remote control DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 536 of 1285

8W-44 INTERIOR LIGHTING

Component Page

A/C Heater Control...................8W-44-5

Cargo Lamp........................8W-44-4

Center Stack Lamp...................8W-44-5

Decklid Release Switch................8W-44-4

Dome Lamp........................8W-44-2

Dome Lamp/Intrusion Sensor...........8W-44-2

Fuse 13 (PDC).....................8W-44-2, 4

G101..............................8W-44-4

G201..............................8W-44-5

G203..............................8W-44-5

G204..........................8W-44-3, 4, 5

G301..............................8W-44-2

Glove Box Lamp/Switch...............8W-44-4Component Page

Headlamp Leveling Switch.............8W-44-5

Instrument Cluster.................8W-44-3, 5

Left Visor/Vanity Lamp................8W-44-4

Map/Reading Lamps................8W-44-2, 3

Power Distribution Center...........8W-44-2, 4

PRNDL Lamp.......................8W-44-5

Radio.............................8W-44-5

Rear Window Defogger Switch..........8W-44-5

Remote Keyless Entry Module..........8W-44-2

Right Visor/Vanity Lamp..............8W-44-4

Traction Control Switch...............8W-44-5

Underhood Lamp....................8W-44-4

PL8W - 44 INTERIOR LIGHTING 8W - 44 - 1

Page 537 of 1285

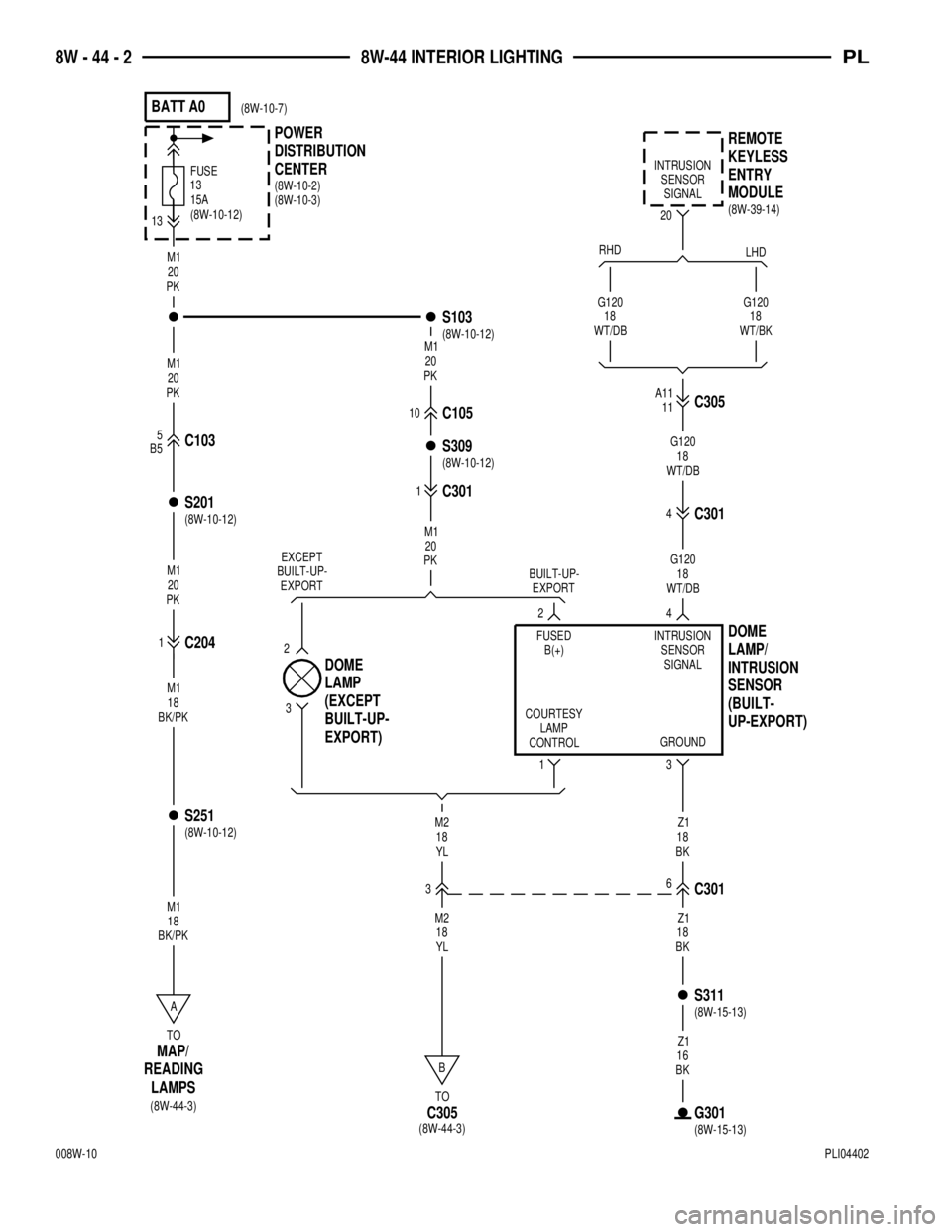

M1

18

BK/PK

C2041M1

20

PK

S201

B5C1035M1

20

PK

15A

FUSE

13

M1

20

PK

2013

BATT A0

S103

10C105

S309

C3011

M1

20

PK

3 2(EXCEPT LAMP

DOME

BUILT-UP-

EXPORT)MODULE ENTRY

KEYLESS

REMOTE

UP-EXPORT) (BUILT- LAMP/ DOME

FUSED

B(+)

COURTESY

LAMP

CONTROLGROUND

3 1

POWER

DISTRIBUTION

CENTER

G120

18

WT/DB

G120

18

WT/DB

C30511

C3014 A11

S251

A

(8W-44-3)

36C301

G301

S311

B

(8W-44-3)BUILT-UP-

EXPORT EXCEPT

BUILT-UP-

EXPORT

TO

LAMPS READINGMAP/TO

C305

Z1

18

BK

Z1

18

BK

Z1

16

BK

M2

18

YL

M2

18

YL

M1

18

BK/PK

INTRUSION

SENSOR

M1

20

PK

24

WT/DB18 G120

G120

18

WT/BK

RHD

LHD

SIGNAL SENSOR INTRUSION INTRUSION

SENSOR

SIGNAL

(8W-10-12)(8W-10-12)(8W-10-7)

(8W-10-12)

(8W-10-12)(8W-39-14) (8W-10-2)

(8W-10-3)

(8W-10-12)

(8W-15-13) (8W-15-13)

8W - 44 - 2 8W-44 INTERIOR LIGHTINGPL

008W-10PLI04402

Page 612 of 1285

Component Page

PRNDL Lamp......................8W-80-39

Proportional Evap/Purge Solenoid.......8W-80-39

Radiator Fan Motor.................8W-80-39

Radio.............................8W-80-39

Rear Window Defogger Switch.........8W-80-40

Remote Keyless Entry Module.........8W-80-40

Right Back-Up Lamp................8W-80-41

Right City Lamp....................8W-80-41

Right Front Door Speaker.............8W-80-41

Right Front Fog Lamp...............8W-80-41

Right Front Side Marker Lamp........8W-80-42

Right Front Turn Signal Lamp.........8W-80-42

Right Front Wheel Speed Sensor.......8W-80-42

Right Headlamp....................8W-80-42

Right Headlamp Leveling Motor........8W-80-43

Right Instrument Panel Speaker.......8W-80-43

Right License Lamp.................8W-80-43

Right Park/Turn Signal Lamp..........8W-80-43

Right Rear Door Lock Motor...........8W-80-43

Right Rear Fog Lamp................8W-80-44

Right Rear Speaker..................8W-80-44

Right Rear Turn Signal Lamp..........8W-80-44Component Page

Right Rear Wheel Speed Sensor........8W-80-44

Right Repeater Lamp................8W-80-44

Right Tail/Stop Lamp................8W-80-45

Right Tail/Stop/Turn Signal Lamp......8W-80-45

Seat Belt Switch....................8W-80-45

Sentry Key Immobilizer Module........8W-80-45

Siren.............................8W-80-45

Sunroof Control Module..............8W-80-46

Sunroof Motor......................8W-80-46

Sunroof Switch.....................8W-80-46

Sunroof Vent Switch.................8W-80-46

Throttle Position Sensor..............8W-80-46

Torque Converter Clutch Solenoid.......8W-80-47

Traction Control Switch..............8W-80-47

Trunk Key Cylinder Switch............8W-80-47

Underhood Lamp...................8W-80-47

Vehicle Speed Control Servo...........8W-80-47

Vehicle Speed Sensor................8W-80-48

Windshield Washer Pump.............8W-80-48

Wipe/Wash Switch...................8W-80-48

Wiper Motor.......................8W-80-48

PL8W - 80 CONNECTOR PIN-OUTS 8W - 80 - 3

Page 649 of 1285

LHD

RHD

Z2 22BK/LGGROUND

F9 20RD/BKFUSED B(+)

PASSENGER DOOR SWITCH MUX

P96 20LG/BK

- -

L7 20BK/YLDIMMER SWITCH LOW BEAM OUTPUT

REMOTE KEYLESS

ENTRY MODULE

1411

12

13

9 5

6

8 7 3

4 2 1CIRCUIT CAV

10

21 15

18

19 17 16

20

24 23 22

25

26

F35 18RDHEADLAMP SWITCH OUTPUT

P33 18OR/BKFUSED B(+)

P34 18PK/BKDOOR LOCK DRIVER

P36 18PK/VTDOOR UNLOCK DRIVER

M9 20DB/ORDOOR UNLOCK DRIVER

PASSENGER DOOR AJAR/ RKE SENSE

P97 20LGDRIVER DOOR SWITCH MUX

Z1 20BKGROUND

X161 20WTRKE ANTENNA

X5 22WT/RDDISPLAY BACKLIGHT

Q2 16LG/BKDECKLID RELEASE RELAY OUTPUT

G69 20BK/ORVTSS INDICATOR DRIVER

X3 22BK/RDHORN RELAY CONTROL

D25 20VT/YLPCI BUS

G120 18WT/BKINTRUSION SENSOR SIGNAL

M1 20PKFUSED B(+)

G5 20DB/WTFUSED IGNITION SWITCH OUTPUT (ST-RUN)

G70 20BR/TNHOOD AJAR SWITCH SENSE

G71 20VT/YLDECKLID SECURITY SWITCH SENSE

G75 18TNDRIVER DOOR AJAR SWITCH SENSE

X161 20WTJAPAN ANTENNA L4 16VT/WT

BUILT-UP-EXPORT

1

13

14

26REAR WINDOW DEFOGGER RELAY OUTPUT

C15 12BKPANEL LAMPS DRIVER

E2 20OR Z2 22BK/LGGROUND F20 20WTFUSED IGNITION SWITCH OUTPUT (RUN) A4 12BK/RDFUSED B(+)

SWITCH

51

DEFOGGER REAR WINDOW

FUNCTION

CAV CIRCUIT

1

2

4 3

5

F35 18RD/YL

FUSED B(+) 3

5

C15 12BK/WTRAER WINDOW DEFOGGER RELAY OUTPUT

INTRUSION SENSOR SIGNAL

G120 18WT/DB20

BLACK

BLACK

FUNCTION

8W - 80 - 40 8W-80 CONNECTOR PIN-OUTSPL

J008W-10PLI08040

Page 681 of 1285

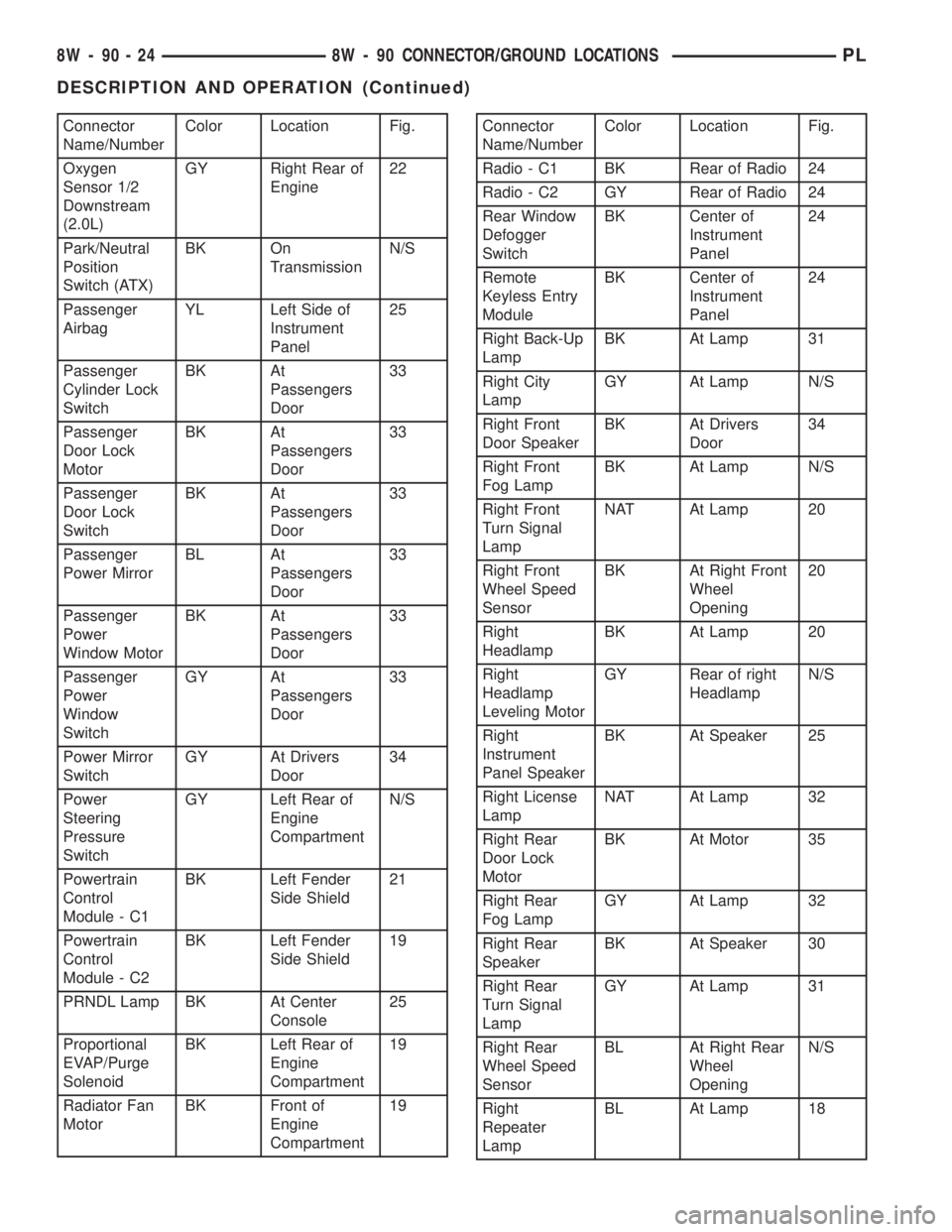

Connector

Name/NumberColor Location Fig.

Oxygen

Sensor 1/2

Downstream

(2.0L)GY Right Rear of

Engine22

Park/Neutral

Position

Switch (ATX)BK On

TransmissionN/S

Passenger

AirbagYL Left Side of

Instrument

Panel25

Passenger

Cylinder Lock

SwitchBK At

Passengers

Door33

Passenger

Door Lock

MotorBK At

Passengers

Door33

Passenger

Door Lock

SwitchBK At

Passengers

Door33

Passenger

Power MirrorBL At

Passengers

Door33

Passenger

Power

Window MotorBK At

Passengers

Door33

Passenger

Power

Window

SwitchGY At

Passengers

Door33

Power Mirror

SwitchGY At Drivers

Door34

Power

Steering

Pressure

SwitchGY Left Rear of

Engine

CompartmentN/S

Powertrain

Control

Module - C1BK Left Fender

Side Shield21

Powertrain

Control

Module - C2BK Left Fender

Side Shield19

PRNDL Lamp BK At Center

Console25

Proportional

EVAP/Purge

SolenoidBK Left Rear of

Engine

Compartment19

Radiator Fan

MotorBK Front of

Engine

Compartment19Connector

Name/NumberColor Location Fig.

Radio - C1 BK Rear of Radio 24

Radio - C2 GY Rear of Radio 24

Rear Window

Defogger

SwitchBK Center of

Instrument

Panel24

Remote

Keyless Entry

ModuleBK Center of

Instrument

Panel24

Right Back-Up

LampBK At Lamp 31

Right City

LampGY At Lamp N/S

Right Front

Door SpeakerBK At Drivers

Door34

Right Front

Fog LampBK At Lamp N/S

Right Front

Turn Signal

LampNAT At Lamp 20

Right Front

Wheel Speed

SensorBK At Right Front

Wheel

Opening20

Right

HeadlampBK At Lamp 20

Right

Headlamp

Leveling MotorGY Rear of right

HeadlampN/S

Right

Instrument

Panel SpeakerBK At Speaker 25

Right License

LampNAT At Lamp 32

Right Rear

Door Lock

MotorBK At Motor 35

Right Rear

Fog LampGY At Lamp 32

Right Rear

SpeakerBK At Speaker 30

Right Rear

Turn Signal

LampGY At Lamp 31

Right Rear

Wheel Speed

SensorBL At Right Rear

Wheel

OpeningN/S

Right

Repeater

LampBL At Lamp 18

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 1176 of 1285

SPECIFICATIONS

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other

underhood services, the hood latch release mecha-

nism and safety catch should be inspected, cleaned,

and lubricated. During the winter season, external

door lock cylinders should be lubricated to assure

proper operation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Decklid Hinges

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Decklid Latch

MOPARTMULTIPURPOSE GREASE OR

EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Decklid Lock Cylinder

SPECIAL TOOLS

BODY

STICK, TRIM C 4755

PLBODY 23 - 59

Page 1177 of 1285

SPECIFICATIONS

TABLE OF CONTENTS

page page

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS........60

BODY GAP AND FLUSH MEASUREMENTS.....61

BODY OPENING DIMENSION...............62BODY SEALING LOCATIONS................64

STRUCTURAL ADHESIVE LOCATIONS........74

TORQUE SPECIFICATIONS.................76

WELD LOCATIONS.......................77

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door Hinges ± Hinge Pin and Pivot Contact

Areas

²Hood Hinges ± Pivot Points

²Liftgate Hinges

²Decklid Hinges

MOPARTSPRAY WHITE CUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Decklid Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Decklid Lock Cylinder

23 - 60 BODYPL