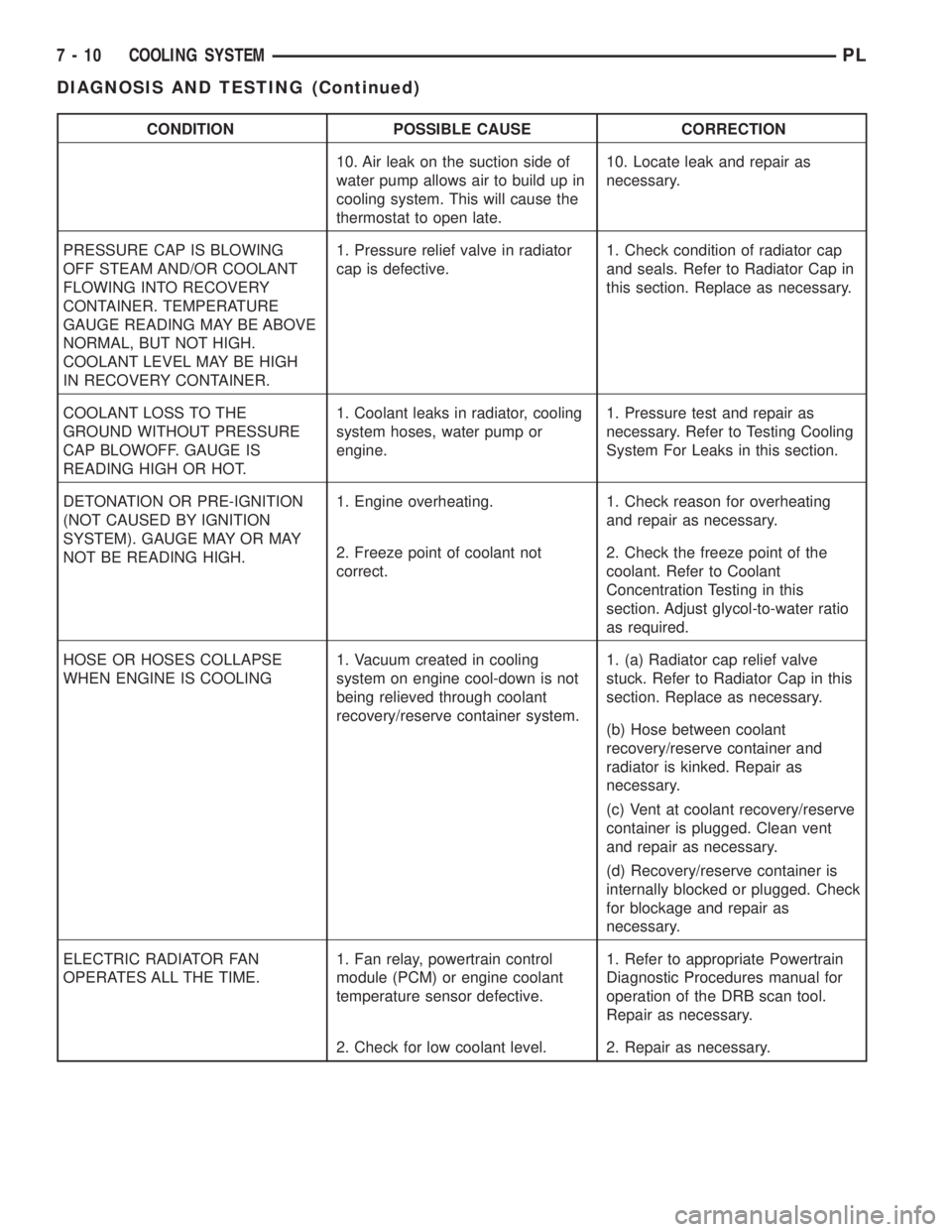

CONDITION POSSIBLE CAUSE CORRECTION

10. Air leak on the suction side of

water pump allows air to build up in

cooling system. This will cause the

thermostat to open late.10. Locate leak and repair as

necessary.

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT

FLOWING INTO RECOVERY

CONTAINER. TEMPERATURE

GAUGE READING MAY BE ABOVE

NORMAL, BUT NOT HIGH.

COOLANT LEVEL MAY BE HIGH

IN RECOVERY CONTAINER.1. Pressure relief valve in radiator

cap is defective.1. Check condition of radiator cap

and seals. Refer to Radiator Cap in

this section. Replace as necessary.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. Refer to Testing Cooling

System For Leaks in this section.

DETONATION OR PRE-IGNITION

(NOT CAUSED BY IGNITION

SYSTEM). GAUGE MAY OR MAY

NOT BE READING HIGH.1. Engine overheating. 1. Check reason for overheating

and repair as necessary.

2. Freeze point of coolant not

correct.2. Check the freeze point of the

coolant. Refer to Coolant

Concentration Testing in this

section. Adjust glycol-to-water ratio

as required.

HOSE OR HOSES COLLAPSE

WHEN ENGINE IS COOLING1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

recovery/reserve container system.1. (a) Radiator cap relief valve

stuck. Refer to Radiator Cap in this

section. Replace as necessary.

(b) Hose between coolant

recovery/reserve container and

radiator is kinked. Repair as

necessary.

(c) Vent at coolant recovery/reserve

container is plugged. Clean vent

and repair as necessary.

(d) Recovery/reserve container is

internally blocked or plugged. Check

for blockage and repair as

necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME.1. Fan relay, powertrain control

module (PCM) or engine coolant

temperature sensor defective.1. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

2. Check for low coolant level. 2. Repair as necessary.

7 - 10 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 191 of 1285

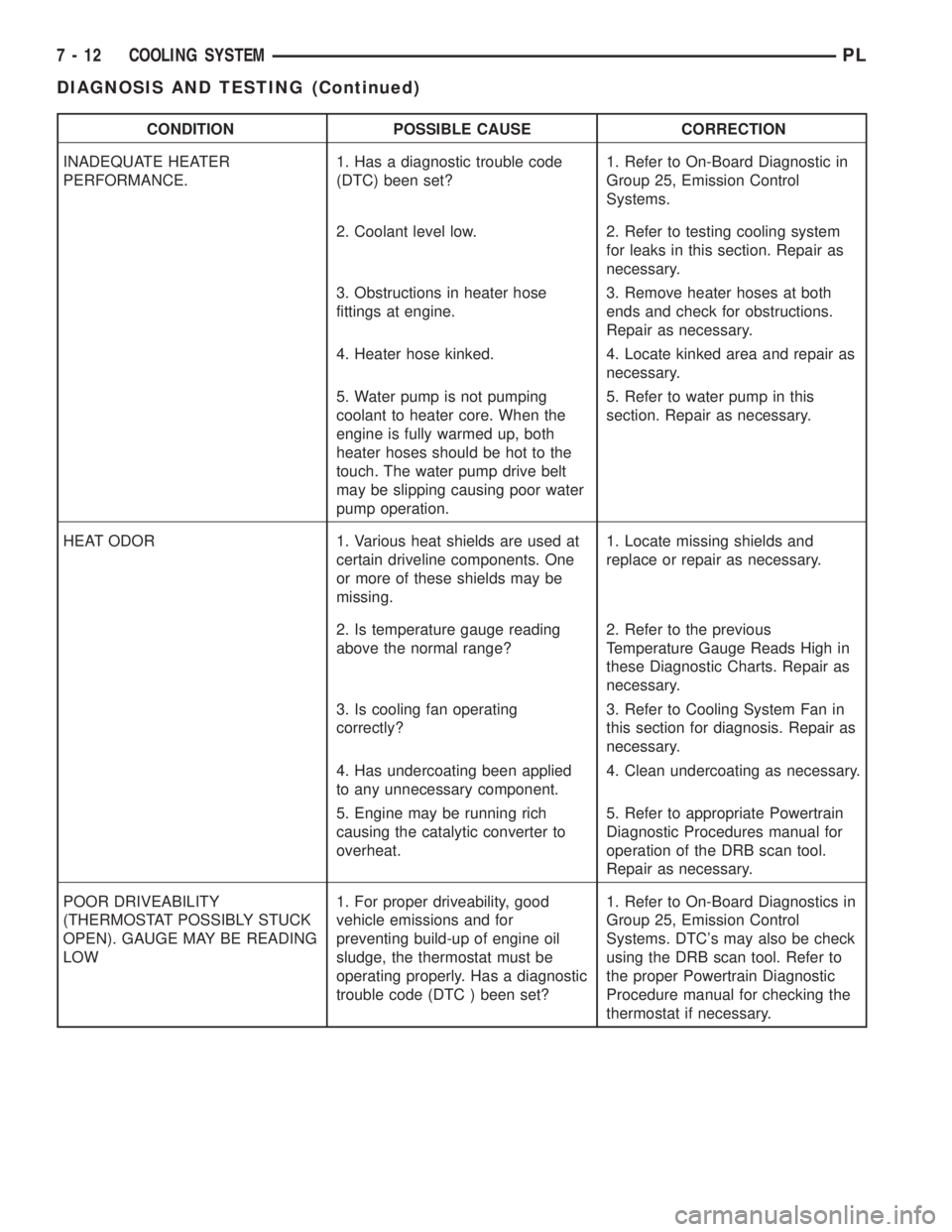

CONDITION POSSIBLE CAUSE CORRECTION

INADEQUATE HEATER

PERFORMANCE.1. Has a diagnostic trouble code

(DTC) been set?1. Refer to On-Board Diagnostic in

Group 25, Emission Control

Systems.

2. Coolant level low. 2. Refer to testing cooling system

for leaks in this section. Repair as

necessary.

3. Obstructions in heater hose

fittings at engine.3. Remove heater hoses at both

ends and check for obstructions.

Repair as necessary.

4. Heater hose kinked. 4. Locate kinked area and repair as

necessary.

5. Water pump is not pumping

coolant to heater core. When the

engine is fully warmed up, both

heater hoses should be hot to the

touch. The water pump drive belt

may be slipping causing poor water

pump operation.5. Refer to water pump in this

section. Repair as necessary.

HEAT ODOR 1. Various heat shields are used at

certain driveline components. One

or more of these shields may be

missing.1. Locate missing shields and

replace or repair as necessary.

2. Is temperature gauge reading

above the normal range?2. Refer to the previous

Temperature Gauge Reads High in

these Diagnostic Charts. Repair as

necessary.

3. Is cooling fan operating

correctly?3. Refer to Cooling System Fan in

this section for diagnosis. Repair as

necessary.

4. Has undercoating been applied

to any unnecessary component.4. Clean undercoating as necessary.

5. Engine may be running rich

causing the catalytic converter to

overheat.5. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

POOR DRIVEABILITY

(THERMOSTAT POSSIBLY STUCK

OPEN). GAUGE MAY BE READING

LOW1. For proper driveability, good

vehicle emissions and for

preventing build-up of engine oil

sludge, the thermostat must be

operating properly. Has a diagnostic

trouble code (DTC ) been set?1. Refer to On-Board Diagnostics in

Group 25, Emission Control

Systems. DTC's may also be check

using the DRB scan tool. Refer to

the proper Powertrain Diagnostic

Procedure manual for checking the

thermostat if necessary.

7 - 12 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 193 of 1285

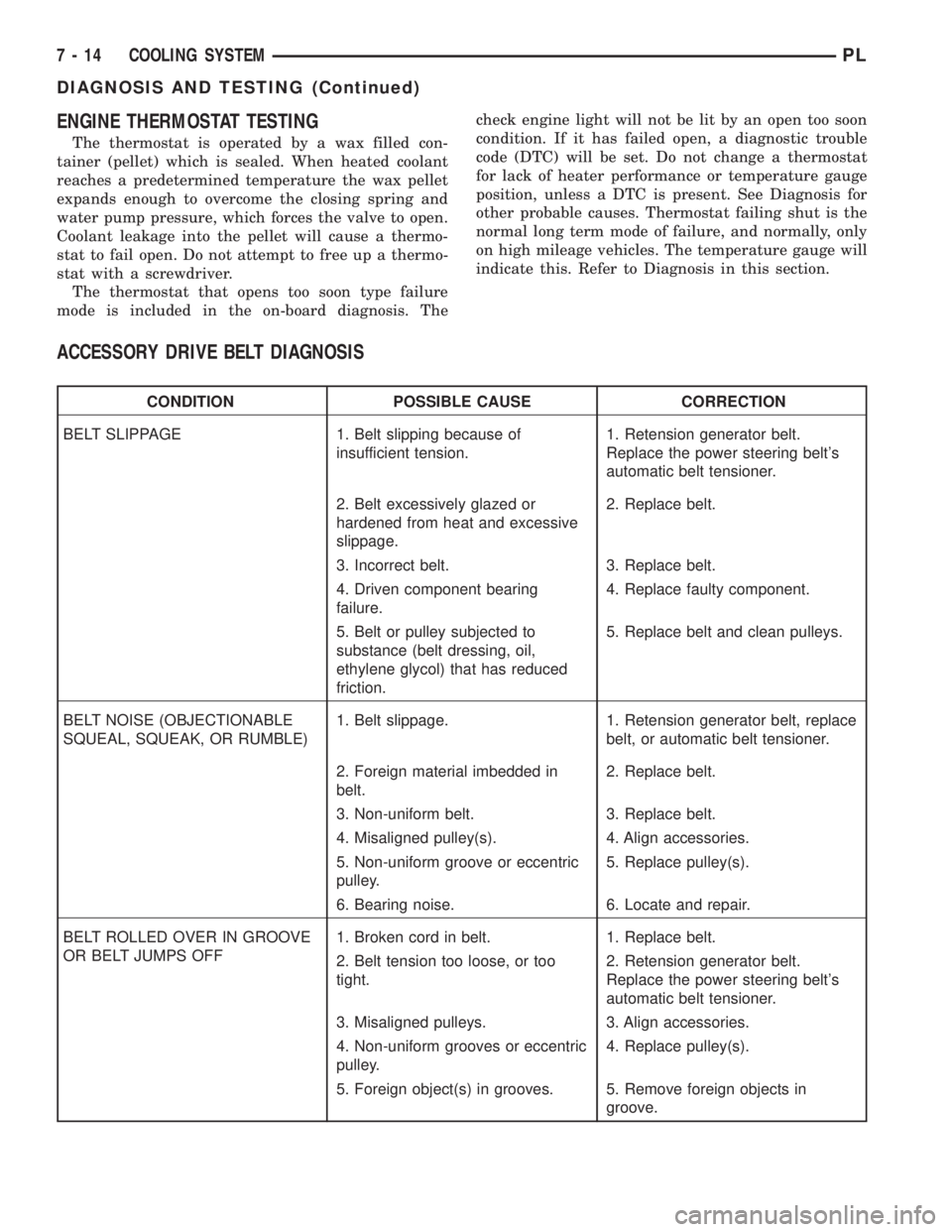

ENGINE THERMOSTAT TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.

The thermostat that opens too soon type failure

mode is included in the on-board diagnosis. Thecheck engine light will not be lit by an open too soon

condition. If it has failed open, a diagnostic trouble

code (DTC) will be set. Do not change a thermostat

for lack of heater performance or temperature gauge

position, unless a DTC is present. See Diagnosis for

other probable causes. Thermostat failing shut is the

normal long term mode of failure, and normally, only

on high mileage vehicles. The temperature gauge will

indicate this. Refer to Diagnosis in this section.

ACCESSORY DRIVE BELT DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

BELT SLIPPAGE 1. Belt slipping because of

insufficient tension.1. Retension generator belt.

Replace the power steering belt's

automatic belt tensioner.

2. Belt excessively glazed or

hardened from heat and excessive

slippage.2. Replace belt.

3. Incorrect belt. 3. Replace belt.

4. Driven component bearing

failure.4. Replace faulty component.

5. Belt or pulley subjected to

substance (belt dressing, oil,

ethylene glycol) that has reduced

friction.5. Replace belt and clean pulleys.

BELT NOISE (OBJECTIONABLE

SQUEAL, SQUEAK, OR RUMBLE)1. Belt slippage. 1. Retension generator belt, replace

belt, or automatic belt tensioner.

2. Foreign material imbedded in

belt.2. Replace belt.

3. Non-uniform belt. 3. Replace belt.

4. Misaligned pulley(s). 4. Align accessories.

5. Non-uniform groove or eccentric

pulley.5. Replace pulley(s).

6. Bearing noise. 6. Locate and repair.

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt. 1. Replace belt.

2. Belt tension too loose, or too

tight.2. Retension generator belt.

Replace the power steering belt's

automatic belt tensioner.

3. Misaligned pulleys. 3. Align accessories.

4. Non-uniform grooves or eccentric

pulley.4. Replace pulley(s).

5. Foreign object(s) in grooves. 5. Remove foreign objects in

groove.

7 - 14 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 194 of 1285

WATER PUMP DIAGNOSIS

A quick flow test to tell whether or not the pump is

working is to see if the heater warms properly. A

defective pump will not be able to circulate heated

coolant through the long heater hose.

Another flow test to help determine pump opera-

tion:

WARNING: DO NOT remove radiator cap if the cool-

ing system is hot or under pressure.

(1) Remove cooling system pressure cap.

(2) Remove a small amount of coolant from the

system.

(3) Start the engine and warm up until thermostat

opens.

(4) With the thermostat open and coolant level low,

visually inspect for coolant flow. If flow is present,

the water pump is pumping coolant through the sys-

tem.

COOLING SYSTEM FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedures:

(1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper

radiator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE THE COOLING SYS-

TEM PRESSURE CAP WITH THE SYSTEM HOT AND

UNDER PRESSURE BECAUSE SERIOUS BURNS

FROM COOLANT CAN OCCUR.

(2) Remove pressure cap when engine is cold,

remove small amount of coolant Idle engine until

thermostat opens, you should observe coolant flow

while looking down the filler neck. Once flow is

detected install the pressure cap.

ELECTRIC FAN MOTOR TEST

Refer to Powertrain Diagnostic Manual for proce-

dure.

COOLANT CONCENTRATION TESTING

Coolant concentration should be checked when any

additional coolant was added to system or after a

coolant drain, flush and refill. The coolant mixture

offers optimum engine cooling and protection against

corrosion when mixed to a freeze point of -37ÉC

(-34ÉF) to -59ÉC (-50ÉF). The use of a hydrometer or a

refractometer can be used to test coolant concentra-

tion.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mix-

ture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, andhigher the freeze protection (up to a maximum of

70% by volume glycol).

A refractometer will test the amount of glycol in a

coolant mixture by measuring the amount a beam of

light bends as it passes through the fluid.

Some coolant manufactures use other types of gly-

cols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freez-

ing protection and corrosion protection and is only

recommended for limited usage. Refer to appropriate

Technical Service Bulletin(s) regarding use of propy-

lene glycol based coolants.

CAUTION: Do not mix types of coolantÐcorrosion

protection will be severely reduced.

Because ethylene glycol and propylene glycol do

not have the same specific gravities, the use of a

hydrometer will be inaccurate. Therefore, Special

Tool 8286 refractometer, is recommended when test-

ing either ethylene or propylene glycol coolants.

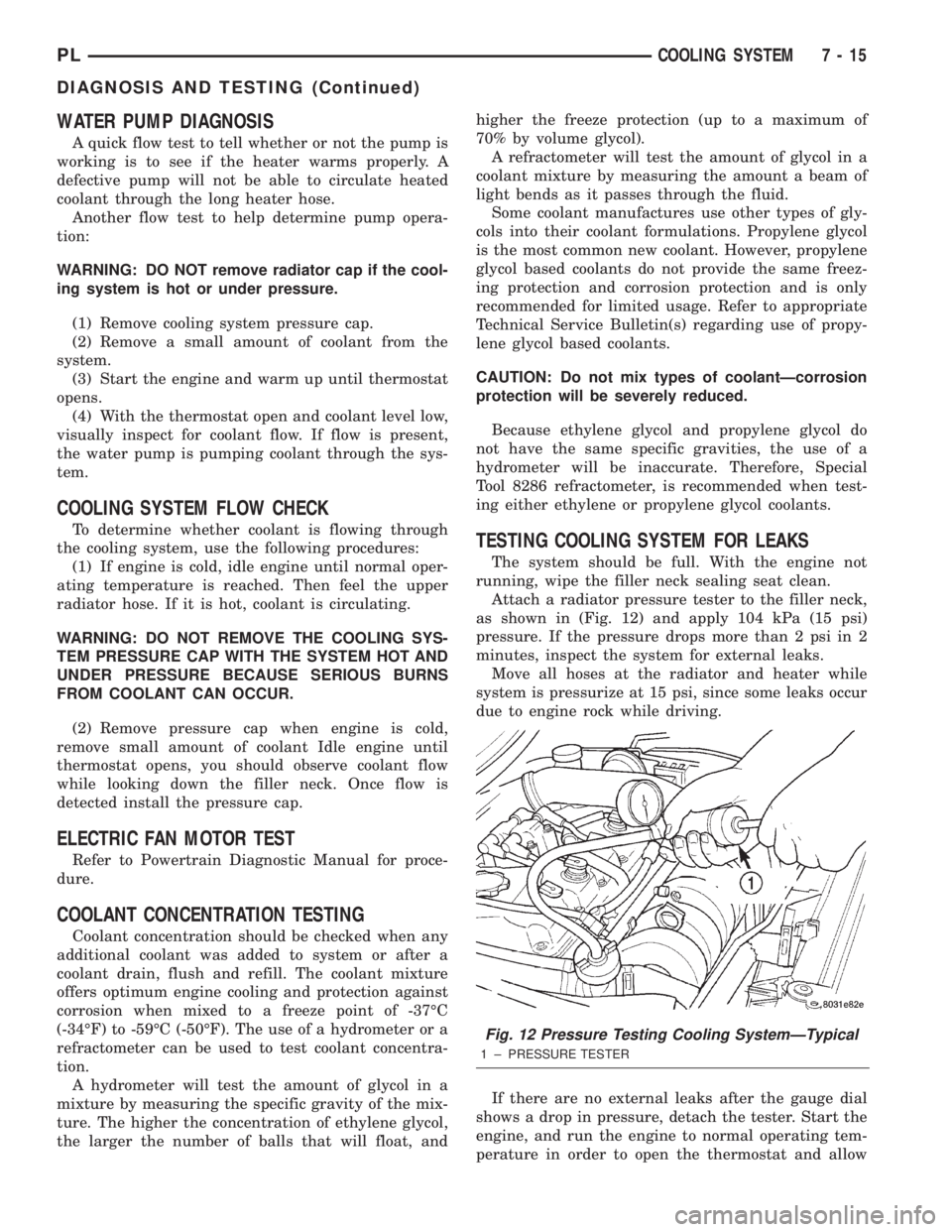

TESTING COOLING SYSTEM FOR LEAKS

The system should be full. With the engine not

running, wipe the filler neck sealing seat clean.

Attach a radiator pressure tester to the filler neck,

as shown in (Fig. 12) and apply 104 kPa (15 psi)

pressure. If the pressure drops more than 2 psi in 2

minutes, inspect the system for external leaks.

Move all hoses at the radiator and heater while

system is pressurize at 15 psi, since some leaks occur

due to engine rock while driving.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start the

engine, and run the engine to normal operating tem-

perature in order to open the thermostat and allow

Fig. 12 Pressure Testing Cooling SystemÐTypical

1 ± PRESSURE TESTER

PLCOOLING SYSTEM 7 - 15

DIAGNOSIS AND TESTING (Continued)

Page 195 of 1285

the coolant to expand. Reattach the tester. If the nee-

dle on the dial fluctuates it indicates a combustion

leak, usually a head gasket leak.

WARNING: WITH THE PRESSURE TESTER IN

PLACE PRESSURE BUILDS UP QUICKLY. ANY

EXCESSIVE PRESSURE BUILD-UP DUE TO CON-

TINUOUS ENGINE OPERATION MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block,

or cracked cylinder head.

There may be internal leaks, which can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil, it indicates an inter-

nal leak in the engine. If there is an internal leak,

the engine must be disassembled for repair.

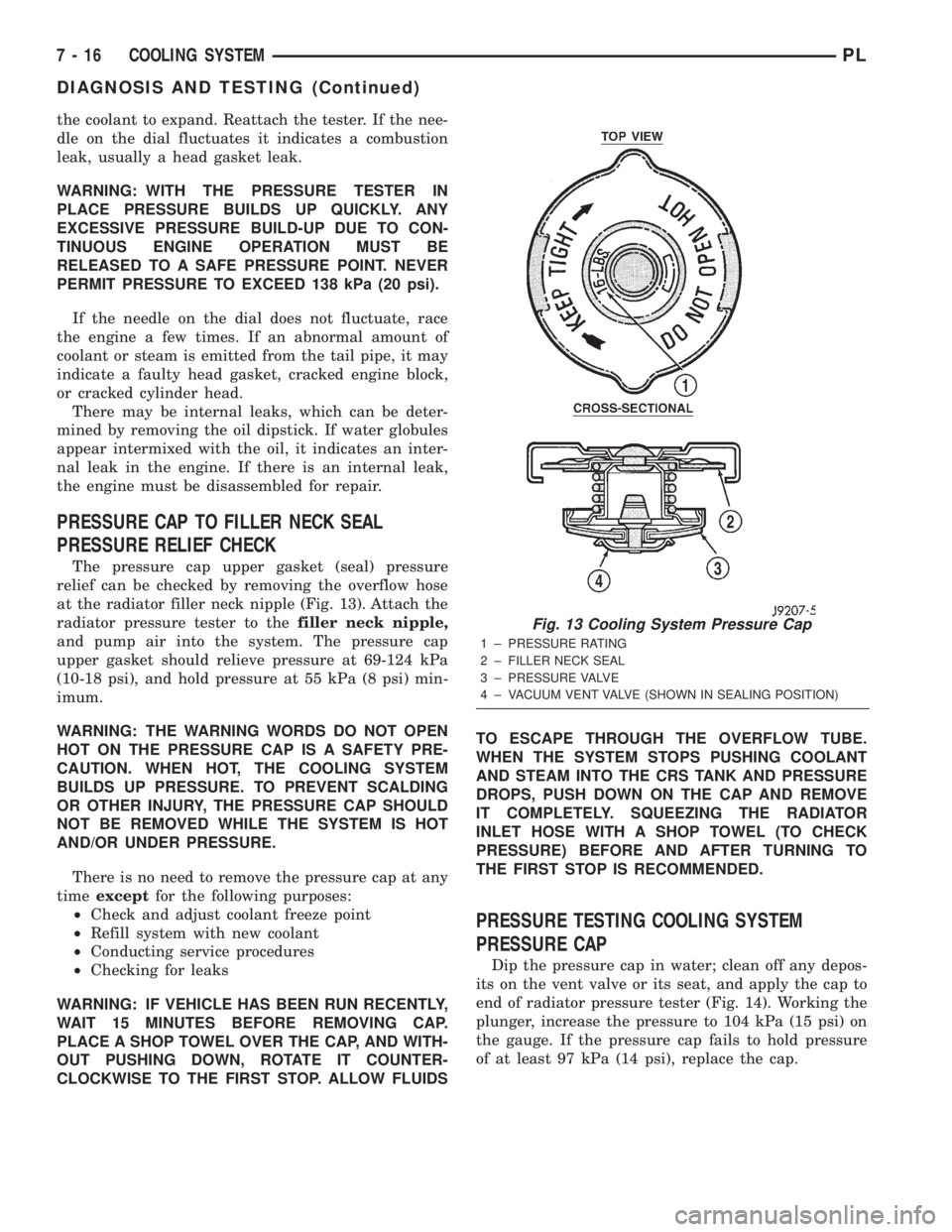

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 13). Attach the

radiator pressure tester to thefiller neck nipple,

and pump air into the system. The pressure cap

upper gasket should relieve pressure at 69-124 kPa

(10-18 psi), and hold pressure at 55 kPa (8 psi) min-

imum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE PRESSURE CAP IS A SAFETY PRE-

CAUTION. WHEN HOT, THE COOLING SYSTEM

BUILDS UP PRESSURE. TO PREVENT SCALDING

OR OTHER INJURY, THE PRESSURE CAP SHOULD

NOT BE REMOVED WHILE THE SYSTEM IS HOT

AND/OR UNDER PRESSURE.

There is no need to remove the pressure cap at any

timeexceptfor the following purposes:

²Check and adjust coolant freeze point

²Refill system with new coolant

²Conducting service procedures

²Checking for leaks

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP.

PLACE A SHOP TOWEL OVER THE CAP, AND WITH-

OUT PUSHING DOWN, ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDSTO ESCAPE THROUGH THE OVERFLOW TUBE.

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS, PUSH DOWN ON THE CAP AND REMOVE

IT COMPLETELY. SQUEEZING THE RADIATOR

INLET HOSE WITH A SHOP TOWEL (TO CHECK

PRESSURE) BEFORE AND AFTER TURNING TO

THE FIRST STOP IS RECOMMENDED.

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water; clean off any depos-

its on the vent valve or its seat, and apply the cap to

end of radiator pressure tester (Fig. 14). Working the

plunger, increase the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the cap.

Fig. 13 Cooling System Pressure Cap

1 ± PRESSURE RATING

2 ± FILLER NECK SEAL

3 ± PRESSURE VALVE

4 ± VACUUM VENT VALVE (SHOWN IN SEALING POSITION)

7 - 16 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)