flat tire DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1078 of 1285

CLEANING AND INSPECTION

CLEANING TIRES

Remove the protective coating on the tires before

delivery of a vehicle. This coating may cause deteri-

oration of the tires.

To remove the protective coating, apply warm

water and let it soak for a few minutes. Afterwards,

scrub the coating away with a soft bristle brush.Steam cleaning may also be used to remove the coat-

ing.

NOTE: DO NOT use gasoline, mineral oil, oil-based

solvent or a wire brush for cleaning.

SPECIFICATIONS

TIRE SPECIFICATIONS

The following guide should help you understand the tire designations:

P Passenger car tire (or ªTº for temporary-use tire).

185 Nominal width of tire in millimeters.

70 Tire height-to-width ratio.

R Radial-ply tire (or ªDº for bias-ply tire).

14 Nominal rim diameter in inches.

Do not install smaller than minimum size tires shown on the tire inflation placard on the vehicle.

PLTIRES AND WHEELS 22 - 9

Page 1079 of 1285

WHEELS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

WHEEL................................10

WHEEL COVER (LOCK-ON).................11

DIAGNOSIS AND TESTING

WHEEL INSPECTION......................11

TIRE AND WHEEL RUNOUT................12

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE................13REMOVAL AND INSTALLATION

WHEEL COVER (LOCK-ON).................15

WHEEL COVER RETAINING NUT............15

TIRE AND WHEEL ASSEMBLY...............16

SPECIFICATIONS

WHEEL SPECIFICATIONS..................17

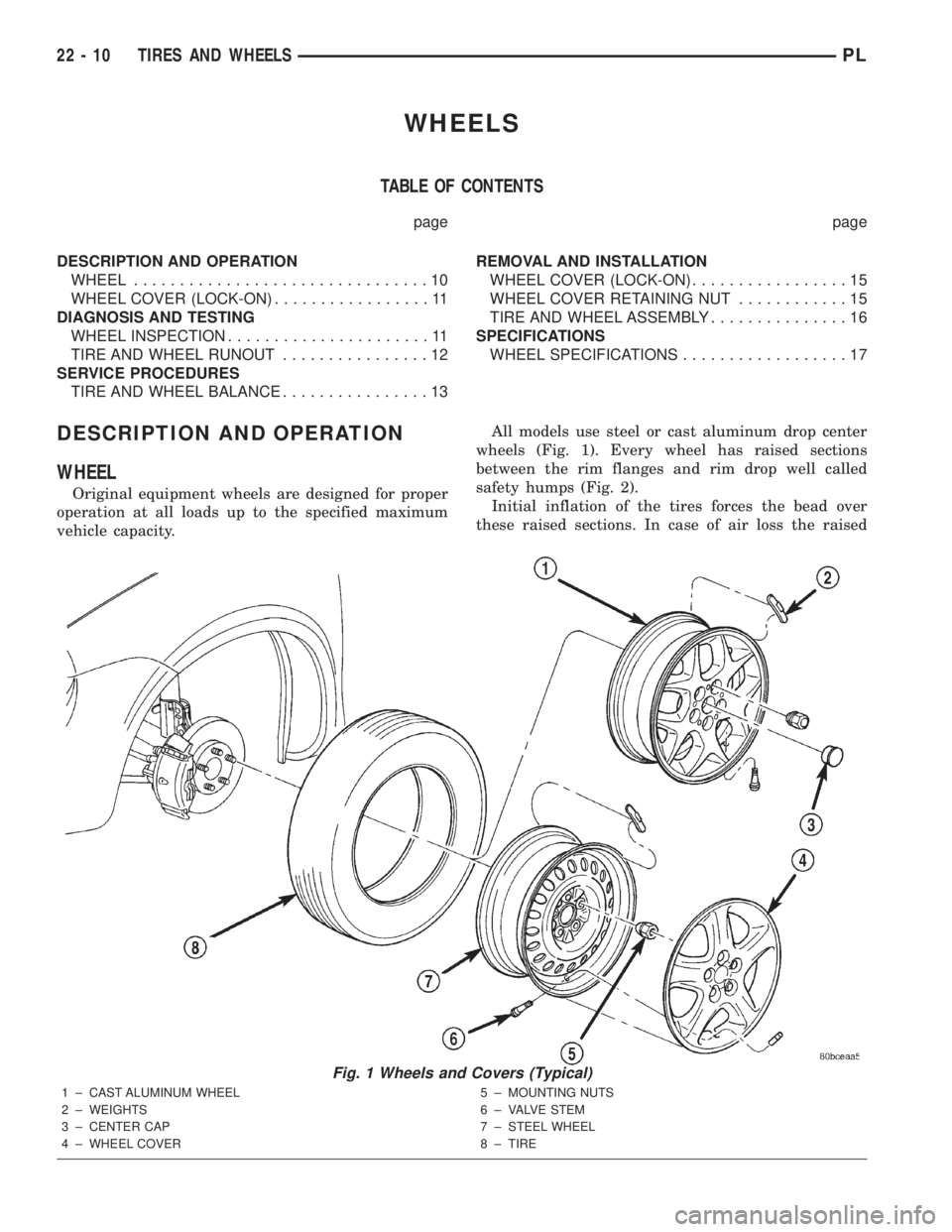

DESCRIPTION AND OPERATION

WHEEL

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.All models use steel or cast aluminum drop center

wheels (Fig. 1). Every wheel has raised sections

between the rim flanges and rim drop well called

safety humps (Fig. 2).

Initial inflation of the tires forces the bead over

these raised sections. In case of air loss the raised

Fig. 1 Wheels and Covers (Typical)

1 ± CAST ALUMINUM WHEEL

2 ± WEIGHTS

3 ± CENTER CAP

4 ± WHEEL COVER5 ± MOUNTING NUTS

6 ± VALVE STEM

7 ± STEEL WHEEL

8 ± TIRE

22 - 10 TIRES AND WHEELSPL

Page 1081 of 1285

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY AFFECT

THE SAFETY AND HANDLING OF THE VEHICLE.

USED WHEELS ARE NOT RECOMMENDED. THE

SERVICE HISTORY OF THE WHEEL MAY HAVE

INCLUDED SEVERE TREATMENT OR VERY HIGH

MILEAGE. THE RIM COULD FAIL WITHOUT WARN-

ING.

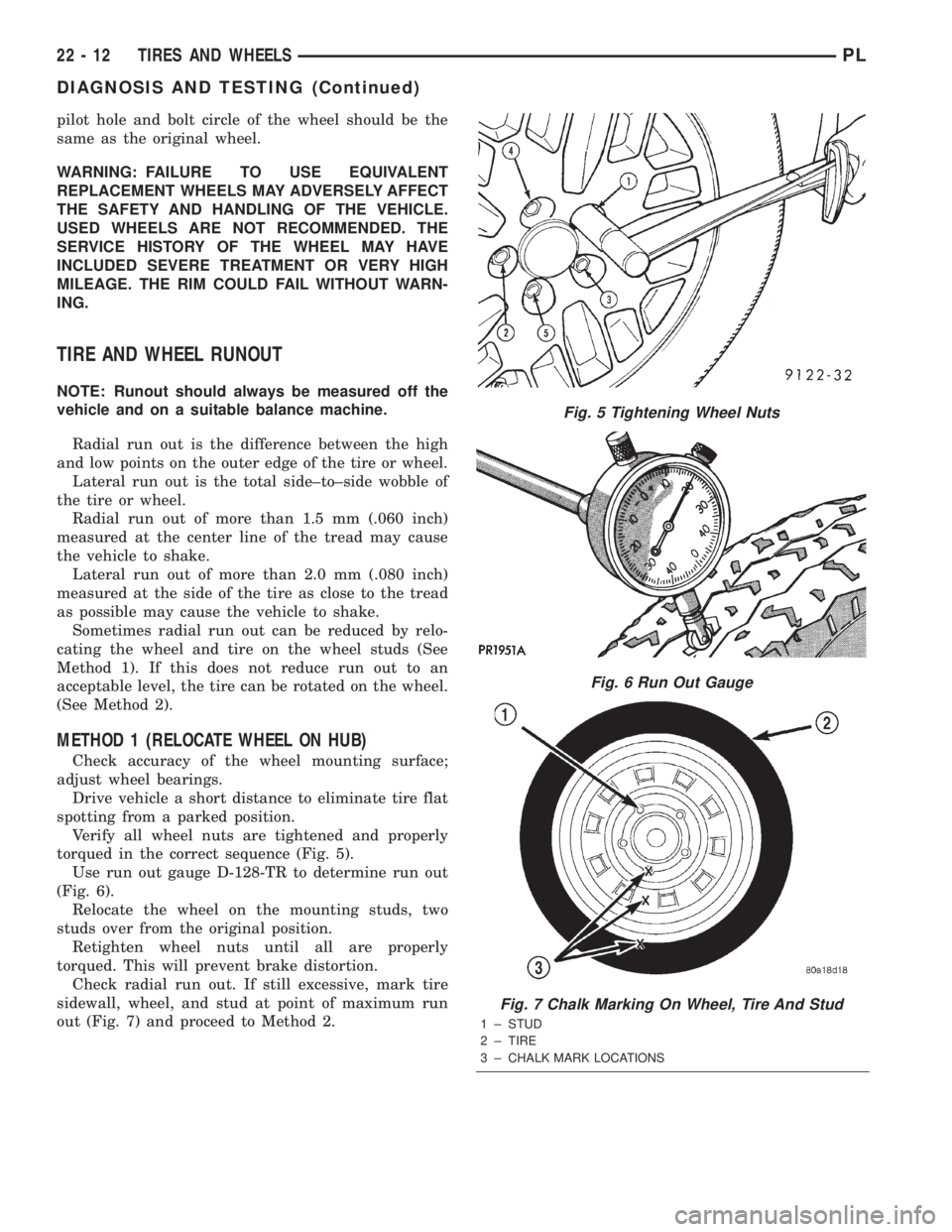

TIRE AND WHEEL RUNOUT

NOTE: Runout should always be measured off the

vehicle and on a suitable balance machine.

Radial run out is the difference between the high

and low points on the outer edge of the tire or wheel.

Lateral run out is the total side±to±side wobble of

the tire or wheel.

Radial run out of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral run out of more than 2.0 mm (.080 inch)

measured at the side of the tire as close to the tread

as possible may cause the vehicle to shake.

Sometimes radial run out can be reduced by relo-

cating the wheel and tire on the wheel studs (See

Method 1). If this does not reduce run out to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

Check accuracy of the wheel mounting surface;

adjust wheel bearings.

Drive vehicle a short distance to eliminate tire flat

spotting from a parked position.

Verify all wheel nuts are tightened and properly

torqued in the correct sequence (Fig. 5).

Use run out gauge D-128-TR to determine run out

(Fig. 6).

Relocate the wheel on the mounting studs, two

studs over from the original position.

Retighten wheel nuts until all are properly

torqued. This will prevent brake distortion.

Check radial run out. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum run

out (Fig. 7) and proceed to Method 2.

Fig. 5 Tightening Wheel Nuts

Fig. 6 Run Out Gauge

Fig. 7 Chalk Marking On Wheel, Tire And Stud

1 ± STUD

2 ± TIRE

3 ± CHALK MARK LOCATIONS

22 - 12 TIRES AND WHEELSPL

DIAGNOSIS AND TESTING (Continued)