wiper fluid DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 305 of 1285

WINDSHIELD WASHER SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

WINDSHIELD WASHER NOZZLE(S)............8

WINDSHIELD WASHER SYSTEM.............8

DIAGNOSIS AND TESTING

WINDSHIELD WASHER SYSTEM.............9REMOVAL AND INSTALLATION

WINDSHIELD WASHER HOSE................9

WINDSHIELD WASHER NOZZLES.............9

WINDSHIELD WASHER RESERVOIR..........10

WINDSHIELD WASHER PUMP...............10

DESCRIPTION AND OPERATION

WINDSHIELD WASHER NOZZLE(S)

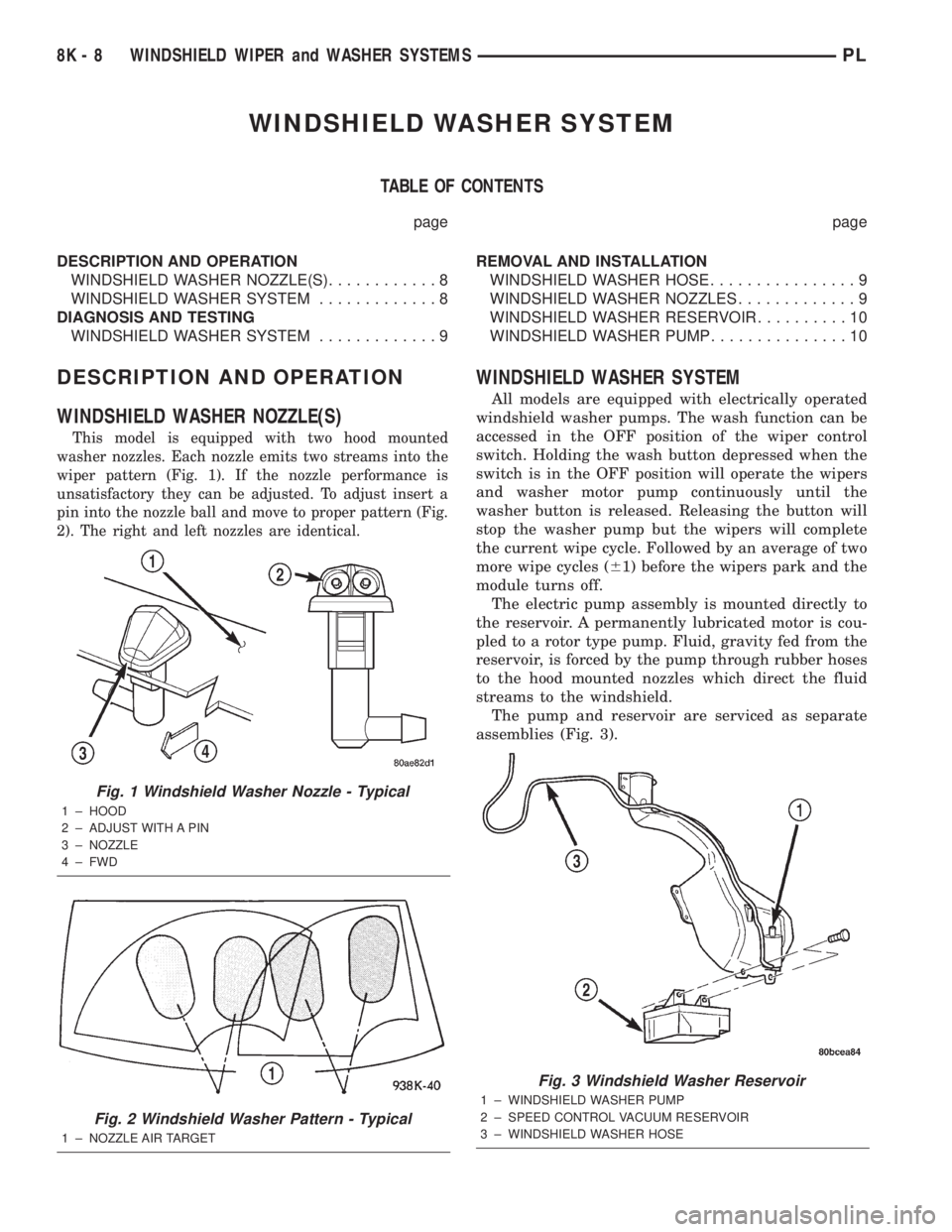

This model is equipped with two hood mounted

washer nozzles. Each nozzle emits two streams into the

wiper pattern (Fig. 1). If the nozzle performance is

unsatisfactory they can be adjusted. To adjust insert a

pin into the nozzle ball and move to proper pattern (Fig.

2). The right and left nozzles are identical.

WINDSHIELD WASHER SYSTEM

All models are equipped with electrically operated

windshield washer pumps. The wash function can be

accessed in the OFF position of the wiper control

switch. Holding the wash button depressed when the

switch is in the OFF position will operate the wipers

and washer motor pump continuously until the

washer button is released. Releasing the button will

stop the washer pump but the wipers will complete

the current wipe cycle. Followed by an average of two

more wipe cycles (61) before the wipers park and the

module turns off.

The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated motor is cou-

pled to a rotor type pump. Fluid, gravity fed from the

reservoir, is forced by the pump through rubber hoses

to the hood mounted nozzles which direct the fluid

streams to the windshield.

The pump and reservoir are serviced as separate

assemblies (Fig. 3).

Fig. 1 Windshield Washer Nozzle - Typical

1 ± HOOD

2 ± ADJUST WITH A PIN

3 ± NOZZLE

4 ± FWD

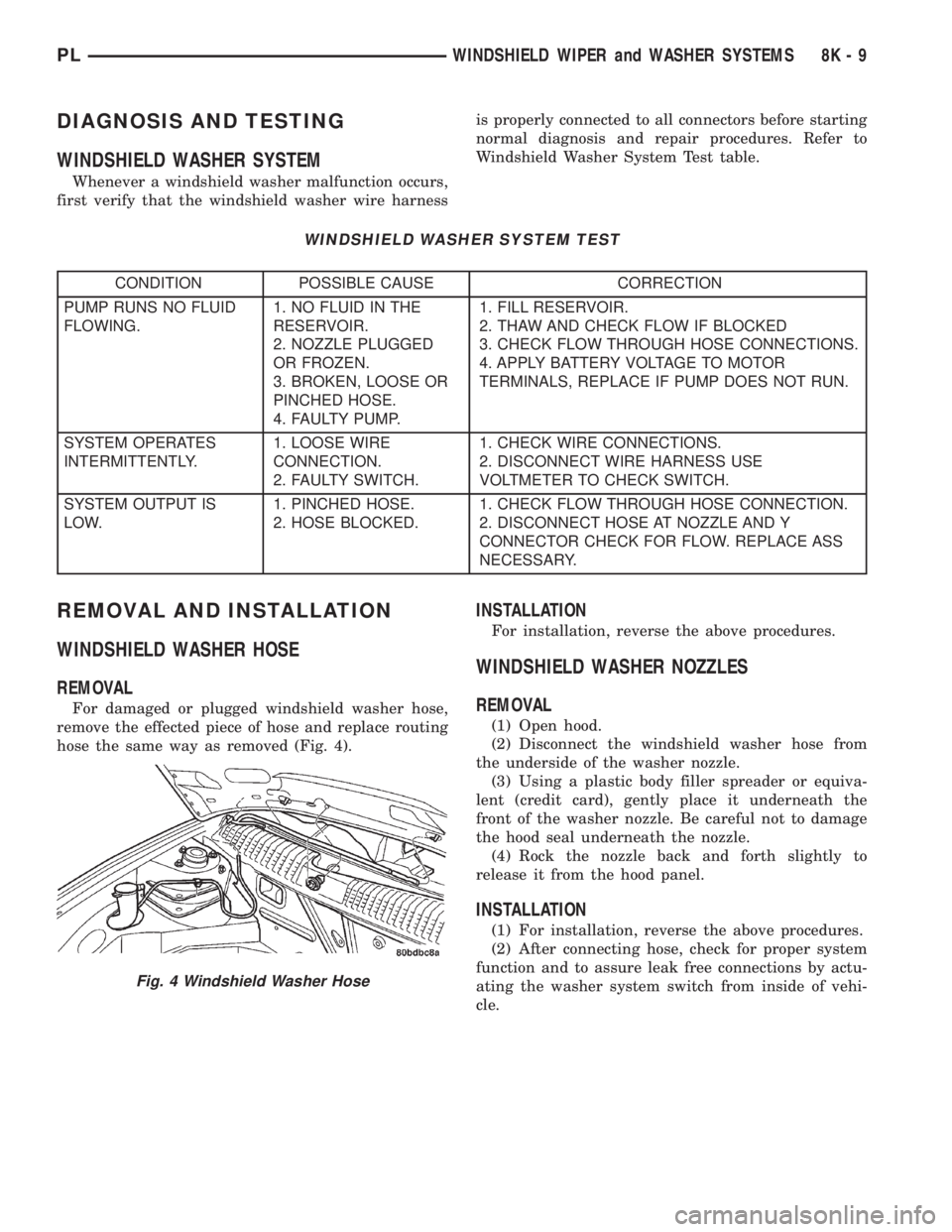

Fig. 2 Windshield Washer Pattern - Typical

1 ± NOZZLE AIR TARGET

Fig. 3 Windshield Washer Reservoir

1 ± WINDSHIELD WASHER PUMP

2 ± SPEED CONTROL VACUUM RESERVOIR

3 ± WINDSHIELD WASHER HOSE

8K - 8 WINDSHIELD WIPER and WASHER SYSTEMSPL

Page 306 of 1285

DIAGNOSIS AND TESTING

WINDSHIELD WASHER SYSTEM

Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harnessis properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer System Test table.

WINDSHIELD WASHER SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

PUMP RUNS NO FLUID

FLOWING.1. NO FLUID IN THE

RESERVOIR.

2. NOZZLE PLUGGED

OR FROZEN.

3. BROKEN, LOOSE OR

PINCHED HOSE.

4. FAULTY PUMP.1. FILL RESERVOIR.

2. THAW AND CHECK FLOW IF BLOCKED

3. CHECK FLOW THROUGH HOSE CONNECTIONS.

4. APPLY BATTERY VOLTAGE TO MOTOR

TERMINALS, REPLACE IF PUMP DOES NOT RUN.

SYSTEM OPERATES

INTERMITTENTLY.1. LOOSE WIRE

CONNECTION.

2. FAULTY SWITCH.1. CHECK WIRE CONNECTIONS.

2. DISCONNECT WIRE HARNESS USE

VOLTMETER TO CHECK SWITCH.

SYSTEM OUTPUT IS

LOW.1. PINCHED HOSE.

2. HOSE BLOCKED.1. CHECK FLOW THROUGH HOSE CONNECTION.

2. DISCONNECT HOSE AT NOZZLE AND Y

CONNECTOR CHECK FOR FLOW. REPLACE ASS

NECESSARY.

REMOVAL AND INSTALLATION

WINDSHIELD WASHER HOSE

REMOVAL

For damaged or plugged windshield washer hose,

remove the effected piece of hose and replace routing

hose the same way as removed (Fig. 4).

INSTALLATION

For installation, reverse the above procedures.

WINDSHIELD WASHER NOZZLES

REMOVAL

(1) Open hood.

(2) Disconnect the windshield washer hose from

the underside of the washer nozzle.

(3) Using a plastic body filler spreader or equiva-

lent (credit card), gently place it underneath the

front of the washer nozzle. Be careful not to damage

the hood seal underneath the nozzle.

(4) Rock the nozzle back and forth slightly to

release it from the hood panel.

INSTALLATION

(1) For installation, reverse the above procedures.

(2) After connecting hose, check for proper system

function and to assure leak free connections by actu-

ating the washer system switch from inside of vehi-

cle.

Fig. 4 Windshield Washer Hose

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 9

Page 909 of 1285

(25) Turn the key to OFF and remove the scan tool

from the vehicle.

(26) Test the operation of the horn, wipers and any

other functions that are steering column operated. If

applicable, reset the radio and the clock.

(27) If the steering column is a tilt column, verify

the tilt mechanism operates properly.

(28) Road test the vehicle to ensure proper opera-

tion of the steering system and the speed control sys-

tem.

STEERING COLUMN LOWER COUPLING

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section and in STEERING

GEAR.

REMOVAL

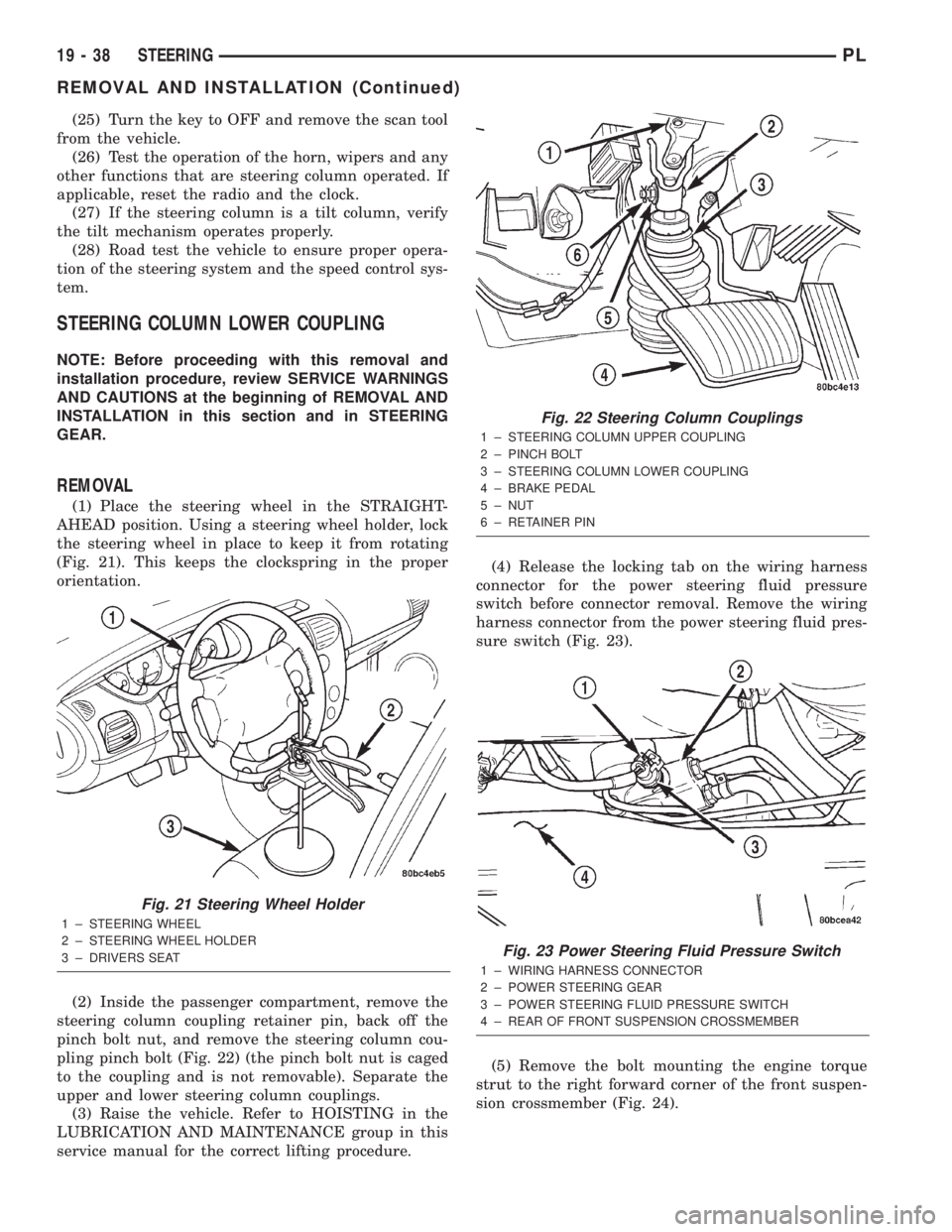

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 21). This keeps the clockspring in the proper

orientation.

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 22) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.(4) Release the locking tab on the wiring harness

connector for the power steering fluid pressure

switch before connector removal. Remove the wiring

harness connector from the power steering fluid pres-

sure switch (Fig. 23).

(5) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 24).

Fig. 21 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 22 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 23 Power Steering Fluid Pressure Switch

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 38 STEERINGPL

REMOVAL AND INSTALLATION (Continued)