starter motor DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 752 of 1285

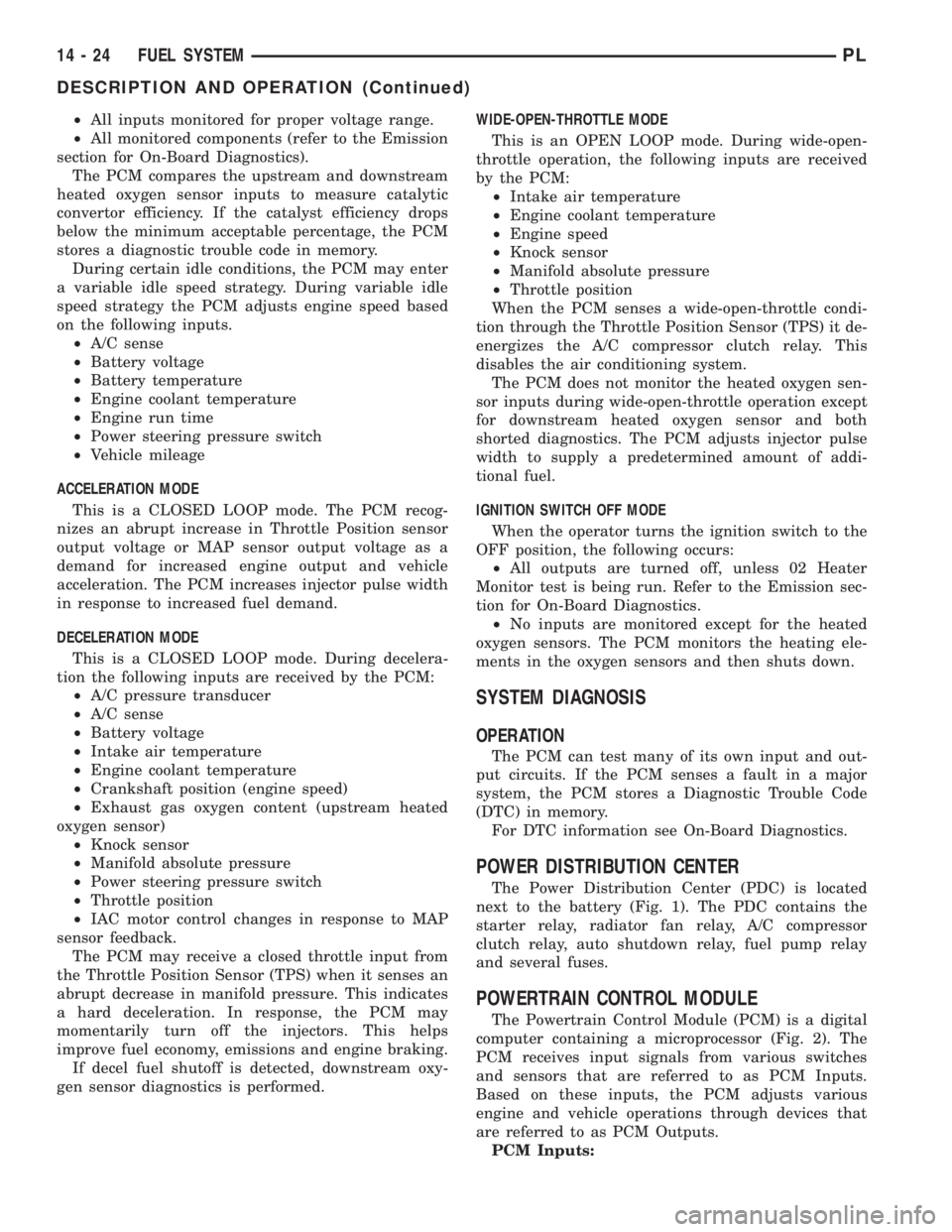

(2) Install intake manifold to lower support

bracket bolts (Fig. 31). Tighten bolts to 11 N´m (95

in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

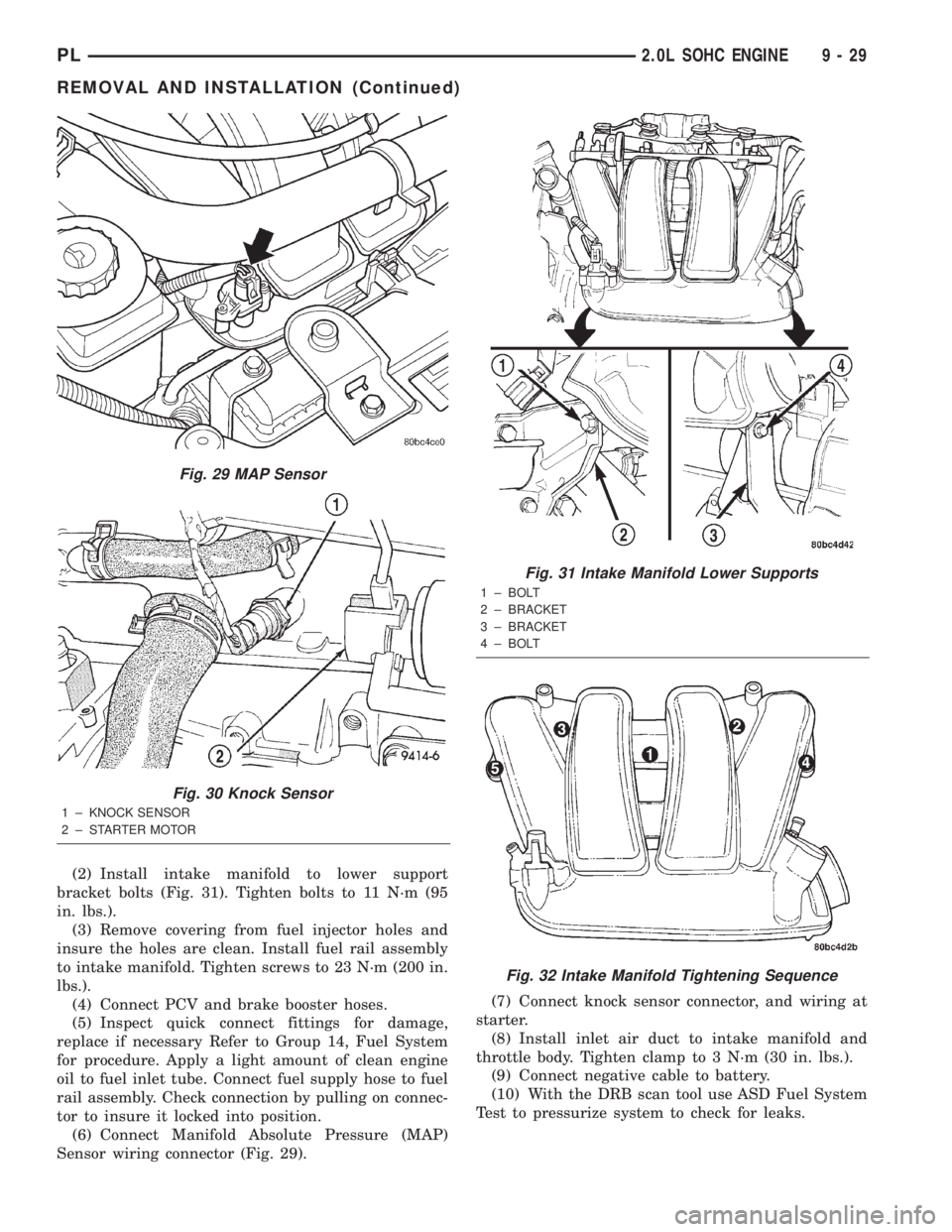

(6) Connect Manifold Absolute Pressure (MAP)

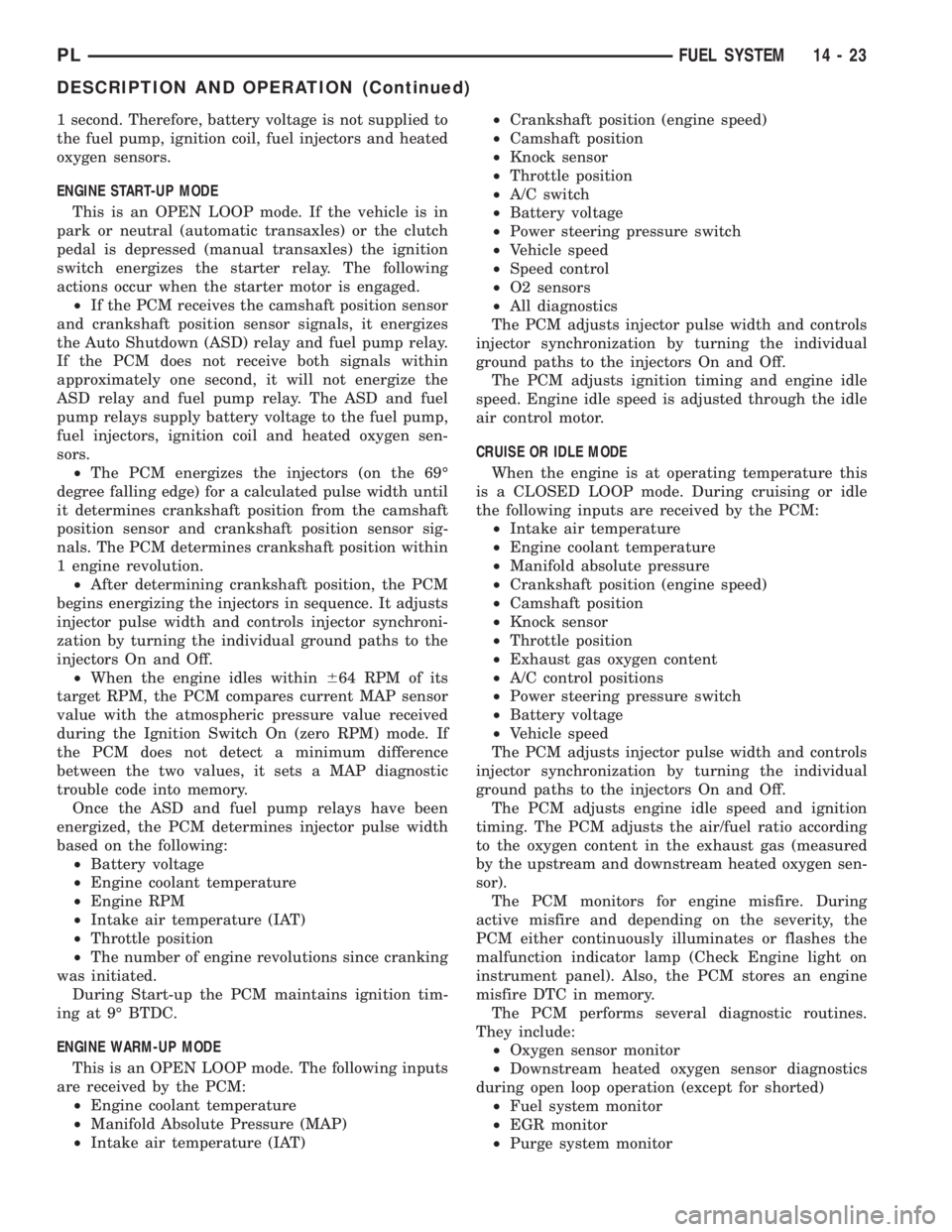

Sensor wiring connector (Fig. 29).(7) Connect knock sensor connector, and wiring at

starter.

(8) Install inlet air duct to intake manifold and

throttle body. Tighten clamp to 3 N´m (30 in. lbs.).

(9) Connect negative cable to battery.

(10) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

Fig. 29 MAP Sensor

Fig. 30 Knock Sensor

1 ± KNOCK SENSOR

2 ± STARTER MOTOR

Fig. 31 Intake Manifold Lower Supports

1 ± BOLT

2 ± BRACKET

3 ± BRACKET

4 ± BOLT

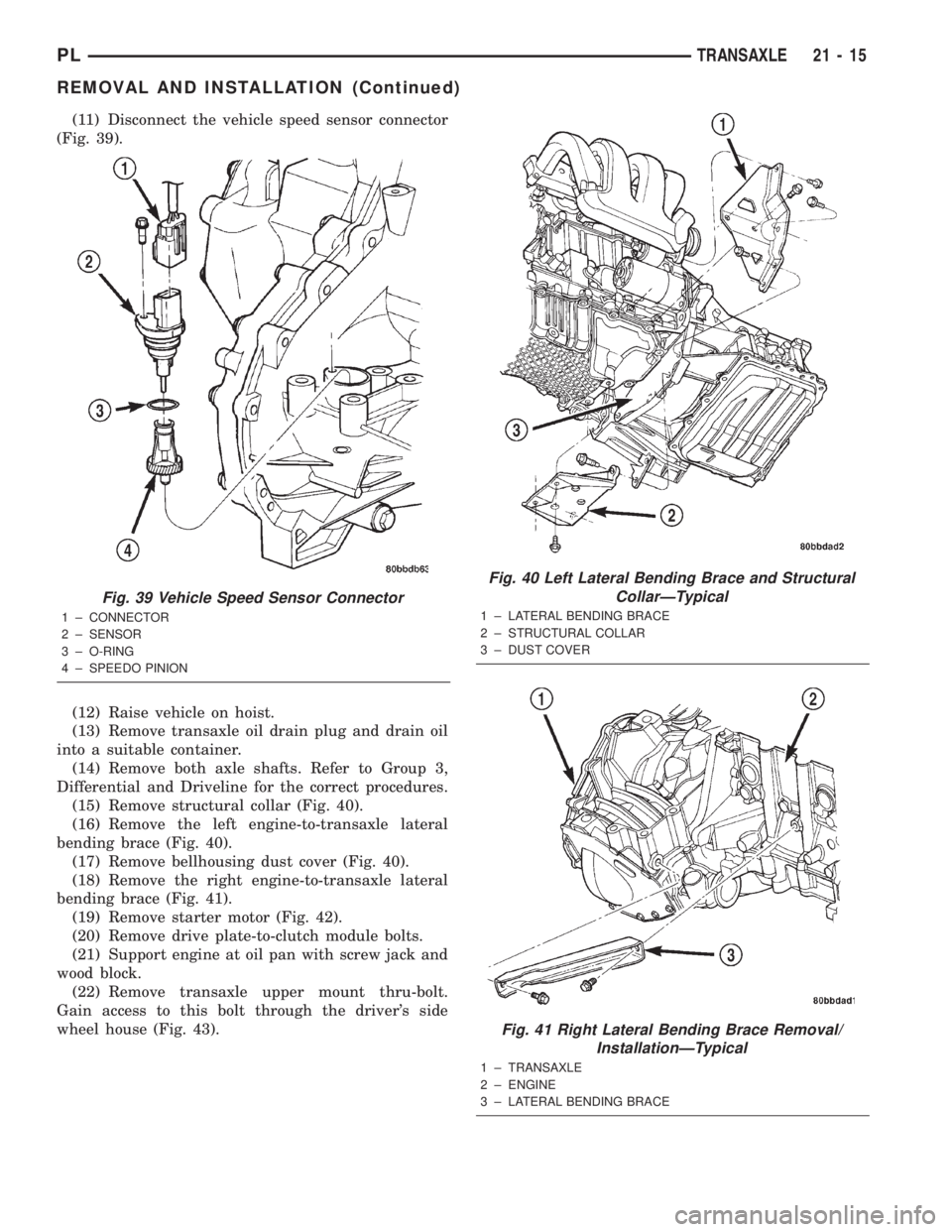

Fig. 32 Intake Manifold Tightening Sequence

PL2.0L SOHC ENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)

Page 844 of 1285

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

ENGINE START-UP MODE

This is an OPEN LOOP mode. If the vehicle is in

park or neutral (automatic transaxles) or the clutch

pedal is depressed (manual transaxles) the ignition

switch energizes the starter relay. The following

actions occur when the starter motor is engaged.

²If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the Auto Shutdown (ASD) relay and fuel pump relay.

If the PCM does not receive both signals within

approximately one second, it will not energize the

ASD relay and fuel pump relay. The ASD and fuel

pump relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil and heated oxygen sen-

sors.

²The PCM energizes the injectors (on the 69É

degree falling edge) for a calculated pulse width until

it determines crankshaft position from the camshaft

position sensor and crankshaft position sensor sig-

nals. The PCM determines crankshaft position within

1 engine revolution.

²After determining crankshaft position, the PCM

begins energizing the injectors in sequence. It adjusts

injector pulse width and controls injector synchroni-

zation by turning the individual ground paths to the

injectors On and Off.

²When the engine idles within664 RPM of its

target RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode. If

the PCM does not detect a minimum difference

between the two values, it sets a MAP diagnostic

trouble code into memory.

Once the ASD and fuel pump relays have been

energized, the PCM determines injector pulse width

based on the following:

²Battery voltage

²Engine coolant temperature

²Engine RPM

²Intake air temperature (IAT)

²Throttle position

²The number of engine revolutions since cranking

was initiated.

During Start-up the PCM maintains ignition tim-

ing at 9É BTDC.

ENGINE WARM-UP MODE

This is an OPEN LOOP mode. The following inputs

are received by the PCM:

²Engine coolant temperature

²Manifold Absolute Pressure (MAP)

²Intake air temperature (IAT)²Crankshaft position (engine speed)

²Camshaft position

²Knock sensor

²Throttle position

²A/C switch

²Battery voltage

²Power steering pressure switch

²Vehicle speed

²Speed control

²O2 sensors

²All diagnostics

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising or idle

the following inputs are received by the PCM:

²Intake air temperature

²Engine coolant temperature

²Manifold absolute pressure

²Crankshaft position (engine speed)

²Camshaft position

²Knock sensor

²Throttle position

²Exhaust gas oxygen content

²A/C control positions

²Power steering pressure switch

²Battery voltage

²Vehicle speed

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas (measured

by the upstream and downstream heated oxygen sen-

sor).

The PCM monitors for engine misfire. During

active misfire and depending on the severity, the

PCM either continuously illuminates or flashes the

malfunction indicator lamp (Check Engine light on

instrument panel). Also, the PCM stores an engine

misfire DTC in memory.

The PCM performs several diagnostic routines.

They include:

²Oxygen sensor monitor

²Downstream heated oxygen sensor diagnostics

during open loop operation (except for shorted)

²Fuel system monitor

²EGR monitor

²Purge system monitor

PLFUEL SYSTEM 14 - 23

DESCRIPTION AND OPERATION (Continued)

Page 845 of 1285

²All inputs monitored for proper voltage range.

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic

convertor efficiency. If the catalyst efficiency drops

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in response to MAP

sensor feedback.

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

SYSTEM DIAGNOSIS

OPERATION

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information see On-Board Diagnostics.

POWER DISTRIBUTION CENTER

The Power Distribution Center (PDC) is located

next to the battery (Fig. 1). The PDC contains the

starter relay, radiator fan relay, A/C compressor

clutch relay, auto shutdown relay, fuel pump relay

and several fuses.

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various

engine and vehicle operations through devices that

are referred to as PCM Outputs.

PCM Inputs:

14 - 24 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 928 of 1285

(11) Disconnect the vehicle speed sensor connector

(Fig. 39).

(12) Raise vehicle on hoist.

(13) Remove transaxle oil drain plug and drain oil

into a suitable container.

(14) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.

(15) Remove structural collar (Fig. 40).

(16) Remove the left engine-to-transaxle lateral

bending brace (Fig. 40).

(17) Remove bellhousing dust cover (Fig. 40).

(18) Remove the right engine-to-transaxle lateral

bending brace (Fig. 41).

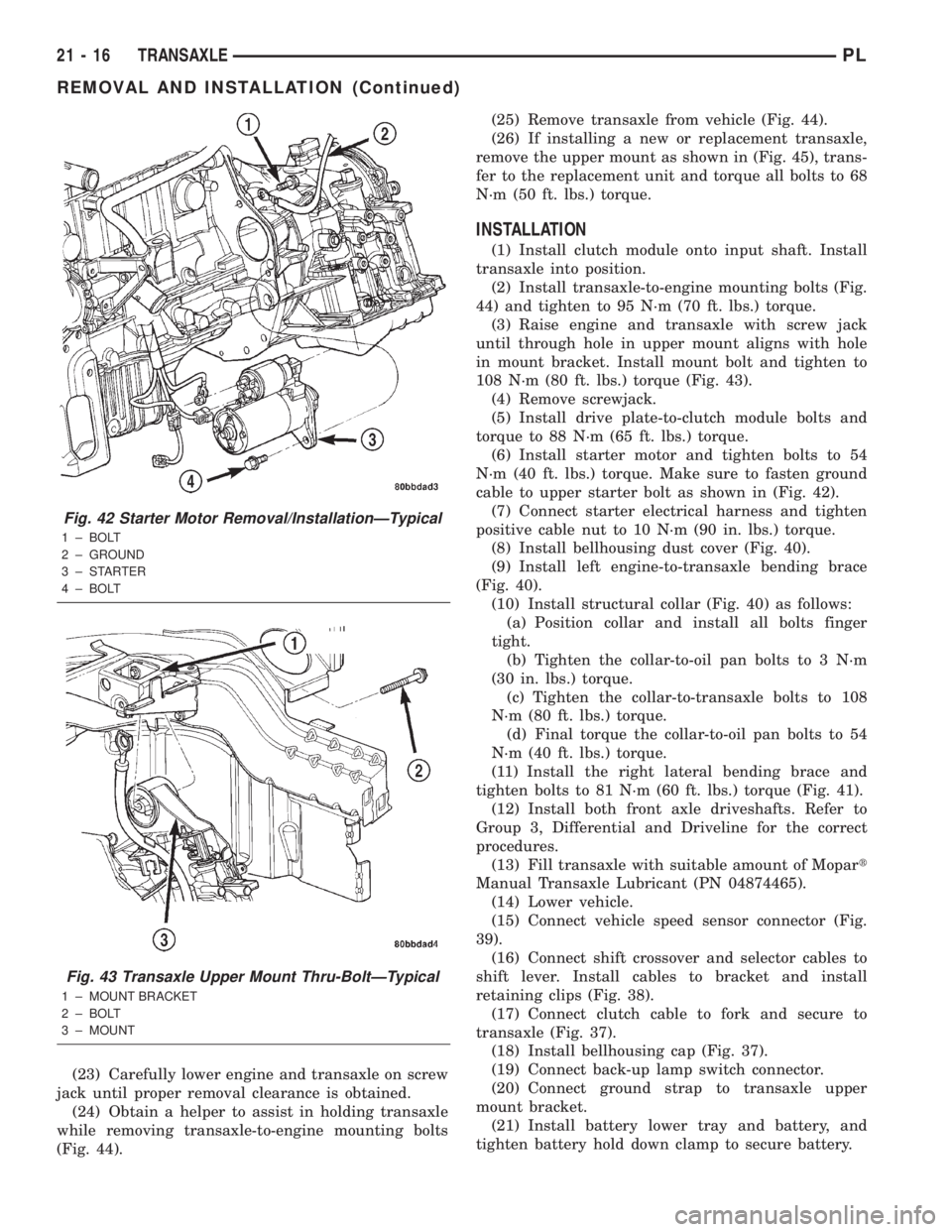

(19) Remove starter motor (Fig. 42).

(20) Remove drive plate-to-clutch module bolts.

(21) Support engine at oil pan with screw jack and

wood block.

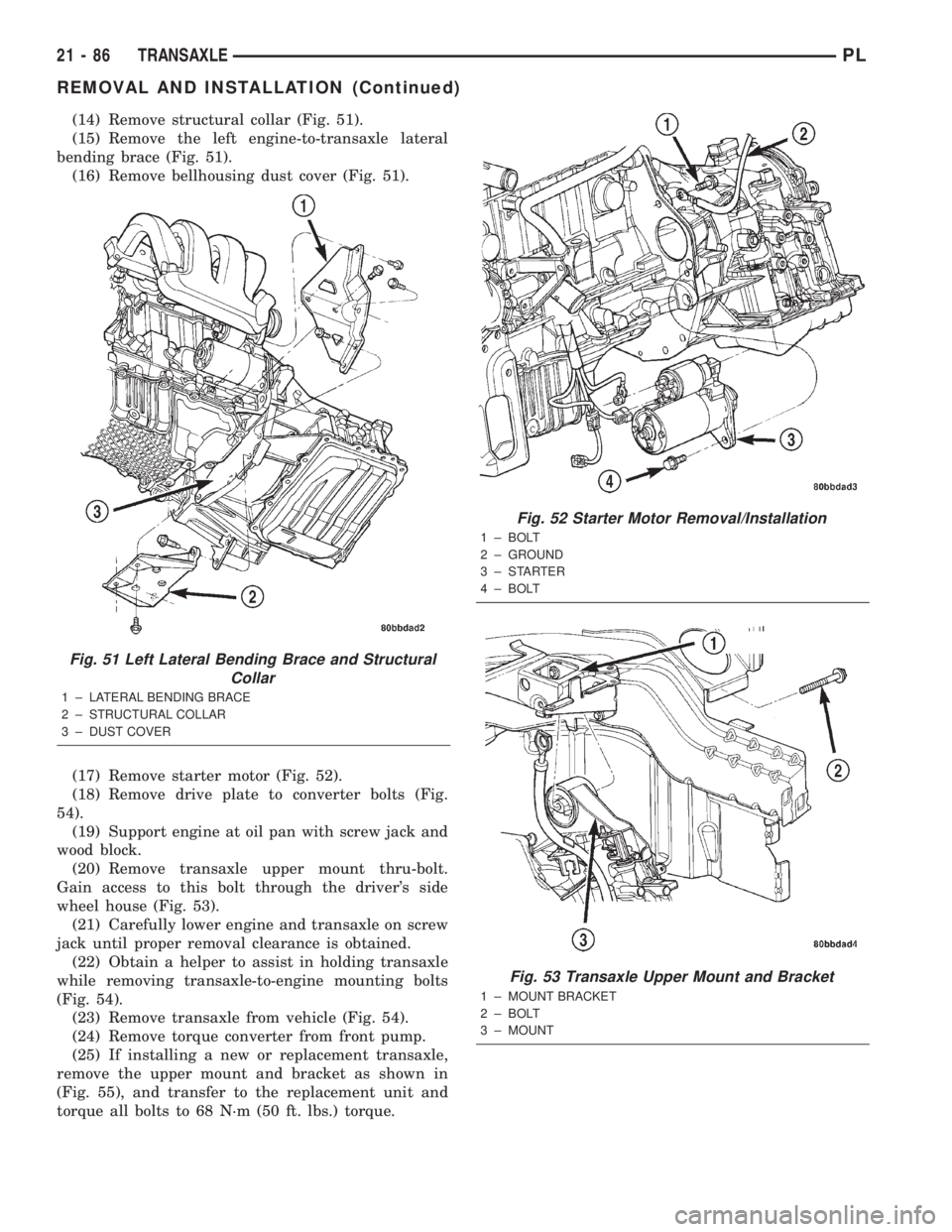

(22) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 43).

Fig. 39 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

4 ± SPEEDO PINION

Fig. 40 Left Lateral Bending Brace and Structural

CollarÐTypical

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 41 Right Lateral Bending Brace Removal/

InstallationÐTypical

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

PLTRANSAXLE 21 - 15

REMOVAL AND INSTALLATION (Continued)

Page 929 of 1285

(23) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

(24) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 44).(25) Remove transaxle from vehicle (Fig. 44).

(26) If installing a new or replacement transaxle,

remove the upper mount as shown in (Fig. 45), trans-

fer to the replacement unit and torque all bolts to 68

N´m (50 ft. lbs.) torque.

INSTALLATION

(1) Install clutch module onto input shaft. Install

transaxle into position.

(2) Install transaxle-to-engine mounting bolts (Fig.

44) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 43).

(4) Remove screwjack.

(5) Install drive plate-to-clutch module bolts and

torque to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 42).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 40).

(9) Install left engine-to-transaxle bending brace

(Fig. 40).

(10) Install structural collar (Fig. 40) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(11) Install the right lateral bending brace and

tighten bolts to 81 N´m (60 ft. lbs.) torque (Fig. 41).

(12) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(13) Fill transaxle with suitable amount of Mopart

Manual Transaxle Lubricant (PN 04874465).

(14) Lower vehicle.

(15) Connect vehicle speed sensor connector (Fig.

39).

(16) Connect shift crossover and selector cables to

shift lever. Install cables to bracket and install

retaining clips (Fig. 38).

(17) Connect clutch cable to fork and secure to

transaxle (Fig. 37).

(18) Install bellhousing cap (Fig. 37).

(19) Connect back-up lamp switch connector.

(20) Connect ground strap to transaxle upper

mount bracket.

(21) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

Fig. 42 Starter Motor Removal/InstallationÐTypical

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 43 Transaxle Upper Mount Thru-BoltÐTypical

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

21 - 16 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 999 of 1285

(14) Remove structural collar (Fig. 51).

(15) Remove the left engine-to-transaxle lateral

bending brace (Fig. 51).

(16) Remove bellhousing dust cover (Fig. 51).

(17) Remove starter motor (Fig. 52).

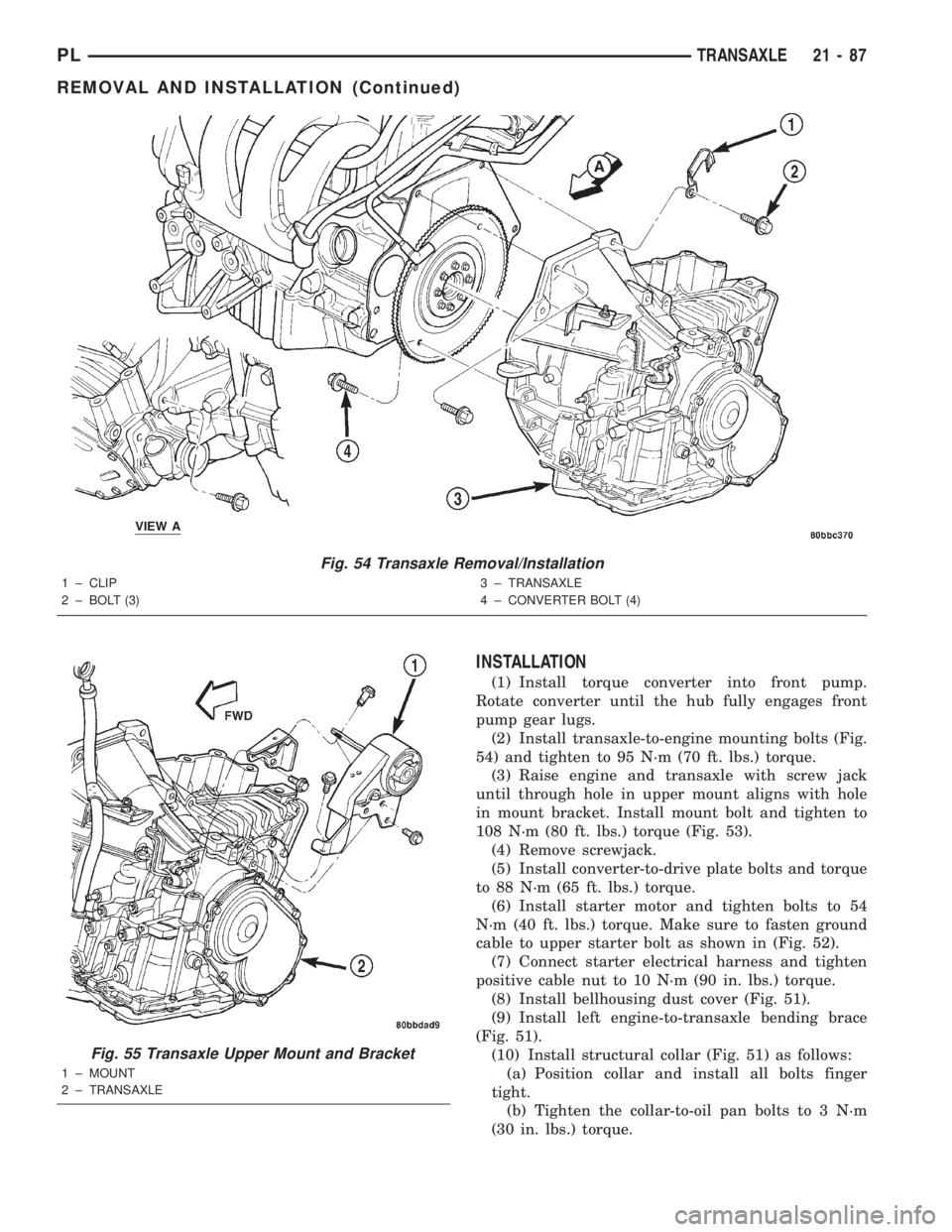

(18) Remove drive plate to converter bolts (Fig.

54).

(19) Support engine at oil pan with screw jack and

wood block.

(20) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 53).

(21) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

(22) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 54).

(23) Remove transaxle from vehicle (Fig. 54).

(24) Remove torque converter from front pump.

(25) If installing a new or replacement transaxle,

remove the upper mount and bracket as shown in

(Fig. 55), and transfer to the replacement unit and

torque all bolts to 68 N´m (50 ft. lbs.) torque.

Fig. 51 Left Lateral Bending Brace and Structural

Collar

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 52 Starter Motor Removal/Installation

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 53 Transaxle Upper Mount and Bracket

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

21 - 86 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1000 of 1285

INSTALLATION

(1) Install torque converter into front pump.

Rotate converter until the hub fully engages front

pump gear lugs.

(2) Install transaxle-to-engine mounting bolts (Fig.

54) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 53).

(4) Remove screwjack.

(5) Install converter-to-drive plate bolts and torque

to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 52).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 51).

(9) Install left engine-to-transaxle bending brace

(Fig. 51).

(10) Install structural collar (Fig. 51) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

Fig. 54 Transaxle Removal/Installation

1 ± CLIP

2 ± BOLT (3)3 ± TRANSAXLE

4 ± CONVERTER BOLT (4)

Fig. 55 Transaxle Upper Mount and Bracket

1 ± MOUNT

2 ± TRANSAXLE

PLTRANSAXLE 21 - 87

REMOVAL AND INSTALLATION (Continued)