width DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 12 of 1285

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT........................ 1

FRONT SUSPENSION....................... 9REAR SUSPENSION....................... 35

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

WHEEL ALIGNMENT.......................1

DIAGNOSIS AND TESTING

SUSPENSION AND STEERING DIAGNOSIS.....3

SERVICE PROCEDURES

CURB HEIGHT MEASUREMENT..............5WHEEL ALIGNMENT.......................5

SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS.........8

DESCRIPTION AND OPERATION

WHEEL ALIGNMENT

Proper vehicle wheel alignment is the proper

adjustment of all interrelated front and rear suspen-

sion angles. These angles are what affects the han-

dling and steering of the vehicle when it is in motion.

The method of checking a vehicle's front and rear

wheel alignment will vary depending on the type and

manufacturer of the equipment being used. Instruc-

tions furnished by the manufacturer of the equip-

ment being used should always be followed to ensure

accuracy of the alignment, except when alignment

specifications recommended by this corporation differ.

Typical wheel alignment angles and measurements

are camber, caster, toe, and thrust angle.

²Camber is the number of degrees the top of the

tire and wheel are tilted either inward or outward

(Fig. 1). Camber is a tire wearing angle. Excessive

negative camber will cause tread wear at the inside

of the tire, while excessive positive camber will cause

outside tire wear.²Caster is the number of degrees of forward or

rearward tilt of the steering knuckle. Forward tilt

provides a negative caster angle, while rearward tilt

provides a positive caster angle. Caster is not adjust-

able on this vehicle.

²Cross Camber is the difference between left and

right camber. The right side camber is to be sub-

tracted from the left, resulting in the cross camber

reading. For example, if the left camber is +0.3É and

the right camber is 0.0É, the cross camber would be

+0.3É.

²Toe is measured in degrees or inches and is the

difference in width between the centered leading and

trailing edges of the tires on the same axle (Fig. 1).

Toe-in means that the front width is more narrow

than the rear. Toe-out means that the front width is

wider than the rear.

²Thrust Angle is defined as the average of the toe

settings on each rear wheel. If this measurement is

out of specification, readjust the rear wheel toe so

that each wheel has 1/2 of the total toe measure-

ment. When readjusting, do not exceed the total toe

specification.

PLSUSPENSION 2 - 1

Page 139 of 1285

If the brake shoe assemblies do not require

replacement, reinstall the assemblies making sure

each brake shoe is returned to the original position.

Refer to DISC BRAKE SHOES in the REMOVAL

AND INSTALLATION section in this section of this

service manual group.

CALIPER INSPECTION

Check for brake fluid leaks in and around the boot

area. Check for any ruptures, brittleness or damage

to the piston dust boot. If the boot is damaged, or a

fluid leak is visible, disassemble the caliper assembly

and install a new seal and boot, and a piston if it is

scored. Refer to DISC BRAKE CALIPER in the DIS-

ASSEMBLY AND ASSEMBLY section in this section

of this service manual group.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to DISC BRAKE

CALIPER in the DISASSEMBLY AND ASSEMBLY

section in this section of this service manual group.

DISC BRAKES (REAR)

BRAKE SHOES

Clean the rear brake shoes and calipers with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary.

Remove the rear disc brake shoes. Refer to DISC

BRAKE SHOES in the REMOVAL AND INSTALLA-

TION section in this section of this service manual

group.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.0 mm (9/32 inch) or

less, they should be replaced.

Replace both brake shoe assemblies (inboard and

outboard). It is necessary that both front wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

If the brake shoe assemblies do not require

replacement, reinstall the assemblies making sure

each brake shoe is returned to the original position.

Refer to DISC BRAKE SHOES in the REMOVAL

AND INSTALLATION section in this section of this

service manual group.

CALIPER INSPECTION

Check for brake fluid leaks in and around the boot

area. Check for any ruptures, brittleness or damage

to the piston dust boot. If the boot is damaged, or afluid leak is visible, disassemble the caliper assembly

and install a new seal and boot, and a piston if it is

scored. Refer to DISC BRAKE CALIPER in the DIS-

ASSEMBLY AND ASSEMBLY section in this section

of this service manual group.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to DISC BRAKE

CALIPER in the DISASSEMBLY AND ASSEMBLY

section in this section of this service manual group.

DRUM BRAKES (REAR)

BRAKE SHOES

Clean the rear brake shoes and springs with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

Rear brake shoe lining should show contact across

the entire width of the lining and also from the heel

to the toe of the lining. Replace the shoes if noted

otherwise.

Brake shoes with lack of contact at the toe or heel

of the brake shoe lining may be improperly ground.

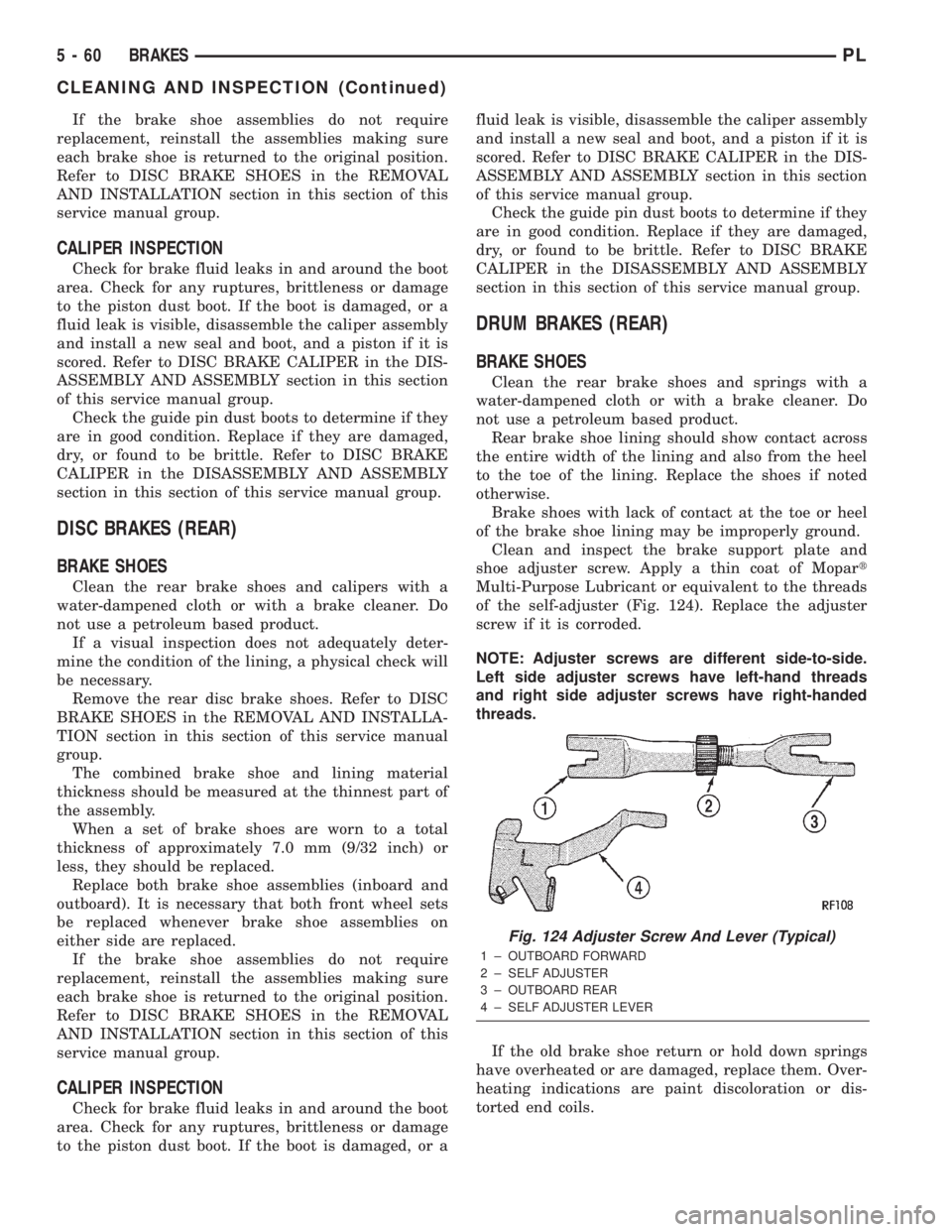

Clean and inspect the brake support plate and

shoe adjuster screw. Apply a thin coat of Mopart

Multi-Purpose Lubricant or equivalent to the threads

of the self-adjuster (Fig. 124). Replace the adjuster

screw if it is corroded.

NOTE: Adjuster screws are different side-to-side.

Left side adjuster screws have left-hand threads

and right side adjuster screws have right-handed

threads.

If the old brake shoe return or hold down springs

have overheated or are damaged, replace them. Over-

heating indications are paint discoloration or dis-

torted end coils.

Fig. 124 Adjuster Screw And Lever (Typical)

1 ± OUTBOARD FORWARD

2 ± SELF ADJUSTER

3 ± OUTBOARD REAR

4 ± SELF ADJUSTER LEVER

5 - 60 BRAKESPL

CLEANING AND INSPECTION (Continued)

Page 239 of 1285

The PCM sends approximately 8 volts to the Hall-

effect sensor. This voltage is required to operate the

Hall-effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.CAMSHAFT POSITION SENSORÐPCM INPUT

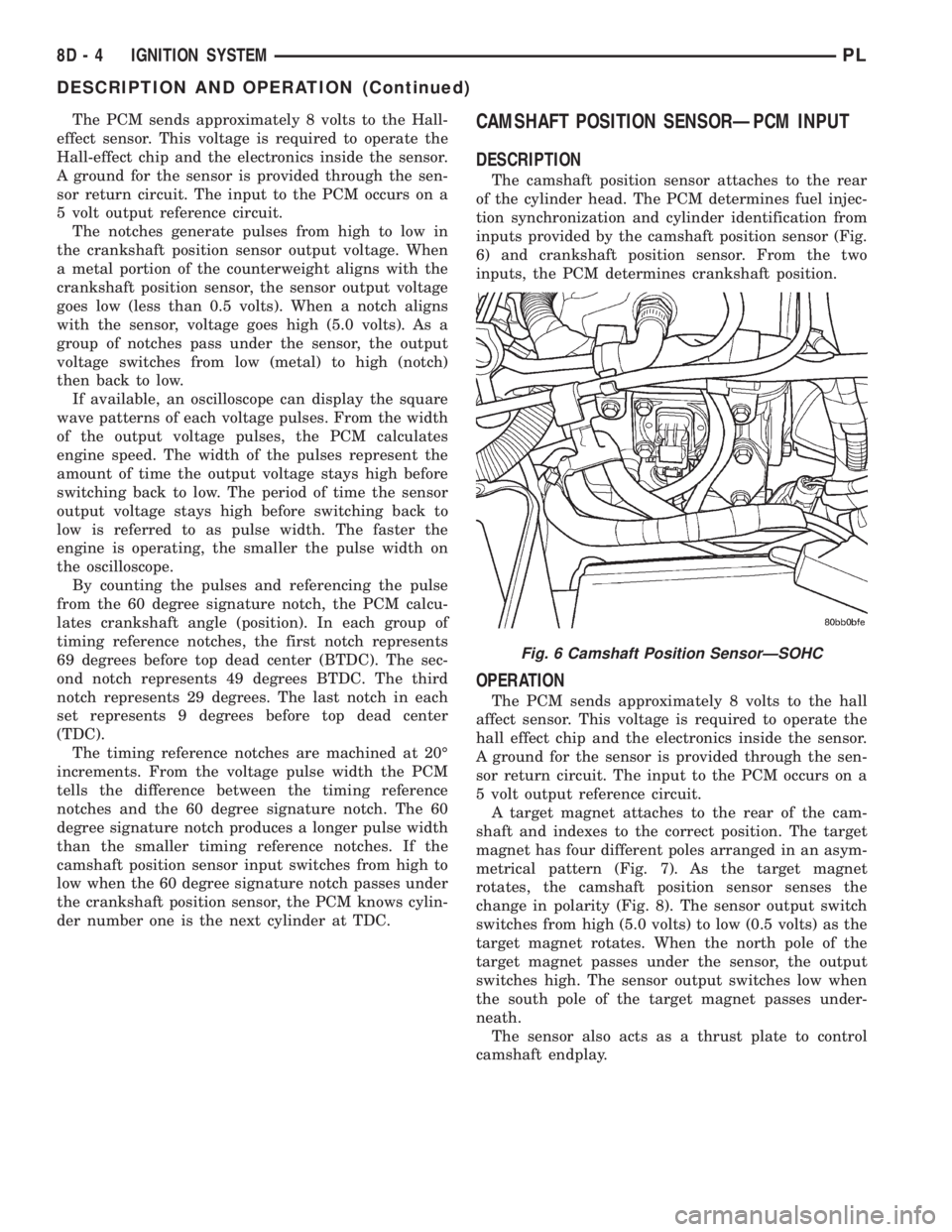

DESCRIPTION

The camshaft position sensor attaches to the rear

of the cylinder head. The PCM determines fuel injec-

tion synchronization and cylinder identification from

inputs provided by the camshaft position sensor (Fig.

6) and crankshaft position sensor. From the two

inputs, the PCM determines crankshaft position.

OPERATION

The PCM sends approximately 8 volts to the hall

affect sensor. This voltage is required to operate the

hall effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

A target magnet attaches to the rear of the cam-

shaft and indexes to the correct position. The target

magnet has four different poles arranged in an asym-

metrical pattern (Fig. 7). As the target magnet

rotates, the camshaft position sensor senses the

change in polarity (Fig. 8). The sensor output switch

switches from high (5.0 volts) to low (0.5 volts) as the

target magnet rotates. When the north pole of the

target magnet passes under the sensor, the output

switches high. The sensor output switches low when

the south pole of the target magnet passes under-

neath.

The sensor also acts as a thrust plate to control

camshaft endplay.

Fig. 6 Camshaft Position SensorÐSOHC

8D - 4 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 724 of 1285

ENGINE

TABLE OF CONTENTS

page page

STANDARD SERVICE PROCEDURES........... 1

ENGINE DIAGNOSIS........................ 82.0L SOHC ENGINE....................... 15

STANDARD SERVICE PROCEDURES

TABLE OF CONTENTS

page page

GENERAL INFORMATION

FORM-IN-PLACE GASKETS & SEALERS........1

ENGINE GASKET SURFACE PREPARATION.....2

CRANKSHAFT DAMPER BOLT ACCESS PLUG . . . 2

ENGINE CORE PLUGS.....................2

ENGINE PERFORMANCE...................3HONING CYLINDER BORES.................3

MEASURING WITH PLASTIGAGE.............4

REPAIR OF DAMAGED OR WORN THREADS....5

HYDROSTATIC LOCKED ENGINE.............5

CHECKING ENGINE OIL LEVEL..............6

ENGINE OIL SERVICE......................7

GENERAL INFORMATION

FORM-IN-PLACE GASKETS & SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Alwaysinspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANT

MopartBed Plate Sealant is a unique (green-in-

color) anaerobic type gasket material that is specially

made to seal the area between the bedplate and cyl-

inder block without disturbing the bearing clearance

or alignment of these components. The material

cures slowly in the absence of air when torqued

between two metallic surfaces, and will rapidly cure

when heat is applied.

PLENGINE 9 - 1

Page 728 of 1285

²When checking #2 main bearing shim #1 & #3

main bearing.

²When checking #3 main bearing shim #2 & #4

main bearing.

²When checking #4 main bearing shim #3 main

bearing.

NOTE: REMOVE ALL SHIMS BEFORE REASSEM-

BLING ENGINE

ALTERNATIVE METHOD

The weight of the crankshaft can be supported by a

jack under the counterweight adjacent to the bearing

being checked.

PLASTIGAGE PROCEDURE

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 5). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

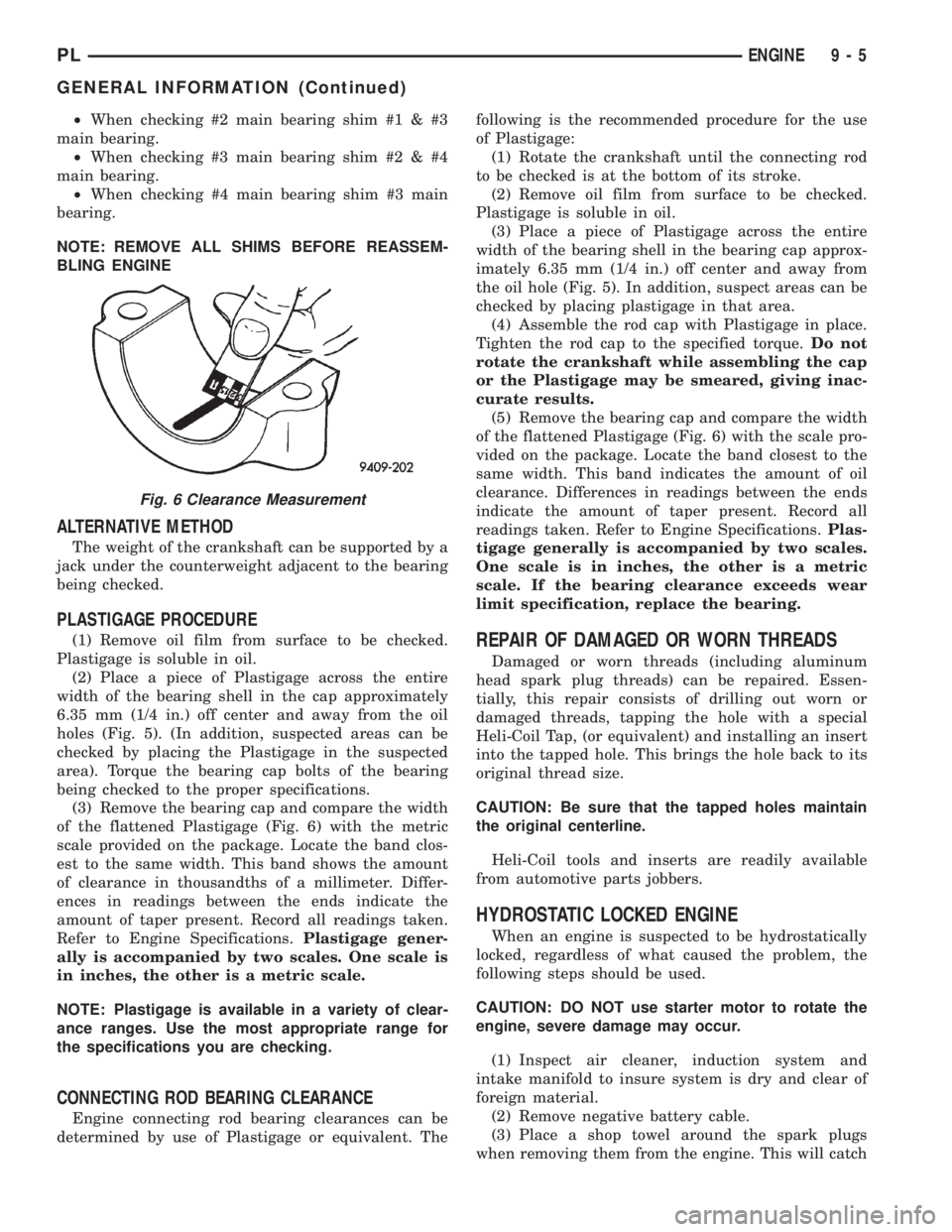

(3) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 6) with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Refer to Engine Specifications.Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage or equivalent. Thefollowing is the recommended procedure for the use

of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is at the bottom of its stroke.

(2) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole (Fig. 5). In addition, suspect areas can be

checked by placing plastigage in that area.

(4) Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque.Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 6) with the scale pro-

vided on the package. Locate the band closest to the

same width. This band indicates the amount of oil

clearance. Differences in readings between the ends

indicate the amount of taper present. Record all

readings taken. Refer to Engine Specifications.Plas-

tigage generally is accompanied by two scales.

One scale is in inches, the other is a metric

scale. If the bearing clearance exceeds wear

limit specification, replace the bearing.

REPAIR OF DAMAGED OR WORN THREADS

Damaged or worn threads (including aluminum

head spark plug threads) can be repaired. Essen-

tially, this repair consists of drilling out worn or

damaged threads, tapping the hole with a special

Heli-Coil Tap, (or equivalent) and installing an insert

into the tapped hole. This brings the hole back to its

original thread size.

CAUTION: Be sure that the tapped holes maintain

the original centerline.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

Fig. 6 Clearance Measurement

PLENGINE 9 - 5

GENERAL INFORMATION (Continued)

Page 737 of 1285

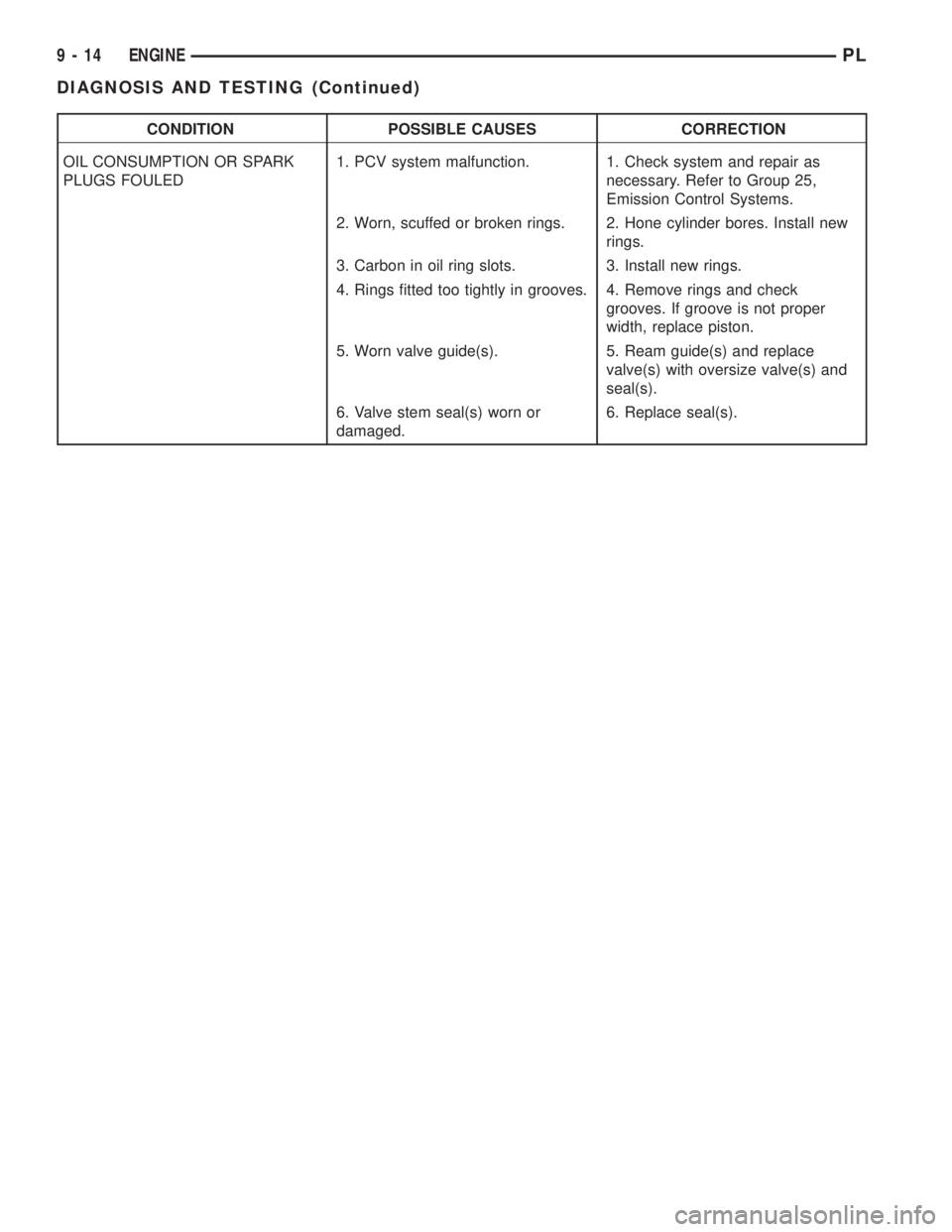

CONDITION POSSIBLE CAUSES CORRECTION

OIL CONSUMPTION OR SPARK

PLUGS FOULED1. PCV system malfunction. 1. Check system and repair as

necessary. Refer to Group 25,

Emission Control Systems.

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new

rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check

grooves. If groove is not proper

width, replace piston.

5. Worn valve guide(s). 5. Ream guide(s) and replace

valve(s) with oversize valve(s) and

seal(s).

6. Valve stem seal(s) worn or

damaged.6. Replace seal(s).

9 - 14 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 785 of 1285

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. The intake valve seat must be ser-

viced when the valve seat width is 2.0 mm (0.079 in.)

or greater. The exhaust valve seat must be serviced

when the valve seat width is 2.5 mm (0.098 in.) or

greater. Otherwise the cylinder head must be

replaced.

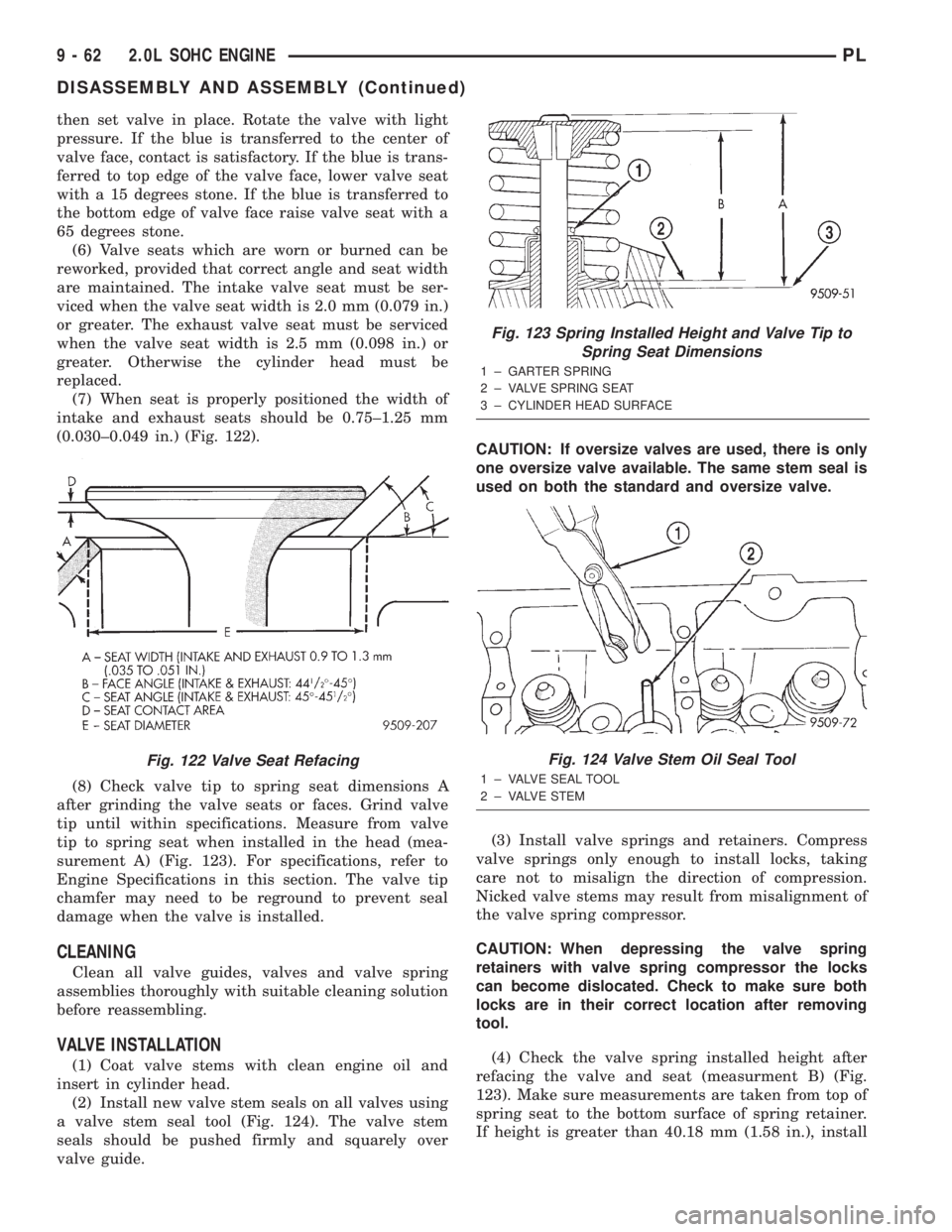

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.75±1.25 mm

(0.030±0.049 in.) (Fig. 122).

(8) Check valve tip to spring seat dimensions A

after grinding the valve seats or faces. Grind valve

tip until within specifications. Measure from valve

tip to spring seat when installed in the head (mea-

surement A) (Fig. 123). For specifications, refer to

Engine Specifications in this section. The valve tip

chamfer may need to be reground to prevent seal

damage when the valve is installed.

CLEANING

Clean all valve guides, valves and valve spring

assemblies thoroughly with suitable cleaning solution

before reassembling.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 124). The valve stem

seals should be pushed firmly and squarely over

valve guide.CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height after

refacing the valve and seat (measurment B) (Fig.

123). Make sure measurements are taken from top of

spring seat to the bottom surface of spring retainer.

If height is greater than 40.18 mm (1.58 in.), install

Fig. 122 Valve Seat Refacing

Fig. 123 Spring Installed Height and Valve Tip to

Spring Seat Dimensions

1 ± GARTER SPRING

2 ± VALVE SPRING SEAT

3 ± CYLINDER HEAD SURFACE

Fig. 124 Valve Stem Oil Seal Tool

1 ± VALVE SEAL TOOL

2 ± VALVE STEM

9 - 62 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 792 of 1285

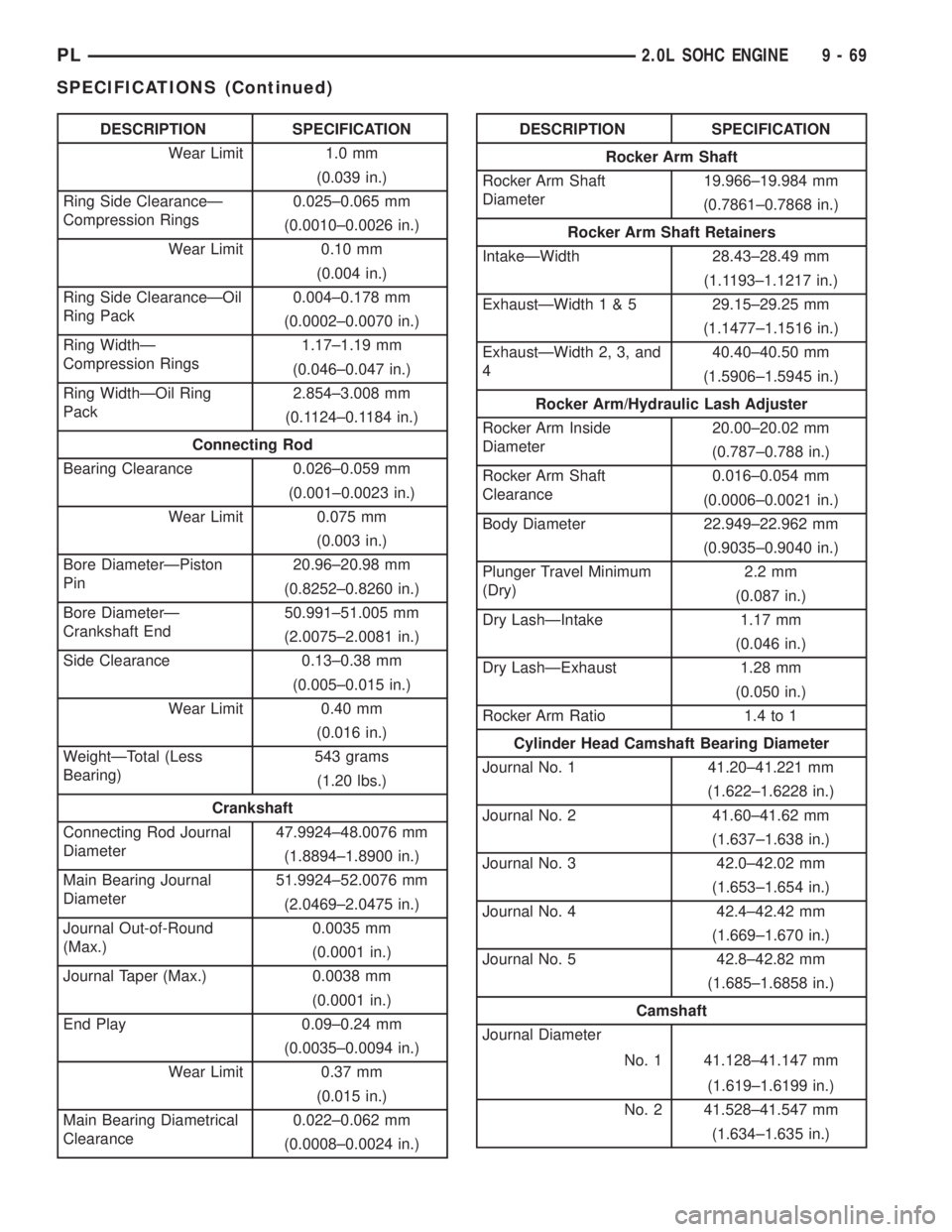

DESCRIPTION SPECIFICATION

Wear Limit 1.0 mm

(0.039 in.)

Ring Side ClearanceÐ

Compression Rings0.025±0.065 mm

(0.0010±0.0026 in.)

Wear Limit 0.10 mm

(0.004 in.)

Ring Side ClearanceÐOil

Ring Pack0.004±0.178 mm

(0.0002±0.0070 in.)

Ring WidthÐ

Compression Rings1.17±1.19 mm

(0.046±0.047 in.)

Ring WidthÐOil Ring

Pack2.854±3.008 mm

(0.1124±0.1184 in.)

Connecting Rod

Bearing Clearance 0.026±0.059 mm

(0.001±0.0023 in.)

Wear Limit 0.075 mm

(0.003 in.)

Bore DiameterÐPiston

Pin20.96±20.98 mm

(0.8252±0.8260 in.)

Bore DiameterÐ

Crankshaft End50.991±51.005 mm

(2.0075±2.0081 in.)

Side Clearance 0.13±0.38 mm

(0.005±0.015 in.)

Wear Limit 0.40 mm

(0.016 in.)

WeightÐTotal (Less

Bearing)543 grams

(1.20 lbs.)

Crankshaft

Connecting Rod Journal

Diameter47.9924±48.0076 mm

(1.8894±1.8900 in.)

Main Bearing Journal

Diameter51.9924±52.0076 mm

(2.0469±2.0475 in.)

Journal Out-of-Round

(Max.)0.0035 mm

(0.0001 in.)

Journal Taper (Max.) 0.0038 mm

(0.0001 in.)

End Play 0.09±0.24 mm

(0.0035±0.0094 in.)

Wear Limit 0.37 mm

(0.015 in.)

Main Bearing Diametrical

Clearance0.022±0.062 mm

(0.0008±0.0024 in.)DESCRIPTION SPECIFICATION

Rocker Arm Shaft

Rocker Arm Shaft

Diameter19.966±19.984 mm

(0.7861±0.7868 in.)

Rocker Arm Shaft Retainers

IntakeÐWidth 28.43±28.49 mm

(1.1193±1.1217 in.)

ExhaustÐWidth1&529.15±29.25 mm

(1.1477±1.1516 in.)

ExhaustÐWidth 2, 3, and

440.40±40.50 mm

(1.5906±1.5945 in.)

Rocker Arm/Hydraulic Lash Adjuster

Rocker Arm Inside

Diameter20.00±20.02 mm

(0.787±0.788 in.)

Rocker Arm Shaft

Clearance0.016±0.054 mm

(0.0006±0.0021 in.)

Body Diameter 22.949±22.962 mm

(0.9035±0.9040 in.)

Plunger Travel Minimum

(Dry)2.2 mm

(0.087 in.)

Dry LashÐIntake 1.17 mm

(0.046 in.)

Dry LashÐExhaust 1.28 mm

(0.050 in.)

Rocker Arm Ratio 1.4 to 1

Cylinder Head Camshaft Bearing Diameter

Journal No. 1 41.20±41.221 mm

(1.622±1.6228 in.)

Journal No. 2 41.60±41.62 mm

(1.637±1.638 in.)

Journal No. 3 42.0±42.02 mm

(1.653±1.654 in.)

Journal No. 4 42.4±42.42 mm

(1.669±1.670 in.)

Journal No. 5 42.8±42.82 mm

(1.685±1.6858 in.)

Camshaft

Journal Diameter

No. 1 41.128±41.147 mm

(1.619±1.6199 in.)

No. 2 41.528±41.547 mm

(1.634±1.635 in.)

PL2.0L SOHC ENGINE 9 - 69

SPECIFICATIONS (Continued)

Page 793 of 1285

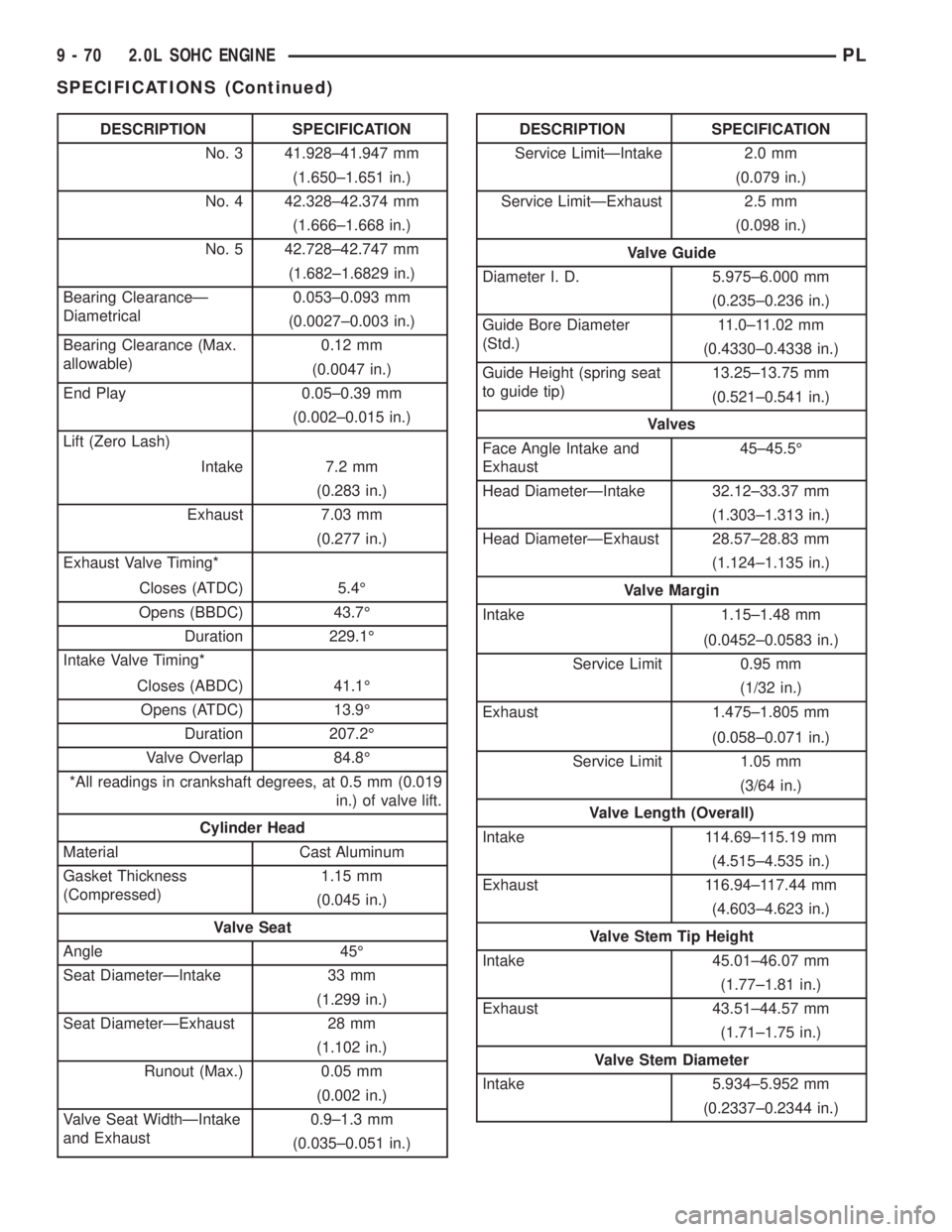

DESCRIPTION SPECIFICATION

No. 3 41.928±41.947 mm

(1.650±1.651 in.)

No. 4 42.328±42.374 mm

(1.666±1.668 in.)

No. 5 42.728±42.747 mm

(1.682±1.6829 in.)

Bearing ClearanceÐ

Diametrical0.053±0.093 mm

(0.0027±0.003 in.)

Bearing Clearance (Max.

allowable)0.12 mm

(0.0047 in.)

End Play 0.05±0.39 mm

(0.002±0.015 in.)

Lift (Zero Lash)

Intake 7.2 mm

(0.283 in.)

Exhaust 7.03 mm

(0.277 in.)

Exhaust Valve Timing*

Closes (ATDC) 5.4É

Opens (BBDC) 43.7É

Duration 229.1É

Intake Valve Timing*

Closes (ABDC) 41.1É

Opens (ATDC) 13.9É

Duration 207.2É

Valve Overlap 84.8É

*All readings in crankshaft degrees, at 0.5 mm (0.019

in.) of valve lift.

Cylinder Head

Material Cast Aluminum

Gasket Thickness

(Compressed)1.15 mm

(0.045 in.)

Valve Seat

Angle 45É

Seat DiameterÐIntake 33 mm

(1.299 in.)

Seat DiameterÐExhaust 28 mm

(1.102 in.)

Runout (Max.) 0.05 mm

(0.002 in.)

Valve Seat WidthÐIntake

and Exhaust0.9±1.3 mm

(0.035±0.051 in.)DESCRIPTION SPECIFICATION

Service LimitÐIntake 2.0 mm

(0.079 in.)

Service LimitÐExhaust 2.5 mm

(0.098 in.)

Valve Guide

Diameter I. D. 5.975±6.000 mm

(0.235±0.236 in.)

Guide Bore Diameter

(Std.)11.0±11.02 mm

(0.4330±0.4338 in.)

Guide Height (spring seat

to guide tip)13.25±13.75 mm

(0.521±0.541 in.)

Valves

Face Angle Intake and

Exhaust45±45.5É

Head DiameterÐIntake 32.12±33.37 mm

(1.303±1.313 in.)

Head DiameterÐExhaust 28.57±28.83 mm

(1.124±1.135 in.)

Valve Margin

Intake 1.15±1.48 mm

(0.0452±0.0583 in.)

Service Limit 0.95 mm

(1/32 in.)

Exhaust 1.475±1.805 mm

(0.058±0.071 in.)

Service Limit 1.05 mm

(3/64 in.)

Valve Length (Overall)

Intake 114.69±115.19 mm

(4.515±4.535 in.)

Exhaust 116.94±117.44 mm

(4.603±4.623 in.)

Valve Stem Tip Height

Intake 45.01±46.07 mm

(1.77±1.81 in.)

Exhaust 43.51±44.57 mm

(1.71±1.75 in.)

Valve Stem Diameter

Intake 5.934±5.952 mm

(0.2337±0.2344 in.)

9 - 70 2.0L SOHC ENGINEPL

SPECIFICATIONS (Continued)

Page 843 of 1285

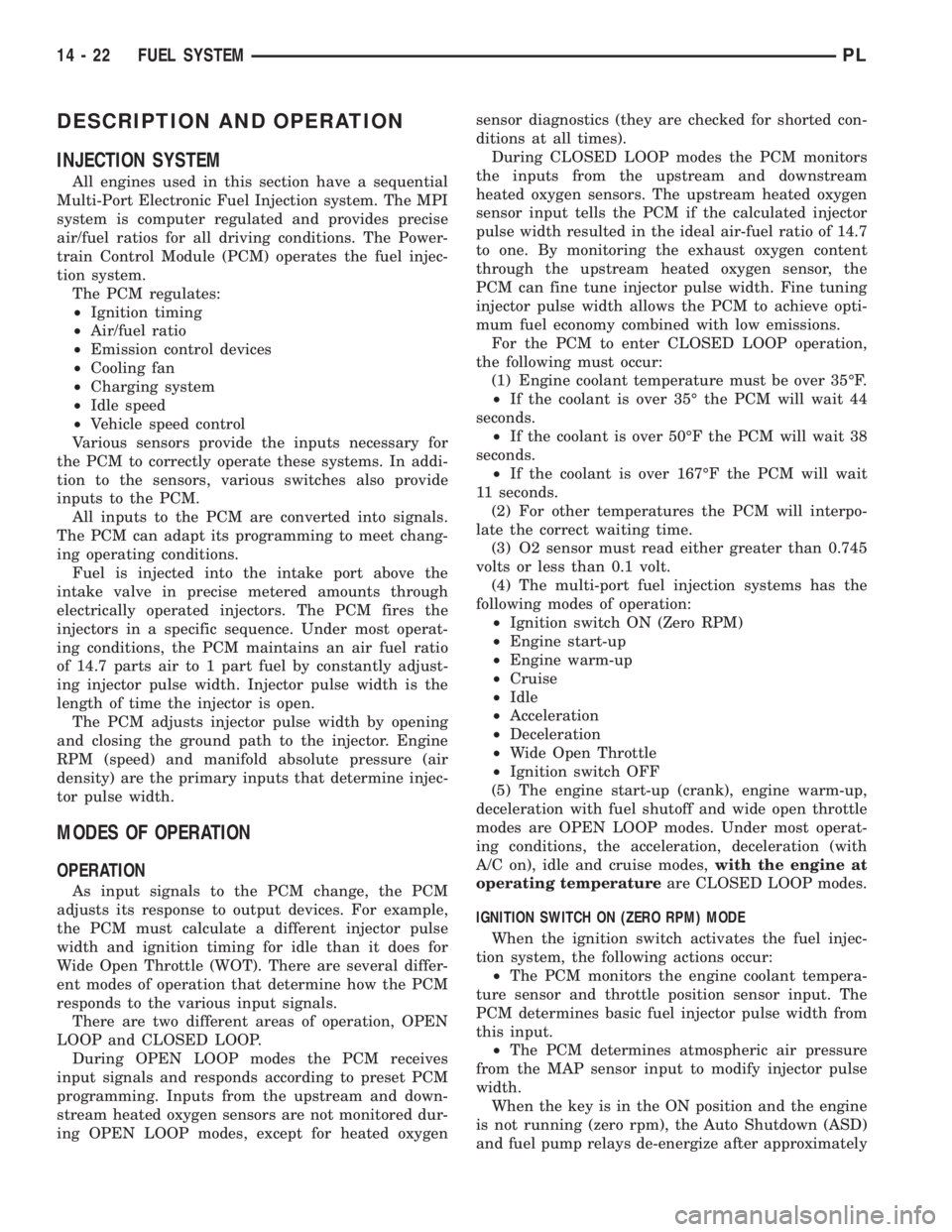

DESCRIPTION AND OPERATION

INJECTION SYSTEM

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygensensor diagnostics (they are checked for shorted con-

ditions at all times).

During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35É the PCM will wait 44

seconds.

²If the coolant is over 50ÉF the PCM will wait 38

seconds.

²If the coolant is over 167ÉF the PCM will wait

11 seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than 0.745

volts or less than 0.1 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

14 - 22 FUEL SYSTEMPL