engine oil capacity DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 3 of 1285

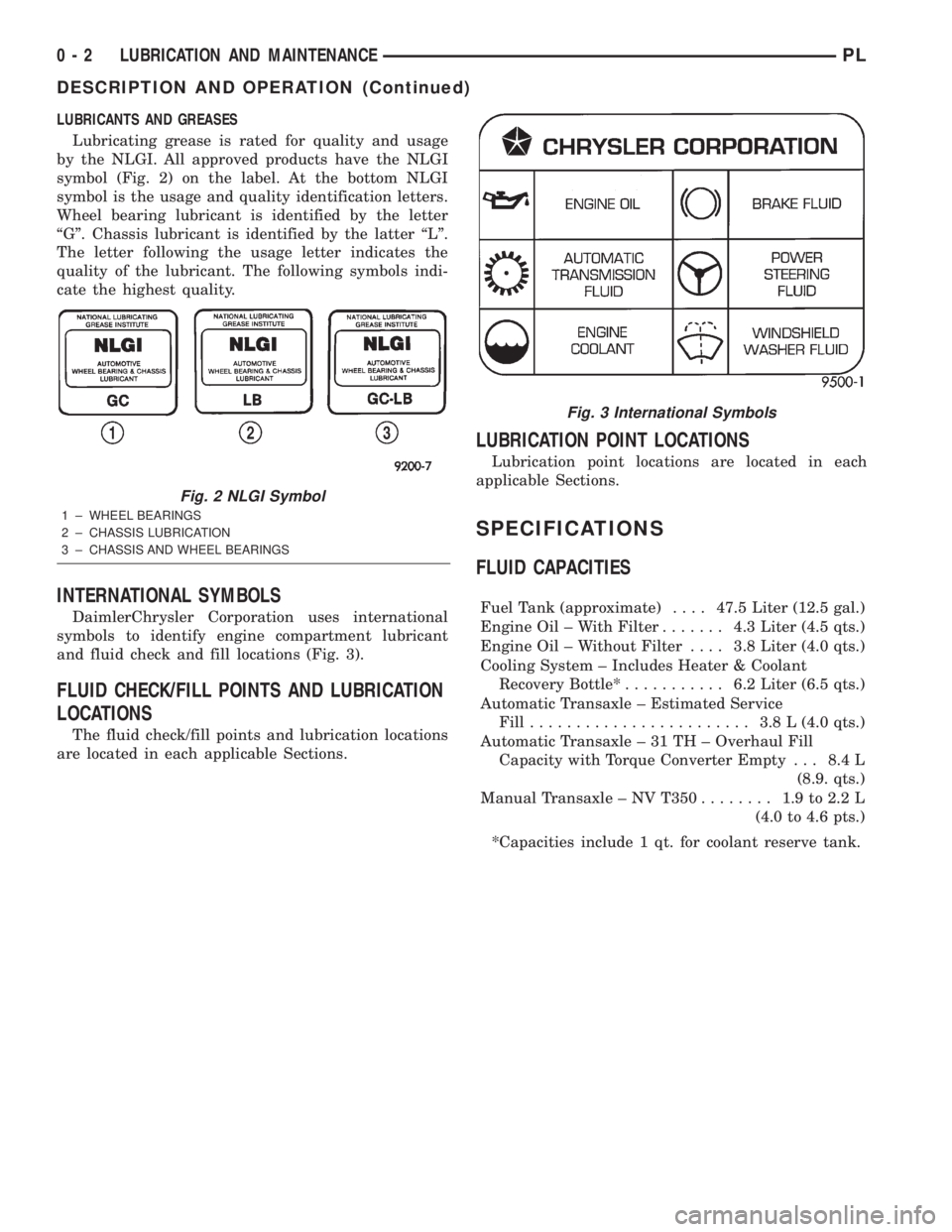

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 2) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

INTERNATIONAL SYMBOLS

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid check and fill locations (Fig. 3).

FLUID CHECK/FILL POINTS AND LUBRICATION

LOCATIONS

The fluid check/fill points and lubrication locations

are located in each applicable Sections.

LUBRICATION POINT LOCATIONS

Lubrication point locations are located in each

applicable Sections.

SPECIFICATIONS

FLUID CAPACITIES

Fuel Tank (approximate)....47.5 Liter (12.5 gal.)

Engine Oil ± With Filter....... 4.3Liter (4.5 qts.)

Engine Oil ± Without Filter.... 3.8Liter (4.0 qts.)

Cooling System ± Includes Heater & Coolant

Recovery Bottle*........... 6.2Liter (6.5 qts.)

Automatic Transaxle ± Estimated Service

Fill........................ 3.8L(4.0 qts.)

Automatic Transaxle ± 31 TH ± Overhaul Fill

Capacity with Torque Converter Empty . . . 8.4 L

(8.9. qts.)

Manual Transaxle ± NV T350........ 1.9to2.2L

(4.0 to 4.6 pts.)

*Capacities include 1 qt. for coolant reserve tank.

Fig. 2 NLGI Symbol

1 ± WHEEL BEARINGS

2 ± CHASSIS LUBRICATION

3 ± CHASSIS AND WHEEL BEARINGS

Fig. 3 International Symbols

0 - 2 LUBRICATION AND MAINTENANCEPL

DESCRIPTION AND OPERATION (Continued)

Page 180 of 1285

COOLING SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

COOLING SYSTEM........................1

COOLANT...............................2

COOLANT PERFORMANCE..................2

COOLANT RECOVERY SYSTEM..............3

ENGINE THERMOSTAT.....................3

RADIATOR..............................3

RADIATOR COOLING FAN MODULE...........3

COOLING SYSTEM PRESSURE CAP..........4

RADIATOR HOSES AND CLAMPS............5

WATER PUMP...........................5

AUTOMATIC TRANSMISSION OIL COOLER.....6

ACCESSORY DRIVE BELTS.................6

ENGINE BLOCK HEATER...................6

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS..............7

ENGINE THERMOSTAT TESTING............14

ACCESSORY DRIVE BELT DIAGNOSIS........14

WATER PUMP DIAGNOSIS................15

COOLING SYSTEM FLOW CHECK...........15

ELECTRIC FAN MOTOR TEST...............15

COOLANT CONCENTRATION TESTING........15

TESTING COOLING SYSTEM FOR LEAKS.....15

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK...............16

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP.......................16

LOW COOLANT LEVEL AERATION...........17

DEAERATION...........................17

TEMPERATURE GAUGE INDICATION.........17

ENGINE BLOCK HEATER..................17

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE.........17COOLANTÐADDING ADDITIONAL...........18

COOLANT LEVELÐSERVICING.............18

COOLING SYSTEMÐDRAINING.............19

COOLING SYSTEMÐREFILLING............19

REMOVAL AND INSTALLATION

WATER PUMP..........................19

WATER PUMP INLET TUBE................20

ENGINE THERMOSTAT....................20

RADIATOR.............................21

RADIATOR DRAINCOCK...................22

COOLING FAN MODULE...................22

COOLANT RECOVERY CONTAINER..........23

ENGINE BLOCK HEATER..................24

ACCESSORY DRIVE BELTS................24

AUTOMATIC BELT TENSIONER & PULLEY....26

DISASSEMBLY AND ASSEMBLY

COOLING FAN MODULE...................26

CLEANING AND INSPECTION

WATER PUMP..........................28

ACCESSORY DRIVE BELT INSPECTION.......28

COOLING SYSTEM CAP...................28

COOLING SYSTEM CLEANING..............28

RADIATOR FLUSHING....................28

REVERSE FLUSHING.....................29

CHEMICAL CLEANING....................29

ADJUSTMENTS

BELT TENSION..........................29

SPECIFICATIONS

COOLING SYSTEM CAPACITY..............30

TORQUE SPECIFICATIONS.................30

SPECIAL TOOLS

COOLING..............................30

DESCRIPTION AND OPERATION

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, and a water pump to

circulate the coolant. The engine cooling module may

consist of a radiator, electric fan motor, fan, shroud,

coolant reserve system, transmission oil cooler, hoses,clamps, air conditioning condenser and transmission

oil lines.

²When the Engine is cold: The thermostat is

closed and the cooling system has no flow through

the radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open

and the cooling system has flow through the radiator,

engine, heater system, and bypass.

PLCOOLING SYSTEM 7 - 1

Page 740 of 1285

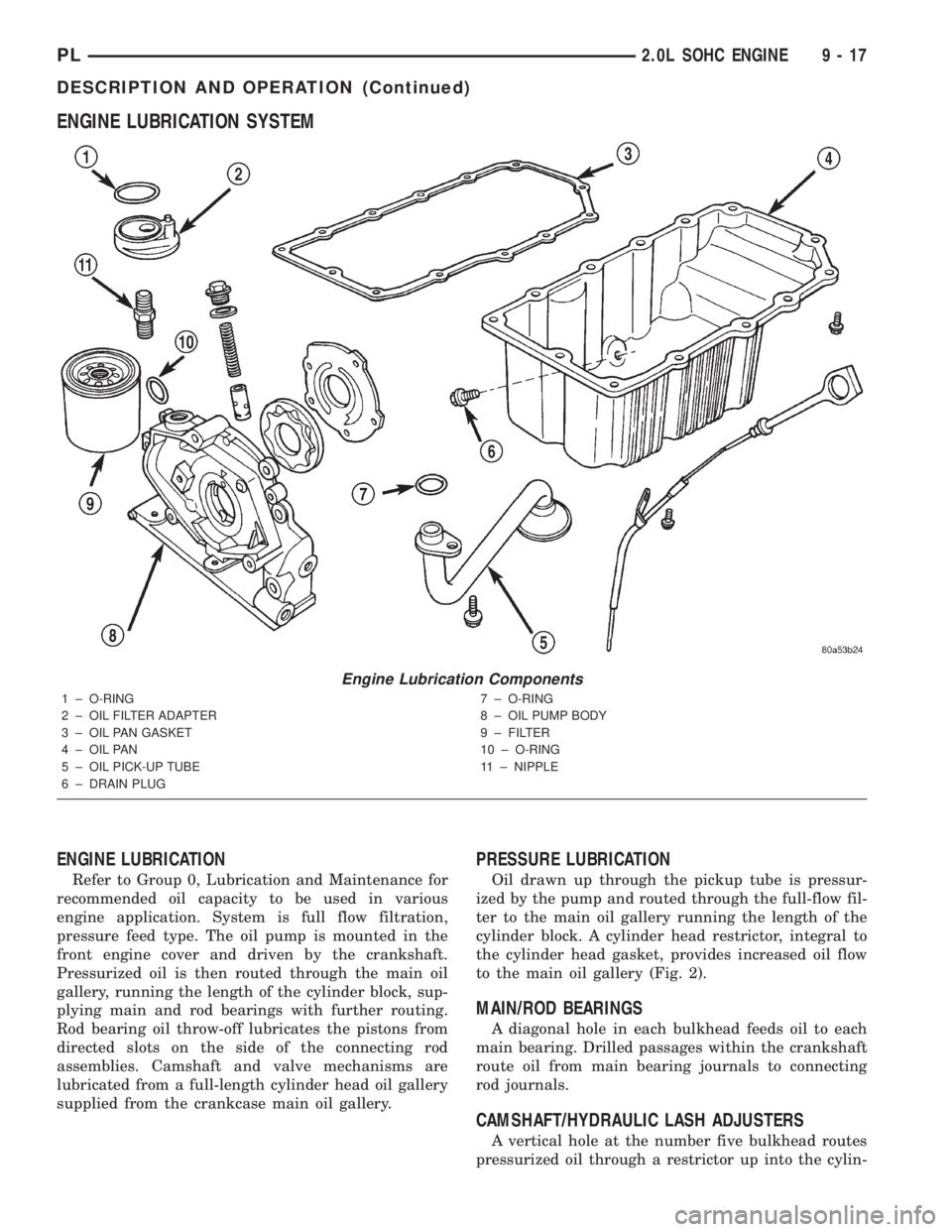

ENGINE LUBRICATION SYSTEM

ENGINE LUBRICATION

Refer to Group 0, Lubrication and Maintenance for

recommended oil capacity to be used in various

engine application. System is full flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

Pressurized oil is then routed through the main oil

gallery, running the length of the cylinder block, sup-

plying main and rod bearings with further routing.

Rod bearing oil throw-off lubricates the pistons from

directed slots on the side of the connecting rod

assemblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full-flow fil-

ter to the main oil gallery running the length of the

cylinder block. A cylinder head restrictor, integral to

the cylinder head gasket, provides increased oil flow

to the main oil gallery (Fig. 2).

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

Engine Lubrication Components

1 ± O-RING

2 ± OIL FILTER ADAPTER

3 ± OIL PAN GASKET

4 ± OIL PAN

5 ± OIL PICK-UP TUBE

6 ± DRAIN PLUG7 ± O-RING

8 ± OIL PUMP BODY

9 ± FILTER

10 ± O-RING

11 ± NIPPLE

PL2.0L SOHC ENGINE 9 - 17

DESCRIPTION AND OPERATION (Continued)

Page 915 of 1285

ferential case transfers torque from the ring gear to the

drive axles by means of differential side gears.

The NV T350 (A-578) transaxle internal components

can only be serviced by separating the case halves.

CAUTION: The transaxle output shaft is serviced as

a unit. No disassembly and reassembly is possible.

Damage to the transaxle may result.

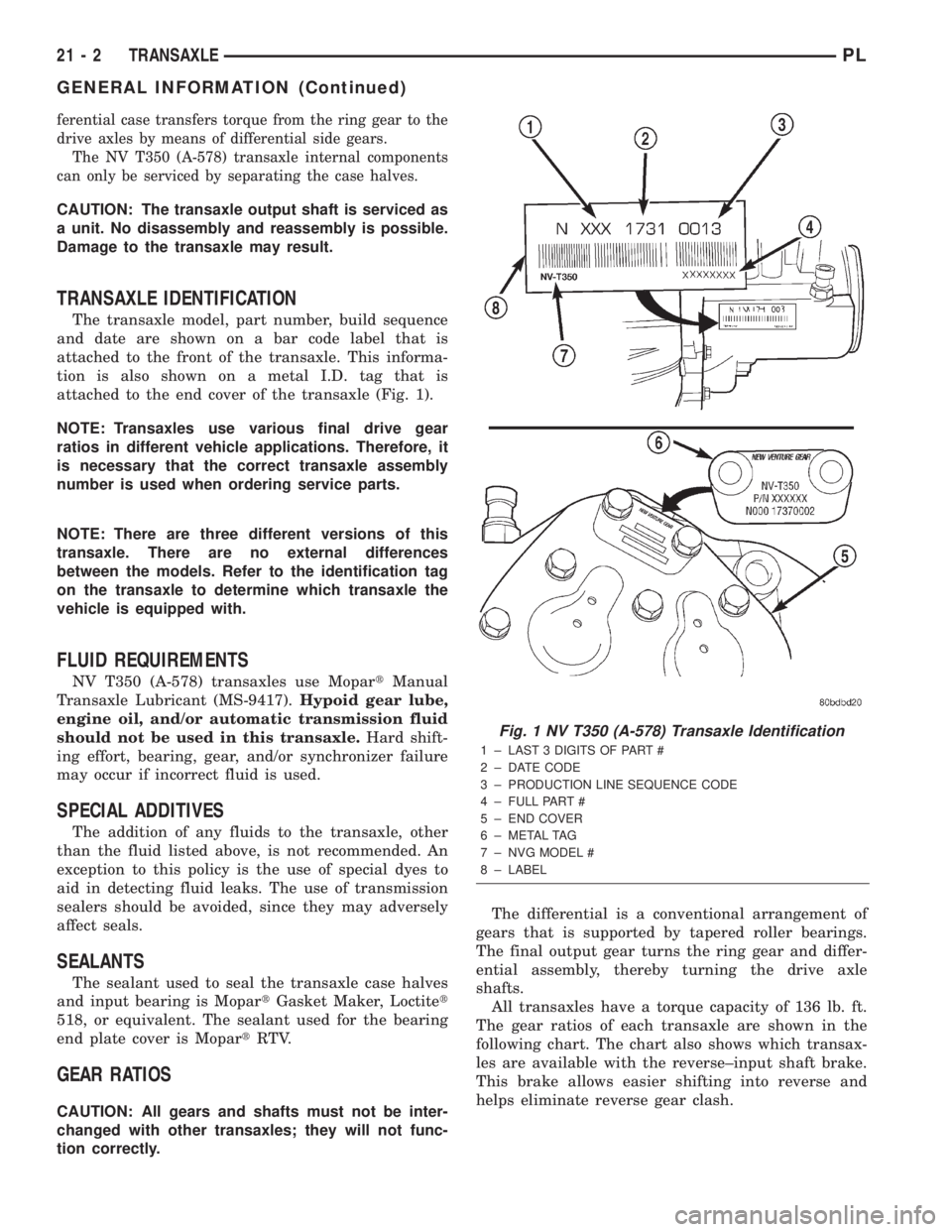

TRANSAXLE IDENTIFICATION

The transaxle model, part number, build sequence

and date are shown on a bar code label that is

attached to the front of the transaxle. This informa-

tion is also shown on a metal I.D. tag that is

attached to the end cover of the transaxle (Fig. 1).

NOTE: Transaxles use various final drive gear

ratios in different vehicle applications. Therefore, it

is necessary that the correct transaxle assembly

number is used when ordering service parts.

NOTE: There are three different versions of this

transaxle. There are no external differences

between the models. Refer to the identification tag

on the transaxle to determine which transaxle the

vehicle is equipped with.

FLUID REQUIREMENTS

NV T350 (A-578) transaxles use MopartManual

Transaxle Lubricant (MS-9417).Hypoid gear lube,

engine oil, and/or automatic transmission fluid

should not be used in this transaxle.Hard shift-

ing effort, bearing, gear, and/or synchronizer failure

may occur if incorrect fluid is used.

SPECIAL ADDITIVES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes to

aid in detecting fluid leaks. The use of transmission

sealers should be avoided, since they may adversely

affect seals.

SEALANTS

The sealant used to seal the transaxle case halves

and input bearing is MopartGasket Maker, Loctitet

518, or equivalent. The sealant used for the bearing

end plate cover is MopartRTV.

GEAR RATIOS

CAUTION: All gears and shafts must not be inter-

changed with other transaxles; they will not func-

tion correctly.The differential is a conventional arrangement of

gears that is supported by tapered roller bearings.

The final output gear turns the ring gear and differ-

ential assembly, thereby turning the drive axle

shafts.

All transaxles have a torque capacity of 136 lb. ft.

The gear ratios of each transaxle are shown in the

following chart. The chart also shows which transax-

les are available with the reverse±input shaft brake.

This brake allows easier shifting into reverse and

helps eliminate reverse gear clash.

Fig. 1 NV T350 (A-578) Transaxle Identification

1 ± LAST 3 DIGITS OF PART #

2 ± DATE CODE

3 ± PRODUCTION LINE SEQUENCE CODE

4 ± FULL PART #

5 ± END COVER

6 ± METAL TAG

7 ± NVG MODEL #

8 ± LABEL

21 - 2 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 917 of 1285

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

FLUID LEAKS

Fluid leaks can occur around the input shaft seal,

axleshaft seals, case split lines, and the end cover. Be

careful not to misdiagnose an input shaft seal leak

for an engine rear main seal leak. Also, the transaxle

case sealer (split line) will accumulate dirt and look

like an oil leak.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

SERVICE PROCEDURES

FLUID DRAIN AND FILL

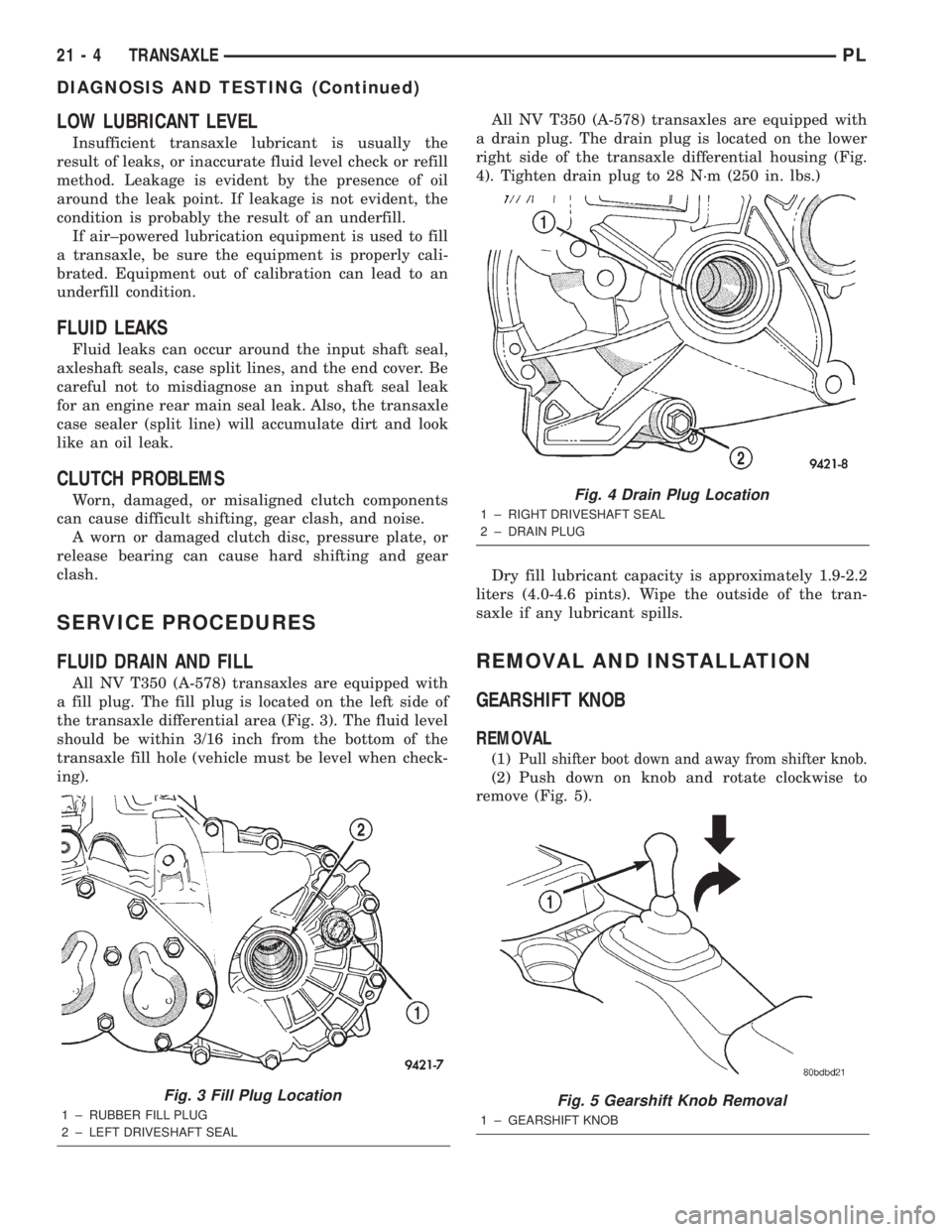

All NV T350 (A-578) transaxles are equipped with

a fill plug. The fill plug is located on the left side of

the transaxle differential area (Fig. 3). The fluid level

should be within 3/16 inch from the bottom of the

transaxle fill hole (vehicle must be level when check-

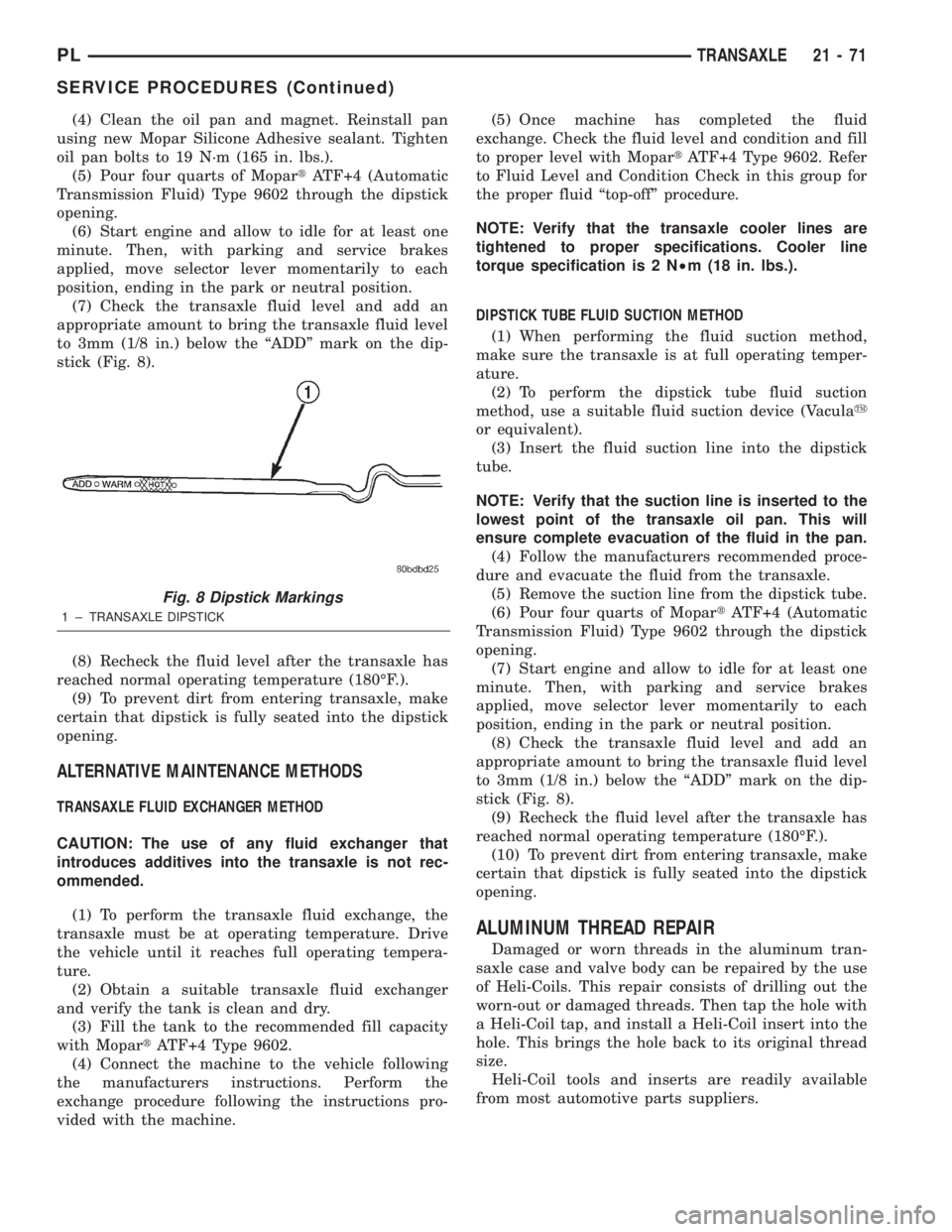

ing).All NV T350 (A-578) transaxles are equipped with

a drain plug. The drain plug is located on the lower

right side of the transaxle differential housing (Fig.

4). Tighten drain plug to 28 N´m (250 in. lbs.)

Dry fill lubricant capacity is approximately 1.9-2.2

liters (4.0-4.6 pints). Wipe the outside of the tran-

saxle if any lubricant spills.

REMOVAL AND INSTALLATION

GEARSHIFT KNOB

REMOVAL

(1)Pull shifter boot down and away from shifter knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 5).

Fig. 3 Fill Plug Location

1 ± RUBBER FILL PLUG

2 ± LEFT DRIVESHAFT SEAL

Fig. 4 Drain Plug Location

1 ± RIGHT DRIVESHAFT SEAL

2 ± DRAIN PLUG

Fig. 5 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

21 - 4 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 984 of 1285

(4) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.).

(5) Pour four quarts of MopartATF+4 (Automatic

Transmission Fluid) Type 9602 through the dipstick

opening.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

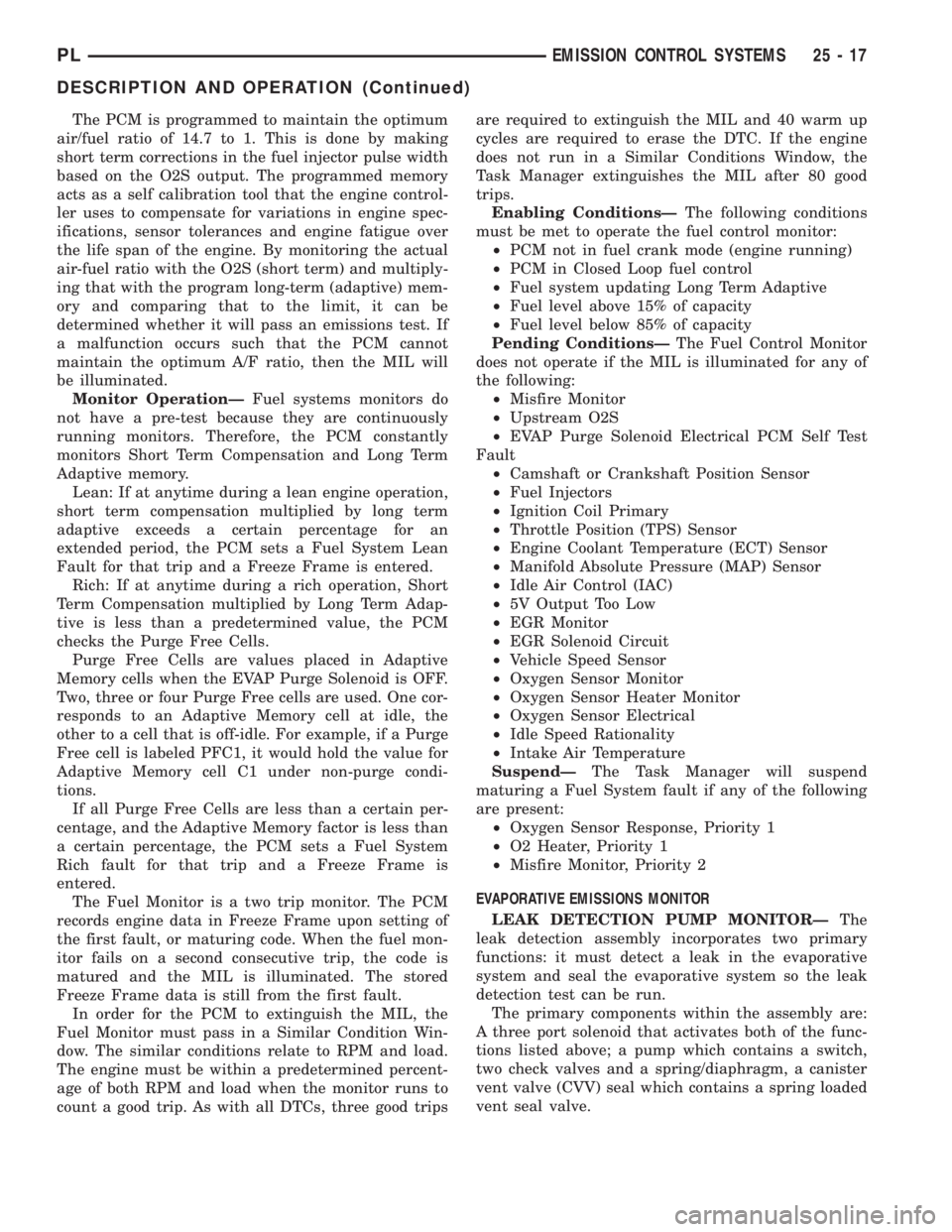

(7) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ªADDº mark on the dip-

stick (Fig. 8).

(8) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(9) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

ALTERNATIVE MAINTENANCE METHODS

TRANSAXLE FLUID EXCHANGER METHOD

CAUTION: The use of any fluid exchanger that

introduces additives into the transaxle is not rec-

ommended.

(1) To perform the transaxle fluid exchange, the

transaxle must be at operating temperature. Drive

the vehicle until it reaches full operating tempera-

ture.

(2) Obtain a suitable transaxle fluid exchanger

and verify the tank is clean and dry.

(3) Fill the tank to the recommended fill capacity

with MopartATF+4 Type 9602.

(4) Connect the machine to the vehicle following

the manufacturers instructions. Perform the

exchange procedure following the instructions pro-

vided with the machine.(5) Once machine has completed the fluid

exchange. Check the fluid level and condition and fill

to proper level with MopartATF+4 Type 9602. Refer

to Fluid Level and Condition Check in this group for

the proper fluid ªtop-offº procedure.

NOTE: Verify that the transaxle cooler lines are

tightened to proper specifications. Cooler line

torque specification is 2 N²m (18 in. lbs.).

DIPSTICK TUBE FLUID SUCTION METHOD

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (Vaculay

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Pour four quarts of MopartATF+4 (Automatic

Transmission Fluid) Type 9602 through the dipstick

opening.

(7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ªADDº mark on the dip-

stick (Fig. 8).

(9) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(10) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

ALUMINUM THREAD REPAIR

Damaged or worn threads in the aluminum tran-

saxle case and valve body can be repaired by the use

of Heli-Coils. This repair consists of drilling out the

worn-out or damaged threads. Then tap the hole with

a Heli-Coil tap, and install a Heli-Coil insert into the

hole. This brings the hole back to its original thread

size.

Heli-Coil tools and inserts are readily available

from most automotive parts suppliers.

Fig. 8 Dipstick Markings

1 ± TRANSAXLE DIPSTICK

PLTRANSAXLE 21 - 71

SERVICE PROCEDURES (Continued)

Page 1104 of 1285

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S output. The programmed memory

acts as a self calibration tool that the engine control-

ler uses to compensate for variations in engine spec-

ifications, sensor tolerances and engine fatigue over

the life span of the engine. By monitoring the actual

air-fuel ratio with the O2S (short term) and multiply-

ing that with the program long-term (adaptive) mem-

ory and comparing that to the limit, it can be

determined whether it will pass an emissions test. If

a malfunction occurs such that the PCM cannot

maintain the optimum A/F ratio, then the MIL will

be illuminated.

Monitor OperationÐFuel systems monitors do

not have a pre-test because they are continuously

running monitors. Therefore, the PCM constantly

monitors Short Term Compensation and Long Term

Adaptive memory.

Lean: If at anytime during a lean engine operation,

short term compensation multiplied by long term

adaptive exceeds a certain percentage for an

extended period, the PCM sets a Fuel System Lean

Fault for that trip and a Freeze Frame is entered.

Rich: If at anytime during a rich operation, Short

Term Compensation multiplied by Long Term Adap-

tive is less than a predetermined value, the PCM

checks the Purge Free Cells.

Purge Free Cells are values placed in Adaptive

Memory cells when the EVAP Purge Solenoid is OFF.

Two, three or four Purge Free cells are used. One cor-

responds to an Adaptive Memory cell at idle, the

other to a cell that is off-idle. For example, if a Purge

Free cell is labeled PFC1, it would hold the value for

Adaptive Memory cell C1 under non-purge condi-

tions.

If all Purge Free Cells are less than a certain per-

centage, and the Adaptive Memory factor is less than

a certain percentage, the PCM sets a Fuel System

Rich fault for that trip and a Freeze Frame is

entered.

The Fuel Monitor is a two trip monitor. The PCM

records engine data in Freeze Frame upon setting of

the first fault, or maturing code. When the fuel mon-

itor fails on a second consecutive trip, the code is

matured and the MIL is illuminated. The stored

Freeze Frame data is still from the first fault.

In order for the PCM to extinguish the MIL, the

Fuel Monitor must pass in a Similar Condition Win-

dow. The similar conditions relate to RPM and load.

The engine must be within a predetermined percent-

age of both RPM and load when the monitor runs to

count a good trip. As with all DTCs, three good tripsare required to extinguish the MIL and 40 warm up

cycles are required to erase the DTC. If the engine

does not run in a Similar Conditions Window, the

Task Manager extinguishes the MIL after 80 good

trips.

Enabling ConditionsÐThe following conditions

must be met to operate the fuel control monitor:

²PCM not in fuel crank mode (engine running)

²PCM in Closed Loop fuel control

²Fuel system updating Long Term Adaptive

²Fuel level above 15% of capacity

²Fuel level below 85% of capacity

Pending ConditionsÐThe Fuel Control Monitor

does not operate if the MIL is illuminated for any of

the following:

²Misfire Monitor

²Upstream O2S

²EVAP Purge Solenoid Electrical PCM Self Test

Fault

²Camshaft or Crankshaft Position Sensor

²Fuel Injectors

²Ignition Coil Primary

²Throttle Position (TPS) Sensor

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Idle Air Control (IAC)

²5V Output Too Low

²EGR Monitor

²EGR Solenoid Circuit

²Vehicle Speed Sensor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Oxygen Sensor Electrical

²Idle Speed Rationality

²Intake Air Temperature

SuspendÐThe Task Manager will suspend

maturing a Fuel System fault if any of the following

are present:

²Oxygen Sensor Response, Priority 1

²O2 Heater, Priority 1

²Misfire Monitor, Priority 2

EVAPORATIVE EMISSIONS MONITOR

LEAK DETECTION PUMP MONITORÐThe

leak detection assembly incorporates two primary

functions: it must detect a leak in the evaporative

system and seal the evaporative system so the leak

detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

PLEMISSION CONTROL SYSTEMS 25 - 17

DESCRIPTION AND OPERATION (Continued)

Page 1237 of 1285

COMPRESSOR FRONT SHAFT SEAL

The compressor front shaft seal is not serviceable.

If a leak is detected at the shaft seal, the compressor

must be replaced as a unit.

CONDENSATION DRAIN TUBE

Condensation that accumulates in the evaporator

housing is drained from a tube through the dash and

on to the ground. This tube must be kept open to

prevent condensate water from collecting in the bot-

tom of the housing.

The tapered end of the drain tube is designed to

keep contaminants from entering the heater A/C unit

housing. If the tube is pinched or blocked, condensate

cannot drain, causing water to back up and spill into

the passenger compartment. It is normal to see con-

densate drainage below the vehicle. If the tube is

damaged, it should be replaced.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain ample temperature levels from the

heating-A/C system, the cooling system must be in

proper working order. Refer to Group 0, Lubrication

and Maintenance or Group 7, Cooling System of this

manual.

The use of a bug screen is not recommended. Any

obstructions forward of the condenser can reduce the

effectiveness of the air conditioning system.

EVAPORATOR PROBE

The evaporator probe can be replaced without hav-

ing to remove the unit housing from the vehicle.

The evaporator probe is located in the unit housing

and placed in the evaporator fins. The probe prevents

evaporator freeze-up. This is done by cycling the com-

pressor clutch OFF when evaporator temperature

drops below freeze point. It cycles ON when the

evaporator temperature rises above freeze point. The

evaporator probe uses a thermistor probe in a capil-

lary tube. The tube is inserted between the evapora-

tor fins in the heater-A/C unit housing.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system.CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

A good rule for the flexible hose lines is to keep

the radius of all bends at least 10 times the diame-

ter of the hose. Sharper bends will reduce the flow

of refrigerant. The flexible hose lines should be

routed so they are at least 3 inches (80 mm) from

the exhaust manifold. Inspect all flexible hose lines

to make sure they are in good condition and prop-

erly routed.

The use of correct wrenches when making con-

nections is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain

stable as long as moisture-free refrigerant and

refrigerant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities.

When opening a refrigeration system, have every-

thing you will need to repair the system ready. This

will minimize the amount of time the system must

be opened. Cap or plug all lines and fittings as

soon as they are opened. This will help prevent the

entrance of dirt and moisture. All new lines and

components should be capped or sealed until they

are ready to be used.

All tools, including the refrigerant dispensing

manifold, the manifold gauge set, and test hoses

should be kept clean and dry.

HIGH PRESSURE CUT OUT SWITCH

The high pressure cut out switch is located on the

rear of the compressor (Fig. 7). It turns off the com-

pressor if the system pressure exceeds 3240 kPa (470

psi).

LOW PRESSURE CUT OFF SWITCH

The Low Pressure Cut Off Switch (Fig. 8) monitors

the refrigerant gas pressure on the suction side of

the system. The low pressure cut off switch is located

on the expansion valve. The low pressure cut off

switch turns off voltage to the compressor clutch coil

when refrigerant gas pressure drops to levels that

could damage the compressor. The low pressure cut

out switch is a sealed factory calibrated unit. It must

be replaced if defective.

24 - 6 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1251 of 1285

(1) Discharge refrigerant system using recovery/re-

cycling equipment if charge is present.

(2) Disconnect refrigerant lines from A/C compres-

sor. Cap the open lines to prevent moisture from

entering system.

(3) Remove compressor from vehicle.

(4) From suction port on top of compressor, drain

lubricant from compressor.

(5) Add system capacity minus the capacity of

components that have not been replaced. Refer to the

Lubricant Capacity Chart. Add lubricant through the

suction port on compressor. This is not to exceed 180

ml (6.10 oz.) in total.

(6) Install compressor and connect refrigerant

lines. Then evacuate and charge refrigerant system.

SYSTEM LEAK CHECKING

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. MIXTURE OF AIR and R-134a CAN BE COM-

BUSTIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

AVOID BREATHING A/C REFRIGERANT AND

LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 345 kPa (50

psi) proceed to Empty Refrigerant System Leak Test.

If liquid line pressure is greater than 345 kPa (50

psi) proceed to low refrigerant level leak test. If the

refrigerant system is empty or low in refrigerant

charge, a leak at any line fitting or component seal is

likely. A review of the fittings, lines and components

for oily residue is an indication of the leak location.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

symptoms.

EMPTY REFRIGERANT SYSTEM LEAK TEST

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approx. 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-tem will not maintain vacuum level, proceed with

this procedure.

(2) Prepare a.284 Kg. (10 oz.) refrigerant charge to

be injected into the system.

(3) Connect and dispense.284 Kg. (10 oz.) of refrig-

erant into the evacuated refrigerant system.

(4) Proceed to Step 2 of Low Refrigerant Level

Leak Test.

LOW REFRIGERANT LEVEL LEAK TEST

(1) Determine if there is any (R-134a) refrigerant

in the system.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set in 100 percent outside air

²Blower switch in the high A/C position

²A/C in the ON position

²Open all windows

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only Chrysler approved refrigerant dye.

If a thorough leak check has been completed with-

out indication of a leak, proceed to System Charge

Level.

REMOVAL AND INSTALLATION

A/C FILTER/DRIER

The filter/drier is mounted in a rubber grommet on

the right side of the engine compartment. The refrig-

erant must be recovered from the A/C system before

replacing the filter/drier assembly.

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY RECOVERED BEFORE PRO-

CEEDING WITH THIS OPERATION.

24 - 20 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)