parking brake DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 984 of 1285

(4) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.).

(5) Pour four quarts of MopartATF+4 (Automatic

Transmission Fluid) Type 9602 through the dipstick

opening.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

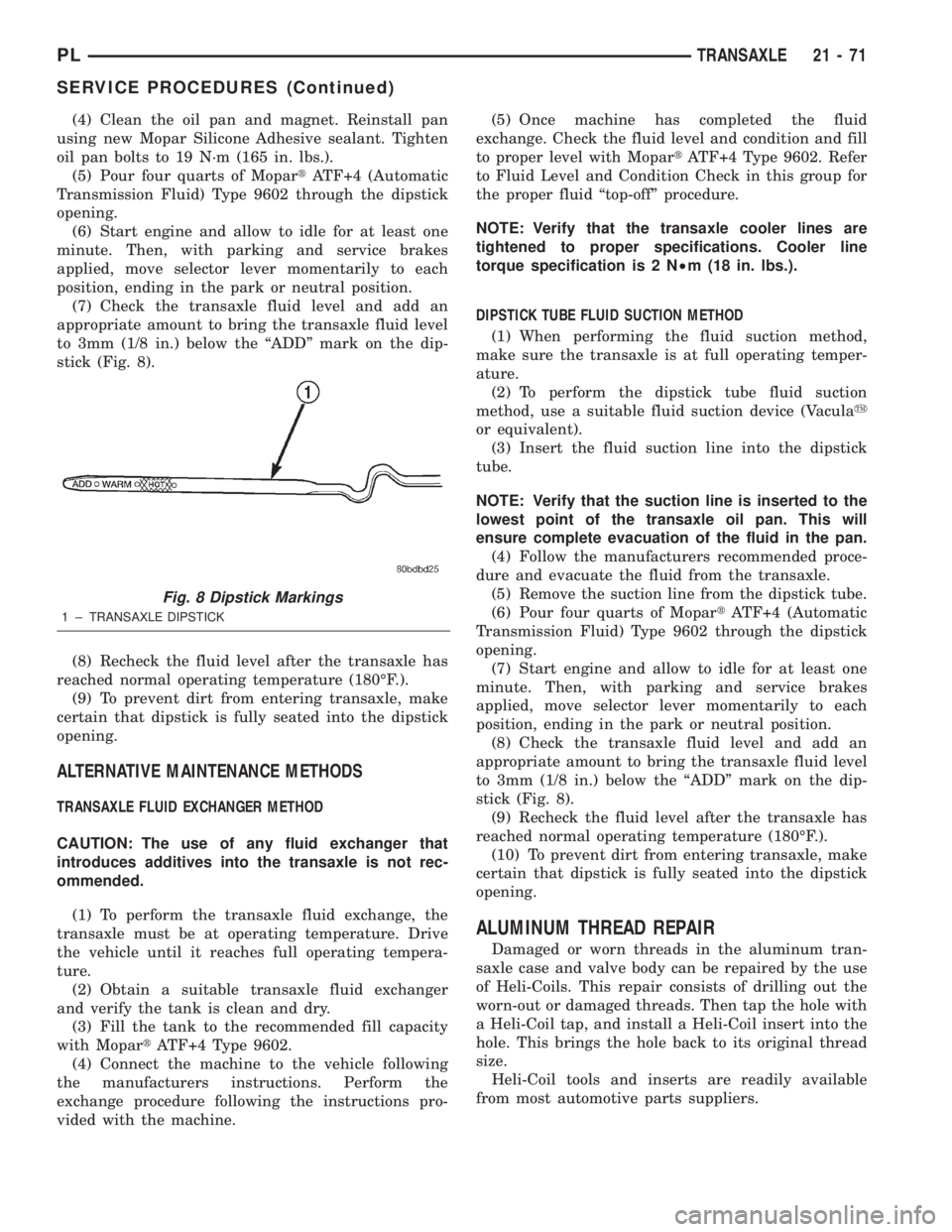

(7) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ªADDº mark on the dip-

stick (Fig. 8).

(8) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(9) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

ALTERNATIVE MAINTENANCE METHODS

TRANSAXLE FLUID EXCHANGER METHOD

CAUTION: The use of any fluid exchanger that

introduces additives into the transaxle is not rec-

ommended.

(1) To perform the transaxle fluid exchange, the

transaxle must be at operating temperature. Drive

the vehicle until it reaches full operating tempera-

ture.

(2) Obtain a suitable transaxle fluid exchanger

and verify the tank is clean and dry.

(3) Fill the tank to the recommended fill capacity

with MopartATF+4 Type 9602.

(4) Connect the machine to the vehicle following

the manufacturers instructions. Perform the

exchange procedure following the instructions pro-

vided with the machine.(5) Once machine has completed the fluid

exchange. Check the fluid level and condition and fill

to proper level with MopartATF+4 Type 9602. Refer

to Fluid Level and Condition Check in this group for

the proper fluid ªtop-offº procedure.

NOTE: Verify that the transaxle cooler lines are

tightened to proper specifications. Cooler line

torque specification is 2 N²m (18 in. lbs.).

DIPSTICK TUBE FLUID SUCTION METHOD

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (Vaculay

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Pour four quarts of MopartATF+4 (Automatic

Transmission Fluid) Type 9602 through the dipstick

opening.

(7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ªADDº mark on the dip-

stick (Fig. 8).

(9) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(10) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

ALUMINUM THREAD REPAIR

Damaged or worn threads in the aluminum tran-

saxle case and valve body can be repaired by the use

of Heli-Coils. This repair consists of drilling out the

worn-out or damaged threads. Then tap the hole with

a Heli-Coil tap, and install a Heli-Coil insert into the

hole. This brings the hole back to its original thread

size.

Heli-Coil tools and inserts are readily available

from most automotive parts suppliers.

Fig. 8 Dipstick Markings

1 ± TRANSAXLE DIPSTICK

PLTRANSAXLE 21 - 71

SERVICE PROCEDURES (Continued)

Page 1171 of 1285

(3) Disengage clips attaching trim to lower quarter

panel.

(4) Remove seat belt from slot in trim panel.

(5) Remove lower quarter trim from vehicle (Fig.

66).

INSTALLATION

(1) Position lower quarter trim panel to vehicle.

(2) Install seat belt to slot in trim panel.

(3) Align locating pins on backside of trim panel to

mating holes in inner quarter panel.

(4) Press clips on trim panel into slots in inner

quarter panel.

(5) Install rear seat back and cushion.

(6) Install upper quarter trim panel.

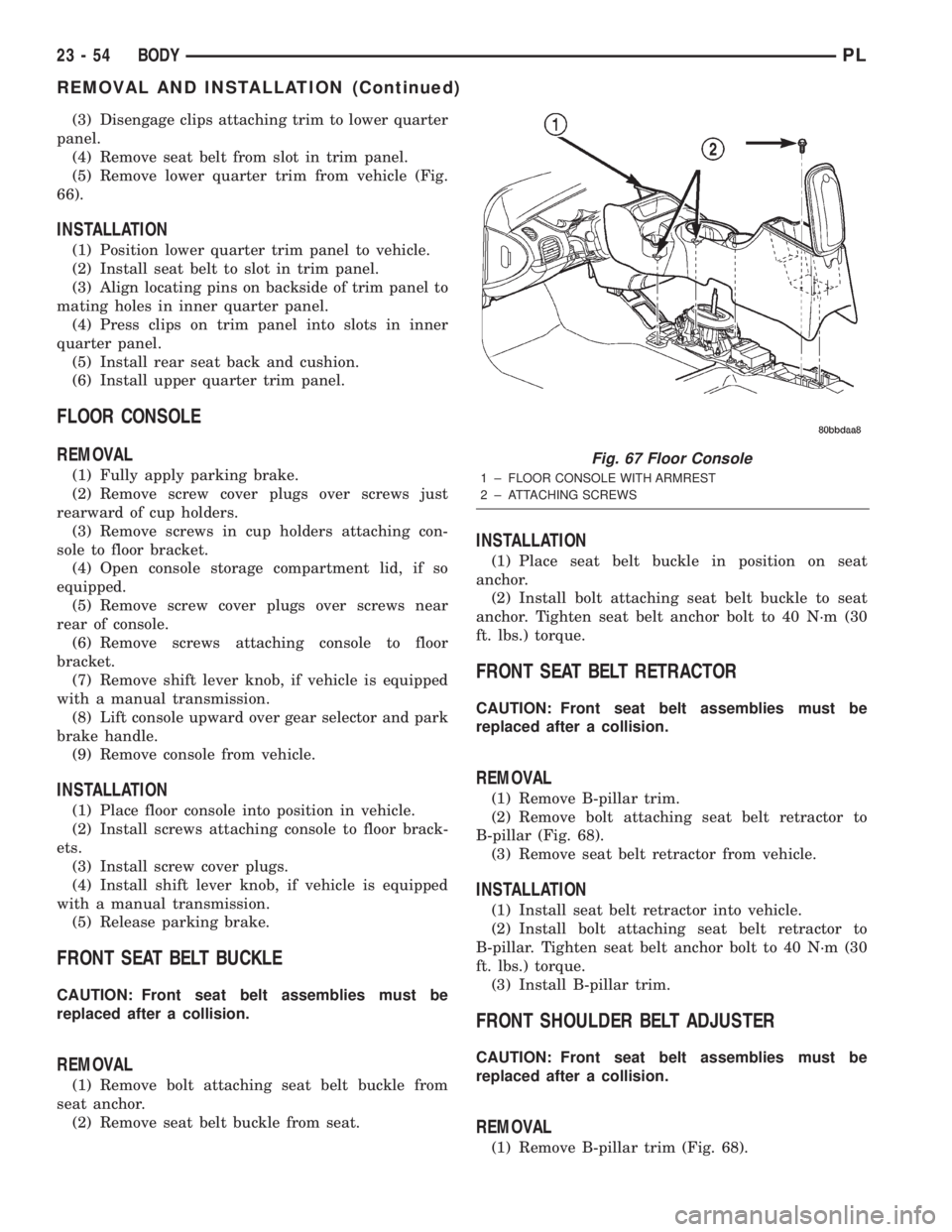

FLOOR CONSOLE

REMOVAL

(1) Fully apply parking brake.

(2) Remove screw cover plugs over screws just

rearward of cup holders.

(3) Remove screws in cup holders attaching con-

sole to floor bracket.

(4) Open console storage compartment lid, if so

equipped.

(5) Remove screw cover plugs over screws near

rear of console.

(6) Remove screws attaching console to floor

bracket.

(7) Remove shift lever knob, if vehicle is equipped

with a manual transmission.

(8) Lift console upward over gear selector and park

brake handle.

(9) Remove console from vehicle.

INSTALLATION

(1) Place floor console into position in vehicle.

(2) Install screws attaching console to floor brack-

ets.

(3) Install screw cover plugs.

(4) Install shift lever knob, if vehicle is equipped

with a manual transmission.

(5) Release parking brake.

FRONT SEAT BELT BUCKLE

CAUTION: Front seat belt assemblies must be

replaced after a collision.

REMOVAL

(1) Remove bolt attaching seat belt buckle from

seat anchor.

(2) Remove seat belt buckle from seat.

INSTALLATION

(1) Place seat belt buckle in position on seat

anchor.

(2) Install bolt attaching seat belt buckle to seat

anchor. Tighten seat belt anchor bolt to 40 N´m (30

ft. lbs.) torque.

FRONT SEAT BELT RETRACTOR

CAUTION: Front seat belt assemblies must be

replaced after a collision.

REMOVAL

(1) Remove B-pillar trim.

(2) Remove bolt attaching seat belt retractor to

B-pillar (Fig. 68).

(3) Remove seat belt retractor from vehicle.

INSTALLATION

(1) Install seat belt retractor into vehicle.

(2) Install bolt attaching seat belt retractor to

B-pillar. Tighten seat belt anchor bolt to 40 N´m (30

ft. lbs.) torque.

(3) Install B-pillar trim.

FRONT SHOULDER BELT ADJUSTER

CAUTION: Front seat belt assemblies must be

replaced after a collision.

REMOVAL

(1) Remove B-pillar trim (Fig. 68).

Fig. 67 Floor Console

1 ± FLOOR CONSOLE WITH ARMREST

2 ± ATTACHING SCREWS

23 - 54 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1176 of 1285

SPECIFICATIONS

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other

underhood services, the hood latch release mecha-

nism and safety catch should be inspected, cleaned,

and lubricated. During the winter season, external

door lock cylinders should be lubricated to assure

proper operation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Decklid Hinges

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Decklid Latch

MOPARTMULTIPURPOSE GREASE OR

EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Decklid Lock Cylinder

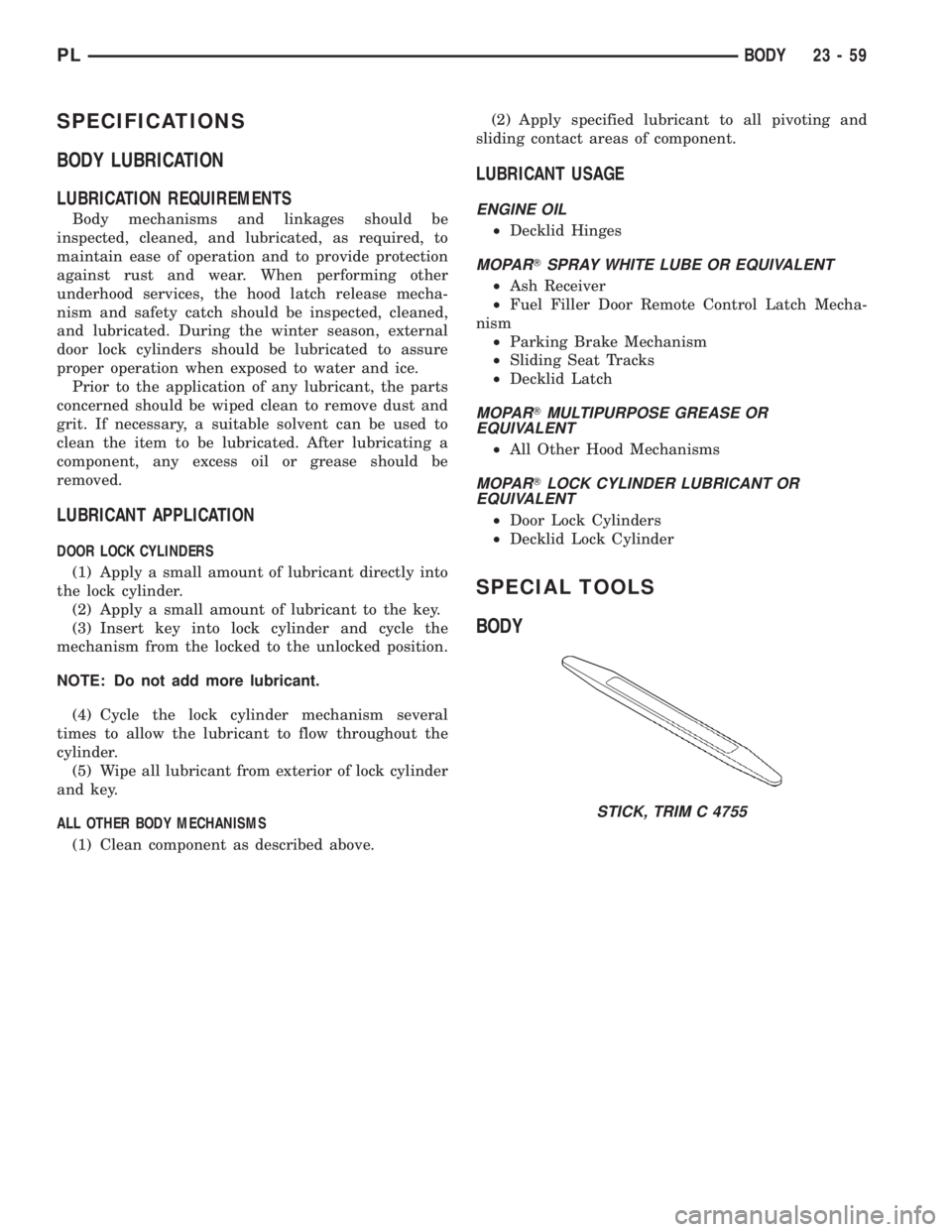

SPECIAL TOOLS

BODY

STICK, TRIM C 4755

PLBODY 23 - 59

Page 1177 of 1285

SPECIFICATIONS

TABLE OF CONTENTS

page page

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS........60

BODY GAP AND FLUSH MEASUREMENTS.....61

BODY OPENING DIMENSION...............62BODY SEALING LOCATIONS................64

STRUCTURAL ADHESIVE LOCATIONS........74

TORQUE SPECIFICATIONS.................76

WELD LOCATIONS.......................77

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door Hinges ± Hinge Pin and Pivot Contact

Areas

²Hood Hinges ± Pivot Points

²Liftgate Hinges

²Decklid Hinges

MOPARTSPRAY WHITE CUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Decklid Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Decklid Lock Cylinder

23 - 60 BODYPL