engine DODGE NEON 2005 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: NEON, Model: DODGE NEON 2005 2.GPages: 246, PDF Size: 3.69 MB

Page 185 of 246

humidity accumulating on the radiator and being vapor-

ized when the thermostat opens, allowing hot coolant to

enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

²Do not overfill the coolant recovery bottle.

²Check coolant freeze point in the radiator and in the

coolant recovery bottle. If antifreeze needs to be

added, contents of coolant recovery bottle must also be

protected against freezing.

²If frequent coolant additions are required, or if the

level in the coolant recovery bottle does not drop when

the engine cools, the cooling system should be pres-

sure tested for leaks.

²Maintain coolant concentration at 50% HOAT engine

coolant (minimum) and distilled water for proper

corrosion protection of your engine which contains

aluminum components.

²Make sure that the radiator and coolant recovery

bottle overflow hoses are not kinked or obstructed.

²Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean, also.

²Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor gas

mileage, and increased emissions.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, checking, tear, cuts, abrasions,

and excessive swelling indicate deterioration of the rub-

ber.

Pay particular attention to the hoses nearest to high heat

sources such as the exhaust manifold. Inspect hose rout-

ing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

MAINTAINING YOUR VEHICLE 185

7

Page 187 of 246

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

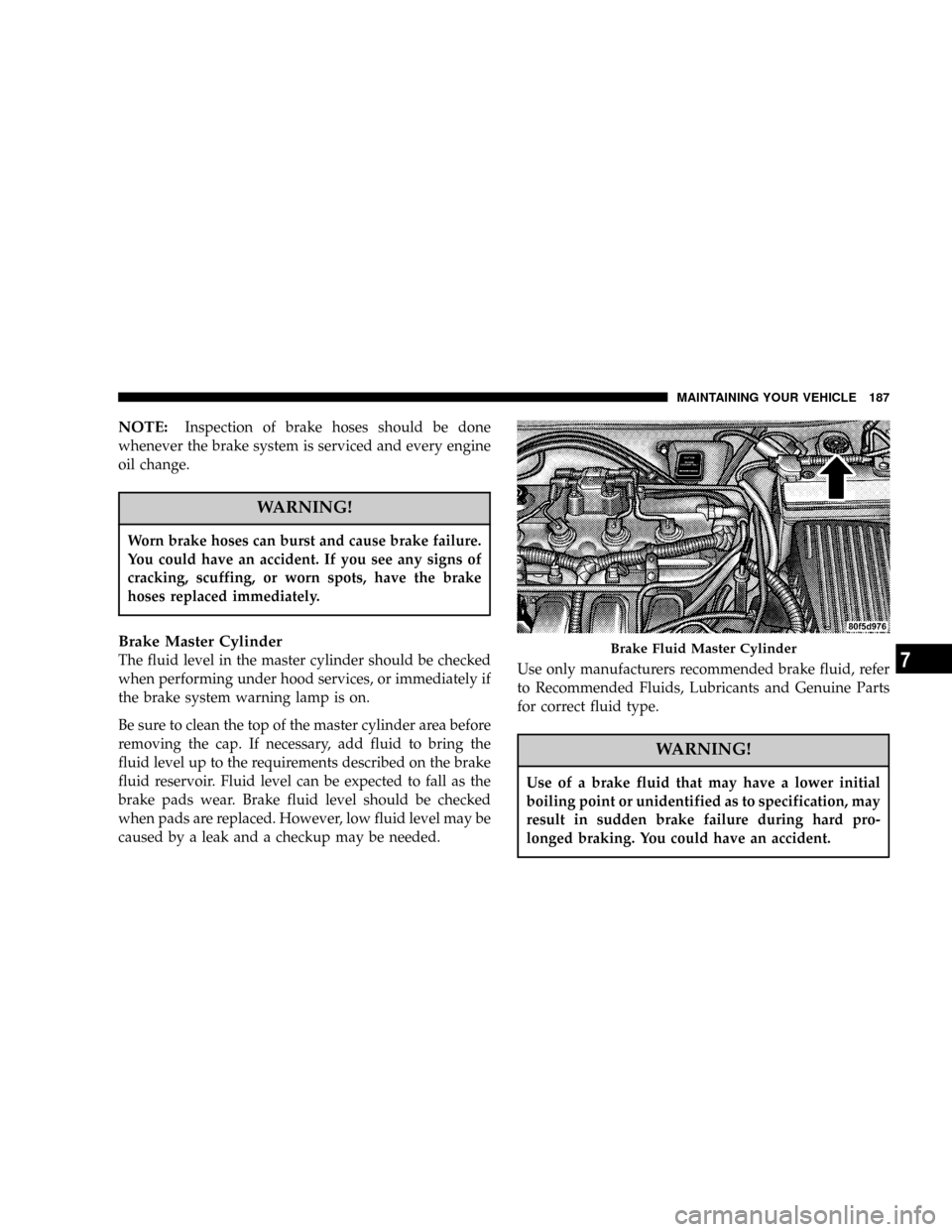

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. Fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.Use only manufacturers recommended brake fluid, refer

to Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

WARNING!

Use of a brake fluid that may have a lower initial

boiling point or unidentified as to specification, may

result in sudden brake failure during hard pro-

longed braking. You could have an accident.

Brake Fluid Master Cylinder

MAINTAINING YOUR VEHICLE 187

7

Page 188 of 246

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Do not allow petroleum based fluid to contaminate the

brake fluid as seal damage will result!

Automatic Transaxle

All front wheel drive vehicles have a transaxle and

differential assembly contained within a single housing.

Selection of Lubricant

It is important that the proper lubricant is used in the

transaxle to assure optimum transaxle performance. Use

only manufacturers recommended transmission fluid,

refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type. It is important that the

transmission fluid be maintained at the prescribed level

using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

Fluid Level Check

The fluid level in the automatic transaxle should be

checked whenever the vehicle is serviced. Operation with

an improper fluid level will greatly reduce the life of the

transaxle and of the fluid.

Procedure for Checking Fluid Level

Check the fluid level while the transmission is at normal

operating temperature. This occurs after at least 15 miles

(25 km) of driving. At normal operating temperature,

which is approximately 180ÉF ( 82ÉC), the fluid cannot be

held comfortably between the fingertips.

188 MAINTAINING YOUR VEHICLE

Page 189 of 246

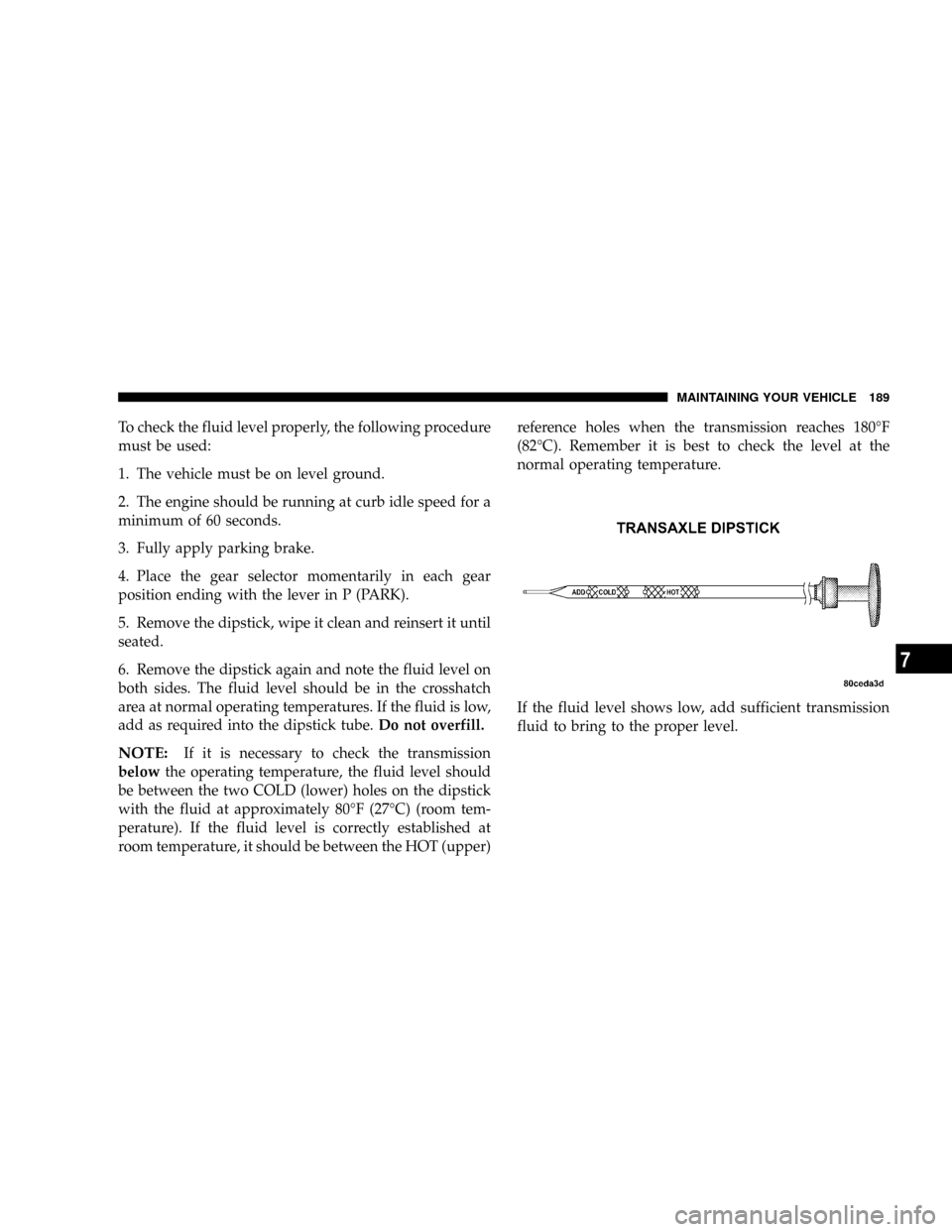

To check the fluid level properly, the following procedure

must be used:

1. The vehicle must be on level ground.

2. The engine should be running at curb idle speed for a

minimum of 60 seconds.

3. Fully apply parking brake.

4. Place the gear selector momentarily in each gear

position ending with the lever in P (PARK).

5. Remove the dipstick, wipe it clean and reinsert it until

seated.

6. Remove the dipstick again and note the fluid level on

both sides. The fluid level should be in the crosshatch

area at normal operating temperatures. If the fluid is low,

add as required into the dipstick tube.Do not overfill.

NOTE:If it is necessary to check the transmission

belowthe operating temperature, the fluid level should

be between the two COLD (lower) holes on the dipstick

with the fluid at approximately 80ÉF (27ÉC) (room tem-

perature). If the fluid level is correctly established at

room temperature, it should be between the HOT (upper)reference holes when the transmission reaches 180ÉF

(82ÉC). Remember it is best to check the level at the

normal operating temperature.

If the fluid level shows low, add sufficient transmission

fluid to bring to the proper level.

MAINTAINING YOUR VEHICLE 189

7

Page 195 of 246

Cleaning Plastic Instrument Cluster Lenses

The lenses in front of the instruments in the vehicle are

molded in clear plastic. When cleaning the lenses, care

must be taken to avoid scratching the plastic.

1. Clean with a wet soft rag. A mild soap solution may be

used, but do not use high alcohol content of abrasive

cleaners. If soap is used, wipe clean with a clean damp

rag.

2. Dry with a soft tissue.

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the fabric.

Sun damage will also weaken the fabric.

If the belts need cleaning, use a mild soap solution or

lukewarm water. Do not remove the belts from the

vehicle to wash them.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

FUSES

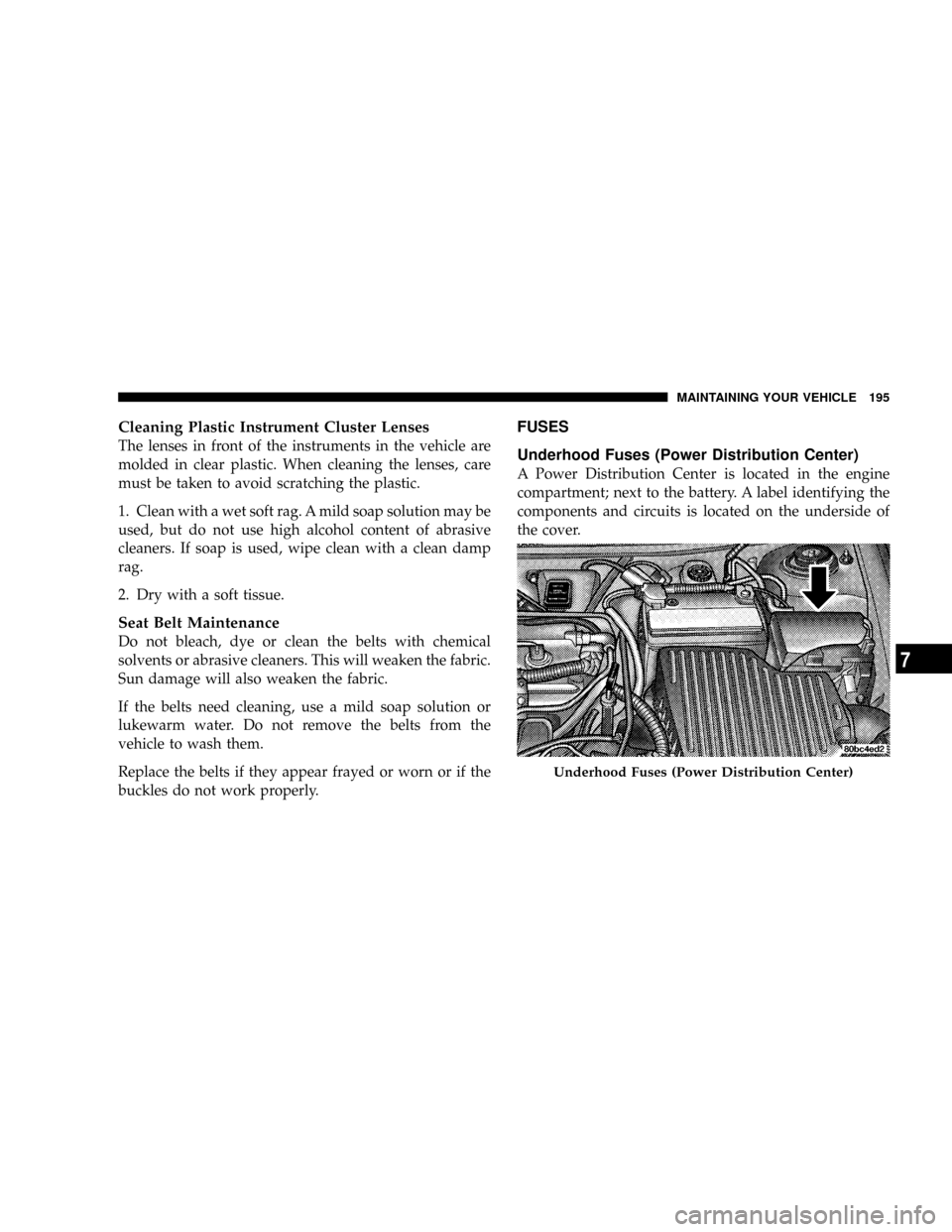

Underhood Fuses (Power Distribution Center)

A Power Distribution Center is located in the engine

compartment; next to the battery. A label identifying the

components and circuits is located on the underside of

the cover.

Underhood Fuses (Power Distribution Center)

MAINTAINING YOUR VEHICLE 195

7

Page 197 of 246

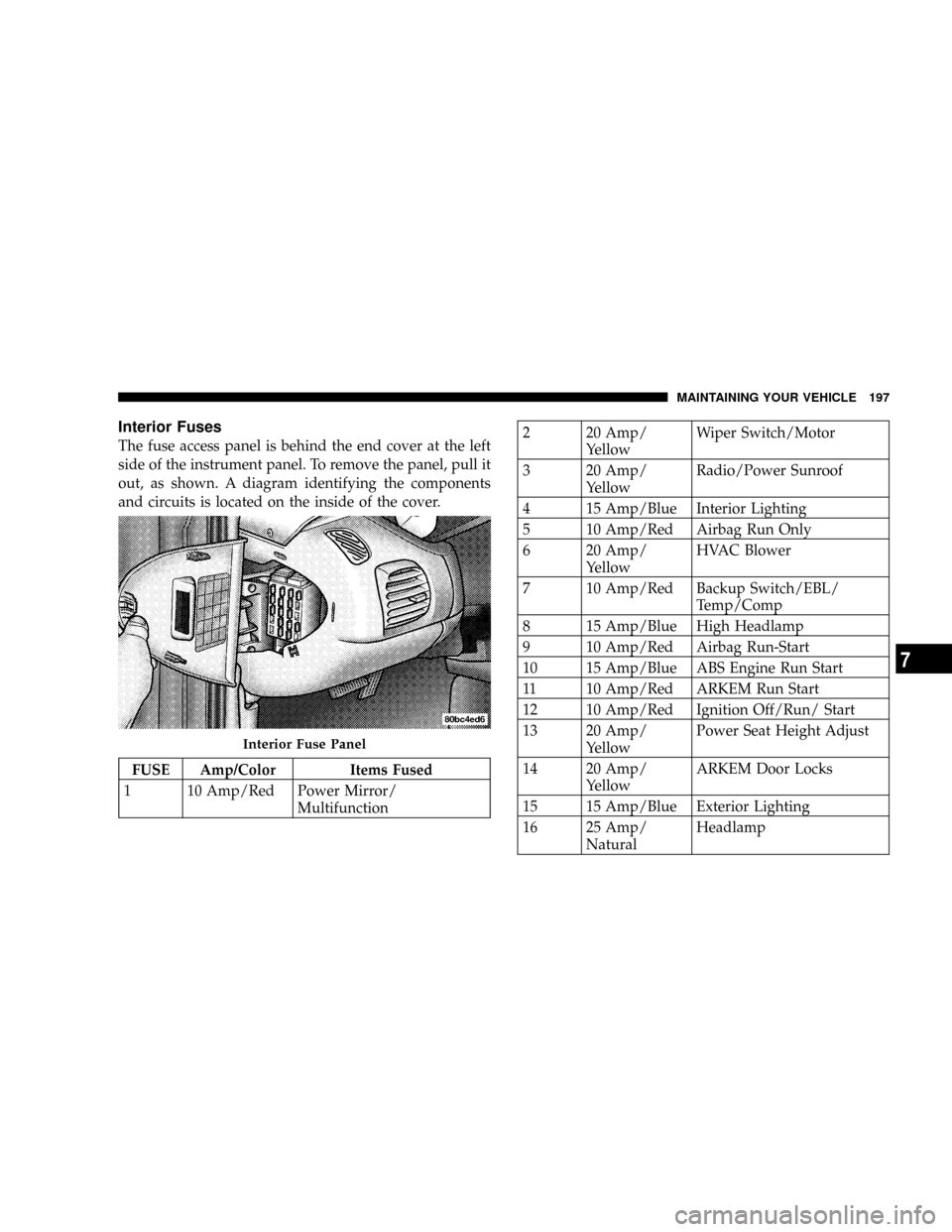

Interior Fuses

The fuse access panel is behind the end cover at the left

side of the instrument panel. To remove the panel, pull it

out, as shown. A diagram identifying the components

and circuits is located on the inside of the cover.

FUSE Amp/Color Items Fused

1 10 Amp/Red Power Mirror/

Multifunction

2 20 Amp/

YellowWiper Switch/Motor

3 20 Amp/

YellowRadio/Power Sunroof

4 15 Amp/Blue Interior Lighting

5 10 Amp/Red Airbag Run Only

6 20 Amp/

YellowHVAC Blower

7 10 Amp/Red Backup Switch/EBL/

Temp/Comp

8 15 Amp/Blue High Headlamp

9 10 Amp/Red Airbag Run-Start

10 15 Amp/Blue ABS Engine Run Start

11 10 Amp/Red ARKEM Run Start

12 10 Amp/Red Ignition Off/Run/ Start

13 20 Amp/

YellowPower Seat Height Adjust

14 20 Amp/

YellowARKEM Door Locks

15 15 Amp/Blue Exterior Lighting

16 25 Amp/

NaturalHeadlamp

Interior Fuse Panel

MAINTAINING YOUR VEHICLE 197

7

Page 202 of 246

FLUIDS AND CAPACITIES

U.S. Metric

Fuel (Approximate)

2.0L Engines 87 Octane 12.5 Gallons 47.5 Liters

Engine Oil-With Filter

2.0 Liter Engines (SAE 5W-20, API Certified Engine Oil) 4.5 qts 4.3 Liters

Cooling System *

2.0 Liter Engines (MopartAntifreeze/Coolant 5 Year/100,000

Mile Formula), or equivalent.6.5 qts 6.2 Liters

* Includes heater and coolant recovery bottle filled to MAX level.

202 MAINTAINING YOUR VEHICLE

Page 203 of 246

RECOMMENDED FLUIDS, LUBRICANTS AND

GENUINE PARTS

Engine

Component Fluids, Lubricants and Genuine Parts

Engine Coolant MopartAntifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or-

ganic Additive Technology) or equivalent

Engine Oil Use API Certified SAE 5W-20 Engine Oil. Refer to your engine oil filler cap

for correct SAE grade meeting DaimlerChrysler Material Standard MS-6395.

Engine Oil Filter Mopar 4105409 or equivalent.

Spark Plugs Refer to the Vehicle Emission Control Information label in the engine com-

partment.

Fuel Selection 87 Octane.

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transmission MopartATF+4 Automatic Transmission Fluid or equivalent.

Manual Transmission Fluid MopartATF+4 Automatic Transmission Fluid or equivalent.

Brake Master Cylinder MopartDOT 3, SAE J1703 should be used. If DOT 3, SAE J1703 brake

fluid is not available, then DOT 4 is acceptable. Use only recommended

brake fluids or equivalent.

Power Steering Reservoir MopartATF+4 Automatic Transmission Fluid or equivalent

MAINTAINING YOUR VEHICLE 203

7

Page 206 of 246

EMISSION CONTROL SYSTEM MAINTENANCE

The ªScheduledº maintenance services, listed inbold

typemust be done at the times or mileages specified to

assure the continued proper functioning of the emission

control system. These, and all other maintenance services

included in this manual, should be done to provide best

vehicle performance and reliability. More frequent main-

tenance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

Inspection and service also should be done any time a

malfunction is suspected.

NOTE:Maintenance, replacement, or repair of the

emission control devices and systems on your vehicle

may be performed by any automotive repair establish-

ment or individual using any automotive part which has

been certified pursuant to U.S. EPA or, in the State of

California, California Air Resources Board regulations.

MAINTENANCE SCHEDULES

There are two maintenance schedules that show the

requiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are operated

under the conditions that are listed below and at the

beginning of the schedule.

²Day or night temperatures are below 32ÉF (0ÉC).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16.2 km).

²More than 50% of your driving is sustained high

speeds during hot weather, above 90ÉF (32ÉC).

²Trailer towing.²L

²Taxi, police or delivery service (commercial ser-

vices).²L

²Off-road or desert operation.

206 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 207 of 246

²If equipped for and operating with E-85 (ethanol)

fuel.

NOTE:IfANYof these apply to you then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule ªBº of the

9Maintenance Schedules9section of this manual.

NOTE:IFANYof these apply to you then flush and

replace the engine coolant every 102,000 miles (163 000

km) or 60 months, whichever comes first, and follow

schedule ªBº of the9Maintenance Schedules9section of

this manual.

NOTE:Most vehicles are operated under the conditions

listed for Schedule9B9.

Second is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under Sched-

ule9B9.

Use the schedule that best describes your driving condi-

tions. Where time and mileage are listed, follow the

interval that occurs first.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²

Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²

Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

MAINTENANCE SCHEDULES 207

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S