fuel DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 735 of 1285

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE MISSES ON

ACCELERATION1. Dirty or incorrectly gapped spark

plugs.1. Clean spark plugs and set gap.

Refer to Group 8D, Ignition System.

2. Contamination in Fuel System. 2. Clean fuel system and replace

fuel filter.

3. Burned, warped, or pitted valves. 3. Replace valves.

4. Faulty coil(s). 4. Test and replace as necessary.

Refer to Group 8D, Ignition System.

ENGINE MISSES AT HIGH SPEED 1. Dirty or incorrect spark plug gap. 1. Clean spark plugs and set gap.

Refer to Group 8D, Ignition System.

2. Faulty coil(s). 2. Test and replace as necessary.

Refer to Group 8D, Ignition System.

3. Dirty fuel injector(s). Test and replace as necessary.

Refer to Group 14, Fuel System.

4. Contamination in fuel system. 4. Clean system and replace fuel

filter.

ENGINE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Low oil pressure. 3. Check and correct engine oil

level.

4. Dirt in tappets/lash adjusters. 4. Replace rocker arm/hydraulic

lash adjuster assembly.

5. Worn rocker arms. 5. Inspect oil supply to rocker arms.

6. Worn tappets/lash adjusters. 6. Install new rocker arm/hydraulic

lash adjuster assembly.

7. Worn valve guides. 7. Ream guides and install new

valves with oversize stems.

8. Excessive runout of valve seats

on valve faces.8. Grind valve seats and valves.

9. Missing adjuster pivot. 9. Replace rocker arm/hydraulic

lash adjuster assembly.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Connecting rod journal

out-of-round.5. Replace crankshaft or grind

surface.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

9 - 12 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 748 of 1285

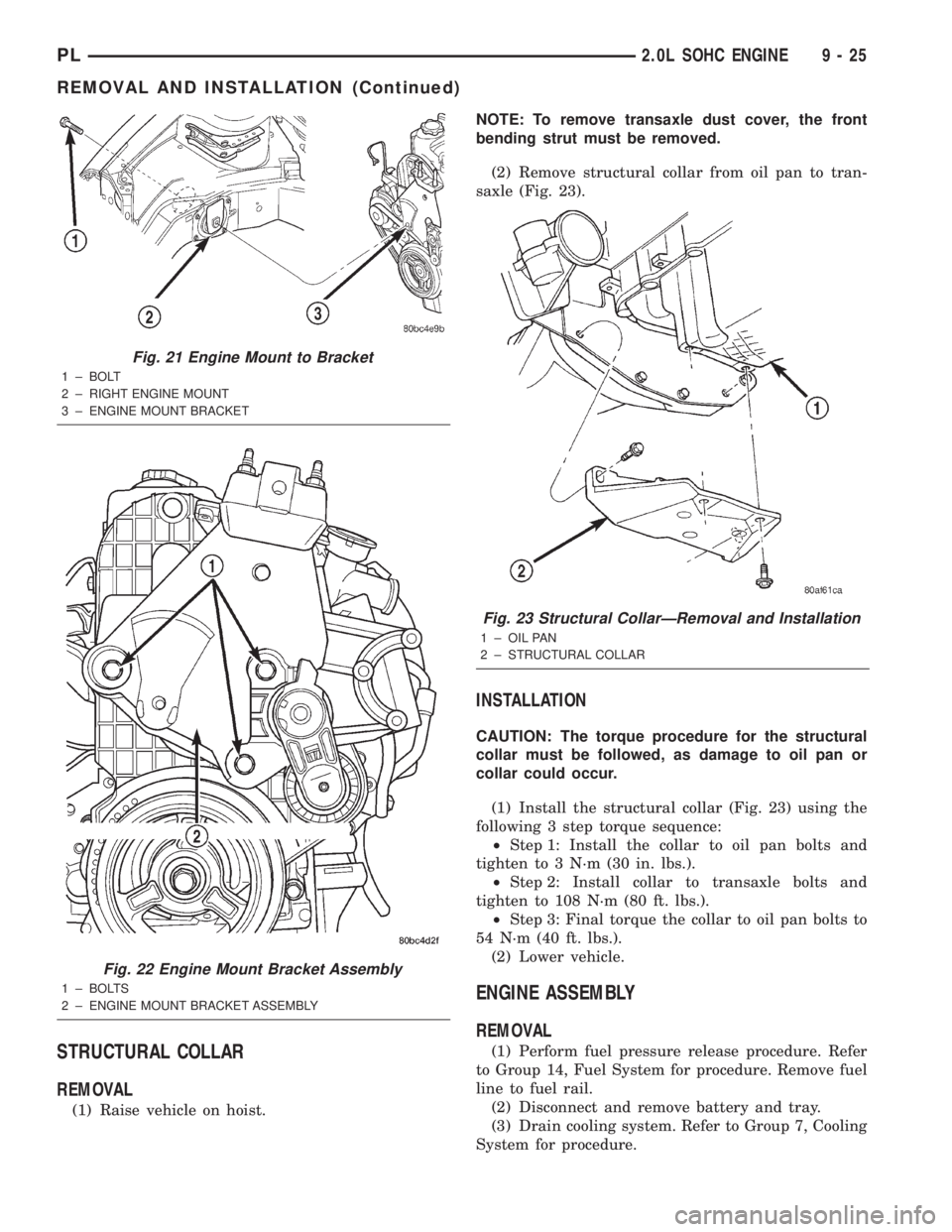

STRUCTURAL COLLAR

REMOVAL

(1) Raise vehicle on hoist.NOTE: To remove transaxle dust cover, the front

bending strut must be removed.

(2) Remove structural collar from oil pan to tran-

saxle (Fig. 23).

INSTALLATION

CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(1) Install the structural collar (Fig. 23) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(2) Lower vehicle.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect and remove battery and tray.

(3) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

Fig. 21 Engine Mount to Bracket

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

Fig. 22 Engine Mount Bracket Assembly

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET ASSEMBLY

Fig. 23 Structural CollarÐRemoval and Installation

1 ± OIL PAN

2 ± STRUCTURAL COLLAR

PL2.0L SOHC ENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)

Page 750 of 1285

(8) Install lower engine torque strut. Refer to pro-

cedure in this section.

(9) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System for procedure and torque

specifications.

(10) Connect the downstream oxygen sensor.

(11) Install A/C compressor and hoses. Refer to

Group 24, Heater and Air Conditioning for procedure.

(12) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(13) Install inner splash shield.

(14) Install wheels and lower vehicle.

(15) Install power steering pump and reservoir.

Refer to Group 7, Cooling System Accessory Drive

Section for belt tension adjustment.

(16)Manual Transmission:Connect clutch cable,

reverse light electrical connector and shift linkages.

Refer to Group 6, Clutch.

(17)Automatic Transmission:Connect shifter,

kickdown linkage and cooler lines. Refer to Group 21,

Transaxle for procedures.

(18) Connect fuel line and heater hoses.

(19)

Install all ground straps. Connect engine wiring

harness. Refer to Group 8, Electrical for procedure.

(20) Install lower radiator hose, fan module, and

upper radiator hose. Refer to Group 7, Cooling Sys-

tem for procedures

(21) Fill cooling system. Refer to Group 7, Cooling

System for filling procedure.

(22) Install battery tray and battery.

(23) Install air cleaner housing assembly and con-

nect intake duct to intake manifold.(24) Connect all throttle body electrical connectors

and linkage.

(25) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

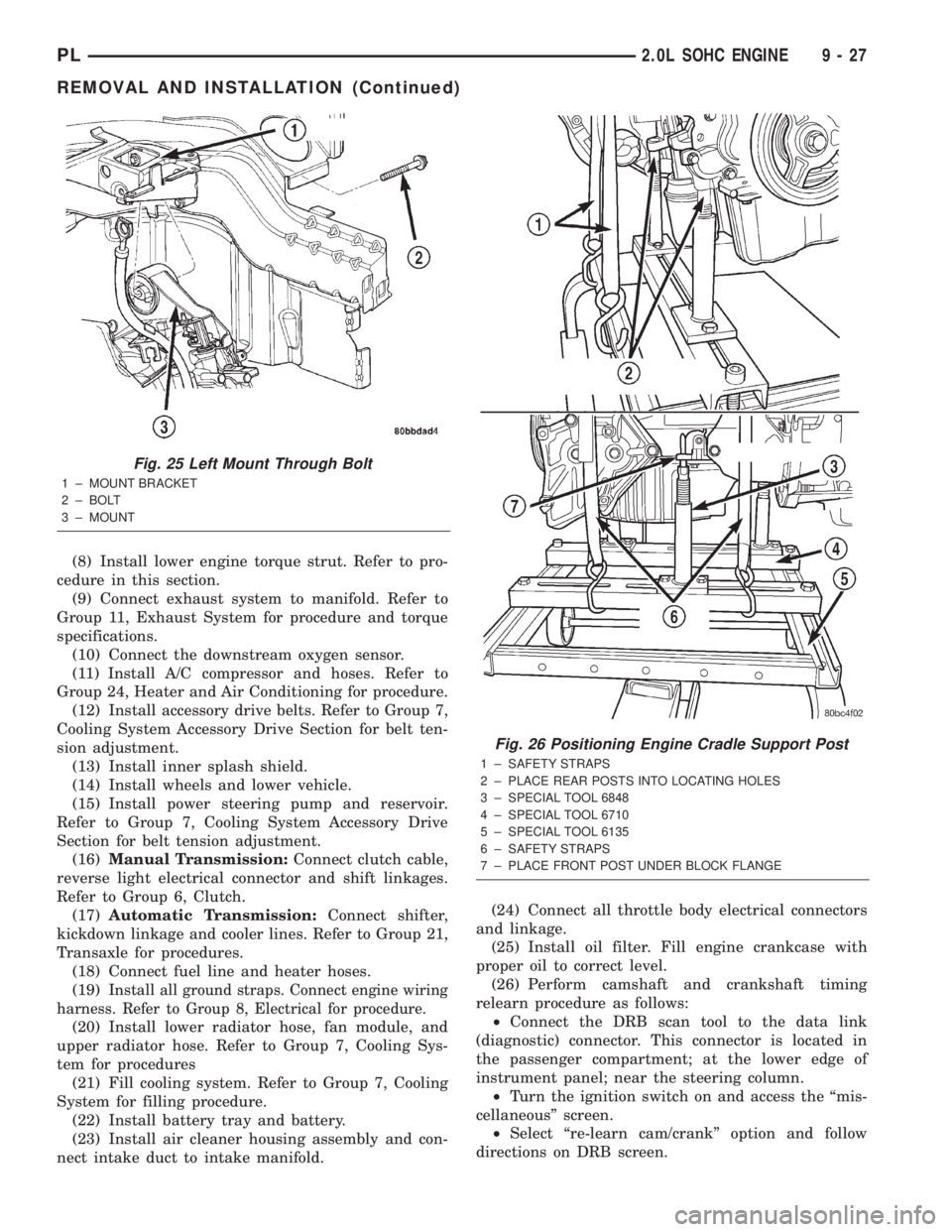

Fig. 25 Left Mount Through Bolt

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

Fig. 26 Positioning Engine Cradle Support Post

1 ± SAFETY STRAPS

2 ± PLACE REAR POSTS INTO LOCATING HOLES

3 ± SPECIAL TOOL 6848

4 ± SPECIAL TOOL 6710

5 ± SPECIAL TOOL 6135

6 ± SAFETY STRAPS

7 ± PLACE FRONT POST UNDER BLOCK FLANGE

PL2.0L SOHC ENGINE 9 - 27

REMOVAL AND INSTALLATION (Continued)

Page 751 of 1285

(27) Start engine and run until operating temper-

ature is reached.

(28) Ensure engine is properly positioned. Refer to

Torque Struts in this section for adjustment proce-

dure.

(29) Adjust transmission linkage, if necessary.

INTAKE MANIFOLD

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove the inlet air duct from intake manifold

to throttle body.

(3) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System for procedures.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSE TO CATCH ANY GASOLINE SPILLAGE

(4) Disconnect fuel supply line quick connect at the

fuel tube assembly. Refer to Group 14, Fuel System

for procedures.

(5) Remove fuel rail assembly attaching screws

and remove fuel rail assembly from engine. Cover

injector holes with suitable covering.

CAUTION: Do not set fuel injectors on their tips,

damage may occur to the injectors

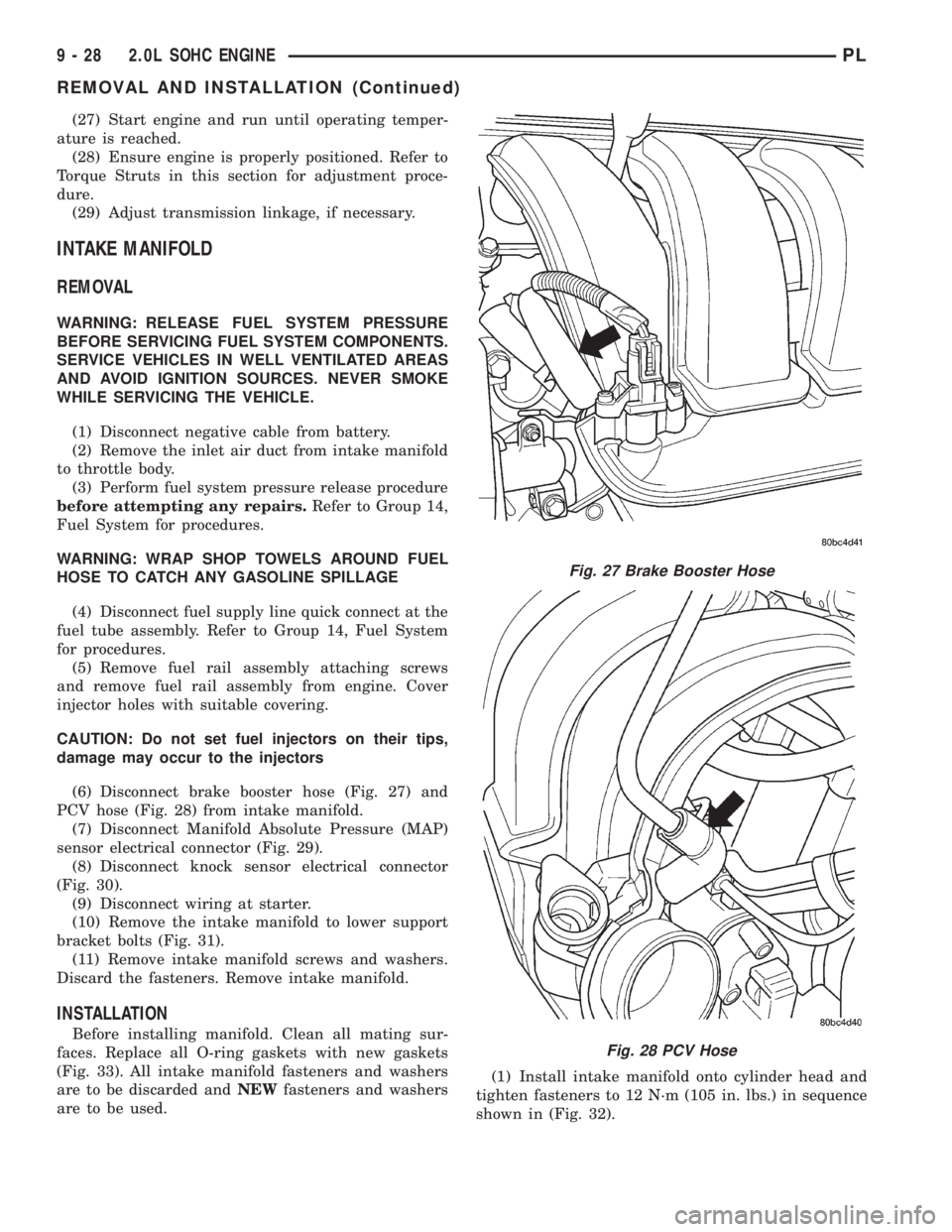

(6) Disconnect brake booster hose (Fig. 27) and

PCV hose (Fig. 28) from intake manifold.

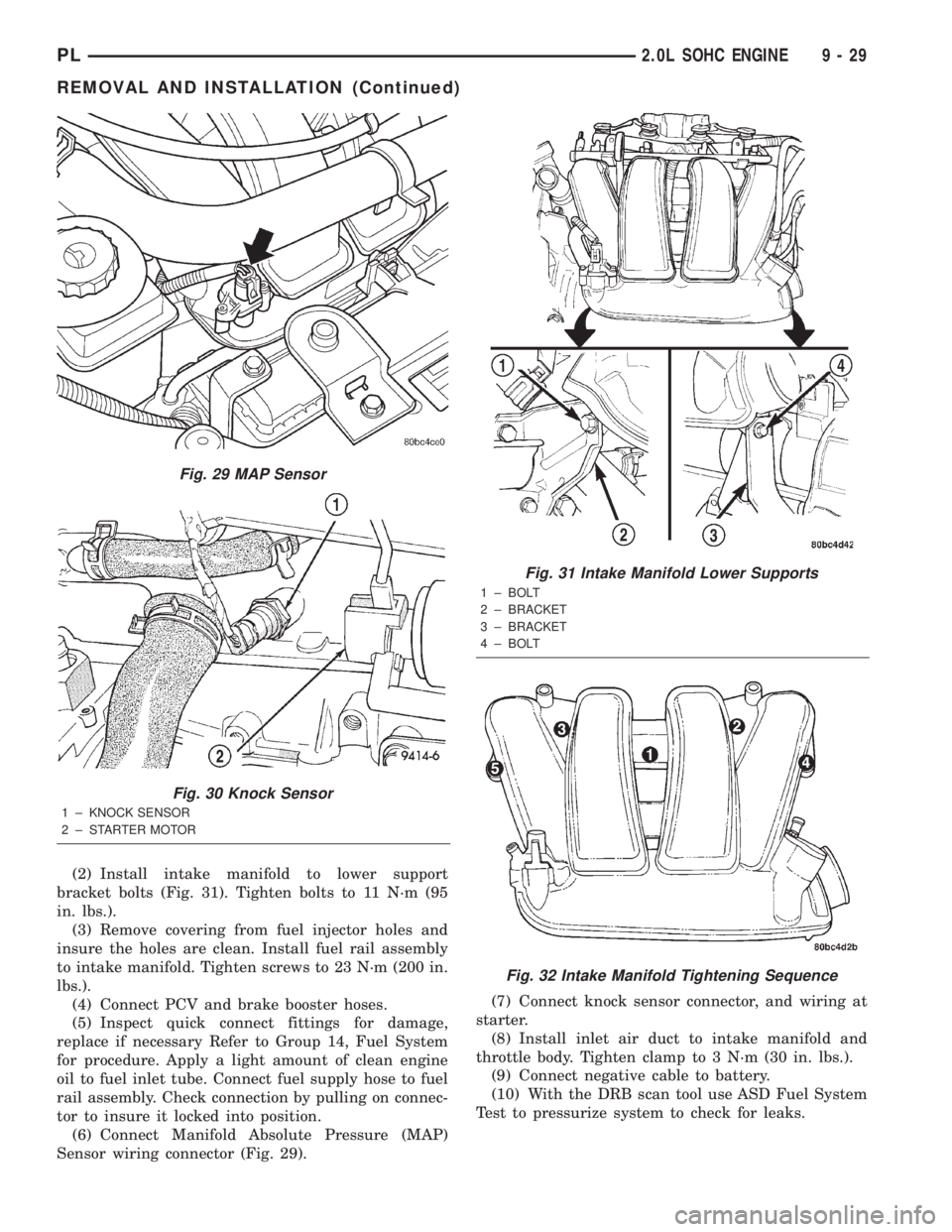

(7) Disconnect Manifold Absolute Pressure (MAP)

sensor electrical connector (Fig. 29).

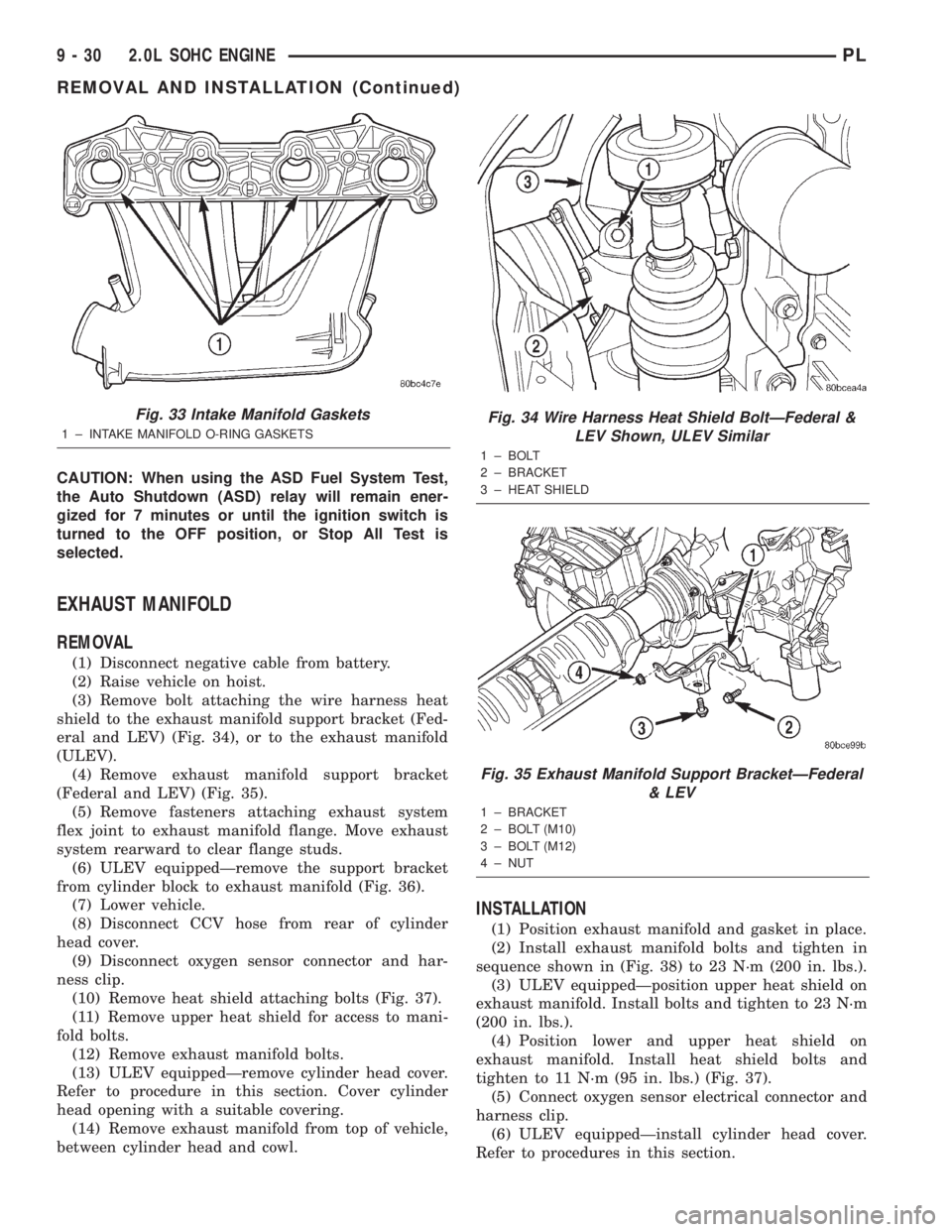

(8) Disconnect knock sensor electrical connector

(Fig. 30).

(9) Disconnect wiring at starter.

(10) Remove the intake manifold to lower support

bracket bolts (Fig. 31).

(11) Remove intake manifold screws and washers.

Discard the fasteners. Remove intake manifold.

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all O-ring gaskets with new gaskets

(Fig. 33). All intake manifold fasteners and washers

are to be discarded andNEWfasteners and washers

are to be used.(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 32).

Fig. 27 Brake Booster Hose

Fig. 28 PCV Hose

9 - 28 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 752 of 1285

(2) Install intake manifold to lower support

bracket bolts (Fig. 31). Tighten bolts to 11 N´m (95

in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Connect Manifold Absolute Pressure (MAP)

Sensor wiring connector (Fig. 29).(7) Connect knock sensor connector, and wiring at

starter.

(8) Install inlet air duct to intake manifold and

throttle body. Tighten clamp to 3 N´m (30 in. lbs.).

(9) Connect negative cable to battery.

(10) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

Fig. 29 MAP Sensor

Fig. 30 Knock Sensor

1 ± KNOCK SENSOR

2 ± STARTER MOTOR

Fig. 31 Intake Manifold Lower Supports

1 ± BOLT

2 ± BRACKET

3 ± BRACKET

4 ± BOLT

Fig. 32 Intake Manifold Tightening Sequence

PL2.0L SOHC ENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)

Page 753 of 1285

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove bolt attaching the wire harness heat

shield to the exhaust manifold support bracket (Fed-

eral and LEV) (Fig. 34), or to the exhaust manifold

(ULEV).

(4) Remove exhaust manifold support bracket

(Federal and LEV) (Fig. 35).

(5) Remove fasteners attaching exhaust system

flex joint to exhaust manifold flange. Move exhaust

system rearward to clear flange studs.

(6) ULEV equippedÐremove the support bracket

from cylinder block to exhaust manifold (Fig. 36).

(7) Lower vehicle.

(8) Disconnect CCV hose from rear of cylinder

head cover.

(9) Disconnect oxygen sensor connector and har-

ness clip.

(10) Remove heat shield attaching bolts (Fig. 37).

(11) Remove upper heat shield for access to mani-

fold bolts.

(12) Remove exhaust manifold bolts.

(13) ULEV equippedÐremove cylinder head cover.

Refer to procedure in this section. Cover cylinder

head opening with a suitable covering.

(14) Remove exhaust manifold from top of vehicle,

between cylinder head and cowl.

INSTALLATION

(1) Position exhaust manifold and gasket in place.

(2) Install exhaust manifold bolts and tighten in

sequence shown in (Fig. 38) to 23 N´m (200 in. lbs.).

(3) ULEV equippedÐposition upper heat shield on

exhaust manifold. Install bolts and tighten to 23 N´m

(200 in. lbs.).

(4) Position lower and upper heat shield on

exhaust manifold. Install heat shield bolts and

tighten to 11 N´m (95 in. lbs.) (Fig. 37).

(5) Connect oxygen sensor electrical connector and

harness clip.

(6) ULEV equippedÐinstall cylinder head cover.

Refer to procedures in this section.

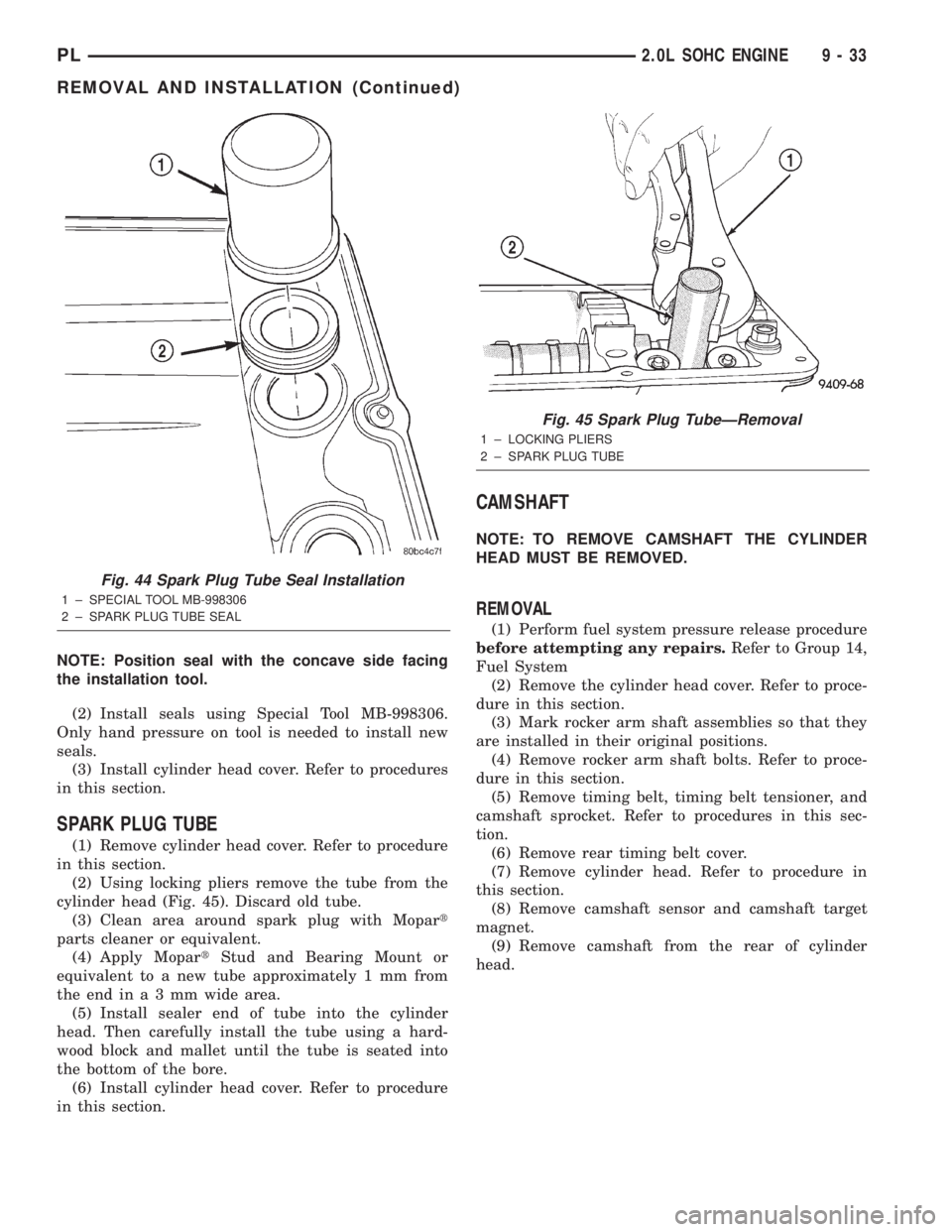

Fig. 33 Intake Manifold Gaskets

1 ± INTAKE MANIFOLD O-RING GASKETS

Fig. 34 Wire Harness Heat Shield BoltÐFederal &

LEV Shown, ULEV Similar

1 ± BOLT

2 ± BRACKET

3 ± HEAT SHIELD

Fig. 35 Exhaust Manifold Support BracketÐFederal

& LEV

1 ± BRACKET

2 ± BOLT (M10)

3 ± BOLT (M12)

4 ± NUT

9 - 30 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 756 of 1285

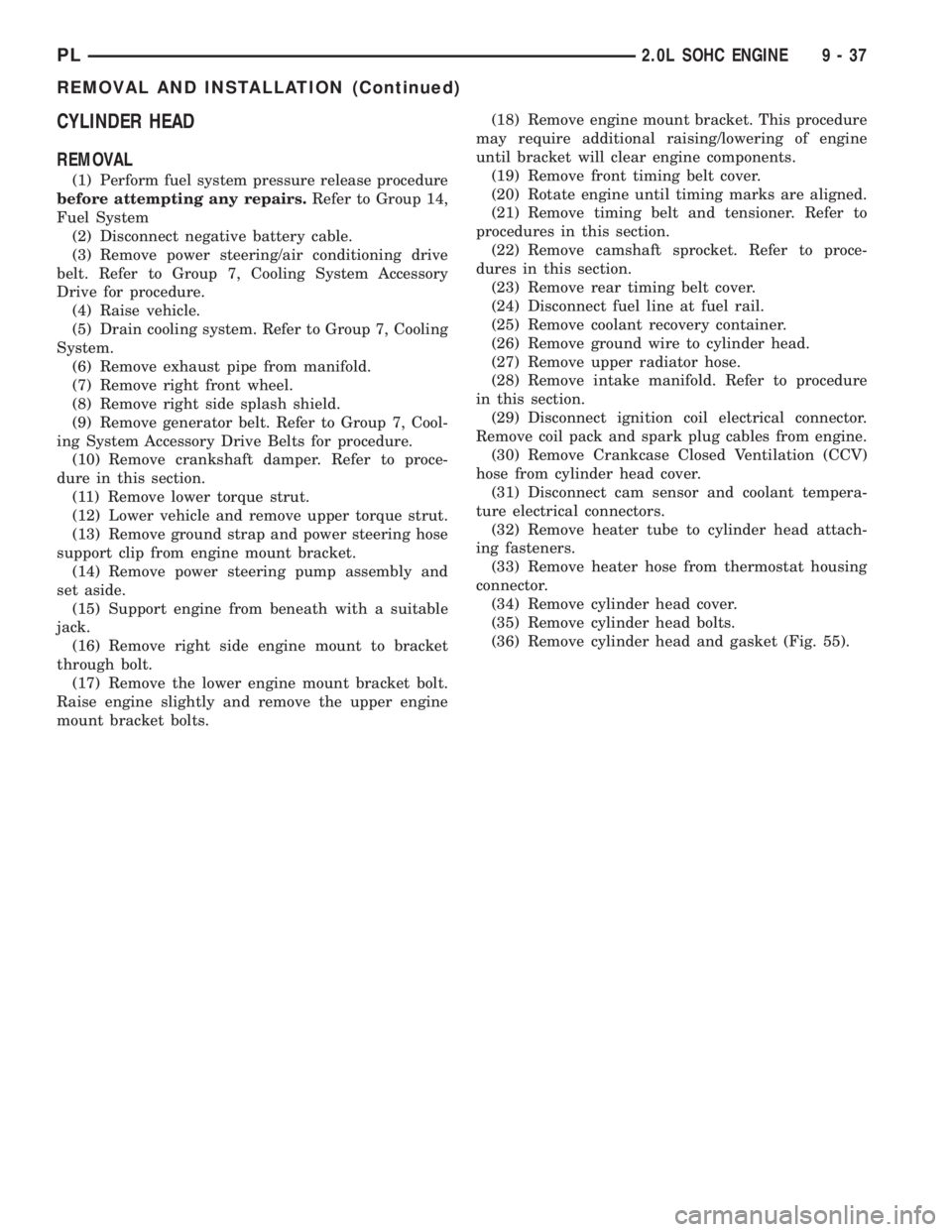

NOTE: Position seal with the concave side facing

the installation tool.

(2) Install seals using Special Tool MB-998306.

Only hand pressure on tool is needed to install new

seals.

(3) Install cylinder head cover. Refer to procedures

in this section.

SPARK PLUG TUBE

(1) Remove cylinder head cover. Refer to procedure

in this section.

(2) Using locking pliers remove the tube from the

cylinder head (Fig. 45). Discard old tube.

(3) Clean area around spark plug with Mopart

parts cleaner or equivalent.

(4) Apply MopartStud and Bearing Mount or

equivalent to a new tube approximately 1 mm from

theendina3mmwide area.

(5) Install sealer end of tube into the cylinder

head. Then carefully install the tube using a hard-

wood block and mallet until the tube is seated into

the bottom of the bore.

(6) Install cylinder head cover. Refer to procedure

in this section.

CAMSHAFT

NOTE: TO REMOVE CAMSHAFT THE CYLINDER

HEAD MUST BE REMOVED.

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Remove the cylinder head cover. Refer to proce-

dure in this section.

(3) Mark rocker arm shaft assemblies so that they

are installed in their original positions.

(4) Remove rocker arm shaft bolts. Refer to proce-

dure in this section.

(5) Remove timing belt, timing belt tensioner, and

camshaft sprocket. Refer to procedures in this sec-

tion.

(6) Remove rear timing belt cover.

(7) Remove cylinder head. Refer to procedure in

this section.

(8) Remove camshaft sensor and camshaft target

magnet.

(9) Remove camshaft from the rear of cylinder

head.

Fig. 44 Spark Plug Tube Seal Installation

1 ± SPECIAL TOOL MB-998306

2 ± SPARK PLUG TUBE SEAL

Fig. 45 Spark Plug TubeÐRemoval

1 ± LOCKING PLIERS

2 ± SPARK PLUG TUBE

PL2.0L SOHC ENGINE 9 - 33

REMOVAL AND INSTALLATION (Continued)

Page 760 of 1285

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Disconnect negative battery cable.

(3) Remove power steering/air conditioning drive

belt. Refer to Group 7, Cooling System Accessory

Drive for procedure.

(4) Raise vehicle.

(5) Drain cooling system. Refer to Group 7, Cooling

System.

(6) Remove exhaust pipe from manifold.

(7) Remove right front wheel.

(8) Remove right side splash shield.

(9) Remove generator belt. Refer to Group 7, Cool-

ing System Accessory Drive Belts for procedure.

(10) Remove crankshaft damper. Refer to proce-

dure in this section.

(11) Remove lower torque strut.

(12) Lower vehicle and remove upper torque strut.

(13) Remove ground strap and power steering hose

support clip from engine mount bracket.

(14) Remove power steering pump assembly and

set aside.

(15) Support engine from beneath with a suitable

jack.

(16) Remove right side engine mount to bracket

through bolt.

(17) Remove the lower engine mount bracket bolt.

Raise engine slightly and remove the upper engine

mount bracket bolts.(18) Remove engine mount bracket. This procedure

may require additional raising/lowering of engine

until bracket will clear engine components.

(19) Remove front timing belt cover.

(20) Rotate engine until timing marks are aligned.

(21) Remove timing belt and tensioner. Refer to

procedures in this section.

(22) Remove camshaft sprocket. Refer to proce-

dures in this section.

(23) Remove rear timing belt cover.

(24) Disconnect fuel line at fuel rail.

(25) Remove coolant recovery container.

(26) Remove ground wire to cylinder head.

(27) Remove upper radiator hose.

(28) Remove intake manifold. Refer to procedure

in this section.

(29) Disconnect ignition coil electrical connector.

Remove coil pack and spark plug cables from engine.

(30) Remove Crankcase Closed Ventilation (CCV)

hose from cylinder head cover.

(31) Disconnect cam sensor and coolant tempera-

ture electrical connectors.

(32) Remove heater tube to cylinder head attach-

ing fasteners.

(33) Remove heater hose from thermostat housing

connector.

(34) Remove cylinder head cover.

(35) Remove cylinder head bolts.

(36) Remove cylinder head and gasket (Fig. 55).

PL2.0L SOHC ENGINE 9 - 37

REMOVAL AND INSTALLATION (Continued)

Page 763 of 1285

(13) Install ignition coil and spark plug cables.

Connect coil electrical connector.

(14) Install intake manifold. Refer to procedure in

this section.

(15) Install upper radiator hose.

(16) Install ground wire to cylinder head.

(17) Install coolant recovery container.

(18) Connect fuel line to fuel rail.

(19) Install rear timing belt cover, camshaft

sprocket, and timing belt tensioner and timing belt.

Refer to procedures in this section.

(20) Install front timing belt cover.

(21) Install engine mount bracket.

(22) Position engine and install right side engine

mount to engine mount bracket bolt. Tighten bolt to

118 N´m (87 ft. lbs.). Remove jack from beneath

engine.

(23) Install power steering pump assembly.

(24) Install power steering hose support clip and

ground strap to engine mount bracket.

(25) Install upper torque strut.

(26) Raise vehicle.

(27) Install lower torque strut.

(28) Install crankshaft damper.

(29) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Belt for procedure.

(30) Install right side splash shield and front

wheel.

(31) Install exhaust pipe to exhaust manifold

flange.

(32) Lower vehicle and fill cooling system. Refer to

Group 7, Cooling System for procedure.

(33) Connect negative cable to battery.

(34) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

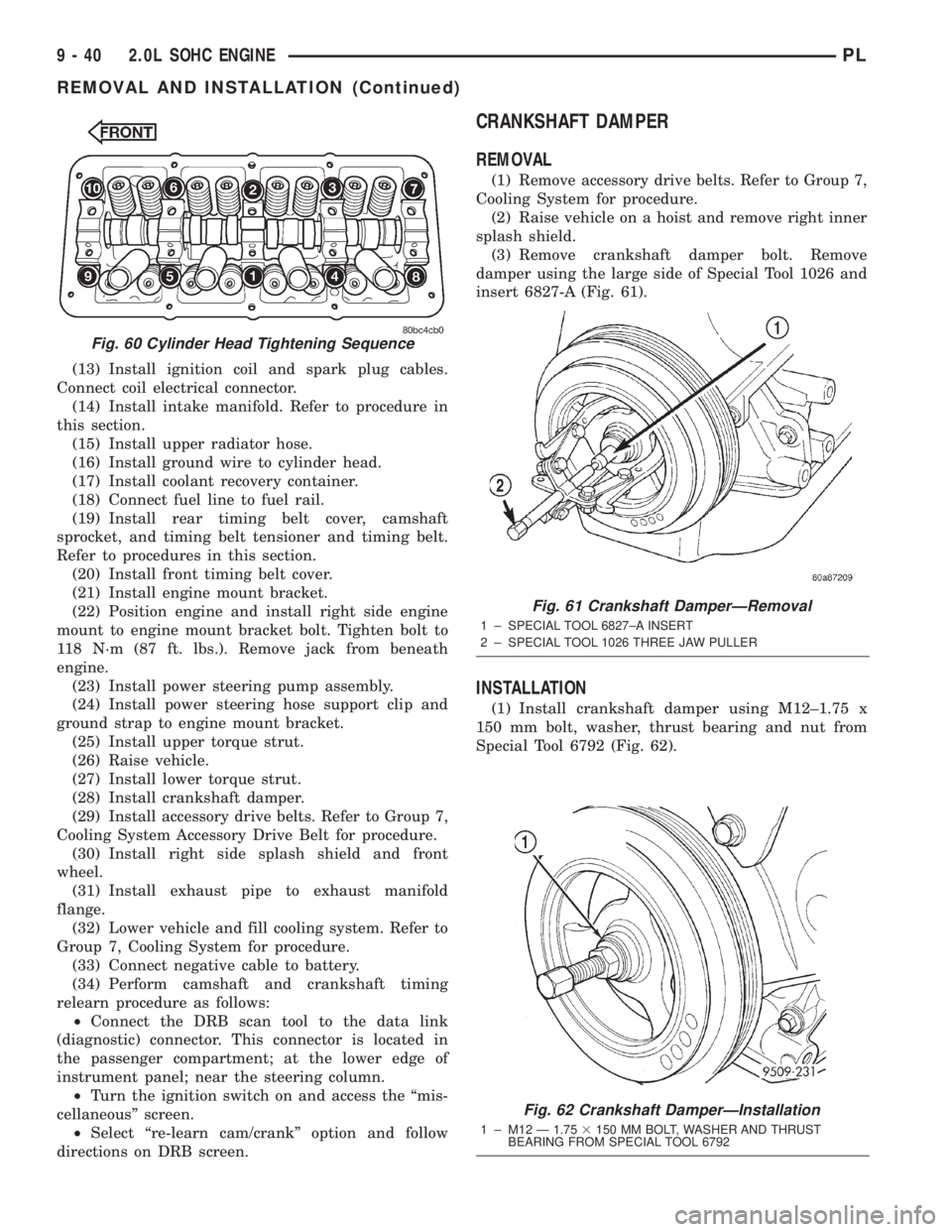

CRANKSHAFT DAMPER

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(2) Raise vehicle on a hoist and remove right inner

splash shield.

(3) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827-A (Fig. 61).

INSTALLATION

(1) Install crankshaft damper using M12±1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792 (Fig. 62).

Fig. 62 Crankshaft DamperÐInstallation

1 ± M12 Ð 1.753150 MM BOLT, WASHER AND THRUST

BEARING FROM SPECIAL TOOL 6792

Fig. 60 Cylinder Head Tightening Sequence

Fig. 61 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 6827±A INSERT

2 ± SPECIAL TOOL 1026 THREE JAW PULLER

9 - 40 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 799 of 1285

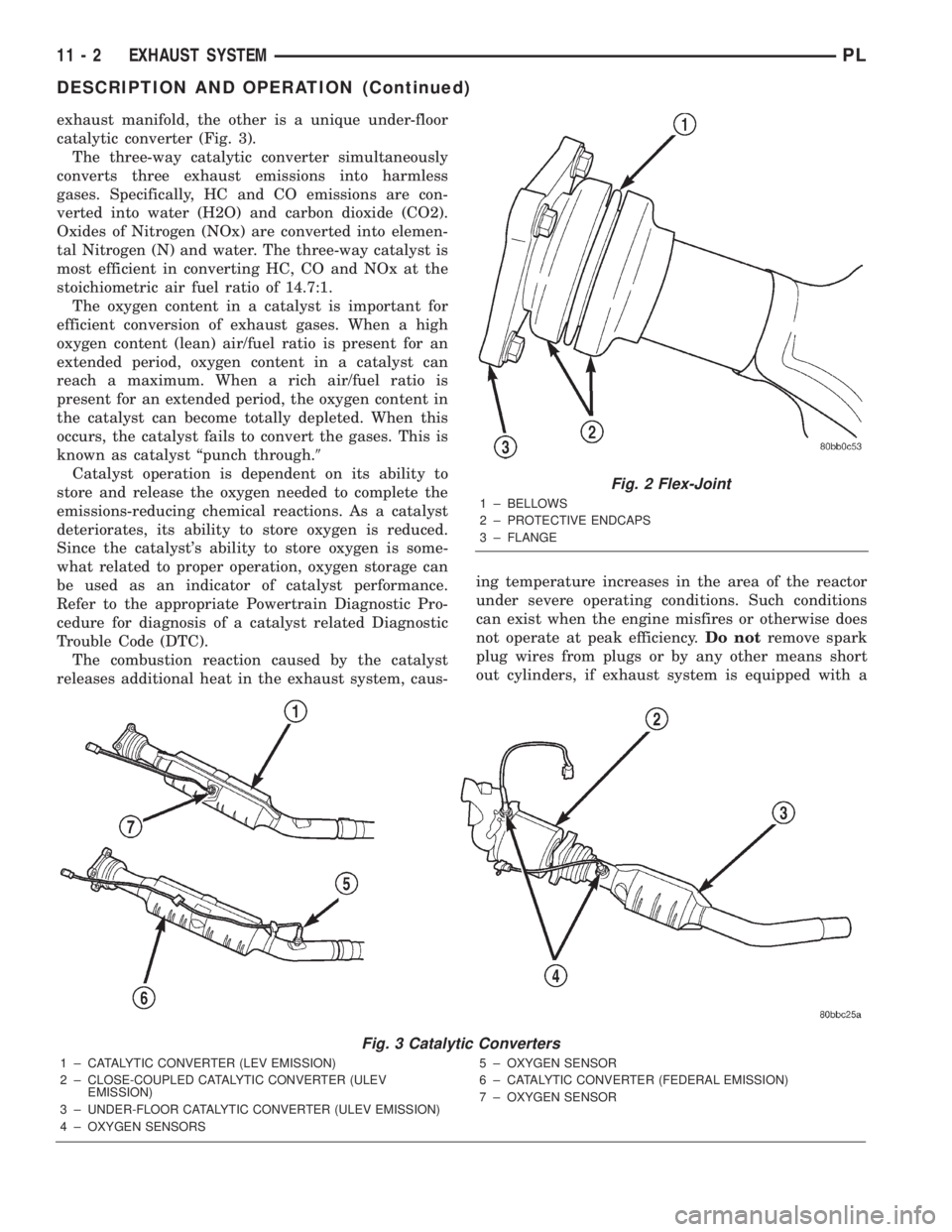

exhaust manifold, the other is a unique under-floor

catalytic converter (Fig. 3).

The three-way catalytic converter simultaneously

converts three exhaust emissions into harmless

gases. Specifically, HC and CO emissions are con-

verted into water (H2O) and carbon dioxide (CO2).

Oxides of Nitrogen (NOx) are converted into elemen-

tal Nitrogen (N) and water. The three-way catalyst is

most efficient in converting HC, CO and NOx at the

stoichiometric air fuel ratio of 14.7:1.

The oxygen content in a catalyst is important for

efficient conversion of exhaust gases. When a high

oxygen content (lean) air/fuel ratio is present for an

extended period, oxygen content in a catalyst can

reach a maximum. When a rich air/fuel ratio is

present for an extended period, the oxygen content in

the catalyst can become totally depleted. When this

occurs, the catalyst fails to convert the gases. This is

known as catalyst ªpunch through.9

Catalyst operation is dependent on its ability to

store and release the oxygen needed to complete the

emissions-reducing chemical reactions. As a catalyst

deteriorates, its ability to store oxygen is reduced.

Since the catalyst's ability to store oxygen is some-

what related to proper operation, oxygen storage can

be used as an indicator of catalyst performance.

Refer to the appropriate Powertrain Diagnostic Pro-

cedure for diagnosis of a catalyst related Diagnostic

Trouble Code (DTC).

The combustion reaction caused by the catalyst

releases additional heat in the exhaust system, caus-ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency.Do notremove spark

plug wires from plugs or by any other means short

out cylinders, if exhaust system is equipped with a

Fig. 2 Flex-Joint

1 ± BELLOWS

2 ± PROTECTIVE ENDCAPS

3 ± FLANGE

Fig. 3 Catalytic Converters

1 ± CATALYTIC CONVERTER (LEV EMISSION)

2 ± CLOSE-COUPLED CATALYTIC CONVERTER (ULEV

EMISSION)

3 ± UNDER-FLOOR CATALYTIC CONVERTER (ULEV EMISSION)

4 ± OXYGEN SENSORS5 ± OXYGEN SENSOR

6 ± CATALYTIC CONVERTER (FEDERAL EMISSION)

7 ± OXYGEN SENSOR

11 - 2 EXHAUST SYSTEMPL

DESCRIPTION AND OPERATION (Continued)