power steering DODGE NEON 2005 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: NEON, Model: DODGE NEON 2005 2.GPages: 246, PDF Size: 3.69 MB

Page 7 of 246

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

CONTENTS

mA Word About Your Keys................. 9

NIgnition Key Removal................... 9

NLocking Doors With The Key..............10

NKey-In-Ignition Reminder................11

mSentry Key............................11

NReplacement Keys......................12

NSentry Key Programming.................12

NGeneral Information....................13

mSteering Wheel Lock Ð If Equipped.........13

NTo Manually Lock The Steering Wheel.......13

NTo Release The Steering Wheel Lock.........13NAutomatic Transaxle Ignition Interlock System . .14

mDoor Locks...........................14

NManual Door Locks.....................14

NPower Door Locks Ð If Equipped..........15

NCentral Locking/Unlocking Ð If Equipped....15

NAutomatic Door Locks Ð If Equipped.......16

N

Child-Protection Door Lock System (Rear Doors).17

mInternal Emergency Trunk Lid Release.......18

mRemote Trunk Lid Release Ð If Equipped.....18

mRemote Keyless Entry Ð If Equipped........19

NTo Unlock The Doors...................19

2

Page 38 of 246

²In moderate to severe side collisions, the side airbag

inflator on the crash side of the vehicle is triggered by

the appropriate SIACM, releasing a quantity of non-

toxic gas. The inflating side airbag exits through the

seat seam into the space between the occupant and the

door. The side airbag moves at a very high speed and

with such a high force, that it could injure you if you

are not seated properly, or if items are positioned in

the area where the side airbag inflates. This especially

applies to children.

Enhanced Accident Response Time Ð If Equipped

If the airbags deploy after an impact and the electrical

system remains functional, vehicles equipped with

power door locks will unlock automatically. In addition,

approximately 10 seconds after the vehicle has stopped

moving, the interior lights will light until the ignition

switch is turned off.

Maintaining Your Airbag Systems

WARNING!

²Modifications to any part of the airbag system

could cause it to fail when you need it. You could

be injured because the airbags are not there to

protect you. Do not modify the components or

wiring, including adding any kind of badges or

stickers to the steering wheel hub trim cover or

the upper right side of the instrument panel. Do

not modify the front bumper, vehicle body struc-

ture, or frame.

²You need proper knee impact protection in a

collision. Do not mount or locate any aftermarket

equipment on or behind the knee bolster.

²It is dangerous to try to repair any part of the

airbag system yourself. Be sure to tell anyone who

works on your vehicle that it has airbags.

38 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 50 of 246

NPassing Light.........................62

mWindshield Wipers And Washers...........63

NWindshield Washers....................63

NMist Function.........................63

NIntermittent Wiper System................64

NLo Speed Wipers.......................64

NHi Speed Wipers.......................64

mTilt Steering Column.....................64

mElectronic Speed Control Ð If Equipped......65

NTo Activate...........................65

NTo Set At A Desired Speed................66NTo Deactivate.........................66

NTo Resume Speed......................66

NTo Vary The Speed Setting................66

NManual Transaxle......................67

NTo Accelerate For Passing................67

mPower Sunroof Ð If Equipped.............68

NSunroof Maintenance....................69

NWind Buffeting........................69

mConsole Features.......................70

NAsh Receiver And Cigar Lighter............70

50 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 112 of 246

mPower Steering........................124

mTire Safety Information..................124

NTire Markings........................124

NTire Identification Number (TIN)..........127

NTire Loading And Tire Pressure...........128

mTiresÐGeneral Information...............132

NTire Pressure.........................132

NTire Inflation Pressures.................133

NRadial-Ply Tires......................135

NCompact Spare Tire Ð If Equipped.........135

NLimited Use Spare Ð If Equipped.........136

NTire Spinning........................137

NTread Wear Indicators..................137

NReplacement Tires.....................138

NAlignment And Balance.................139

mTire Chains...........................139

mSnow Tires...........................140

mTire Rotation Recommendations...........141

mFuel Requirements.....................141

NSpark Knock.........................142

NReformulated Gasoline.................142

NGasoline/Oxygenate Blends..............142

NMMT In Gasoline.....................143

NMaterials Added To Fuel................143

NFuel System Cautions..................143

NCarbon Monoxide Warnings..............144

mAdding Fuel..........................144

NFuel Tank Filler Cap...................144

mVehicle Loading.......................146

mTrailer Towing........................146

112 STARTING AND OPERATING

Page 124 of 246

POWER STEERING

The power assisted steering system of your vehicle

provides mechanical steering capability in the event

power assist is lost.

If for some reason the hydraulic pressure is interrupted,

it will still be possible to steer your vehicle. Under these

conditions you will observe a substantial increase in

steering effort.

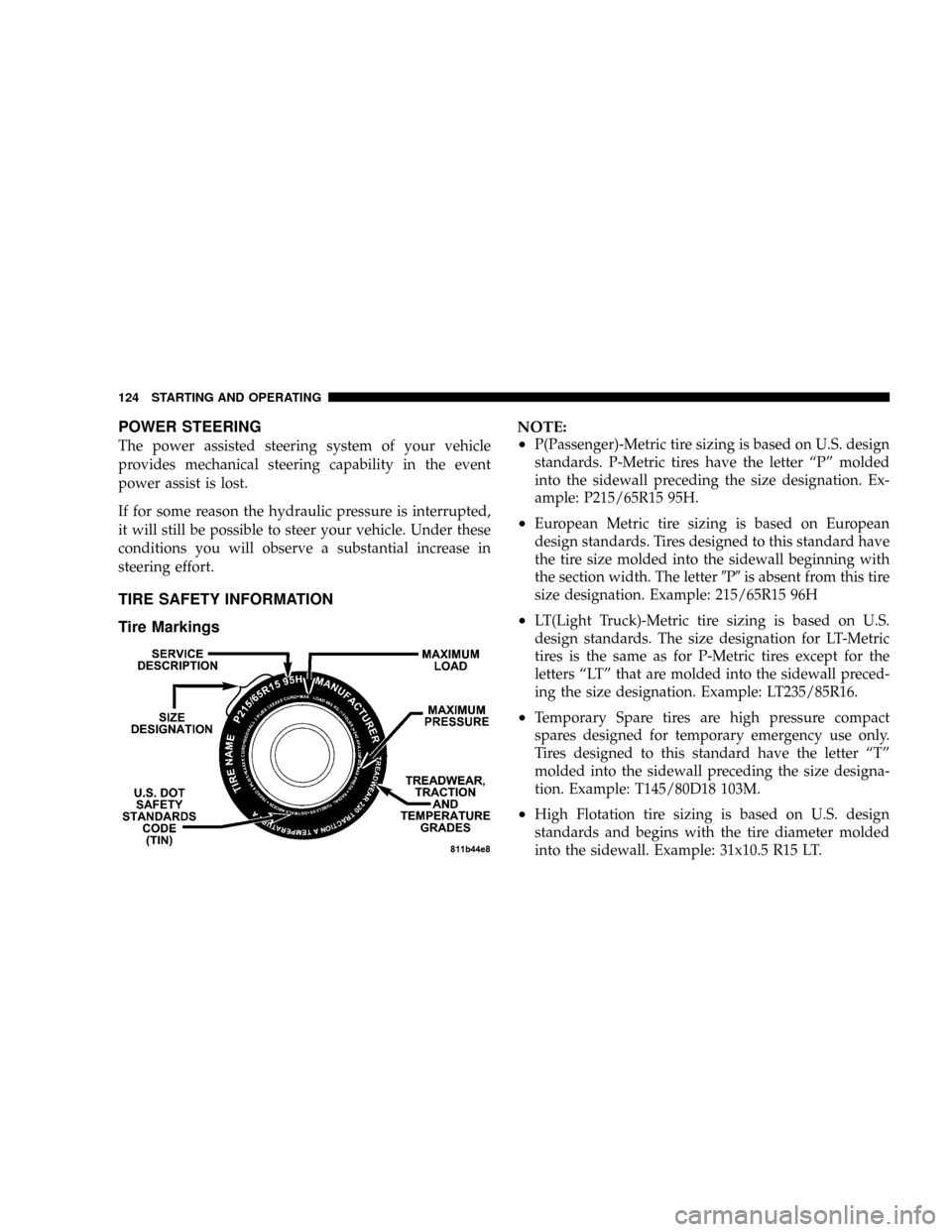

TIRE SAFETY INFORMATION

Tire MarkingsNOTE:

²

P(Passenger)-Metric tire sizing is based on U.S. design

standards. P-Metric tires have the letter ªPº molded

into the sidewall preceding the size designation. Ex-

ample: P215/65R15 95H.

²European Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with

the section width. The letter9P9is absent from this tire

size designation. Example: 215/65R15 96H

²LT(Light Truck)-Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters ªLTº that are molded into the sidewall preced-

ing the size designation. Example: LT235/85R16.

²Temporary Spare tires are high pressure compact

spares designed for temporary emergency use only.

Tires designed to this standard have the letter ªTº

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.

²High Flotation tire sizing is based on U.S. design

standards and begins with the tire diameter molded

into the sidewall. Example: 31x10.5 R15 LT.

124 STARTING AND OPERATING

Page 163 of 246

MAINTAINING YOUR VEHICLE

CONTENTS

m2.0L Engine Compartment...............165

mOnboard Diagnostic System Ð OBD II......166

mEmissions Inspection And Maintenance

Programs

............................167

mReplacement Parts.....................168

mDealer Service........................168

mMaintenance Procedures.................169

NEngine Oil..........................169

NIgnition Wiring System.................175

NCrankcase Emission Control System........175

NFuel Filter..........................175

NAir Cleaner Element (Filter)..............175NMaintenance-Free Battery................176

NAir Conditioner......................177

NPower Steering Fluid Check..............178

NFront Suspension Ball Joints..............178

NBody Lubrication.....................178

NWindshield Wiper Blades................179

NWindshield Wiper Blade Replacement.......179

NWindshield Washer Aiming..............180

NWindshield Washer Reservoir.............180

NExhaust System......................180

NCooling System.......................181

7

Page 178 of 246

Power Steering Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Recommended Fluids, Lubricants, and

Genuine Parts for correct fluid types.

Front Suspension Ball Joints

There are two front suspension lower ball joints that are

permanently lubricated. Inspect these ball joints when-

ever under-vehicle service is done. Damaged seals

should be replaced to prevent leakage or grease contami-

nation.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, trunk and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

178 MAINTAINING YOUR VEHICLE

Page 186 of 246

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could cause failure.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.

186 MAINTAINING YOUR VEHICLE

Page 203 of 246

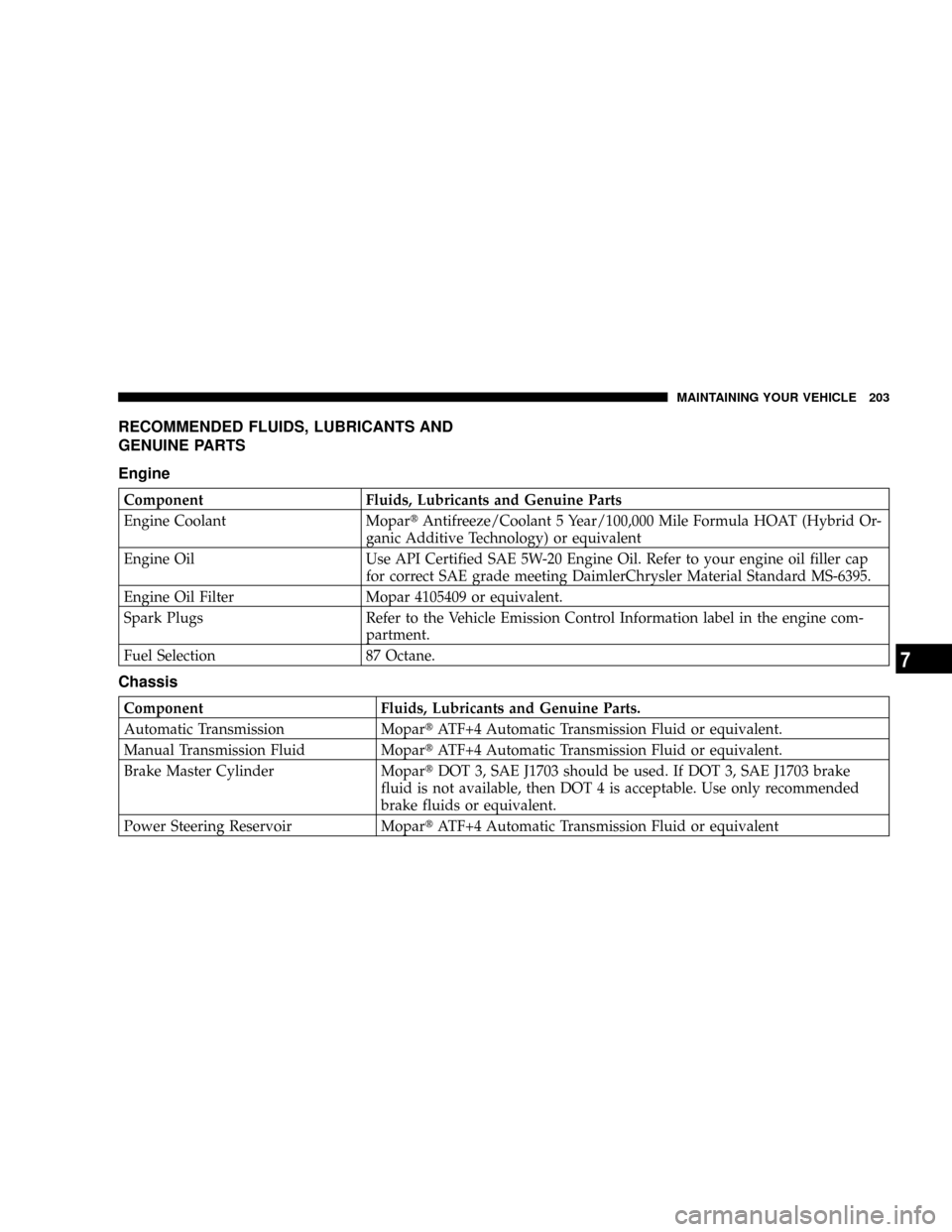

RECOMMENDED FLUIDS, LUBRICANTS AND

GENUINE PARTS

Engine

Component Fluids, Lubricants and Genuine Parts

Engine Coolant MopartAntifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or-

ganic Additive Technology) or equivalent

Engine Oil Use API Certified SAE 5W-20 Engine Oil. Refer to your engine oil filler cap

for correct SAE grade meeting DaimlerChrysler Material Standard MS-6395.

Engine Oil Filter Mopar 4105409 or equivalent.

Spark Plugs Refer to the Vehicle Emission Control Information label in the engine com-

partment.

Fuel Selection 87 Octane.

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transmission MopartATF+4 Automatic Transmission Fluid or equivalent.

Manual Transmission Fluid MopartATF+4 Automatic Transmission Fluid or equivalent.

Brake Master Cylinder MopartDOT 3, SAE J1703 should be used. If DOT 3, SAE J1703 brake

fluid is not available, then DOT 4 is acceptable. Use only recommended

brake fluids or equivalent.

Power Steering Reservoir MopartATF+4 Automatic Transmission Fluid or equivalent

MAINTAINING YOUR VEHICLE 203

7

Page 208 of 246

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and add

as needed.

²Check all lights and all other electrical items for correct

operation.

²Check rubber seals on each side of the radiator for

proper fit.

At Each Oil Change

²

Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension compo-

nents.

²Check the automatic transaxle fluid level.

²Check the manual transaxle fluid level and fill plug

condition.

²Check the coolant level, hoses, and clamps.

208 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S