service reset DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 154 of 1285

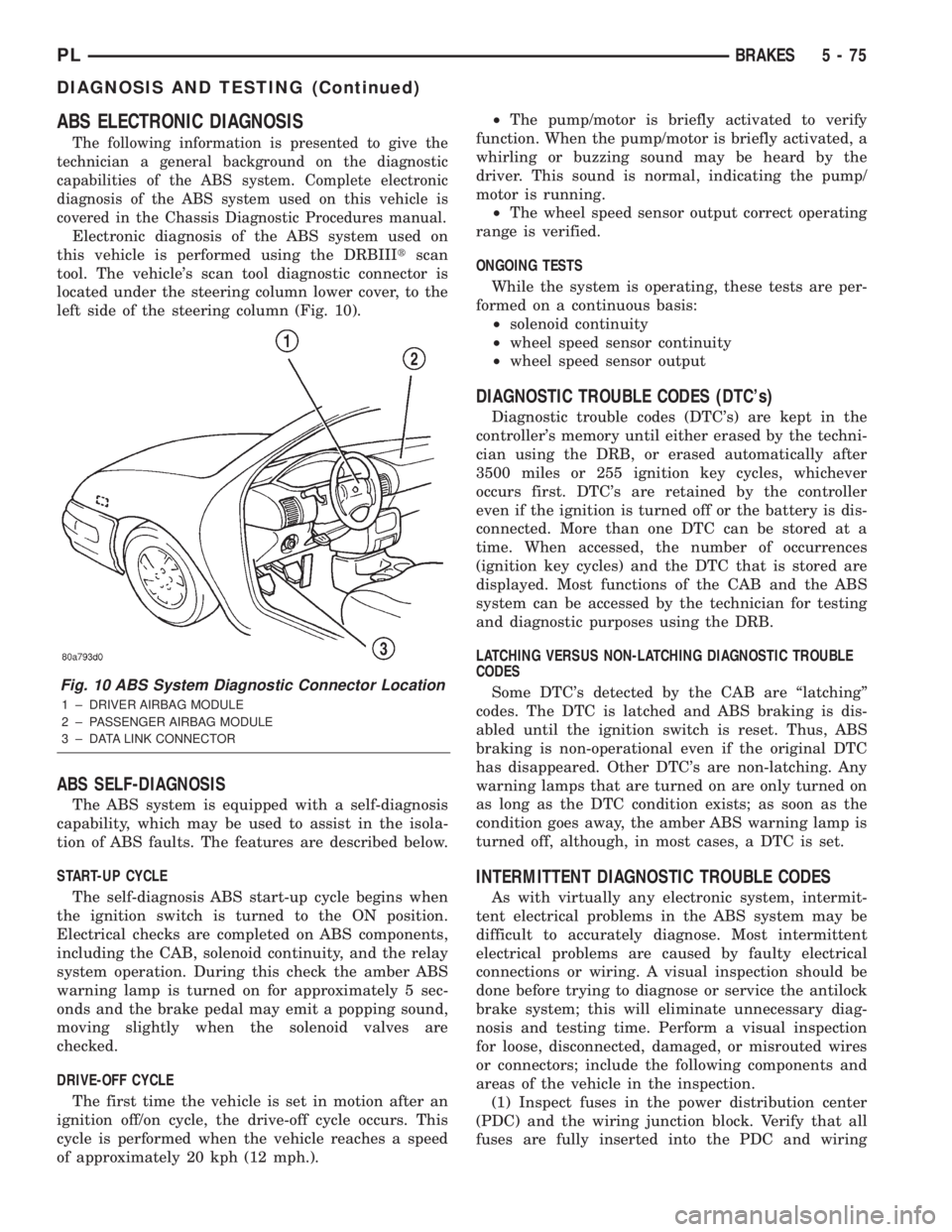

ABS ELECTRONIC DIAGNOSIS

The following information is presented to give the

technician a general background on the diagnostic

capabilities of the ABS system. Complete electronic

diagnosis of the ABS system used on this vehicle is

covered in the Chassis Diagnostic Procedures manual.

Electronic diagnosis of the ABS system used on

this vehicle is performed using the DRBIIItscan

tool. The vehicle's scan tool diagnostic connector is

located under the steering column lower cover, to the

left side of the steering column (Fig. 10).

ABS SELF-DIAGNOSIS

The ABS system is equipped with a self-diagnosis

capability, which may be used to assist in the isola-

tion of ABS faults. The features are described below.

START-UP CYCLE

The self-diagnosis ABS start-up cycle begins when

the ignition switch is turned to the ON position.

Electrical checks are completed on ABS components,

including the CAB, solenoid continuity, and the relay

system operation. During this check the amber ABS

warning lamp is turned on for approximately 5 sec-

onds and the brake pedal may emit a popping sound,

moving slightly when the solenoid valves are

checked.

DRIVE-OFF CYCLE

The first time the vehicle is set in motion after an

ignition off/on cycle, the drive-off cycle occurs. This

cycle is performed when the vehicle reaches a speed

of approximately 20 kph (12 mph.).²The pump/motor is briefly activated to verify

function. When the pump/motor is briefly activated, a

whirling or buzzing sound may be heard by the

driver. This sound is normal, indicating the pump/

motor is running.

²The wheel speed sensor output correct operating

range is verified.

ONGOING TESTS

While the system is operating, these tests are per-

formed on a continuous basis:

²solenoid continuity

²wheel speed sensor continuity

²wheel speed sensor output

DIAGNOSTIC TROUBLE CODES (DTC's)

Diagnostic trouble codes (DTC's) are kept in the

controller's memory until either erased by the techni-

cian using the DRB, or erased automatically after

3500 miles or 255 ignition key cycles, whichever

occurs first. DTC's are retained by the controller

even if the ignition is turned off or the battery is dis-

connected. More than one DTC can be stored at a

time. When accessed, the number of occurrences

(ignition key cycles) and the DTC that is stored are

displayed. Most functions of the CAB and the ABS

system can be accessed by the technician for testing

and diagnostic purposes using the DRB.

LATCHING VERSUS NON-LATCHING DIAGNOSTIC TROUBLE

CODES

Some DTC's detected by the CAB are ªlatchingº

codes. The DTC is latched and ABS braking is dis-

abled until the ignition switch is reset. Thus, ABS

braking is non-operational even if the original DTC

has disappeared. Other DTC's are non-latching. Any

warning lamps that are turned on are only turned on

as long as the DTC condition exists; as soon as the

condition goes away, the amber ABS warning lamp is

turned off, although, in most cases, a DTC is set.

INTERMITTENT DIAGNOSTIC TROUBLE CODES

As with virtually any electronic system, intermit-

tent electrical problems in the ABS system may be

difficult to accurately diagnose. Most intermittent

electrical problems are caused by faulty electrical

connections or wiring. A visual inspection should be

done before trying to diagnose or service the antilock

brake system; this will eliminate unnecessary diag-

nosis and testing time. Perform a visual inspection

for loose, disconnected, damaged, or misrouted wires

or connectors; include the following components and

areas of the vehicle in the inspection.

(1) Inspect fuses in the power distribution center

(PDC) and the wiring junction block. Verify that all

fuses are fully inserted into the PDC and wiring

Fig. 10 ABS System Diagnostic Connector Location

1 ± DRIVER AIRBAG MODULE

2 ± PASSENGER AIRBAG MODULE

3 ± DATA LINK CONNECTOR

PLBRAKES 5 - 75

DIAGNOSIS AND TESTING (Continued)

Page 166 of 1285

CLUTCH

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

MODULAR CLUTCH ASSEMBLY..............1

CLUTCH CABLE..........................1

CLUTCH INTERLOCK/UPSTOP SWITCH........1

DIAGNOSIS AND TESTING

CLUTCH SYSTEM DIAGNOSIS...............2

DRIVE PLATE MISALIGNMENT..............5

CLUTCH CHATTER COMPLAINTS............5

CLASH±INTO±REVERSE COMPLAINTS........5

CLUTCH INTERLOCK/UPSTOP SWITCH........5REMOVAL AND INSTALLATION

CLUTCH CABLE..........................7

CLUTCH INTERLOCK/UPSTOP SWITCH........8

MODULAR CLUTCH ASSEMBLY..............8

RELEASE BEARING AND FORK.............12

CLEANING AND INSPECTION

CLUTCH CONTAMINATION.................12

CLEANING PRECAUTIONS.................13

SPECIFICATIONS

TORQUE...............................13

DESCRIPTION AND OPERATION

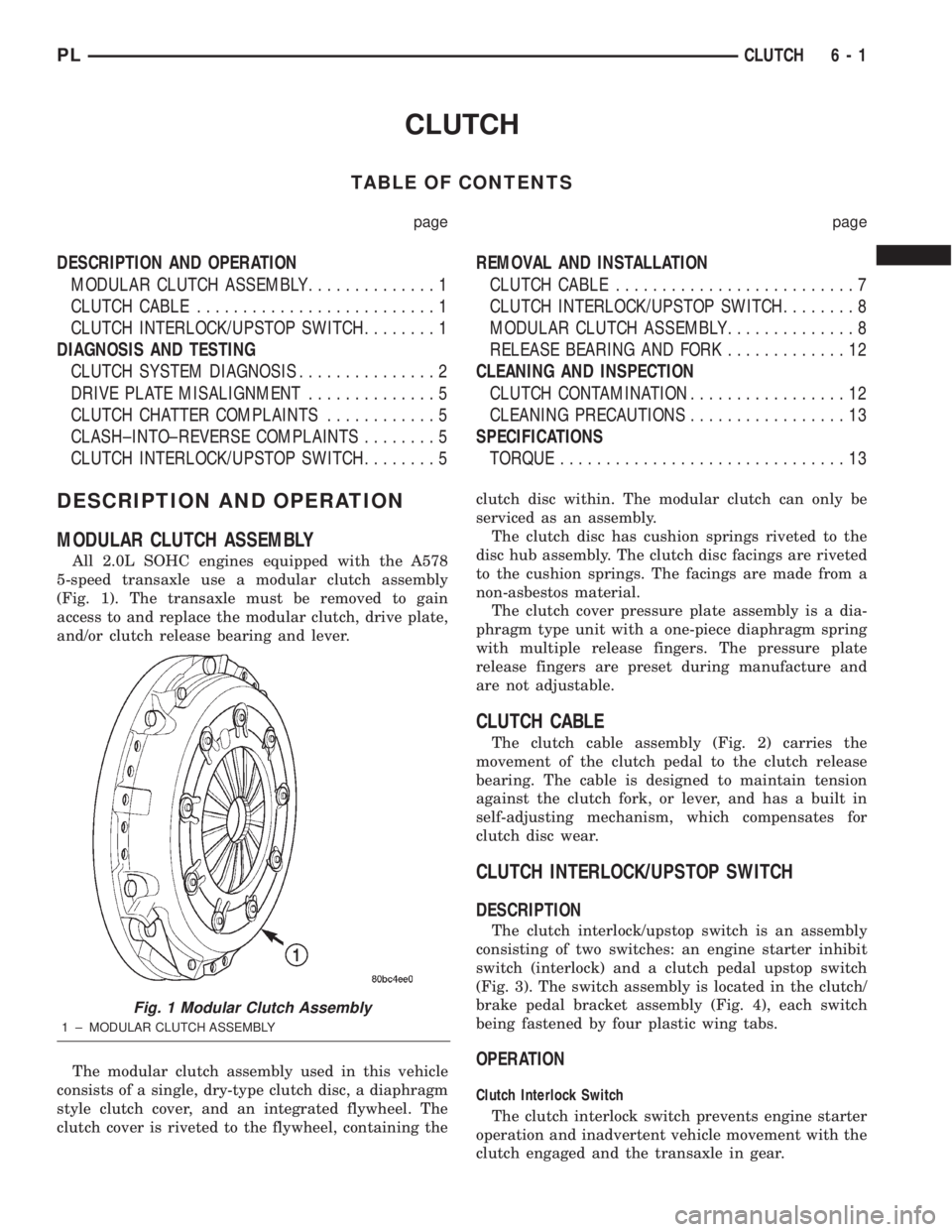

MODULAR CLUTCH ASSEMBLY

All 2.0L SOHC engines equipped with the A578

5-speed transaxle use a modular clutch assembly

(Fig. 1). The transaxle must be removed to gain

access to and replace the modular clutch, drive plate,

and/or clutch release bearing and lever.

The modular clutch assembly used in this vehicle

consists of a single, dry-type clutch disc, a diaphragm

style clutch cover, and an integrated flywheel. The

clutch cover is riveted to the flywheel, containing theclutch disc within. The modular clutch can only be

serviced as an assembly.

The clutch disc has cushion springs riveted to the

disc hub assembly. The clutch disc facings are riveted

to the cushion springs. The facings are made from a

non-asbestos material.

The clutch cover pressure plate assembly is a dia-

phragm type unit with a one-piece diaphragm spring

with multiple release fingers. The pressure plate

release fingers are preset during manufacture and

are not adjustable.

CLUTCH CABLE

The clutch cable assembly (Fig. 2) carries the

movement of the clutch pedal to the clutch release

bearing. The cable is designed to maintain tension

against the clutch fork, or lever, and has a built in

self-adjusting mechanism, which compensates for

clutch disc wear.

CLUTCH INTERLOCK/UPSTOP SWITCH

DESCRIPTION

The clutch interlock/upstop switch is an assembly

consisting of two switches: an engine starter inhibit

switch (interlock) and a clutch pedal upstop switch

(Fig. 3). The switch assembly is located in the clutch/

brake pedal bracket assembly (Fig. 4), each switch

being fastened by four plastic wing tabs.

OPERATION

Clutch Interlock Switch

The clutch interlock switch prevents engine starter

operation and inadvertent vehicle movement with the

clutch engaged and the transaxle in gear.

Fig. 1 Modular Clutch Assembly

1 ± MODULAR CLUTCH ASSEMBLY

PLCLUTCH 6 - 1

Page 249 of 1285

DESCRIPTION AND OPERATION

HEADLAMP SWITCH

The headlamp switch is part of the Multi-Function

Switch. Refer to Group 8J, Turn Signal and Flasher

for the Multi-Function Switch Test, Removal and

Installation procedures.

INSTRUMENT CLUSTER

There are two conventional instrument cluster

assemblies available. The clusters electronically drive

the speedometer, odometer, gauges, and tachometer

(if equipped). Refer to (Fig. 2) and (Fig. 3).

The instrument cluster controls the courtesy

lamps, it receives and sends messages to other mod-

ules via the PCI bus circuit, it controls all the instru-

ment illumination and the chime is also an integral

part of the cluster. The front turn signals are wired

through the cluster and then go to the front lamps.

The reason being that the DRL module is built into

the cluster (if equipped).

All gauges in the electronic clusters are the analog

type gauges. When the ignition switch is moved to

the OFF position, the cluster drives each gauge to its

lowest position. The individual gauges are not servi-

cable and require complete replacement of the cluster

if one or more gauges are inoperable.

One button is used to switch the display from trip

to total mileage. Holding the button when the display

is in the trip mode will reset the trip mileage. This

button is also used to put the cluster in self-diagnos-

tic mode. Refer to Service Procedures, Cluster Self-

Diagnostics in this section. Most of the indicators will

come on briefly for a bulb heck when the ignition is

turned from OFF to ON. All of the LED's are replace-

able.

In the event that the instrument cluster looses

communication with all other modules on the PCI

bus, the cluster will display ªnobusº in the VF dis-

play. The VF display also displays ªDoorº, ªCruiseº,

ªTracº, and odometer trip or total.

If the cluster does not detect voltage on the cour-

tesy lamp circuit, the message ªFUSEº will alternate

with the odometer/trip odometer for 30 seconds after

the ignition is turned on and for 15 seconds after the

vehicle is first moved. The lack of voltage can be due

to the M1 Fused B(+) (IOD) fuse being open, a bad or

missing courtesy lamp bulb, or a circuit problem.

WARNING AND INDICATOR LAMPS

The instrument cluster has warning lamps and

indicators for the following systems:

²Airbag

²Anti-lock Brakes (ABS) if equipped

²Brake warning

²Charging System²Front fog lamps (if equipped)

²High beam indicator

²Low fuel (premium cluster only)

²Low oil pressure

²Malfunction indicator (service engine soon) lamp

²Right and left turn signals

²Seat belt warning

²Security system

²Trac-Off (ABS equipped vehicles only)

The instrument cluster has a Vacuum Fluorescent

(VF) display for the following systems:

²Cruise

²Door (ajar)

²Odometer

²Set (cruise)

²Trac

²Trip

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM

For testing of this system refer to Group 8M, Pas-

sive Restraint Systems.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when the

parking brake is applied with ignition switch turned

to the ON position. The same lamp will also illumi-

nate if one of the two service brake systems fail the

when brake pedal is applied.

To test the system:

²As the ignition switch is turned to the start posi-

tion the lamp should light.

²Turn ignition switch to the ON position and

apply the parking brake. The lamp should light.

If lamp fails to light inspect for:

²A burned out lamp

²Loose, corroded or damaged socket

²A damaged circuit board

²A broken or disconnected wire at the switch

²Defective switch

To test the service brake warning system, refer to

Group 5, Brakes, Hydraulic System Control Valves.

INSTRUMENT CLUSTER LAMPS

Every time the vehicle is switched to the START/

RUN position, the cluster goes through a BULB

CHECK. This tests most of the indicator lamps and

Vacuum Fluorescent (VF) displays. If only one lamp

is out, remove the instrument cluster and replace the

defective bulb or Light Emitting Diode (LED). If

some or all of the lamps fail to light, refer to the

proper Body Diagnostics Procedures Manual.

8E - 2 INSTRUMENT PANEL SYSTEMSPL

Page 251 of 1285

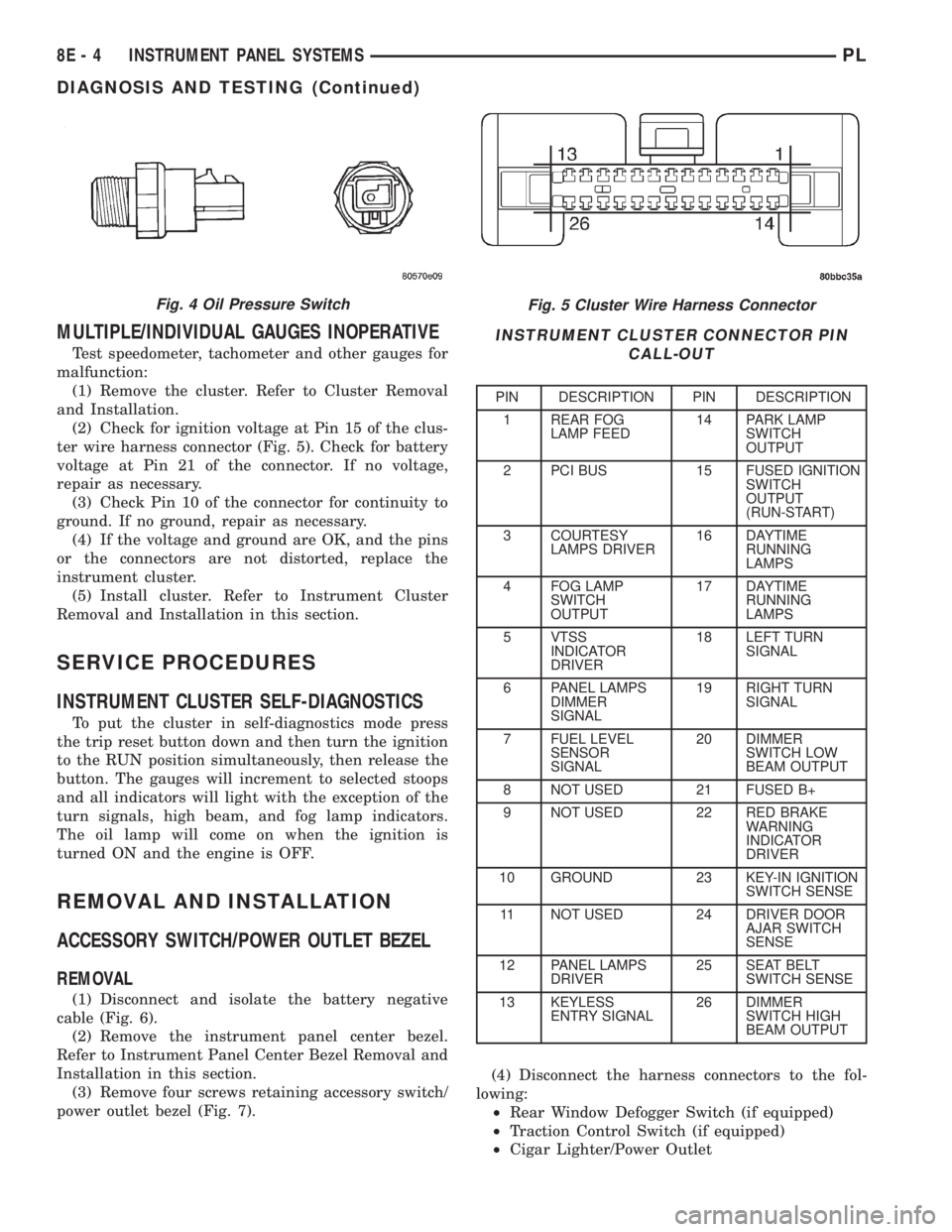

MULTIPLE/INDIVIDUAL GAUGES INOPERATIVE

Test speedometer, tachometer and other gauges for

malfunction:

(1) Remove the cluster. Refer to Cluster Removal

and Installation.

(2) Check for ignition voltage at Pin 15 of the clus-

ter wire harness connector (Fig. 5). Check for battery

voltage at Pin 21 of the connector. If no voltage,

repair as necessary.

(3) Check Pin 10 of the connector for continuity to

ground. If no ground, repair as necessary.

(4) If the voltage and ground are OK, and the pins

or the connectors are not distorted, replace the

instrument cluster.

(5) Install cluster. Refer to Instrument Cluster

Removal and Installation in this section.

SERVICE PROCEDURES

INSTRUMENT CLUSTER SELF-DIAGNOSTICS

To put the cluster in self-diagnostics mode press

the trip reset button down and then turn the ignition

to the RUN position simultaneously, then release the

button. The gauges will increment to selected stoops

and all indicators will light with the exception of the

turn signals, high beam, and fog lamp indicators.

The oil lamp will come on when the ignition is

turned ON and the engine is OFF.

REMOVAL AND INSTALLATION

ACCESSORY SWITCH/POWER OUTLET BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 6).

(2) Remove the instrument panel center bezel.

Refer to Instrument Panel Center Bezel Removal and

Installation in this section.

(3) Remove four screws retaining accessory switch/

power outlet bezel (Fig. 7).(4) Disconnect the harness connectors to the fol-

lowing:

²Rear Window Defogger Switch (if equipped)

²Traction Control Switch (if equipped)

²Cigar Lighter/Power Outlet

Fig. 5 Cluster Wire Harness Connector

INSTRUMENT CLUSTER CONNECTOR PIN

CALL-OUT

PIN DESCRIPTION PIN DESCRIPTION

1 REAR FOG

LAMP FEED14 PARK LAMP

SWITCH

OUTPUT

2 PCI BUS 15 FUSED IGNITION

SWITCH

OUTPUT

(RUN-START)

3 COURTESY

LAMPS DRIVER16 DAYTIME

RUNNING

LAMPS

4 FOG LAMP

SWITCH

OUTPUT17 DAYTIME

RUNNING

LAMPS

5 VTSS

INDICATOR

DRIVER18 LEFT TURN

SIGNAL

6 PANEL LAMPS

DIMMER

SIGNAL19 RIGHT TURN

SIGNAL

7 FUEL LEVEL

SENSOR

SIGNAL20 DIMMER

SWITCH LOW

BEAM OUTPUT

8 NOT USED 21 FUSED B+

9 NOT USED 22 RED BRAKE

WARNING

INDICATOR

DRIVER

10 GROUND 23 KEY-IN IGNITION

SWITCH SENSE

11 NOT USED 24 DRIVER DOOR

AJAR SWITCH

SENSE

12 PANEL LAMPS

DRIVER25 SEAT BELT

SWITCH SENSE

13 KEYLESS

ENTRY SIGNAL26 DIMMER

SWITCH HIGH

BEAM OUTPUT

Fig. 4 Oil Pressure Switch

8E - 4 INSTRUMENT PANEL SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 360 of 1285

POWER DISTRIBUTION SYSTEMS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

POWER DISTRIBUTION SYSTEM.............1

POWER DISTRIBUTION CENTER (PDC).......1

FUSE BLOCK.............................2REMOVAL AND INSTALLATION

FUSE BLOCK.............................2

POWER DISTRIBUTION CENTER (PDC).......2

DESCRIPTION AND OPERATION

POWER DISTRIBUTION SYSTEM

This group covers the various standard and

optional power distribution components used on this

model. Refer to the Component Index of Group 8W -

Wiring Diagrams for complete circuit diagrams of the

various power distribution components.

The power distribution system for this vehicle is

designed to provide safe, reliable, centralized and

convenient to access distribution of the electrical cur-

rent required to operate all of the many standard

and optional factory-installed electrical and electronic

powertrain, chassis, safety, comfort and convenience

systems. At the same time, these systems were

designed to provide centralized locations for conduct-

ing diagnosis of faulty circuits, and for sourcing the

additional current requirements of many aftermarket

vehicle accessory and convenience items.

These power distribution systems also incorporate

various types of circuit control and protection fea-

tures, including:

²Fuses

²Fuse cartridges

²Fusible links

²Automatic resetting circuit breakers

²Relays

²Flashers

²Timers

²Circuit splice blocks.

The power distribution system for this vehicle con-

sists of the following components:

²Power Distribution Center (PDC)

²Fuse Block

Following are general descriptions of the major

components in the power distribution system. Refer

to the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the power distribution system components.

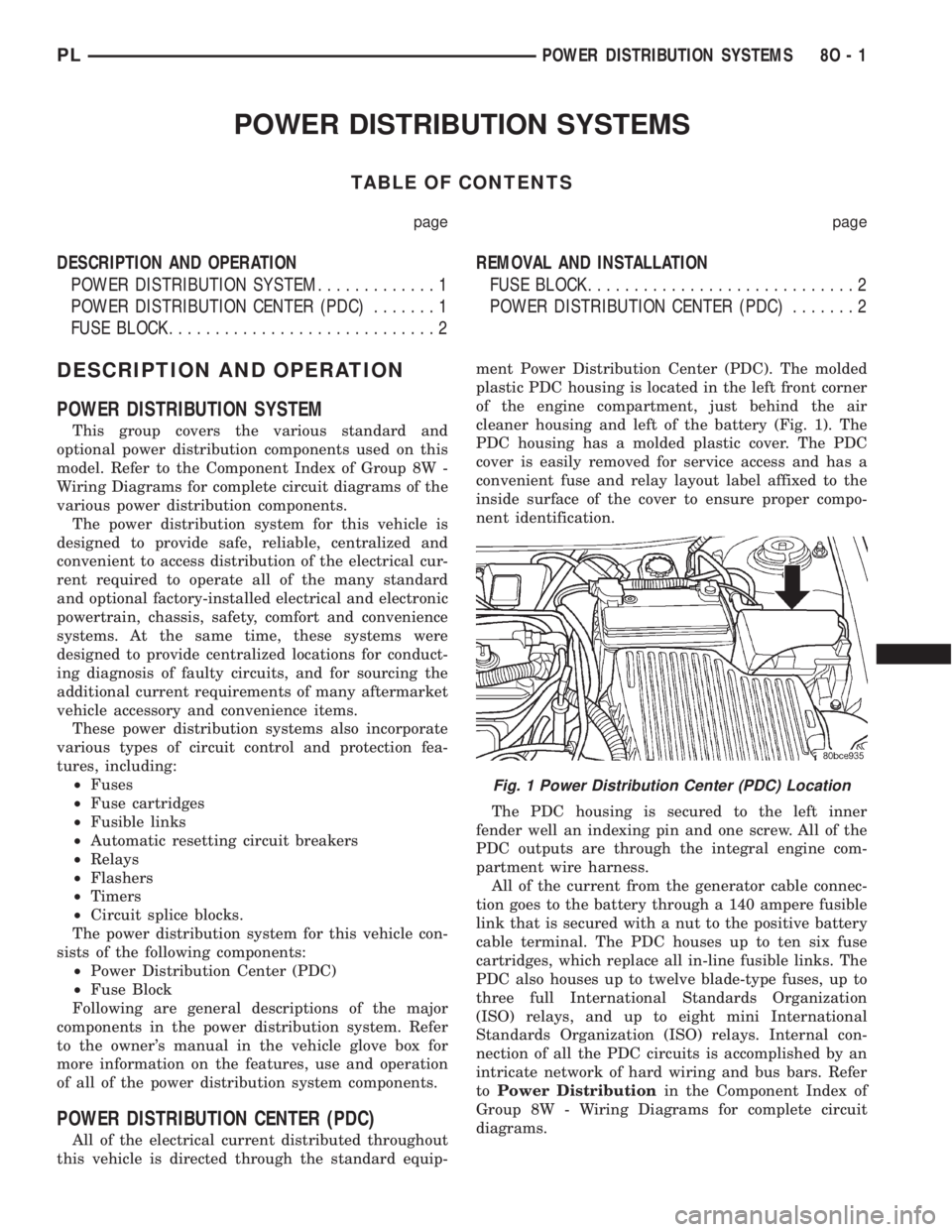

POWER DISTRIBUTION CENTER (PDC)

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-ment Power Distribution Center (PDC). The molded

plastic PDC housing is located in the left front corner

of the engine compartment, just behind the air

cleaner housing and left of the battery (Fig. 1). The

PDC housing has a molded plastic cover. The PDC

cover is easily removed for service access and has a

convenient fuse and relay layout label affixed to the

inside surface of the cover to ensure proper compo-

nent identification.

The PDC housing is secured to the left inner

fender well an indexing pin and one screw. All of the

PDC outputs are through the integral engine com-

partment wire harness.

All of the current from the generator cable connec-

tion goes to the battery through a 140 ampere fusible

link that is secured with a nut to the positive battery

cable terminal. The PDC houses up to ten six fuse

cartridges, which replace all in-line fusible links. The

PDC also houses up to twelve blade-type fuses, up to

three full International Standards Organization

(ISO) relays, and up to eight mini International

Standards Organization (ISO) relays. Internal con-

nection of all the PDC circuits is accomplished by an

intricate network of hard wiring and bus bars. Refer

toPower Distributionin the Component Index of

Group 8W - Wiring Diagrams for complete circuit

diagrams.

Fig. 1 Power Distribution Center (PDC) Location

PLPOWER DISTRIBUTION SYSTEMS 8O - 1

Page 361 of 1285

The fusible link, fuses and relays are available for

service replacement. The PDC unit cannot be

repaired and is only serviced as a unit with the

engine compartment wire harness. If the PDC is

faulty or damaged, the engine compartment wire har-

ness assembly must be replaced.

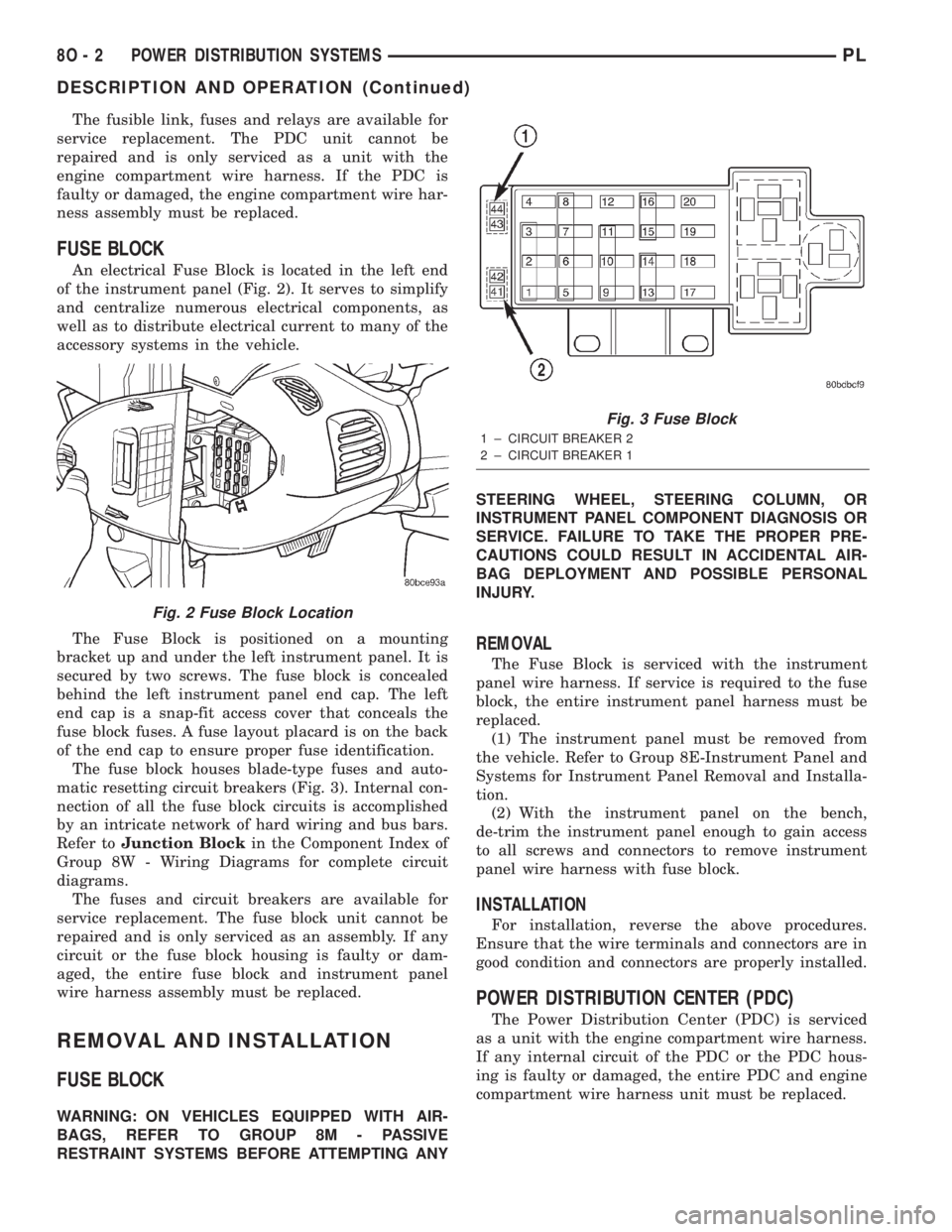

FUSE BLOCK

An electrical Fuse Block is located in the left end

of the instrument panel (Fig. 2). It serves to simplify

and centralize numerous electrical components, as

well as to distribute electrical current to many of the

accessory systems in the vehicle.

The Fuse Block is positioned on a mounting

bracket up and under the left instrument panel. It is

secured by two screws. The fuse block is concealed

behind the left instrument panel end cap. The left

end cap is a snap-fit access cover that conceals the

fuse block fuses. A fuse layout placard is on the back

of the end cap to ensure proper fuse identification.

The fuse block houses blade-type fuses and auto-

matic resetting circuit breakers (Fig. 3). Internal con-

nection of all the fuse block circuits is accomplished

by an intricate network of hard wiring and bus bars.

Refer toJunction Blockin the Component Index of

Group 8W - Wiring Diagrams for complete circuit

diagrams.

The fuses and circuit breakers are available for

service replacement. The fuse block unit cannot be

repaired and is only serviced as an assembly. If any

circuit or the fuse block housing is faulty or dam-

aged, the entire fuse block and instrument panel

wire harness assembly must be replaced.

REMOVAL AND INSTALLATION

FUSE BLOCK

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANYSTEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

The Fuse Block is serviced with the instrument

panel wire harness. If service is required to the fuse

block, the entire instrument panel harness must be

replaced.

(1) The instrument panel must be removed from

the vehicle. Refer to Group 8E-Instrument Panel and

Systems for Instrument Panel Removal and Installa-

tion.

(2) With the instrument panel on the bench,

de-trim the instrument panel enough to gain access

to all screws and connectors to remove instrument

panel wire harness with fuse block.

INSTALLATION

For installation, reverse the above procedures.

Ensure that the wire terminals and connectors are in

good condition and connectors are properly installed.

POWER DISTRIBUTION CENTER (PDC)

The Power Distribution Center (PDC) is serviced

as a unit with the engine compartment wire harness.

If any internal circuit of the PDC or the PDC hous-

ing is faulty or damaged, the entire PDC and engine

compartment wire harness unit must be replaced.

Fig. 2 Fuse Block Location

Fig. 3 Fuse Block

1 ± CIRCUIT BREAKER 2

2 ± CIRCUIT BREAKER 1

8O - 2 POWER DISTRIBUTION SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 406 of 1285

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 16) (Fig. 17).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the

repaired connector, if required.

(9) Connect connector to its mating half/compo-

nent.

(10) Connect battery and test all affected systems.CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be

repaired) from its mating half/component.

(3) Cut off the existing wire connector directly

behind the insulator. Remove six inches of tape from

the harness.

(4) Stagger cut all wires on the harness side at 1/2

inch intervals (Fig. 18).

(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 18).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Be sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires.

(10) Push the two ends of wire together until the

strands of wire are close to the insulation.

(11) Twist the wires together.

(12) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

Fig. 16 Terminal Removal

1 ± CONNECTOR

2 ± FROM SPECIAL TOOL KIT 6680

Fig. 17 Terminal Removal Using Special Tool

1 ± FROM SPECIAL TOOL KIT 6680

2 ± CONNECTOR

PL8W - 01 GENERAL INFORMATION 8W - 01 - 13

SERVICE PROCEDURES (Continued)

Page 877 of 1285

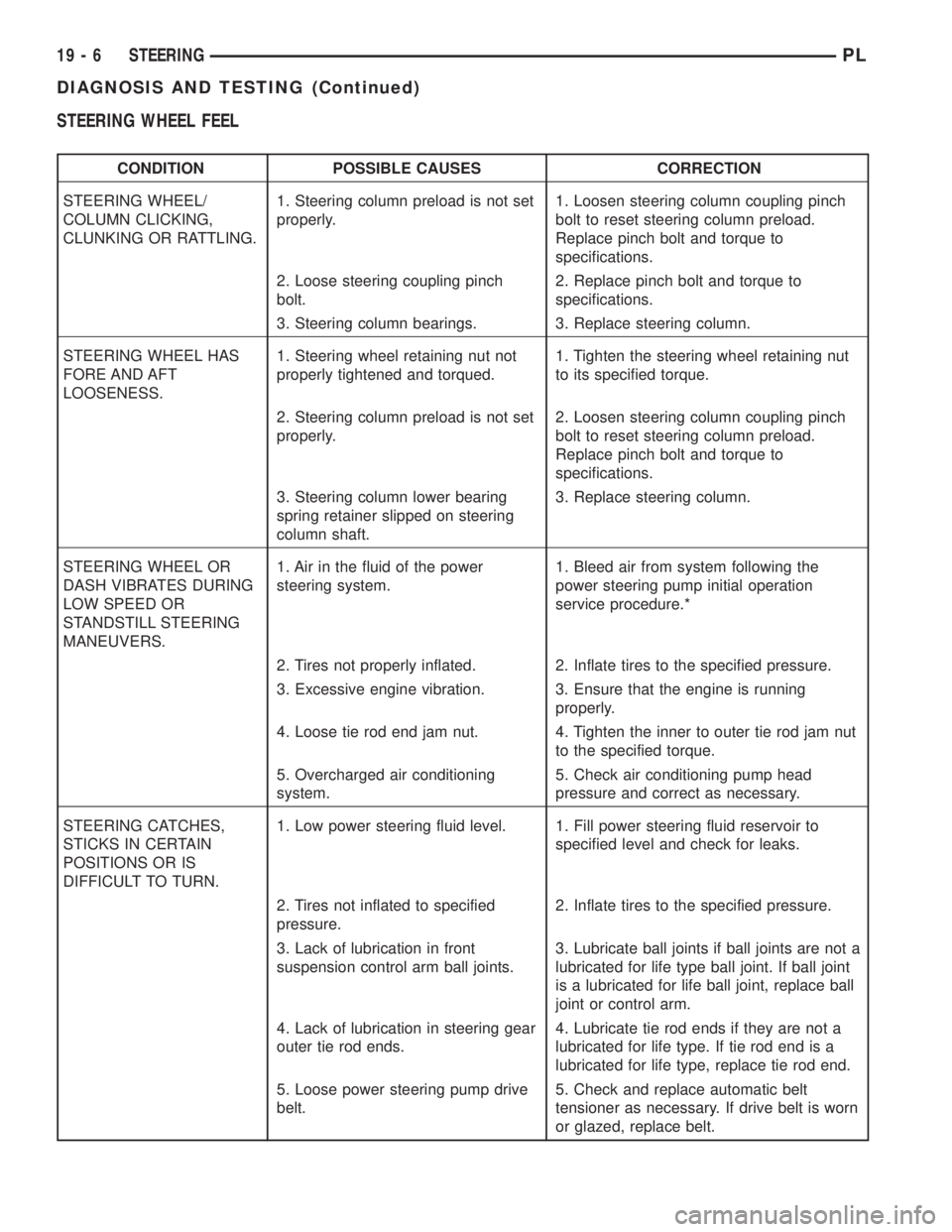

STEERING WHEEL FEEL

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL/

COLUMN CLICKING,

CLUNKING OR RATTLING.1. Steering column preload is not set

properly.1. Loosen steering column coupling pinch

bolt to reset steering column preload.

Replace pinch bolt and torque to

specifications.

2. Loose steering coupling pinch

bolt.2. Replace pinch bolt and torque to

specifications.

3. Steering column bearings. 3. Replace steering column.

STEERING WHEEL HAS

FORE AND AFT

LOOSENESS.1. Steering wheel retaining nut not

properly tightened and torqued.1. Tighten the steering wheel retaining nut

to its specified torque.

2. Steering column preload is not set

properly.2. Loosen steering column coupling pinch

bolt to reset steering column preload.

Replace pinch bolt and torque to

specifications.

3. Steering column lower bearing

spring retainer slipped on steering

column shaft.3. Replace steering column.

STEERING WHEEL OR

DASH VIBRATES DURING

LOW SPEED OR

STANDSTILL STEERING

MANEUVERS.1. Air in the fluid of the power

steering system.1. Bleed air from system following the

power steering pump initial operation

service procedure.*

2. Tires not properly inflated. 2. Inflate tires to the specified pressure.

3. Excessive engine vibration. 3. Ensure that the engine is running

properly.

4. Loose tie rod end jam nut. 4. Tighten the inner to outer tie rod jam nut

to the specified torque.

5. Overcharged air conditioning

system.5. Check air conditioning pump head

pressure and correct as necessary.

STEERING CATCHES,

STICKS IN CERTAIN

POSITIONS OR IS

DIFFICULT TO TURN.1. Low power steering fluid level. 1. Fill power steering fluid reservoir to

specified level and check for leaks.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified pressure.

3. Lack of lubrication in front

suspension control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type ball joint. If ball joint

is a lubricated for life ball joint, replace ball

joint or control arm.

4. Lack of lubrication in steering gear

outer tie rod ends.4. Lubricate tie rod ends if they are not a

lubricated for life type. If tie rod end is a

lubricated for life type, replace tie rod end.

5. Loose power steering pump drive

belt.5. Check and replace automatic belt

tensioner as necessary. If drive belt is worn

or glazed, replace belt.

19 - 6 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 909 of 1285

(25) Turn the key to OFF and remove the scan tool

from the vehicle.

(26) Test the operation of the horn, wipers and any

other functions that are steering column operated. If

applicable, reset the radio and the clock.

(27) If the steering column is a tilt column, verify

the tilt mechanism operates properly.

(28) Road test the vehicle to ensure proper opera-

tion of the steering system and the speed control sys-

tem.

STEERING COLUMN LOWER COUPLING

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section and in STEERING

GEAR.

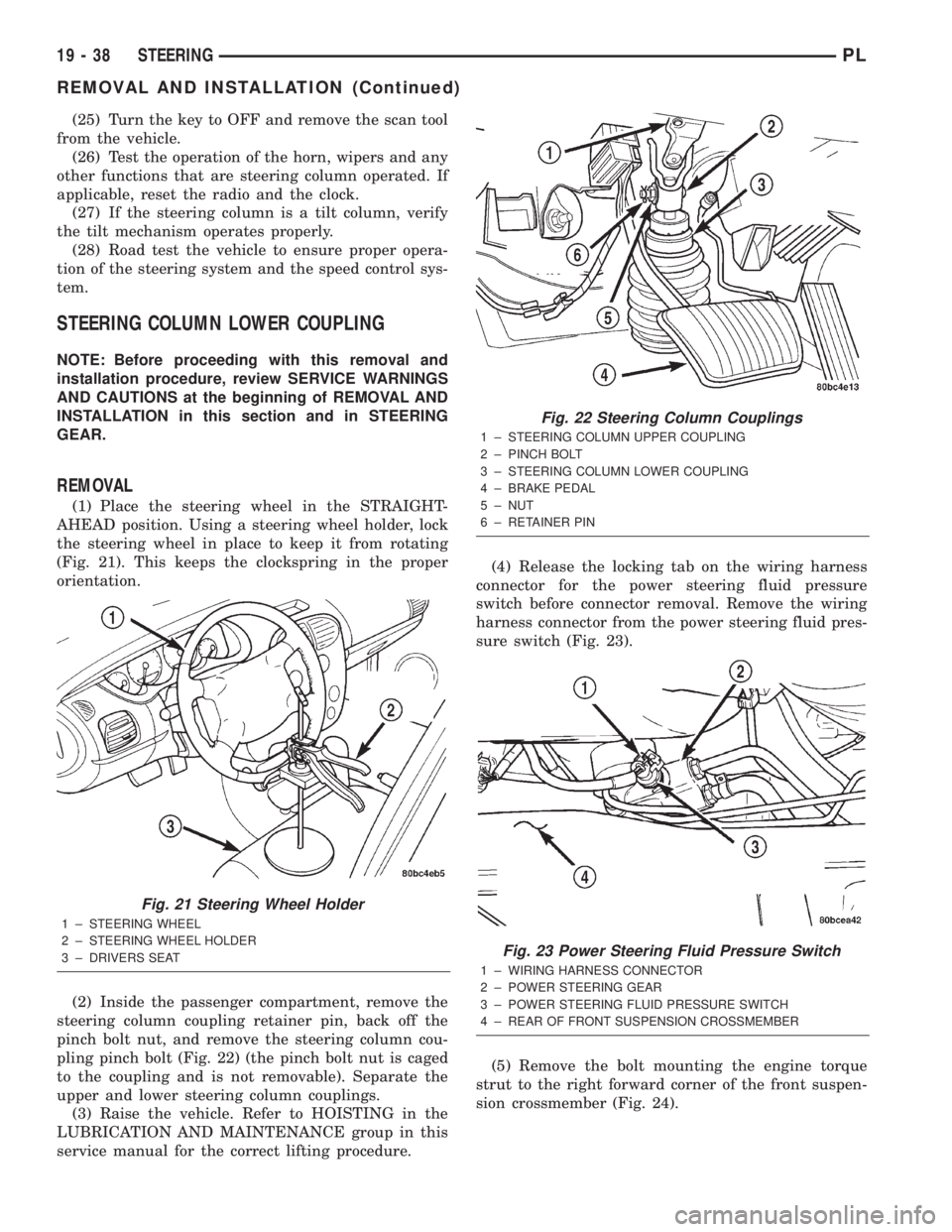

REMOVAL

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 21). This keeps the clockspring in the proper

orientation.

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 22) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.(4) Release the locking tab on the wiring harness

connector for the power steering fluid pressure

switch before connector removal. Remove the wiring

harness connector from the power steering fluid pres-

sure switch (Fig. 23).

(5) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 24).

Fig. 21 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 22 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 23 Power Steering Fluid Pressure Switch

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 38 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1233 of 1285

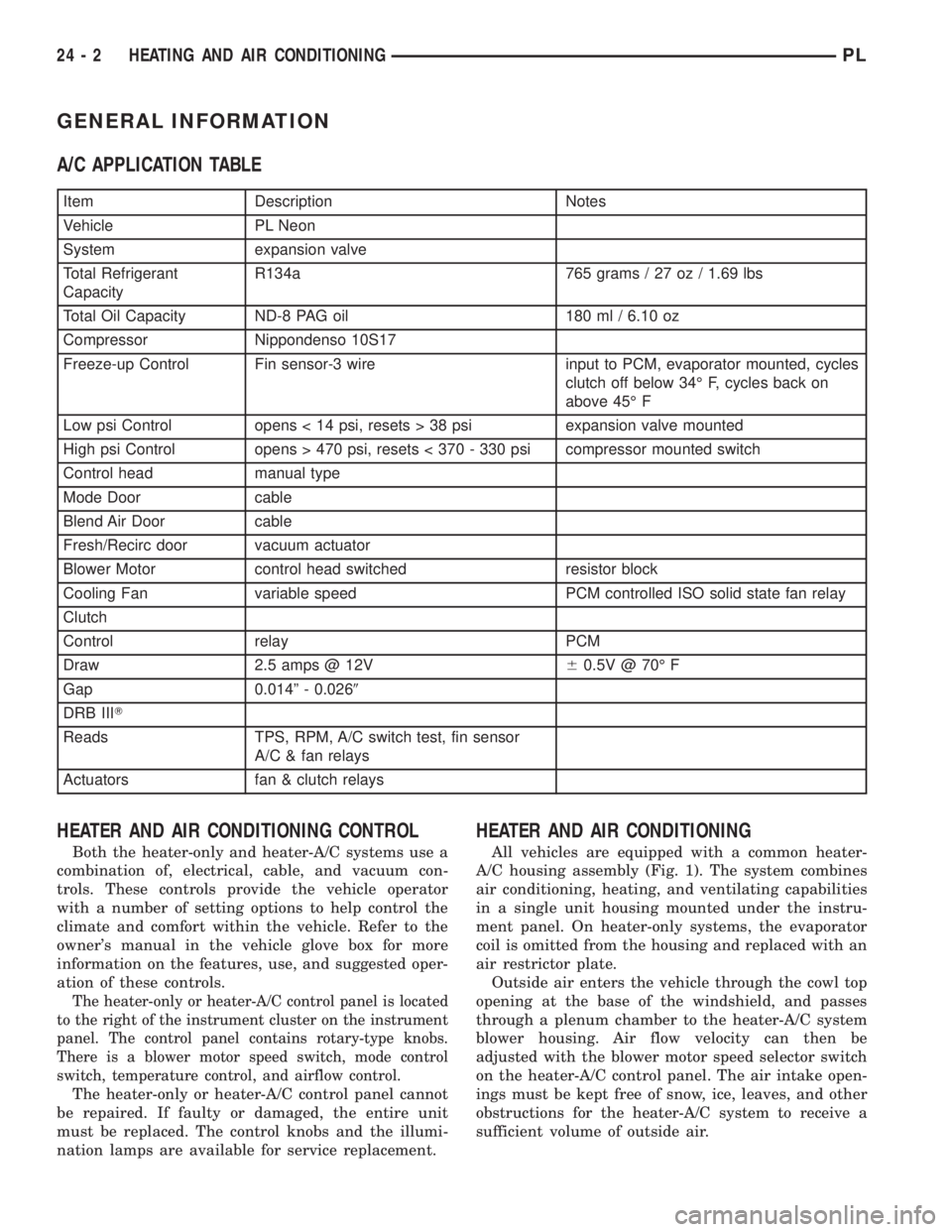

GENERAL INFORMATION

A/C APPLICATION TABLE

Item Description Notes

Vehicle PL Neon

System expansion valve

Total Refrigerant

CapacityR134a 765 grams / 27 oz / 1.69 lbs

Total Oil Capacity ND-8 PAG oil 180 ml / 6.10 oz

Compressor Nippondenso 10S17

Freeze-up Control Fin sensor-3 wire input to PCM, evaporator mounted, cycles

clutch off below 34É F, cycles back on

above 45É F

Low psi Control opens < 14 psi, resets > 38 psi expansion valve mounted

High psi Control opens > 470 psi, resets < 370 - 330 psi compressor mounted switch

Control head manual type

Mode Door cable

Blend Air Door cable

Fresh/Recirc door vacuum actuator

Blower Motor control head switched resistor block

Cooling Fan variable speed PCM controlled ISO solid state fan relay

Clutch

Control relay PCM

Draw 2.5 amps @ 12V60.5V @ 70É F

Gap 0.014º - 0.0269

DRB IIIT

Reads TPS, RPM, A/C switch test, fin sensor

A/C & fan relays

Actuators fan & clutch relays

HEATER AND AIR CONDITIONING CONTROL

Both the heater-only and heater-A/C systems use a

combination of, electrical, cable, and vacuum con-

trols. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or heater-A/C control panel is located

to the right of the instrument cluster on the instrument

panel. The control panel contains rotary-type knobs.

There is a blower motor speed switch, mode control

switch, temperature control, and airflow control.

The heater-only or heater-A/C control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The control knobs and the illumi-

nation lamps are available for service replacement.

HEATER AND AIR CONDITIONING

All vehicles are equipped with a common heater-

A/C housing assembly (Fig. 1). The system combines

air conditioning, heating, and ventilating capabilities

in a single unit housing mounted under the instru-

ment panel. On heater-only systems, the evaporator

coil is omitted from the housing and replaced with an

air restrictor plate.

Outside air enters the vehicle through the cowl top

opening at the base of the windshield, and passes

through a plenum chamber to the heater-A/C system

blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the heater-A/C control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the heater-A/C system to receive a

sufficient volume of outside air.

24 - 2 HEATING AND AIR CONDITIONINGPL