suspension DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 90 of 1285

CONDITION POSSIBLE CAUSES CORRECTION

PEDAL PULSATES/SURGES

DURING BRAKING1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or rotors

as necessary.

PEDAL IS SPONGY 1. Air in brake lines. 1. Bleed brakes.

2. Power brake booster runout

(vacuum assist).2. Check booster vacuum hose and

engine tune for adequate vacuum supply.

Refer to power brake booster in the

diagnosis and testing section.

PREMATURE REAR WHEEL

LOCKUP1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Inoperative proportioning valve

(non-ABS vehicles only).2. Test proportioning valves folowing

procedure listed in diagnosis and testing

section. Replace valves as necessary.

3. ABS EBD not functioning. 3. Refer to the ABS section and Chassis

Diagnostic Procedures manual.

4. Improper power brake booster

assist.4. Refer to power brake booster in the

diagnosis and testing section.

STOP LAMPS STAY ON 1. Brake lamp switch out of

adjustment.1. Adjust brake lamp switch.

2. Brake pedal binding. 2. Inspect and replace as necessary.

3. Obstruction in pedal linkage. 3. Remove obstruction.

4. Power Brake Booster not allowing

pedal to return completely.4. Replace power brake booster.

VEHICLE PULLS TO RIGHT

OR LEFT ON BRAKING1. Frozen brake caliper piston. 1. Replace frozen piston or caliper. Bleed

brakes.

2. Contaminated brake shoe lining. 2. Inspect and clean, or replace shoes.

Repair source of contamination.

3. Pinched brake lines. 3. Replace pinched line.

4. Leaking piston seal. 4. Replace piston seal or brake caliper.

5. Suspension problem. 5. Refer to the Suspension group.

PARKING BRAKE -

EXCESSIVE HANDLE

TRAVEL1. Rear brakes out of adjustment. 1. Adjust rear drum brake shoes, or rear

parking brake shoes on vehicles with rear

disc brakes.

POWER BRAKE BOOSTER

BASIC TEST

(1) With engine off, depress and release the brake

pedal several times to purge all vacuum from the

power brake booster.

(2) Depress and hold the pedal with light effort (15

to 25 lbs. pressure), then start the engine.

The pedal should fall slightly, then hold. Less effort

should be needed to apply the pedal at this time. If

the pedal fell as indicated, perform the VACUUM

LEAK TEST listed after the BASIC TEST. If thepedal did not fall, continue on with this BASIC

TEST.

(3) Disconnect the vacuum hose on the side of the

vacuum check valve that leads to the speed control,

then connect a vacuum gauge to the open vacuum

port on the valve.

(4) Start the engine.

(5) When the engine is at warm operating temper-

ature, allow it to idle and check the vacuum at the

gauge.

PLBRAKES 5 - 11

DIAGNOSIS AND TESTING (Continued)

Page 93 of 1285

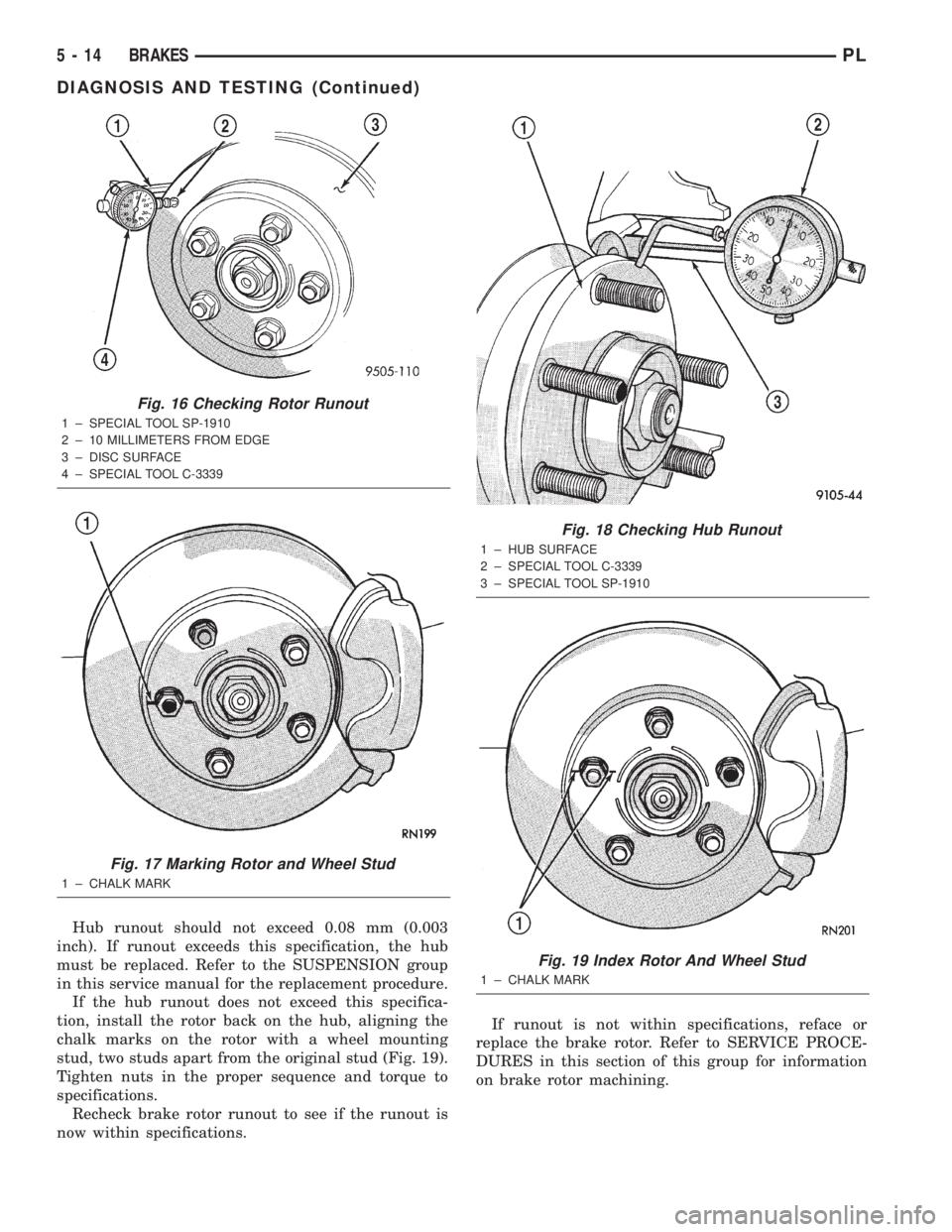

Hub runout should not exceed 0.08 mm (0.003

inch). If runout exceeds this specification, the hub

must be replaced. Refer to the SUSPENSION group

in this service manual for the replacement procedure.

If the hub runout does not exceed this specifica-

tion, install the rotor back on the hub, aligning the

chalk marks on the rotor with a wheel mounting

stud, two studs apart from the original stud (Fig. 19).

Tighten nuts in the proper sequence and torque to

specifications.

Recheck brake rotor runout to see if the runout is

now within specifications.If runout is not within specifications, reface or

replace the brake rotor. Refer to SERVICE PROCE-

DURES in this section of this group for information

on brake rotor machining.

Fig. 16 Checking Rotor Runout

1 ± SPECIAL TOOL SP-1910

2 ± 10 MILLIMETERS FROM EDGE

3 ± DISC SURFACE

4 ± SPECIAL TOOL C-3339

Fig. 17 Marking Rotor and Wheel Stud

1 ± CHALK MARK

Fig. 18 Checking Hub Runout

1 ± HUB SURFACE

2 ± SPECIAL TOOL C-3339

3 ± SPECIAL TOOL SP-1910

Fig. 19 Index Rotor And Wheel Stud

1 ± CHALK MARK

5 - 14 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 126 of 1285

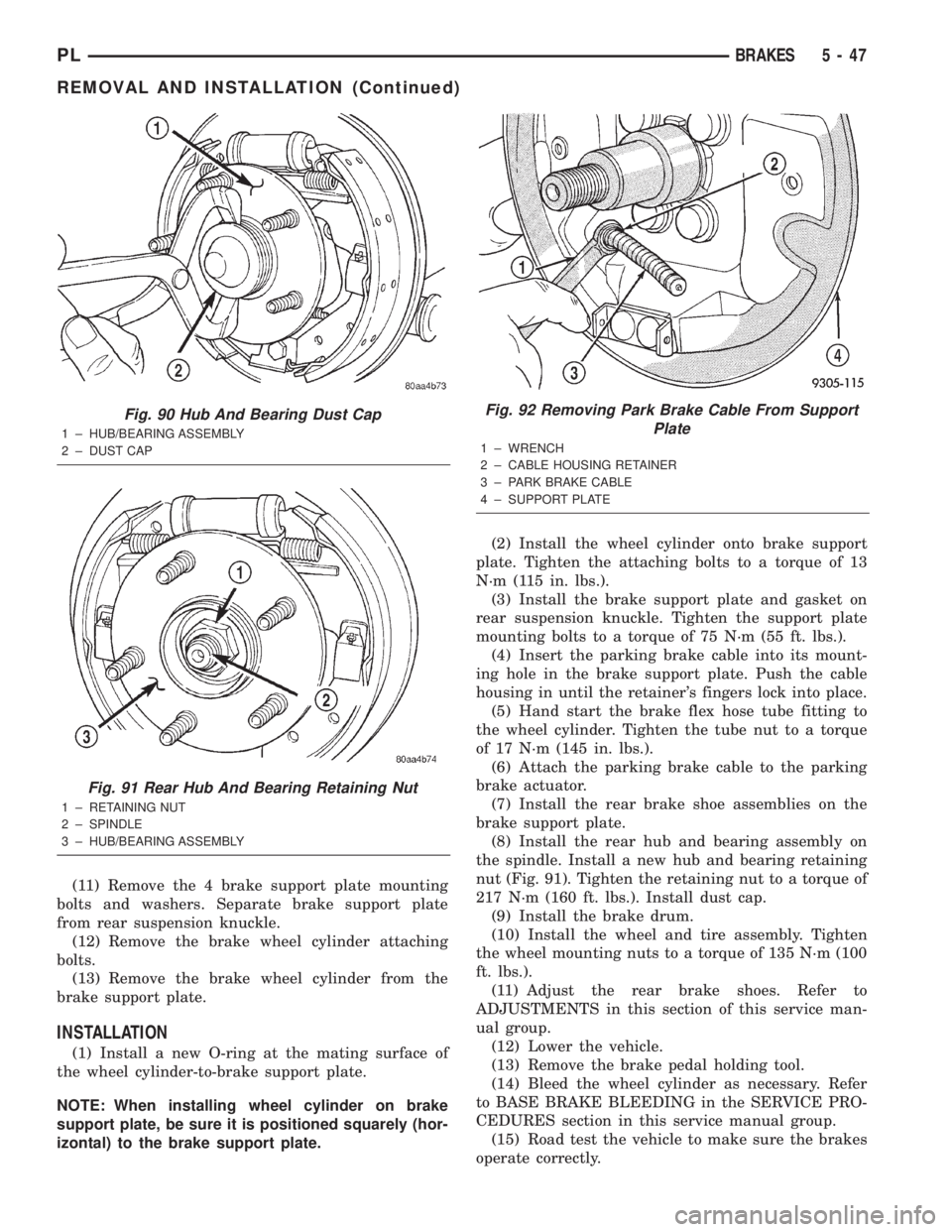

(11) Remove the 4 brake support plate mounting

bolts and washers. Separate brake support plate

from rear suspension knuckle.

(12) Remove the brake wheel cylinder attaching

bolts.

(13) Remove the brake wheel cylinder from the

brake support plate.

INSTALLATION

(1) Install a new O-ring at the mating surface of

the wheel cylinder-to-brake support plate.

NOTE: When installing wheel cylinder on brake

support plate, be sure it is positioned squarely (hor-

izontal) to the brake support plate.(2) Install the wheel cylinder onto brake support

plate. Tighten the attaching bolts to a torque of 13

N´m (115 in. lbs.).

(3) Install the brake support plate and gasket on

rear suspension knuckle. Tighten the support plate

mounting bolts to a torque of 75 N´m (55 ft. lbs.).

(4) Insert the parking brake cable into its mount-

ing hole in the brake support plate. Push the cable

housing in until the retainer's fingers lock into place.

(5) Hand start the brake flex hose tube fitting to

the wheel cylinder. Tighten the tube nut to a torque

of 17 N´m (145 in. lbs.).

(6) Attach the parking brake cable to the parking

brake actuator.

(7) Install the rear brake shoe assemblies on the

brake support plate.

(8) Install the rear hub and bearing assembly on

the spindle. Install a new hub and bearing retaining

nut (Fig. 91). Tighten the retaining nut to a torque of

217 N´m (160 ft. lbs.). Install dust cap.

(9) Install the brake drum.

(10) Install the wheel and tire assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(11) Adjust the rear brake shoes. Refer to

ADJUSTMENTS in this section of this service man-

ual group.

(12) Lower the vehicle.

(13) Remove the brake pedal holding tool.

(14) Bleed the wheel cylinder as necessary. Refer

to BASE BRAKE BLEEDING in the SERVICE PRO-

CEDURES section in this service manual group.

(15) Road test the vehicle to make sure the brakes

operate correctly.

Fig. 90 Hub And Bearing Dust Cap

1 ± HUB/BEARING ASSEMBLY

2 ± DUST CAP

Fig. 91 Rear Hub And Bearing Retaining Nut

1 ± RETAINING NUT

2 ± SPINDLE

3 ± HUB/BEARING ASSEMBLY

Fig. 92 Removing Park Brake Cable From Support

Plate

1 ± WRENCH

2 ± CABLE HOUSING RETAINER

3 ± PARK BRAKE CABLE

4 ± SUPPORT PLATE

PLBRAKES 5 - 47

REMOVAL AND INSTALLATION (Continued)

Page 145 of 1285

NOISE AND BRAKE PEDAL FEEL

During ABS braking, some brake pedal movement

may be felt. In addition, ABS braking will create

ticking, popping, or groaning noises heard by the

driver. This is normal and is due to pressurized fluid

being transferred between the master cylinder and

the brakes. If ABS operation occurs during hard

braking, some pulsation may be felt in the vehicle

body due to fore-and-aft movement of the suspension

as brake pressures are modulated.

At the end of an ABS stop, ABS is turned off when

the vehicle is slowed to a speed of 3±4 mph. There

may be a slight brake pedal drop anytime that the

ABS is deactivated, such as at the end of the stop

when the vehicle speed is less than 3 mph or during

an ABS stop where ABS is no longer required. These

conditions exist when a vehicle is being stopped on a

road surface with patches of ice, loose gravel, or sand

on it. Also, stopping a vehicle on a bumpy road sur-

face activates ABS because of the wheel hop caused

by the bumps.

TIRE NOISE AND MARKS

Although the ABS system prevents complete wheel

lockup, some wheel slip is desired in order to achieve

optimum braking performance. Wheel slip is defined

as follows: 0 percent slip means the wheel is rolling

freely and 100 percent slip means the wheel is fully

locked. During brake pressure modulation, wheel slip

is allowed to reach up to 25±30 percent. This means

that the wheel rolling velocity is 25±30 percent less

than that of a free rolling wheel at a given vehicle

speed. This slip may result in some tire chirping,

depending on the road surface. This sound should not

be interpreted as total wheel lockup.

Complete wheel lockup normally leaves black tire

marks on dry pavement. The ABS will not leave dark

black tire marks since the wheel never reaches a

fully locked condition. However, tire marks may be

noticeable as light patched marks.

START-UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

The ABS warning lamp will also be on for up to 5

seconds after the ignition is turned on. When the

vehicle is first driven off, a humming may be heard

or felt by the driver at approximately 20±40 kph

(12±25 mph). All of these conditions are a normal

function of ABS as the system is performing a diag-

nosis check.

PREMATURE ABS CYCLING

Symptoms of premature ABS cycling include: click-

ing sounds from the solenoid valves; pump/motor

running; and pulsations in the brake pedal. Prema-ture ABS cycling can occur at any braking rate of the

vehicle and on any type of road surface. Neither the

red BRAKE warning lamp, nor the amber ABS warn-

ing lamp, illuminate and no fault codes are stored in

the CAB.

Premature ABS cycling is a condition that needs to

be correctly assessed when diagnosing problems with

the antilock brake system. It may be necessary to use

a DRB scan tool to detect and verify premature ABS

cycling.

Check the following common causes when diagnos-

ing premature ABS cycling: damaged tone wheels;

incorrect tone wheels; damaged steering knuckle

wheel speed sensor mounting bosses; loose wheel

speed sensor mounting bolts; excessive tone wheel

runout; or an excessively large tone wheel-to-wheel

speed sensor air gap. Give special attention to these

components when diagnosing a vehicle exhibiting

premature ABS cycling.

After diagnosing the defective component, repair or

replace it as required. When the component repair or

replacement is completed, test drive the vehicle to

verify that premature ABS cycling has been cor-

rected.

ANTILOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the

antilock brake system components. For information

on servicing base brake system components used in

conjunction with these components, see the BASE

BRAKE SYSTEM found at the beginning of this ser-

vice manual group.

MASTER CYLINDER

A vehicle equipped with ABS uses a different mas-

ter cylinder than a vehicle that is not equipped with

ABS. Vehicles equipped with ABS use a center port

master cylinder with only two outlet ports (Fig. 1).

The brake tubes from the primary and secondary

outlet ports on the master cylinder go directly to the

integrated control unit (ICU).

The master cylinder mounts to the power brake

booster in the same manner a non-ABS master cylin-

der does.

INTEGRATED CONTROL UNIT (ICU)

The hydraulic control unit (HCU) and the control-

ler antilock brake (CAB) used with this antilock

brake system are combined (integrated) into one

unit, which is called the integrated control unit (ICU)

(Fig. 2). The ICU is located on the driver's side of the

vehicle, and is mounted to the left front frame rail

below the master cylinder (Fig. 1).

5 - 66 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 155 of 1285

junction block. A label on the underside of the PDC

cover identifies the locations of the ABS fuses.

(2) Inspect the 25-way electrical connector at the

CAB for damaged, spread, or backed-out wiring ter-

minals. Verify that the 25-way connector is fully

inserted in the socket of the CAB. Be sure that wires

are not stretched tight or pulled out of the connector.

(3) Verify that all the wheel speed sensor connec-

tions are secure.

(4) Look for poor mating of connector halves or ter-

minals not fully seated in the connector body.

(5)

Check for improperly formed or damaged termi-

nals. All connector terminals in a suspect circuit should

be carefully reformed to increase contact tension.

(6) Look for poor terminal-to-wire connections.

This requires removing the terminal from the connec-

tor body to inspect it.

(7) Verify pin presence in the connector assembly

(8) Check for proper ground connections. Check all

ground connections for signs of corrosion, loose fas-

teners, or other potential defects. Refer to the wiring

diagrams for ground locations.

(9) Look for problems with the main power sources

of the vehicle. Inspect the battery, generator, ignition

circuits and other related relays and fuses.

If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record any trouble codes.

Most failures of the ABS disable the ABS function

for the entire ignition cycle even if the fault clears

before key-off. There are some failure conditions,

however, that allow ABS operation to resume during

the ignition cycle in which the trouble occurred even

if the trouble conditions are no longer present.

The following trouble conditions may result in

intermittent illumination of the amber ABS warning

lamp.

²Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.

²High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation resumes.

Additional possible causes that may result in the

illumination of the amber ABS warning lamp are as

follows:

²Any condition that interrupts electrical current

to the CAB may cause the amber ABS warning lamp

to turn on intermittently.

²If PCI communication between the body control-

ler and the CAB is interrupted, the body controller

can turn on the amber ABS warning lamp.

TONE WHEEL

Tone wheels can cause erratic wheel speed sensor

signals. Inspect tone wheels for the following possible

causes:

²missing, chipped, or broken teeth

²contact with the wheel speed sensor

²wheel speed sensor to tone wheel alignment

²wheel speed sensor to tone wheel clearance

²excessive tone wheel runout

²tone wheel loose on its mounting surface

If a front tone wheel is found to need replacement,

the drive shaft must be replaced. No attempt should

be made to replace just the tone wheel. Refer to the

DIFFERENTIAL AND DRIVELINE group in this

service manual for removal and installation.

If a rear tone wheel is found to need replacement,

the rear hub and bearing must be replaced. No

attempt should be made to replace just the tone

wheel. Refer to the SUSPENSION group in this ser-

vice manual for removal and installation.

If wheel speed sensor to tone wheel contact is evi-

dent, determine the cause and correct it before

replacing the wheel speed sensor or tone wheel.

Check the gap between the speed sensor head and

the tone wheel to ensure it is within specifications.

Refer to SPECIFICATIONS in this section of the ser-

vice manual for the minimum and maximum wheel

speed sensor to tone wheel clearance.

Excessive wheel speed sensor runout can cause

erratic wheel speed sensor signals. Refer to SPECI-

FICATIONS in this section of the service manual for

the maximum allowed tone wheel runout. If tone

wheel runout is excessive, determine if it is caused

by a defect in the driveshaft assembly or hub and

bearing. Replace as necessary.

Tone wheels are pressed onto their mounting sur-

faces and should not rotate independently from the

mounting surface. Replacement of the front drive-

shaft or rear hub and bearing is necessary.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swelling indicates the

presence of petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If the fluid sep-

arates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If the brake fluid is contaminated, drain and thor-

oughly flush the brake system. Replace all the rubber

parts or components containing rubber coming into

contact with the brake fluid including: the master

cylinder; proportioning valves; caliper seals; wheel

cylinder seals; ABS hydraulic control unit; and all

hydraulic fluid hoses.

5 - 76 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 160 of 1285

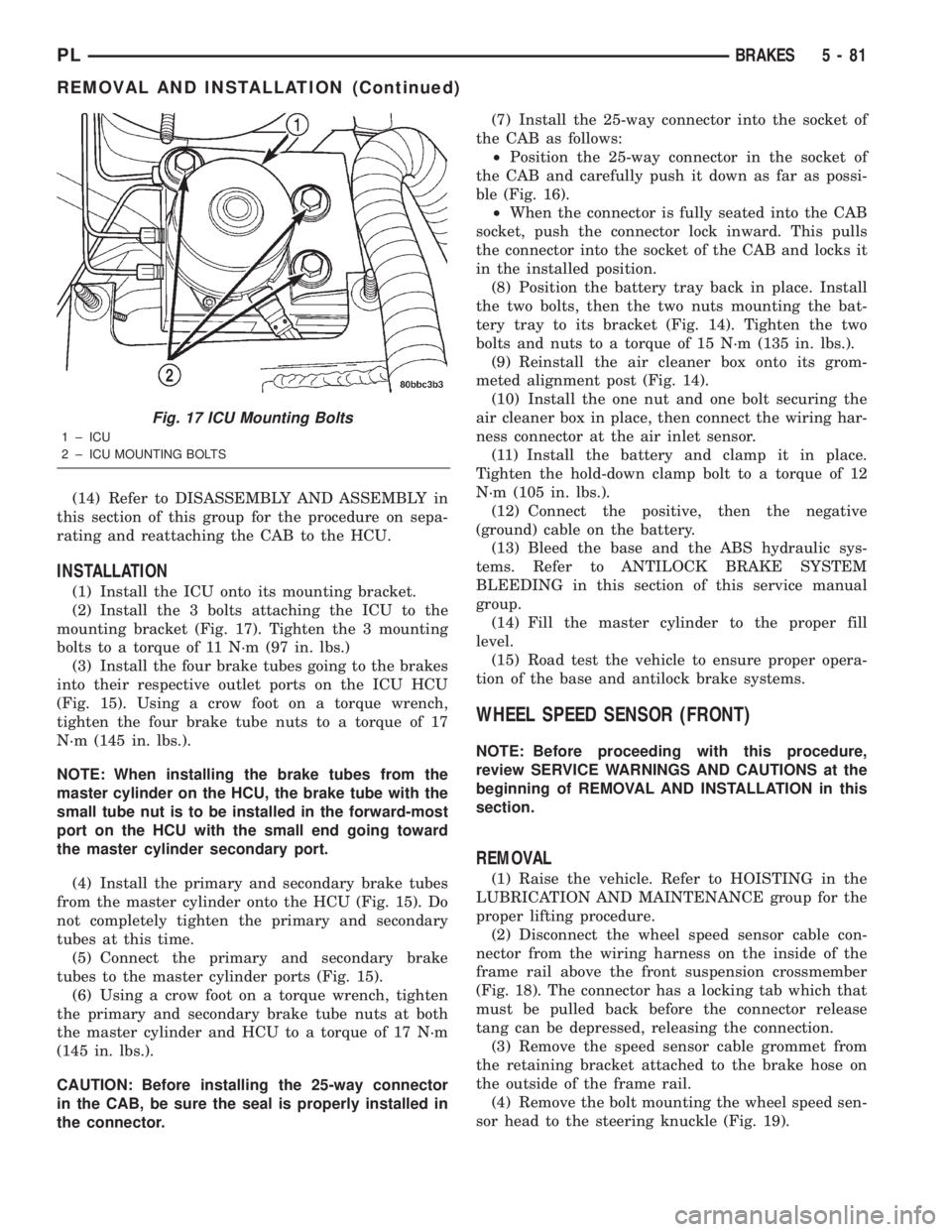

(14) Refer to DISASSEMBLY AND ASSEMBLY in

this section of this group for the procedure on sepa-

rating and reattaching the CAB to the HCU.

INSTALLATION

(1) Install the ICU onto its mounting bracket.

(2) Install the 3 bolts attaching the ICU to the

mounting bracket (Fig. 17). Tighten the 3 mounting

bolts to a torque of 11 N´m (97 in. lbs.)

(3) Install the four brake tubes going to the brakes

into their respective outlet ports on the ICU HCU

(Fig. 15). Using a crow foot on a torque wrench,

tighten the four brake tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: When installing the brake tubes from the

master cylinder on the HCU, the brake tube with the

small tube nut is to be installed in the forward-most

port on the HCU with the small end going toward

the master cylinder secondary port.

(4) Install the primary and secondary brake tubes

from the master cylinder onto the HCU (Fig. 15). Do

not completely tighten the primary and secondary

tubes at this time.

(5) Connect the primary and secondary brake

tubes to the master cylinder ports (Fig. 15).

(6) Using a crow foot on a torque wrench, tighten

the primary and secondary brake tube nuts at both

the master cylinder and HCU to a torque of 17 N´m

(145 in. lbs.).

CAUTION: Before installing the 25-way connector

in the CAB, be sure the seal is properly installed in

the connector.(7) Install the 25-way connector into the socket of

the CAB as follows:

²Position the 25-way connector in the socket of

the CAB and carefully push it down as far as possi-

ble (Fig. 16).

²When the connector is fully seated into the CAB

socket, push the connector lock inward. This pulls

the connector into the socket of the CAB and locks it

in the installed position.

(8) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 14). Tighten the two

bolts and nuts to a torque of 15 N´m (135 in. lbs.).

(9) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 14).

(10) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(11) Install the battery and clamp it in place.

Tighten the hold-down clamp bolt to a torque of 12

N´m (105 in. lbs.).

(12) Connect the positive, then the negative

(ground) cable on the battery.

(13) Bleed the base and the ABS hydraulic sys-

tems. Refer to ANTILOCK BRAKE SYSTEM

BLEEDING in this section of this service manual

group.

(14) Fill the master cylinder to the proper fill

level.

(15) Road test the vehicle to ensure proper opera-

tion of the base and antilock brake systems.

WHEEL SPEED SENSOR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Disconnect the wheel speed sensor cable con-

nector from the wiring harness on the inside of the

frame rail above the front suspension crossmember

(Fig. 18). The connector has a locking tab which that

must be pulled back before the connector release

tang can be depressed, releasing the connection.

(3) Remove the speed sensor cable grommet from

the retaining bracket attached to the brake hose on

the outside of the frame rail.

(4) Remove the bolt mounting the wheel speed sen-

sor head to the steering knuckle (Fig. 19).

Fig. 17 ICU Mounting Bolts

1 ± ICU

2 ± ICU MOUNTING BOLTS

PLBRAKES 5 - 81

REMOVAL AND INSTALLATION (Continued)

Page 168 of 1285

SERVICE DIAGNOSISÐCLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC

FACING COVERED

WITH OIL OR

GREASEOil leak at engine rear main or transaxle

input shaft sealCorrect leak and replace modular clutch

assembly

Too much grease applied to splines of disc

and input shaftApply lighter coating of grease to splines

NO FAULT FOUND

WITH CLUTCH

COMPONENTSProblem actually related to suspension or

driveline componentFurther diagnosis required. Check

engine/transmission mounts, suspension

attaching parts and other driveline

components as needed.

Engine related problems Check EFI and ignition systems

PARTIAL

ENGAGEMENT OF

CLUTCH DISCClutch cover, spring, or release fingers

bent, distorted (rough handling, improper

assembly)Replace modular clutch assembly

Clutch disc damaged or distorted Replace modular clutch assembly

Clutch misalignment Check alignment and runout of flywheel,

disc, or cover. Check clutch housing to

engine dowels and dowel holes for damage.

Correct as necessary.

SERVICE DIAGNOSISÐCLUTCH SLIPS

CONDITION POSSIBLE CAUSES CORRECTION

DISC FACING

WORN OUTNormal wear. Replace modular clutch assembly.

Driver frequently rides (slips) clutch, results

in rapid wear overheating.Replace modular clutch assembly

Insufficient clutch cover diaphragm spring

tensionReplace modular clutch assembly

CLUTCH DISC

FACING

CONTAMINATED

WITH OIL OR

GREASELeak at rear main oil seal or transaxle input

shaft sealReplace leaking seals. Replace modular

clutch assembly.

Excessive amount of grease applied to

input shaft splinesApply less grease to input shaft. Replace

modular clutch assembly

Road splash, water entering housing Seal housing. Inspect clutch assembly.

CLUTCH IS

RUNNING

PARTIALLY

DISENGAGEDRelease bearing sticking or binding, does

not return to normal running position.Verify that bearing is actually binding. Then,

replace bearing and transmission front

bearing retainer if sleeve surface is

damaged.

Cable self-adjuster mechanism sticking or

binding causing high preloadVerify that self-adjuster is free to move

PLCLUTCH 6 - 3

DIAGNOSIS AND TESTING (Continued)

Page 311 of 1285

HEADLAMP ALIGNMENT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

HEADLAMP ALIGNMENT....................4

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION........4ADJUSTMENTS

HEADLAMP ADJUSTMENT USING

ALIGNMENT SCREEN....................4

FOG LAMP ALIGNMENT....................6

DESCRIPTION AND OPERATION

HEADLAMP ALIGNMENT

Headlamps and Fog Lamps should be aligned

using the screen method which is provided in this

section.The preferred headlamp alignment set-

ting is 0 for the left/right adjustment and 0 for

the up/down adjustment.

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens.

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall

(Fig. 1).(3) From the floor up 1.27 meters (5 ft.), tape a

line on the wall at the center line of the vehicle.

Sight along the center line of the vehicle (from rear

of vehicle forward) to verify accuracy of the line

placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) A small dot is molded into each headlamp lens

signifying the center of the headlamp. Measure the

distance from the center of the headlamp to the floor.

Transfer measurement to the alignment screen (with

tape). Use this line for up/down adjustment refer-

ence.

(7) Measure distance from the center line of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle center line. Use these lines for left/

right adjustment reference.

HEADLAMP ADJUSTMENT

The PL headlamp low beam pattern has a distinct

horizontal cutoff line which is used to visually align

the headlamps. A properly aimed headlamp will have

the horizontal cutoff line of the low beam pattern

centered on the low beam pattern centered on the

horizontal center of headlamp line. The side to side

left edge of the low beam hot spot should be located

75 mm (3 inches) to the left of the headlamp center

line (Fig. 1). The high beams on a vehicle with aero

headlamps cannot be aligned. The high beam pattern

should be correct when the low beams are aligned

properly.

To adjust headlamp alignment, rotate alignment

screws to achieve the specified low beam hot spot

pattern.

8L - 4 LAMPSPL

Page 397 of 1285

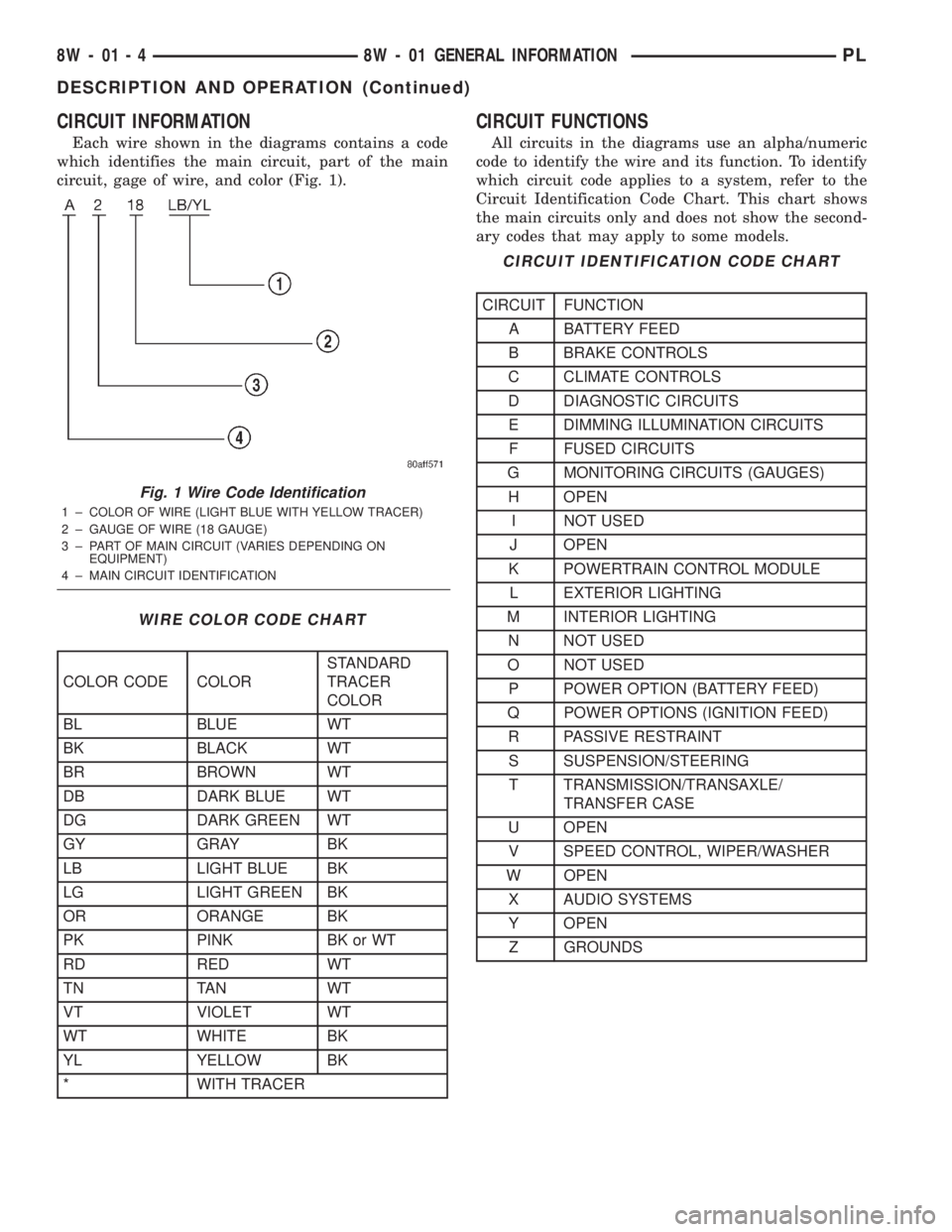

CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 1).

CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

Fig. 1 Wire Code Identification

1 ± COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER)

2 ± GAUGE OF WIRE (18 GAUGE)

3 ± PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 ± MAIN CIRCUIT IDENTIFICATION

WIRE COLOR CODE CHART

COLOR CODE COLORSTANDARD

TRACER

COLOR

BL BLUE WT

BK BLACK WT

BR BROWN WT

DB DARK BLUE WT

DG DARK GREEN WT

GY GRAY BK

LB LIGHT BLUE BK

LG LIGHT GREEN BK

OR ORANGE BK

PK PINK BK or WT

RD RED WT

TN TAN WT

VT VIOLET WT

WT WHITE BK

YL YELLOW BK

* WITH TRACER

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS (GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY FEED)

Q POWER OPTIONS (IGNITION FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

8W - 01 - 4 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 743 of 1285

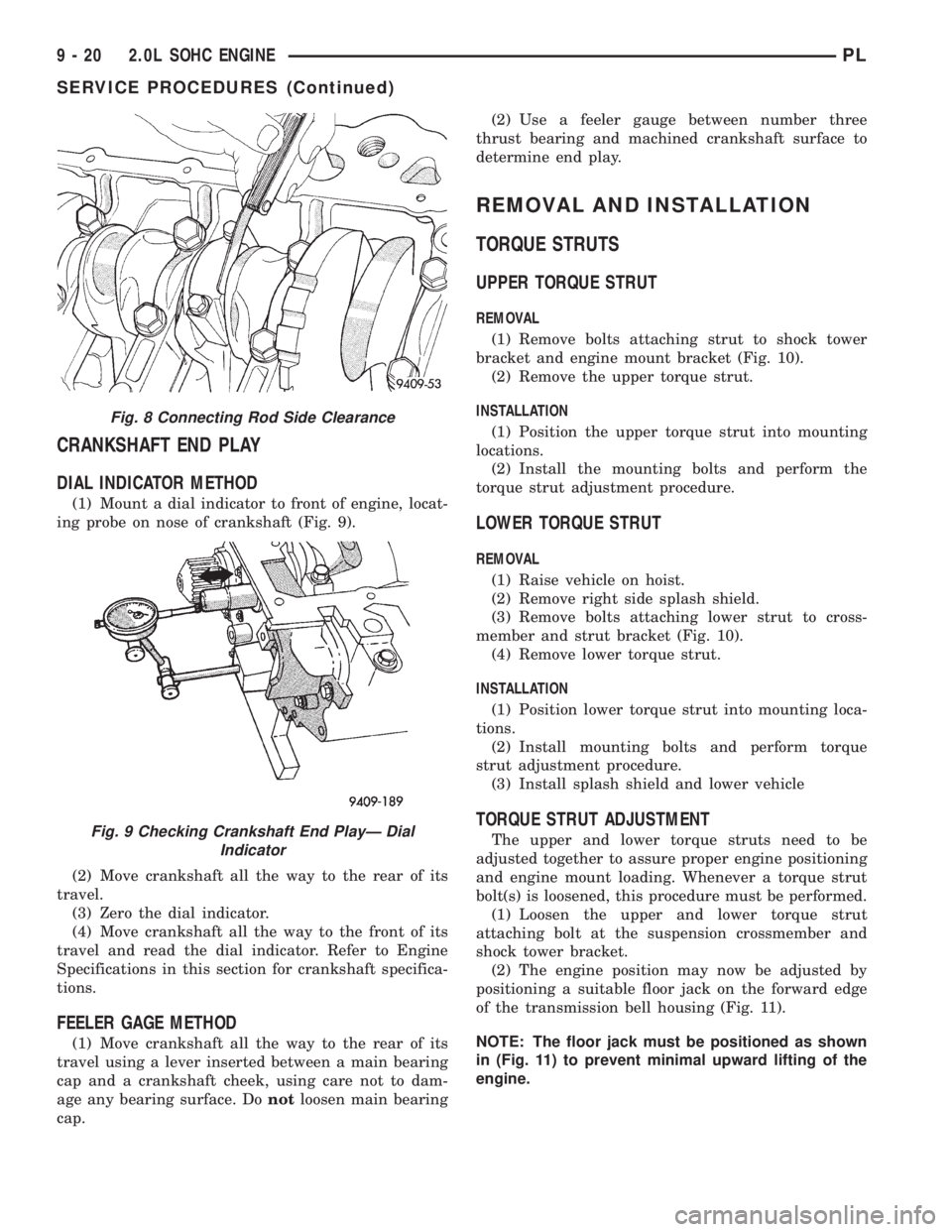

CRANKSHAFT END PLAY

DIAL INDICATOR METHOD

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 9).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front of its

travel and read the dial indicator. Refer to Engine

Specifications in this section for crankshaft specifica-

tions.

FEELER GAGE METHOD

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

cap and a crankshaft cheek, using care not to dam-

age any bearing surface. Donotloosen main bearing

cap.(2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

REMOVAL AND INSTALLATION

TORQUE STRUTS

UPPER TORQUE STRUT

REMOVAL

(1) Remove bolts attaching strut to shock tower

bracket and engine mount bracket (Fig. 10).

(2) Remove the upper torque strut.

INSTALLATION

(1) Position the upper torque strut into mounting

locations.

(2) Install the mounting bolts and perform the

torque strut adjustment procedure.

LOWER TORQUE STRUT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove right side splash shield.

(3) Remove bolts attaching lower strut to cross-

member and strut bracket (Fig. 10).

(4) Remove lower torque strut.

INSTALLATION

(1) Position lower torque strut into mounting loca-

tions.

(2) Install mounting bolts and perform torque

strut adjustment procedure.

(3) Install splash shield and lower vehicle

TORQUE STRUT ADJUSTMENT

The upper and lower torque struts need to be

adjusted together to assure proper engine positioning

and engine mount loading. Whenever a torque strut

bolt(s) is loosened, this procedure must be performed.

(1) Loosen the upper and lower torque strut

attaching bolt at the suspension crossmember and

shock tower bracket.

(2) The engine position may now be adjusted by

positioning a suitable floor jack on the forward edge

of the transmission bell housing (Fig. 11).

NOTE: The floor jack must be positioned as shown

in (Fig. 11) to prevent minimal upward lifting of the

engine.

Fig. 8 Connecting Rod Side Clearance

Fig. 9 Checking Crankshaft End PlayÐ Dial

Indicator

9 - 20 2.0L SOHC ENGINEPL

SERVICE PROCEDURES (Continued)