engine DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1112 of 1285

EVAPORATIVE EMISSION CONTROLS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

EVAPORATION CONTROL SYSTEM..........25

EVAP CANISTER.........................25

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT..............................25

LEAK DETECTION PUMP..................26

LEAK DETECTION PUMP PRESSURE

SWITCH..............................27

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS.............................28POSITIVE CRANKCASE VENTILATION VALVE. . . 28

VEHICLE EMISSION CONTROL

INFORMATION LABEL...................29

REMOVAL AND INSTALLATION

EVAP CANISTER.........................29

LEAK DETECTION PUMP..................30

PROPORTIONAL PURGE SOLENOID VALVE....30

DESCRIPTION AND OPERATION

EVAPORATION CONTROL SYSTEM

OPERATION

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through vent hoses or tubes to an activated carbon

filled evaporative canister. The canister temporarily

holds the vapors. The Powertrain Control Module

(PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions.

All engines use a proportional purge solenoid sys-

tem. The PCM controls vapor flow by operating the

purge solenoid. Refer to Proportional Purge Solenoid

in this section.

NOTE: The evaporative system uses specially man-

ufactured hoses. If they need replacement, only use

fuel resistant hose. Also the hoses must be able to

pass an Ozone compliance test.

NOTE: For more information on Onboard Refueling

Vapor Recovery (ORVR), refer to the Fuel Delivery

section.

EVAP CANISTER

DESCRIPTION

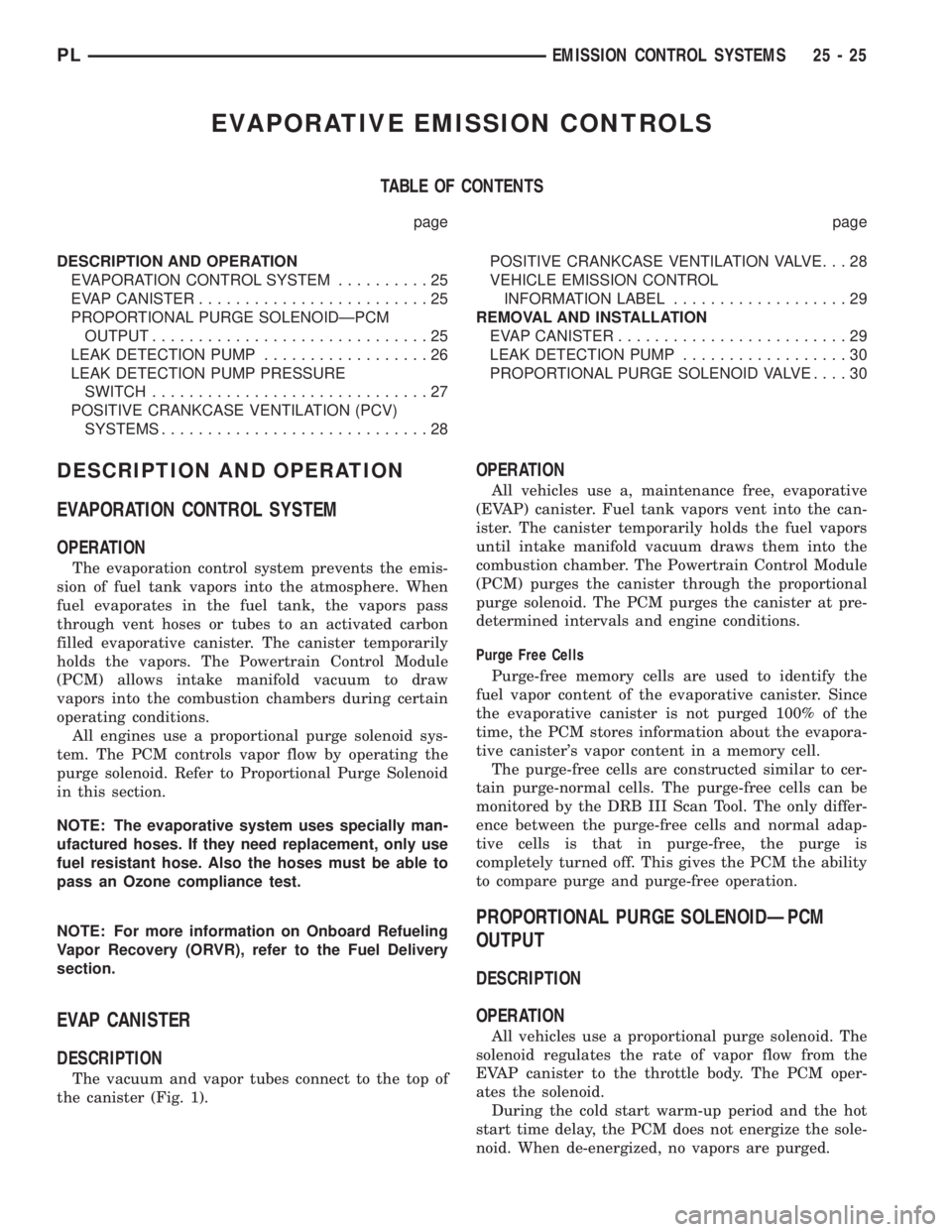

The vacuum and vapor tubes connect to the top of

the canister (Fig. 1).

OPERATION

All vehicles use a, maintenance free, evaporative

(EVAP) canister. Fuel tank vapors vent into the can-

ister. The canister temporarily holds the fuel vapors

until intake manifold vacuum draws them into the

combustion chamber. The Powertrain Control Module

(PCM) purges the canister through the proportional

purge solenoid. The PCM purges the canister at pre-

determined intervals and engine conditions.

Purge Free Cells

Purge-free memory cells are used to identify the

fuel vapor content of the evaporative canister. Since

the evaporative canister is not purged 100% of the

time, the PCM stores information about the evapora-

tive canister's vapor content in a memory cell.

The purge-free cells are constructed similar to cer-

tain purge-normal cells. The purge-free cells can be

monitored by the DRB III Scan Tool. The only differ-

ence between the purge-free cells and normal adap-

tive cells is that in purge-free, the purge is

completely turned off. This gives the PCM the ability

to compare purge and purge-free operation.

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT

DESCRIPTION

OPERATION

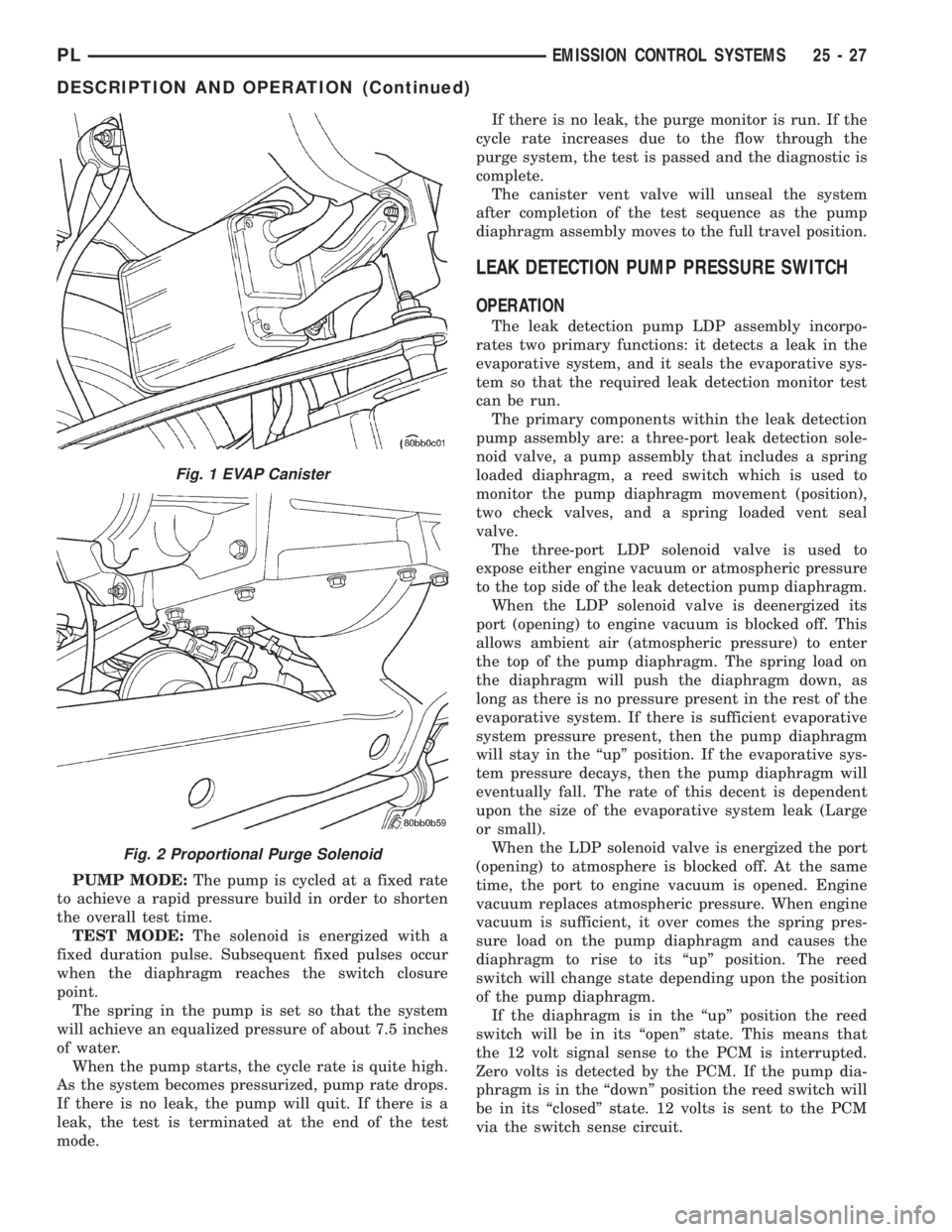

All vehicles use a proportional purge solenoid. The

solenoid regulates the rate of vapor flow from the

EVAP canister to the throttle body. The PCM oper-

ates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

PLEMISSION CONTROL SYSTEMS 25 - 25

Page 1113 of 1285

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid (Fig. 2) and then

adjusts that current to achieve the desired purge

flow. The proportional purge solenoid controls the

purge rate of fuel vapors from the vapor canister and

fuel tank to the engine intake manifold.

LEAK DETECTION PUMP

DESCRIPTION

The leak detection pump is a device used to detect

a leak in the evaporative system.

The pump contains a 3 port solenoid, a pump that

contains a switch, a spring loaded canister vent valve

seal, 2 check valves and a spring/diaphragm.

OPERATION

Immediately after a cold start, when the engine

temperature is between 40ÉF and 86ÉF, the 3 port

solenoid is briefly energized. This initializes the pump

by drawing air into the pump cavity and also closes

the vent seal. During non-test test conditions, the

vent seal is held open by the pump diaphragm assem-

bly which pushes it open at the full travel position.

The vent seal will remain closed while the pump is

cycling. This is due to the operation of the 3 port sole-

noid which prevents the diaphragm assembly from

reaching full travel. After the brief initialization

period, the solenoid is de-energized, allowing atmo-

spheric pressure to enter the pump cavity. This per-

mits the spring to drive the diaphragm which forces

air out of the pump cavity and into the vent system.

When the solenoid is energized and de-energized, the

cycle is repeated creating flow in typical diaphragm

pump fashion. The pump is controlled in 2 modes:

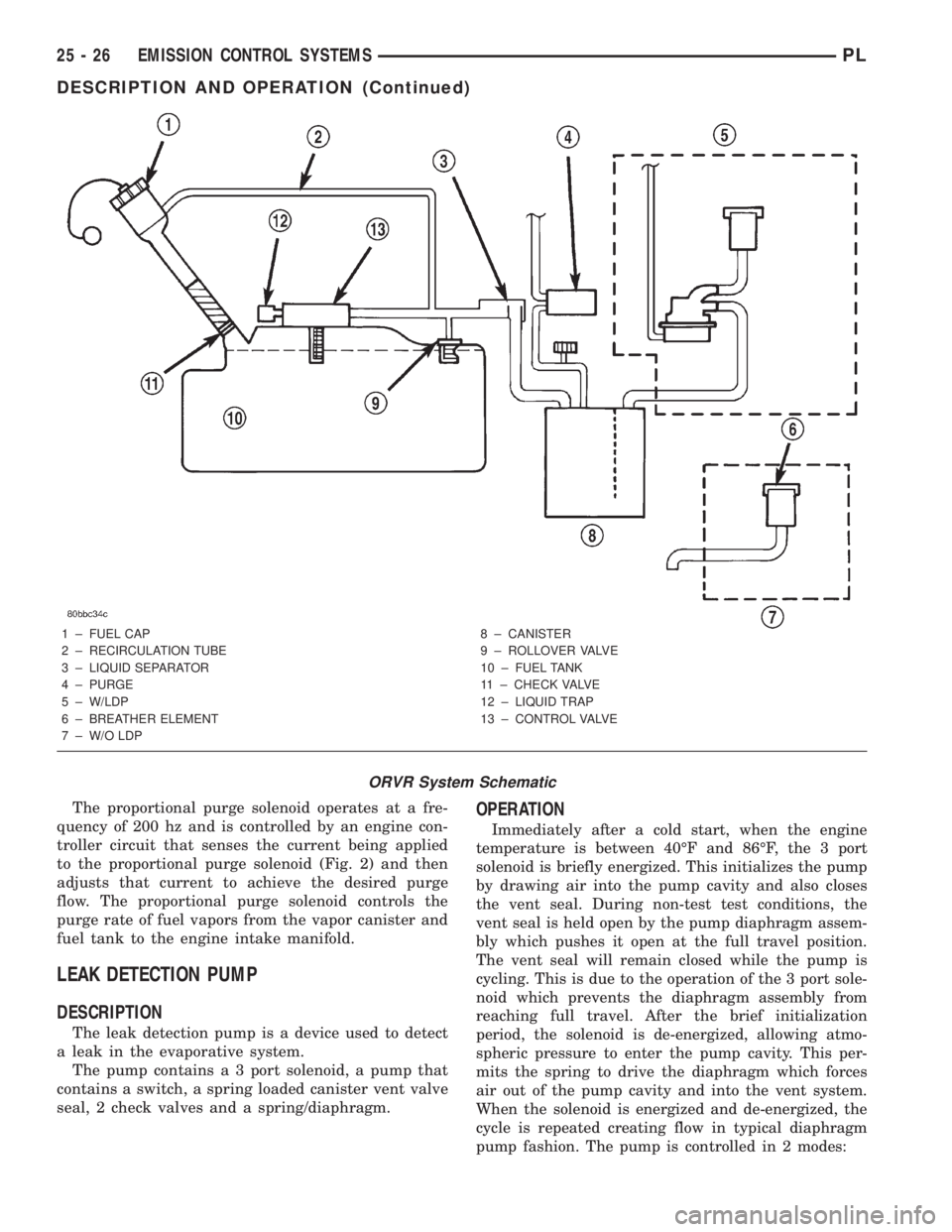

1 ± FUEL CAP

2 ± RECIRCULATION TUBE

3 ± LIQUID SEPARATOR

4 ± PURGE

5 ± W/LDP

6 ± BREATHER ELEMENT

7 ± W/O LDP8 ± CANISTER

9 ± ROLLOVER VALVE

10 ± FUEL TANK

11 ± CHECK VALVE

12 ± LIQUID TRAP

13 ± CONTROL VALVE

ORVR System Schematic

25 - 26 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1114 of 1285

PUMP MODE:The pump is cycled at a fixed rate

to achieve a rapid pressure build in order to shorten

the overall test time.

TEST MODE:The solenoid is energized with a

fixed duration pulse. Subsequent fixed pulses occur

when the diaphragm reaches the switch closure

point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5 inches

of water.

When the pump starts, the cycle rate is quite high.

As the system becomes pressurized, pump rate drops.

If there is no leak, the pump will quit. If there is a

leak, the test is terminated at the end of the test

mode.If there is no leak, the purge monitor is run. If the

cycle rate increases due to the flow through the

purge system, the test is passed and the diagnostic is

complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

LEAK DETECTION PUMP PRESSURE SWITCH

OPERATION

The leak detection pump LDP assembly incorpo-

rates two primary functions: it detects a leak in the

evaporative system, and it seals the evaporative sys-

tem so that the required leak detection monitor test

can be run.

The primary components within the leak detection

pump assembly are: a three-port leak detection sole-

noid valve, a pump assembly that includes a spring

loaded diaphragm, a reed switch which is used to

monitor the pump diaphragm movement (position),

two check valves, and a spring loaded vent seal

valve.

The three-port LDP solenoid valve is used to

expose either engine vacuum or atmospheric pressure

to the top side of the leak detection pump diaphragm.

When the LDP solenoid valve is deenergized its

port (opening) to engine vacuum is blocked off. This

allows ambient air (atmospheric pressure) to enter

the top of the pump diaphragm. The spring load on

the diaphragm will push the diaphragm down, as

long as there is no pressure present in the rest of the

evaporative system. If there is sufficient evaporative

system pressure present, then the pump diaphragm

will stay in the ªupº position. If the evaporative sys-

tem pressure decays, then the pump diaphragm will

eventually fall. The rate of this decent is dependent

upon the size of the evaporative system leak (Large

or small).

When the LDP solenoid valve is energized the port

(opening) to atmosphere is blocked off. At the same

time, the port to engine vacuum is opened. Engine

vacuum replaces atmospheric pressure. When engine

vacuum is sufficient, it over comes the spring pres-

sure load on the pump diaphragm and causes the

diaphragm to rise to its ªupº position. The reed

switch will change state depending upon the position

of the pump diaphragm.

If the diaphragm is in the ªupº position the reed

switch will be in its ªopenº state. This means that

the 12 volt signal sense to the PCM is interrupted.

Zero volts is detected by the PCM. If the pump dia-

phragm is in the ªdownº position the reed switch will

be in its ªclosedº state. 12 volts is sent to the PCM

via the switch sense circuit.

Fig. 1 EVAP Canister

Fig. 2 Proportional Purge Solenoid

PLEMISSION CONTROL SYSTEMS 25 - 27

DESCRIPTION AND OPERATION (Continued)

Page 1115 of 1285

The check valves are one-way valves. The first

check valve is used to draw outside air into the lower

chamber of the LDP (the space that is below the

pump diaphragm). The second check valve is used to

vent this outside air, which has become pressurized

from the fall of the pump diaphragm, into the evap-

orative system.

The spring loaded vent seal valve, inside the LDP

is used to seal off the evaporative system. When the

pump diaphragm is in the ªupº position the spring

pushes the vent seal valve closed. The vent seal valve

opens only when the pump diaphragm is in its ªfull

downº position. When the pump assembly is in its

pump mode the pump diaphragm is not allowed to

descend (fall) so far as to allow the vent seal valve to

open. This allows the leak detection pump to develop

the required pressure within the evaporative system

for system leak testing.

A pressure build up within the evaporative system

may cause pressure on the lower side of the LDP dia-

phragm. This will cause the LDP diaphragm to

remain in its ªupº position (stuck in the up position).

This condition can occur even when the solenoid

valve is deenergized. This condition can be caused by

previous cycling (pumping) of the LDP by the techni-

cian (dealer test). Another way that this condition is

created is immediately following the running of the

vehicle evaporative system monitor. In this case, the

PCM has not yet opened the proportional purge sole-

noid in order to vent the pressure that has been built

up in the evaporative system to the engine combus-

tion system. The technician will need to vent the

evaporative system pressure via the vehicle fuel filler

cap and its fuel filler secondary seal (if so equipped

in the fuel filler neck). This will allow the technician

to cycle the LDP and to watch switch state changes.

After passing the leak detection phase of the test,

system pressure is maintained until the purge sys-

tem is activated, in effect creating a leak. If the dia-

phragm falls (as is expected), causing the reed switch

to change state, then the diagnostic test is completed.

When of the evaporative system leak monitor

begins its various tests, a test is performed to deter-

mine that no part of the evaporative system is

blocked. In this test, the LDP is cycled (pumped) a

calibrated (few) number of times. Pressure should not

build up in the evaporative system. If pressure is

present, then LDP diaphragm is forced to stay in its

ªupº position. The reed switch now stays open and

the PCM senses this open (incorrect) state. The evap-

orative system monitor will fail the test because of a

detected obstruction within the system.

Possible causes:

²Open or shorted LDP switch sense circuit

²Leak Detection Pump switch failure²Open fused ignition switch output

²Restricted, disconnected, or blocked manifold

vacuum source

²Obstruction of hoses or lines

²PCM failure

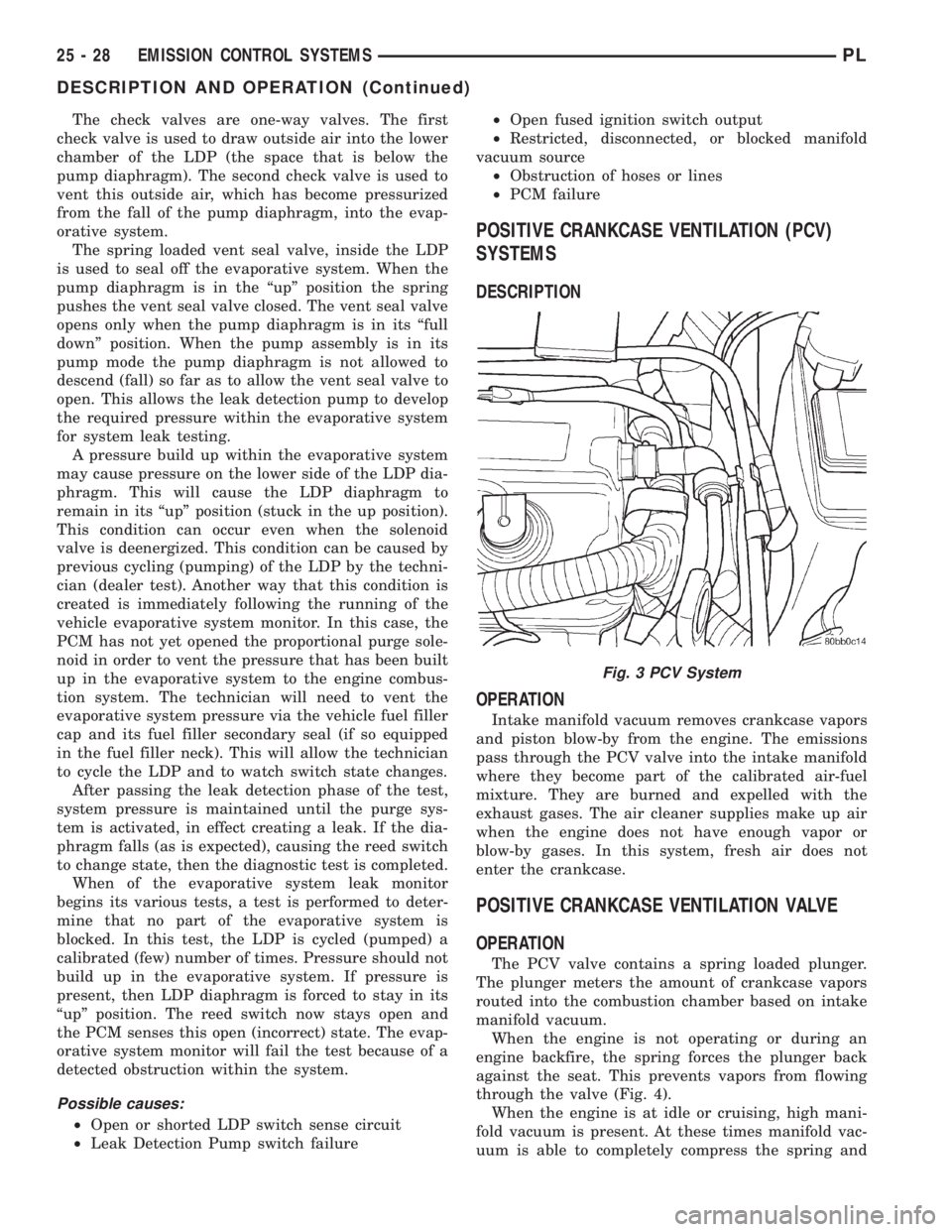

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS

DESCRIPTION

OPERATION

Intake manifold vacuum removes crankcase vapors

and piston blow-by from the engine. The emissions

pass through the PCV valve into the intake manifold

where they become part of the calibrated air-fuel

mixture. They are burned and expelled with the

exhaust gases. The air cleaner supplies make up air

when the engine does not have enough vapor or

blow-by gases. In this system, fresh air does not

enter the crankcase.

POSITIVE CRANKCASE VENTILATION VALVE

OPERATION

The PCV valve contains a spring loaded plunger.

The plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

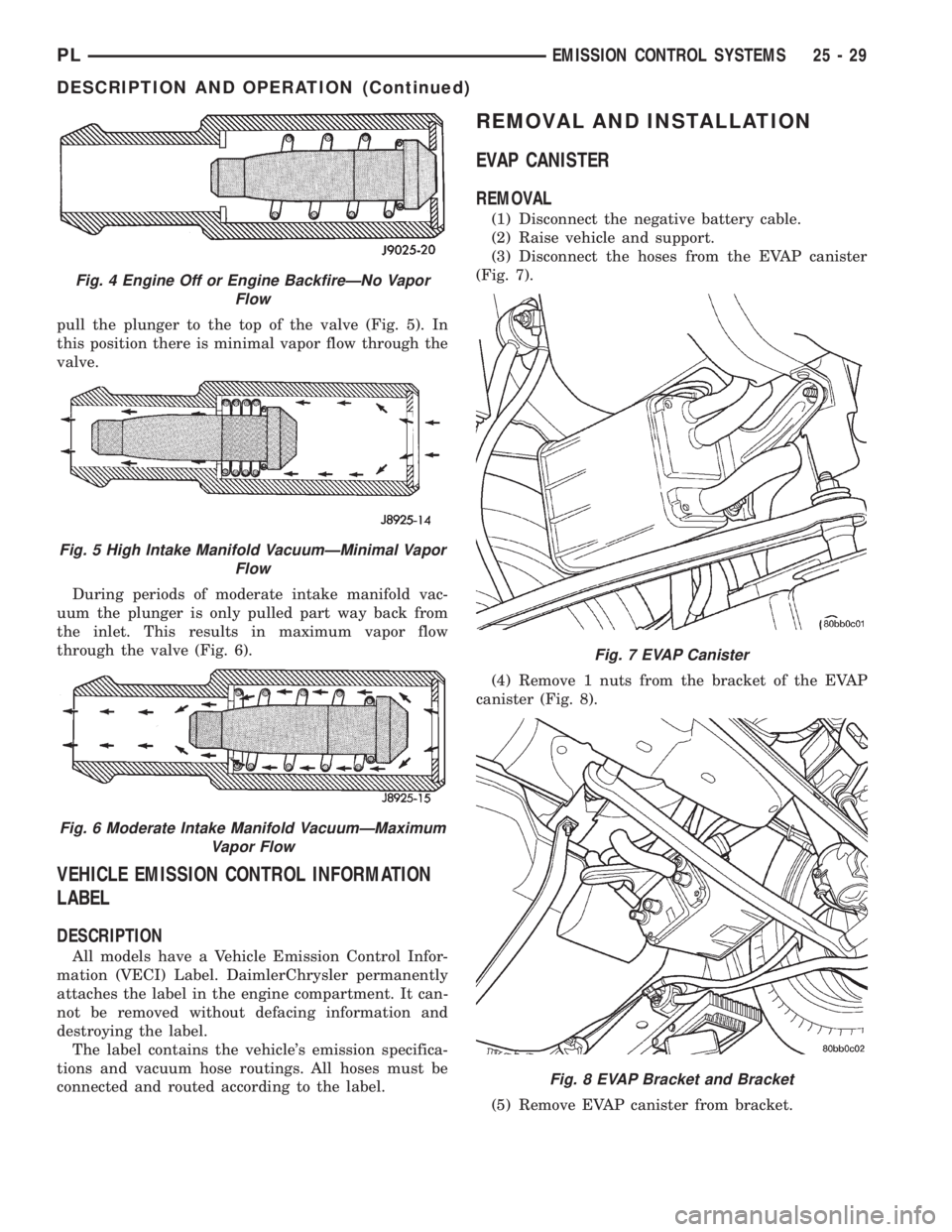

When the engine is not operating or during an

engine backfire, the spring forces the plunger back

against the seat. This prevents vapors from flowing

through the valve (Fig. 4).

When the engine is at idle or cruising, high mani-

fold vacuum is present. At these times manifold vac-

uum is able to completely compress the spring and

Fig. 3 PCV System

25 - 28 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1116 of 1285

pull the plunger to the top of the valve (Fig. 5). In

this position there is minimal vapor flow through the

valve.

During periods of moderate intake manifold vac-

uum the plunger is only pulled part way back from

the inlet. This results in maximum vapor flow

through the valve (Fig. 6).

VEHICLE EMISSION CONTROL INFORMATION

LABEL

DESCRIPTION

All models have a Vehicle Emission Control Infor-

mation (VECI) Label. DaimlerChrysler permanently

attaches the label in the engine compartment. It can-

not be removed without defacing information and

destroying the label.

The label contains the vehicle's emission specifica-

tions and vacuum hose routings. All hoses must be

connected and routed according to the label.

REMOVAL AND INSTALLATION

EVAP CANISTER

REMOVAL

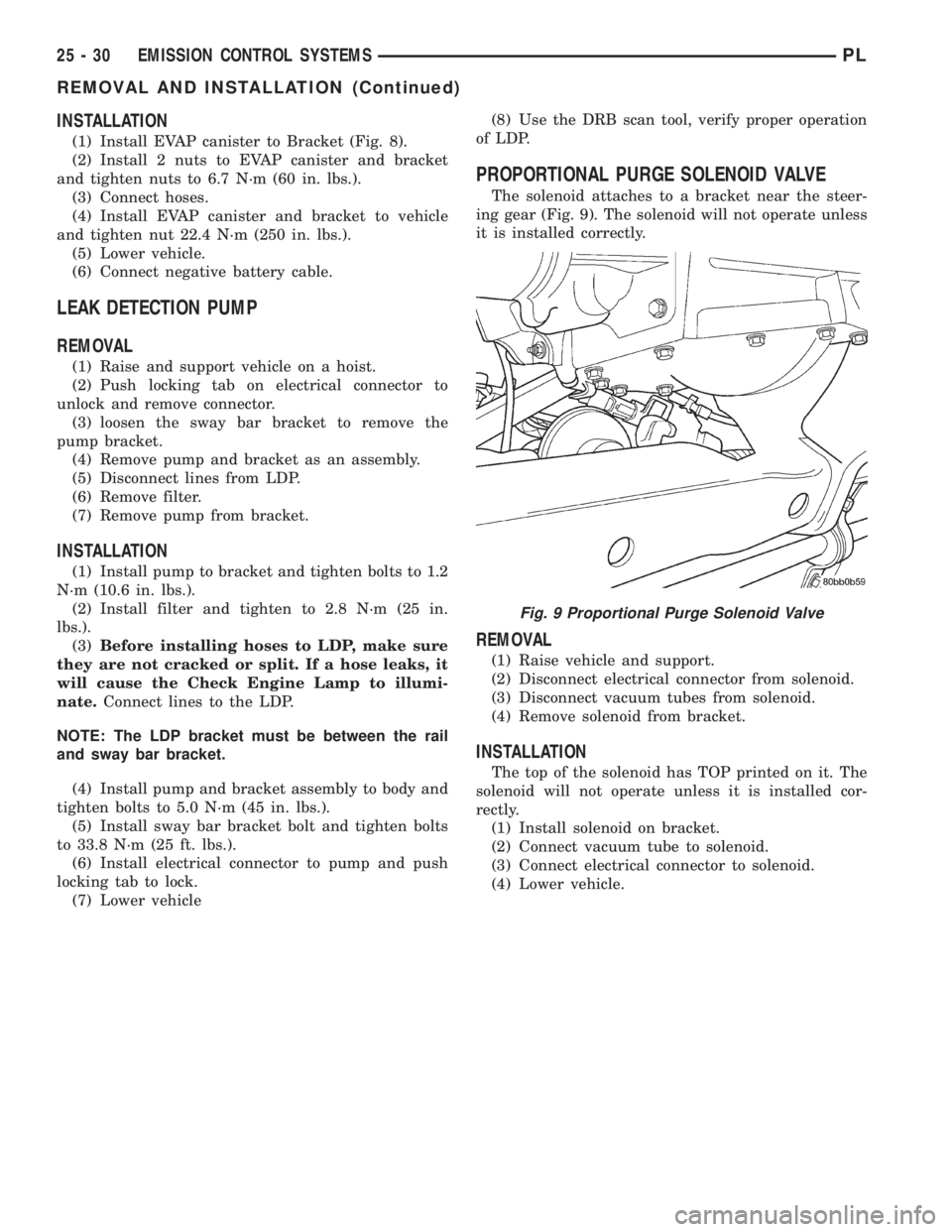

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) Disconnect the hoses from the EVAP canister

(Fig. 7).

(4) Remove 1 nuts from the bracket of the EVAP

canister (Fig. 8).

(5) Remove EVAP canister from bracket.

Fig. 4 Engine Off or Engine BackfireÐNo Vapor

Flow

Fig. 5 High Intake Manifold VacuumÐMinimal Vapor

Flow

Fig. 6 Moderate Intake Manifold VacuumÐMaximum

Vapor Flow

Fig. 7 EVAP Canister

Fig. 8 EVAP Bracket and Bracket

PLEMISSION CONTROL SYSTEMS 25 - 29

DESCRIPTION AND OPERATION (Continued)

Page 1117 of 1285

INSTALLATION

(1) Install EVAP canister to Bracket (Fig. 8).

(2) Install 2 nuts to EVAP canister and bracket

and tighten nuts to 6.7 N´m (60 in. lbs.).

(3) Connect hoses.

(4) Install EVAP canister and bracket to vehicle

and tighten nut 22.4 N´m (250 in. lbs.).

(5) Lower vehicle.

(6) Connect negative battery cable.

LEAK DETECTION PUMP

REMOVAL

(1) Raise and support vehicle on a hoist.

(2) Push locking tab on electrical connector to

unlock and remove connector.

(3) loosen the sway bar bracket to remove the

pump bracket.

(4) Remove pump and bracket as an assembly.

(5) Disconnect lines from LDP.

(6) Remove filter.

(7) Remove pump from bracket.

INSTALLATION

(1) Install pump to bracket and tighten bolts to 1.2

N´m (10.6 in. lbs.).

(2) Install filter and tighten to 2.8 N´m (25 in.

lbs.).

(3)Before installing hoses to LDP, make sure

they are not cracked or split. If a hose leaks, it

will cause the Check Engine Lamp to illumi-

nate.Connect lines to the LDP.

NOTE: The LDP bracket must be between the rail

and sway bar bracket.

(4) Install pump and bracket assembly to body and

tighten bolts to 5.0 N´m (45 in. lbs.).

(5) Install sway bar bracket bolt and tighten bolts

to 33.8 N´m (25 ft. lbs.).

(6) Install electrical connector to pump and push

locking tab to lock.

(7) Lower vehicle(8) Use the DRB scan tool, verify proper operation

of LDP.

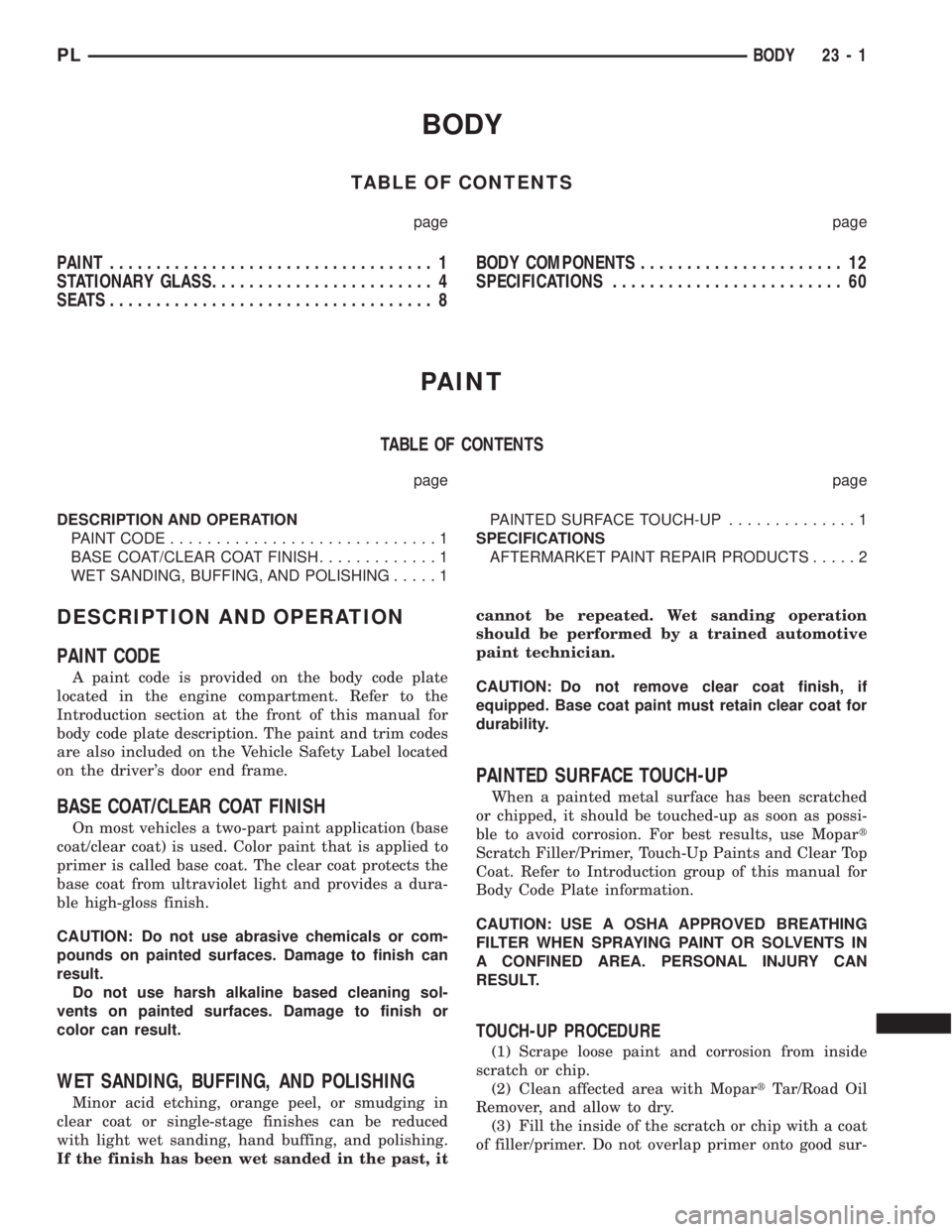

PROPORTIONAL PURGE SOLENOID VALVE

The solenoid attaches to a bracket near the steer-

ing gear (Fig. 9). The solenoid will not operate unless

it is installed correctly.

REMOVAL

(1) Raise vehicle and support.

(2) Disconnect electrical connector from solenoid.

(3) Disconnect vacuum tubes from solenoid.

(4) Remove solenoid from bracket.

INSTALLATION

The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

(4) Lower vehicle.

Fig. 9 Proportional Purge Solenoid Valve

25 - 30 EMISSION CONTROL SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 1118 of 1285

BODY

TABLE OF CONTENTS

page page

PAINT................................... 1

STATIONARY GLASS........................ 4

SEATS ................................... 8BODY COMPONENTS...................... 12

SPECIFICATIONS......................... 60

PAINT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

PAINT CODE.............................1

BASE COAT/CLEAR COAT FINISH.............1

WET SANDING, BUFFING, AND POLISHING.....1PAINTED SURFACE TOUCH-UP..............1

SPECIFICATIONS

AFTERMARKET PAINT REPAIR PRODUCTS.....2

DESCRIPTION AND OPERATION

PAINT CODE

A paint code is provided on the body code plate

located in the engine compartment. Refer to the

Introduction section at the front of this manual for

body code plate description. The paint and trim codes

are also included on the Vehicle Safety Label located

on the driver's door end frame.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two-part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultraviolet light and provides a dura-

ble high-gloss finish.

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning sol-

vents on painted surfaces. Damage to finish or

color can result.

WET SANDING, BUFFING, AND POLISHING

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light wet sanding, hand buffing, and polishing.

If the finish has been wet sanded in the past, itcannot be repeated. Wet sanding operation

should be performed by a trained automotive

paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

CAUTION: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

PLBODY 23 - 1

Page 1135 of 1285

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the lowest point of the water track or

drop. After leak point has been found, repair the leak

and water test to verify that the leak has stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 18 BODYPL

Page 1136 of 1285

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

SERVICE PROCEDURES

HEAT STAKING

(1) Remove trim panel.

(2) Bend or move the trim panel components at

the heat staked joints. Observe the heat staked loca-

tions and/or component seams for looseness.(3) Heat stake the components.

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-

ing the glue. Once the new material is in place, it

may be necessary to use a soldering gun to melt

the newly applied material. Do not over heat the

affected area, damage to the exterior of the trim

panel may occur.

(4) Allow the repaired area to cool and verify the

repair.

(5) Install trim panel.

PLASTIC BODY PANEL REPAIR

DESCRIPTION OPERATION

Resin Transfer Molded (RTM) body panels are rein-

forced with a continuous fiberglass mesh. Epoxy

resin is injected into a gel-coated and fiberglass-lined

mold to form a body panel. Sheet molded compound

(SMC) body panels are constructed with fiberglass

strands usually 1 inch or shorter, epoxy resin formed

into sheet stock and pressed in mold flowing material

to form a sheet molded compound (SMC) body panel.

RTM and SMC body panels can be repaired with

epoxy adhesive after market products. Refer to

instructions provided by the manufacturer of prod-

ucts being used to repair RTM or SMC. Daimler-

Chrysler Corporation recommends that a trained

automotive body technician perform body panel

repair procedures (Fig. 1).

Fig. 1 Panel Repair

PLBODY 23 - 19

DIAGNOSIS AND TESTING (Continued)

Page 1143 of 1285

HOOD

REMOVAL

(1) Raise hood to full up position.

(2) Disengage under hood lamp wire connector

from engine compartment wire harness.

(3) Remove hood cover (Fig. 20).

(4) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.

(5) Remove the top bolts attaching hood to hinge

and loosen the bottom bolts until they can be

removed by hand.

(6) With assistance from a helper at the opposite

side of the vehicle to support the hood, remove bot-

tom bolts attaching hood to hinge.

(7) Remove the hood from the vehicle.

INSTALLATION

(1) Place hood in position on vehicle. With assis-

tance from a helper at the opposite side of the vehicle

to support the hood, install bottom bolts to hold hood

to hinge finger tight.

(2) Install top bolts attaching hood to hinge finger

tight.

(3) Position bolts at marks and tighten bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders.(4) Install hood cover.

(5) Engage under hood lamp wire connector to

engine compartment wire harness.

(6) Verify hood operation and alignment.

HOOD SILENCER

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect hood lamp wire connector and

remove hood lamp (Fig. 21).

(3) Remove fasteners attaching hood silencer to

hood.

(4) Remove hood silencer from vehicle.

INSTALLATION

(1) Place hood silencer in position on vehicle.

(2) Install fastener attaching hood silencer to hood.

(3) Install hood lamp and connect wire connector.

(4) Close hood.

HOOD HINGE

REMOVAL

(1) Support hood on the side that requires hinge

replacement.

(2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height.

(3) Remove bolts holding hood to hinge.

(4) Remove bolts holding hood hinge to load beam

flange and separate hinge from vehicle. If necessary,

paint new hinge before installation.

INSTALLATION

(1) If necessary, paint new hinge before installa-

tion.

(2) Place hinge in position on vehicle.

(3) Install bolts to hold hood hinge to front fender

flange.

(4) Install bolts to hold hood to hinge.

(5) Align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. Shims can be added or removed under hood

hinge to achieve proper hood height.

(6) Remove support from under hood and verify

hood operation.

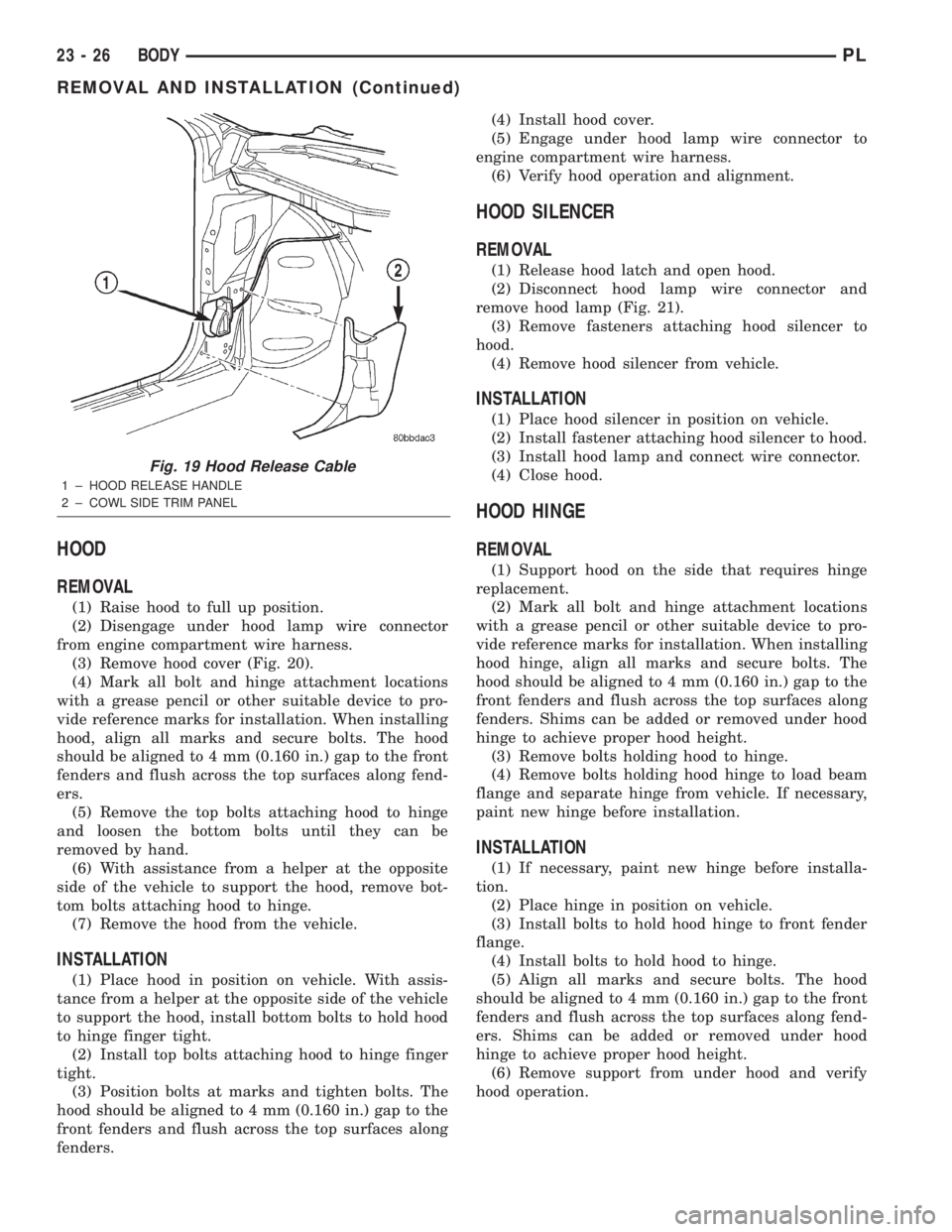

Fig. 19 Hood Release Cable

1 ± HOOD RELEASE HANDLE

2 ± COWL SIDE TRIM PANEL

23 - 26 BODYPL

REMOVAL AND INSTALLATION (Continued)