adding oil DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 180 of 1285

COOLING SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

COOLING SYSTEM........................1

COOLANT...............................2

COOLANT PERFORMANCE..................2

COOLANT RECOVERY SYSTEM..............3

ENGINE THERMOSTAT.....................3

RADIATOR..............................3

RADIATOR COOLING FAN MODULE...........3

COOLING SYSTEM PRESSURE CAP..........4

RADIATOR HOSES AND CLAMPS............5

WATER PUMP...........................5

AUTOMATIC TRANSMISSION OIL COOLER.....6

ACCESSORY DRIVE BELTS.................6

ENGINE BLOCK HEATER...................6

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS..............7

ENGINE THERMOSTAT TESTING............14

ACCESSORY DRIVE BELT DIAGNOSIS........14

WATER PUMP DIAGNOSIS................15

COOLING SYSTEM FLOW CHECK...........15

ELECTRIC FAN MOTOR TEST...............15

COOLANT CONCENTRATION TESTING........15

TESTING COOLING SYSTEM FOR LEAKS.....15

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK...............16

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP.......................16

LOW COOLANT LEVEL AERATION...........17

DEAERATION...........................17

TEMPERATURE GAUGE INDICATION.........17

ENGINE BLOCK HEATER..................17

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE.........17COOLANTÐADDING ADDITIONAL...........18

COOLANT LEVELÐSERVICING.............18

COOLING SYSTEMÐDRAINING.............19

COOLING SYSTEMÐREFILLING............19

REMOVAL AND INSTALLATION

WATER PUMP..........................19

WATER PUMP INLET TUBE................20

ENGINE THERMOSTAT....................20

RADIATOR.............................21

RADIATOR DRAINCOCK...................22

COOLING FAN MODULE...................22

COOLANT RECOVERY CONTAINER..........23

ENGINE BLOCK HEATER..................24

ACCESSORY DRIVE BELTS................24

AUTOMATIC BELT TENSIONER & PULLEY....26

DISASSEMBLY AND ASSEMBLY

COOLING FAN MODULE...................26

CLEANING AND INSPECTION

WATER PUMP..........................28

ACCESSORY DRIVE BELT INSPECTION.......28

COOLING SYSTEM CAP...................28

COOLING SYSTEM CLEANING..............28

RADIATOR FLUSHING....................28

REVERSE FLUSHING.....................29

CHEMICAL CLEANING....................29

ADJUSTMENTS

BELT TENSION..........................29

SPECIFICATIONS

COOLING SYSTEM CAPACITY..............30

TORQUE SPECIFICATIONS.................30

SPECIAL TOOLS

COOLING..............................30

DESCRIPTION AND OPERATION

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, and a water pump to

circulate the coolant. The engine cooling module may

consist of a radiator, electric fan motor, fan, shroud,

coolant reserve system, transmission oil cooler, hoses,clamps, air conditioning condenser and transmission

oil lines.

²When the Engine is cold: The thermostat is

closed and the cooling system has no flow through

the radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open

and the cooling system has flow through the radiator,

engine, heater system, and bypass.

PLCOOLING SYSTEM 7 - 1

Page 197 of 1285

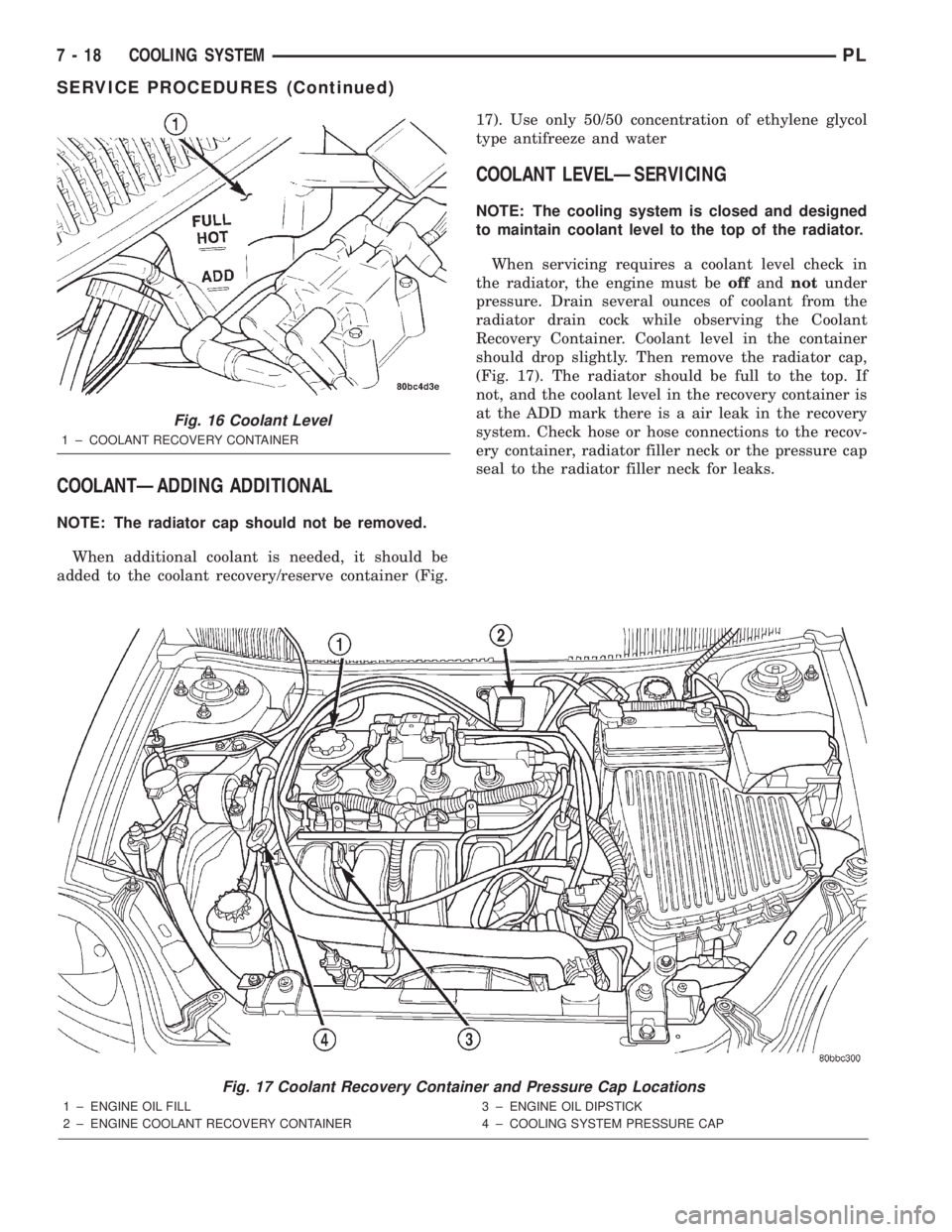

COOLANTÐADDING ADDITIONAL

NOTE: The radiator cap should not be removed.

When additional coolant is needed, it should be

added to the coolant recovery/reserve container (Fig.17). Use only 50/50 concentration of ethylene glycol

type antifreeze and water

COOLANT LEVELÐSERVICING

NOTE: The cooling system is closed and designed

to maintain coolant level to the top of the radiator.

When servicing requires a coolant level check in

the radiator, the engine must beoffandnotunder

pressure. Drain several ounces of coolant from the

radiator drain cock while observing the Coolant

Recovery Container. Coolant level in the container

should drop slightly. Then remove the radiator cap,

(Fig. 17). The radiator should be full to the top. If

not, and the coolant level in the recovery container is

at the ADD mark there is a air leak in the recovery

system. Check hose or hose connections to the recov-

ery container, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

Fig. 17 Coolant Recovery Container and Pressure Cap Locations

1 ± ENGINE OIL FILL

2 ± ENGINE COOLANT RECOVERY CONTAINER3 ± ENGINE OIL DIPSTICK

4 ± COOLING SYSTEM PRESSURE CAP

Fig. 16 Coolant Level

1 ± COOLANT RECOVERY CONTAINER

7 - 18 COOLING SYSTEMPL

SERVICE PROCEDURES (Continued)

Page 730 of 1285

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conforms to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only, engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

SAE 5W-30 engine oil is preferred. Select an engine

oil that is best suited to your particular temperature

range and variation (Fig. 9).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of the engine oil

container.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 10).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Group 0, Lubrication and Mainte-

nance.TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

Refer to Group 0, Lubrication and Maintenance for

Hoisting and Jacking Recommendations.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

Fig. 9 Temperature/Engine Oil Viscosity

Fig. 10 Engine Oil Container Standard Notations

PLENGINE 9 - 7

GENERAL INFORMATION (Continued)

Page 1250 of 1285

Then allow the system to evacuate an additional 10

minutes.

(3) Close all valves. Turn off and disconnect the

vacuum pump.

(4) The refrigerant system is prepared to be

charged with refrigerant.

R-134a REFRIGERANT

This vehicle uses a refrigerant called R-134a. It is

a non-toxic, non-flammable, clear colorless liquefied

gas.

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 in a R-134a system could cause

compressor failure, refrigerant oil to sludge and/or

poor performance.Never add any other type of

refrigerant to a system designed to use R-134a

refrigerant. System failure will occur.

The high pressure service port is located on the

ffilter/drier. The low pressure service port is located

on the suction line near the strut tower.

When servicing a system, it is required that an air

conditioning charging recovery/recycling machine be

used (Fig. 18). Contact an automotive service equip-

ment supplier for proper equipment. Refer to the

operating instructions provided with the equipment

for proper operation.

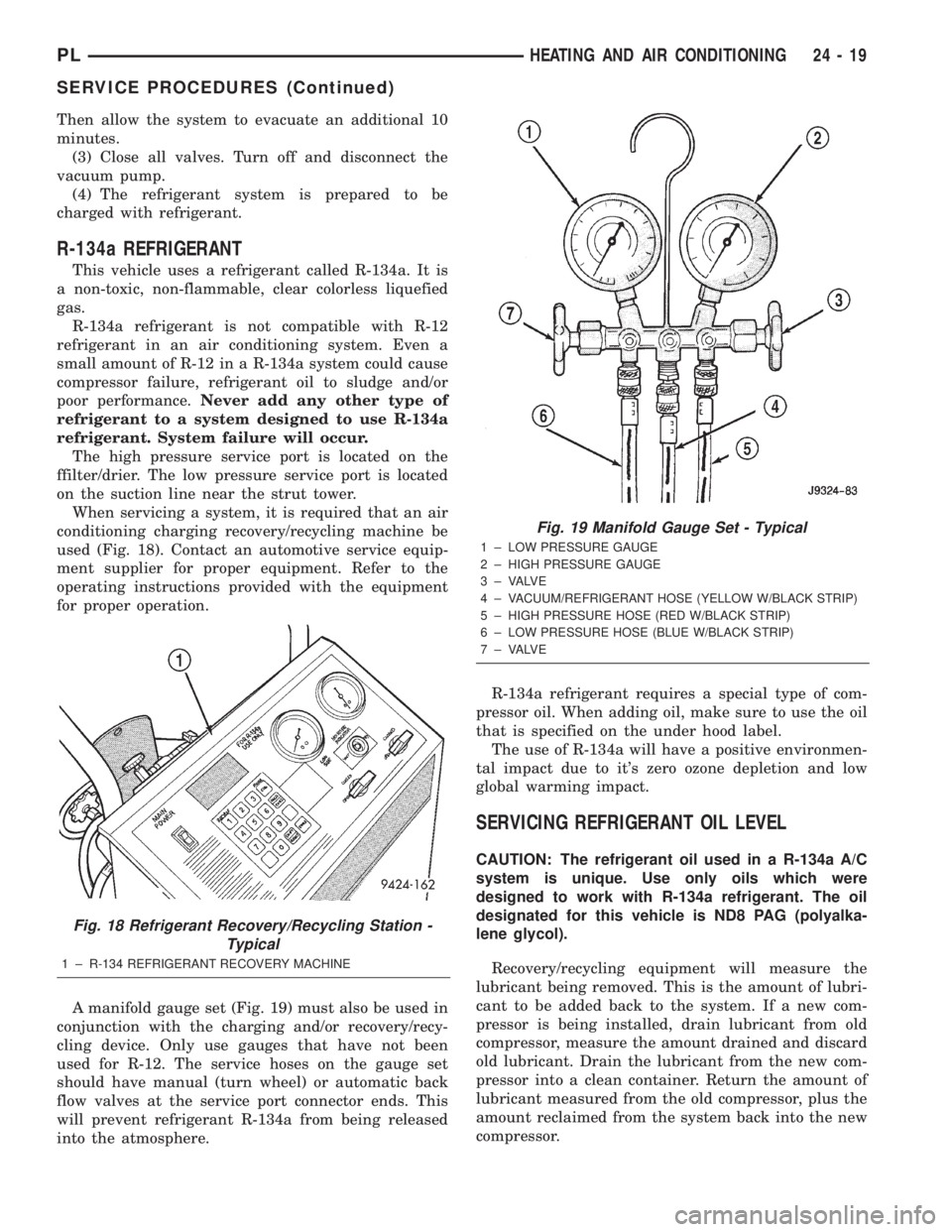

A manifold gauge set (Fig. 19) must also be used in

conjunction with the charging and/or recovery/recy-

cling device. Only use gauges that have not been

used for R-12. The service hoses on the gauge set

should have manual (turn wheel) or automatic back

flow valves at the service port connector ends. This

will prevent refrigerant R-134a from being released

into the atmosphere.R-134a refrigerant requires a special type of com-

pressor oil. When adding oil, make sure to use the oil

that is specified on the under hood label.

The use of R-134a will have a positive environmen-

tal impact due to it's zero ozone depletion and low

global warming impact.

SERVICING REFRIGERANT OIL LEVEL

CAUTION: The refrigerant oil used in a R-134a A/C

system is unique. Use only oils which were

designed to work with R-134a refrigerant. The oil

designated for this vehicle is ND8 PAG (polyalka-

lene glycol).

Recovery/recycling equipment will measure the

lubricant being removed. This is the amount of lubri-

cant to be added back to the system. If a new com-

pressor is being installed, drain lubricant from old

compressor, measure the amount drained and discard

old lubricant. Drain the lubricant from the new com-

pressor into a clean container. Return the amount of

lubricant measured from the old compressor, plus the

amount reclaimed from the system back into the new

compressor.

Fig. 18 Refrigerant Recovery/Recycling Station -

Typical

1 ± R-134 REFRIGERANT RECOVERY MACHINE

Fig. 19 Manifold Gauge Set - Typical

1 ± LOW PRESSURE GAUGE

2 ± HIGH PRESSURE GAUGE

3 ± VALVE

4 ± VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK STRIP)

5 ± HIGH PRESSURE HOSE (RED W/BLACK STRIP)

6 ± LOW PRESSURE HOSE (BLUE W/BLACK STRIP)

7 ± VALVE

PLHEATING AND AIR CONDITIONING 24 - 19

SERVICE PROCEDURES (Continued)