8L Lamps DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 581 of 2627

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

DOME LAMP

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................26

INSTALLATION.........................26

DOOR AJAR SWITCH

DESCRIPTION.........................27

OPERATION...........................27GLOVE BOX LAMP/SWITCH

REMOVAL.............................27

INSTALLATION.........................28

READING LAMP

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................29

DOME LAMP

DESCRIPTION

The dome lamp is controlled by the instrument

cluster which provides power at all times, regardless

of the ignition switch position. The ground circuit for

the lamp is switched through the integral dome lamp

switch or through the door ajar switches via the

instrument cluster.

The dome lamp lens and bulb are available for ser-

vice replacement. If either of the lamp switch or bulb

holders is faulty or damaged, the dome lamp assem-

bly must be replaced.

For service of the dome lamp bulb, refer to the

appropriate wiring information.

OPERATION

The dome lamp is activated by the door ajar

switches via the instrument cluster. When all of the

doors are closed, the lamp can be activated by

depressing the lens. When any door is open, depress-

ing the lamp lense to activate the lamp switch will

not turn the lamps off.

The instrument cluster monitors the door ajar

switches. When a door is open the instrument cluster

grounds the low side drivers to turn on the lamp.

Upon closing all doors, the instrument cluster ini-

tiates a 30 second timer. If any of the doors are

opened during the ªtime outº cycle, the instrument

cluster will reset the timer until all doors are closed.

The instrument cluster will faid to off when the doors

are closed and the ignition is turned ON, the time

out expires or the power locks are activated.

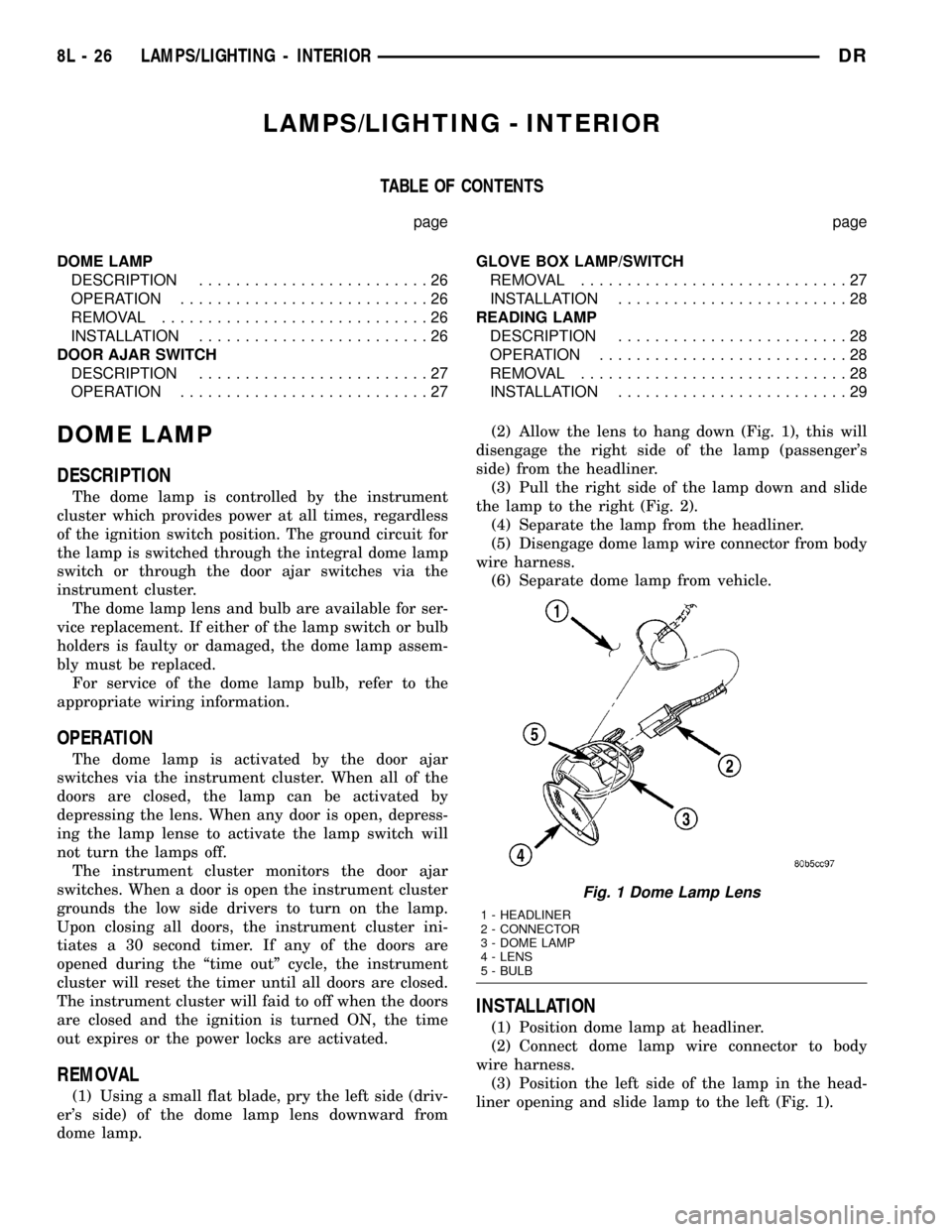

REMOVAL

(1) Using a small flat blade, pry the left side (driv-

er's side) of the dome lamp lens downward from

dome lamp.(2) Allow the lens to hang down (Fig. 1), this will

disengage the right side of the lamp (passenger's

side) from the headliner.

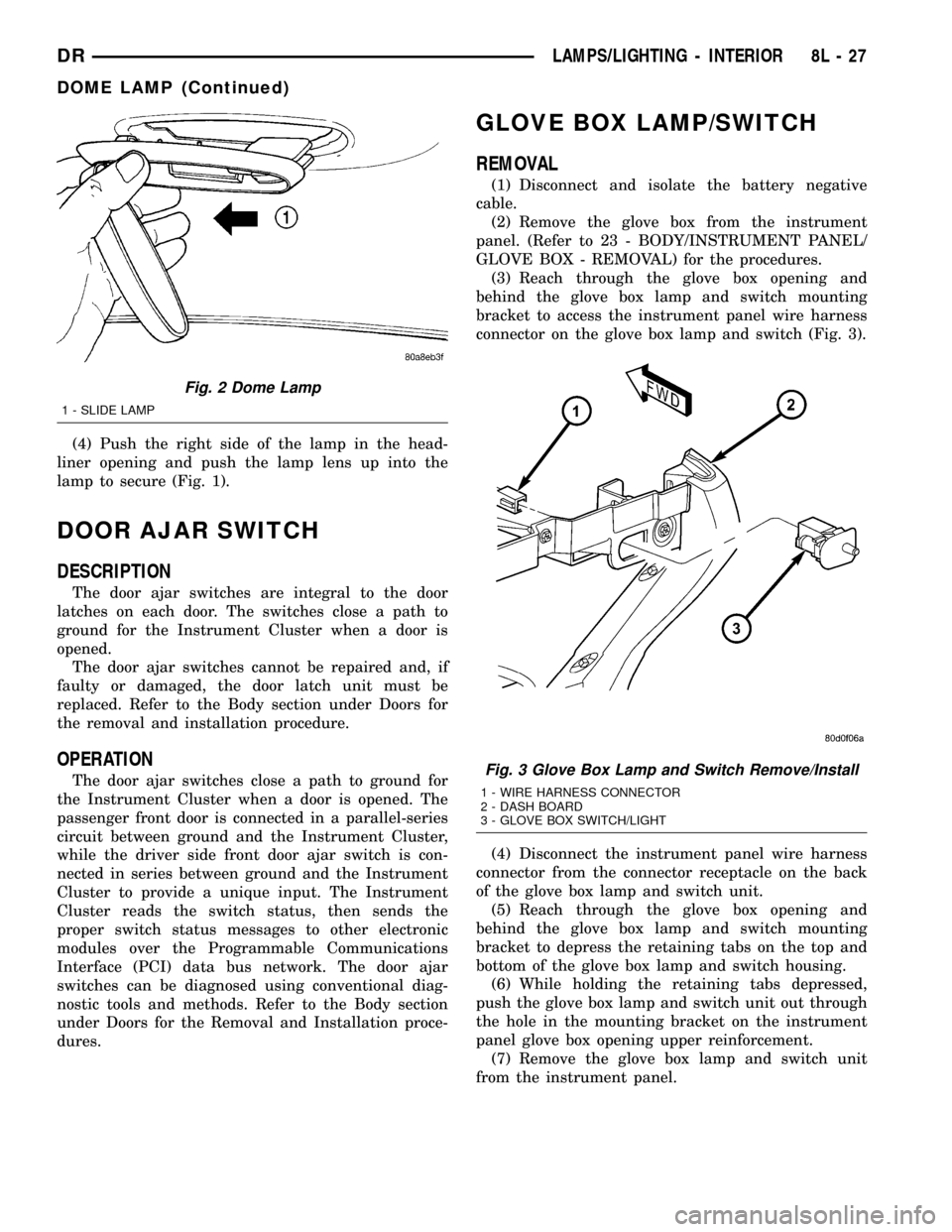

(3) Pull the right side of the lamp down and slide

the lamp to the right (Fig. 2).

(4) Separate the lamp from the headliner.

(5) Disengage dome lamp wire connector from body

wire harness.

(6) Separate dome lamp from vehicle.

INSTALLATION

(1) Position dome lamp at headliner.

(2) Connect dome lamp wire connector to body

wire harness.

(3) Position the left side of the lamp in the head-

liner opening and slide lamp to the left (Fig. 1).

Fig. 1 Dome Lamp Lens

1 - HEADLINER

2 - CONNECTOR

3 - DOME LAMP

4 - LENS

5 - BULB

8L - 26 LAMPS/LIGHTING - INTERIORDR

Page 582 of 2627

(4) Push the right side of the lamp in the head-

liner opening and push the lamp lens up into the

lamp to secure (Fig. 1).

DOOR AJAR SWITCH

DESCRIPTION

The door ajar switches are integral to the door

latches on each door. The switches close a path to

ground for the Instrument Cluster when a door is

opened.

The door ajar switches cannot be repaired and, if

faulty or damaged, the door latch unit must be

replaced. Refer to the Body section under Doors for

the removal and installation procedure.

OPERATION

The door ajar switches close a path to ground for

the Instrument Cluster when a door is opened. The

passenger front door is connected in a parallel-series

circuit between ground and the Instrument Cluster,

while the driver side front door ajar switch is con-

nected in series between ground and the Instrument

Cluster to provide a unique input. The Instrument

Cluster reads the switch status, then sends the

proper switch status messages to other electronic

modules over the Programmable Communications

Interface (PCI) data bus network. The door ajar

switches can be diagnosed using conventional diag-

nostic tools and methods. Refer to the Body section

under Doors for the Removal and Installation proce-

dures.

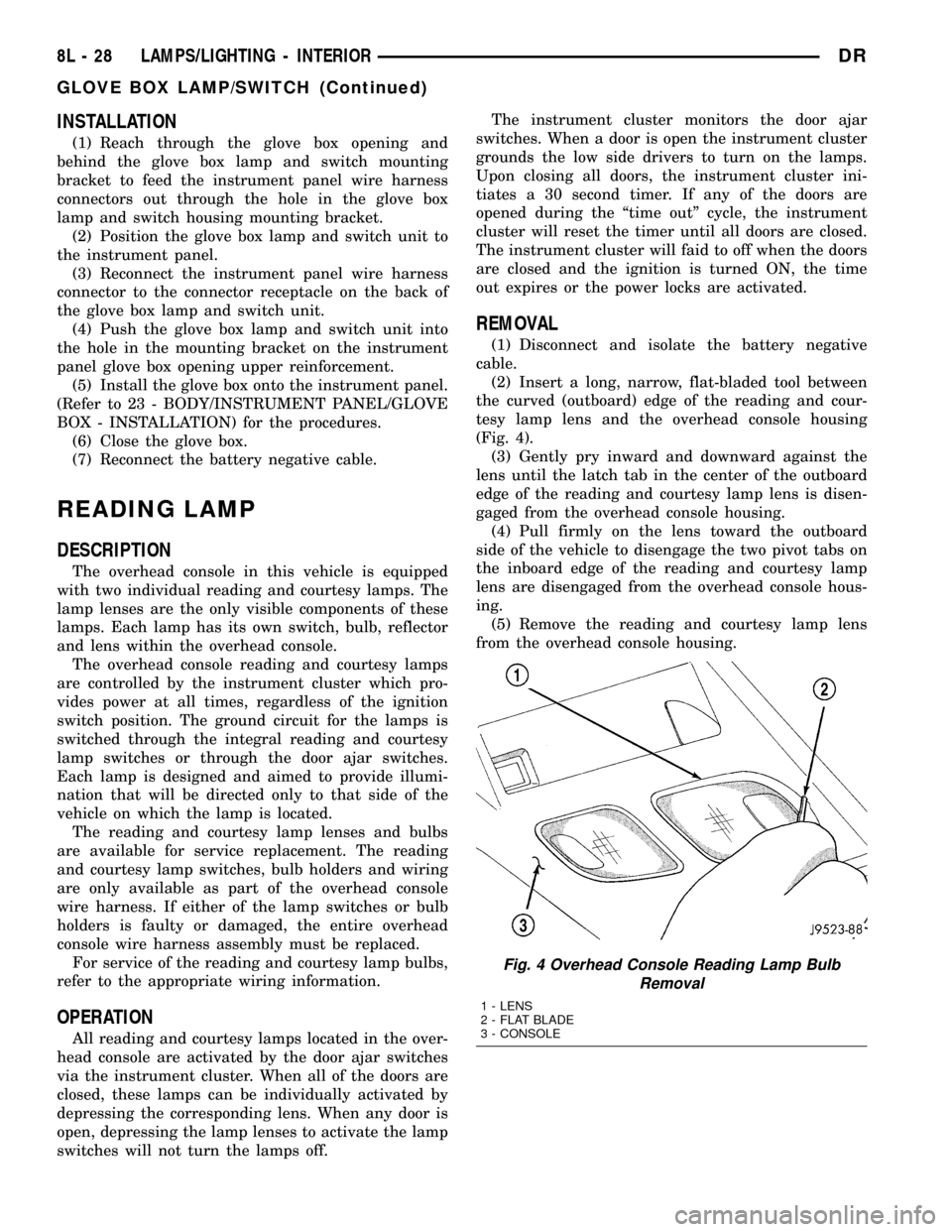

GLOVE BOX LAMP/SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL) for the procedures.

(3) Reach through the glove box opening and

behind the glove box lamp and switch mounting

bracket to access the instrument panel wire harness

connector on the glove box lamp and switch (Fig. 3).

(4) Disconnect the instrument panel wire harness

connector from the connector receptacle on the back

of the glove box lamp and switch unit.

(5) Reach through the glove box opening and

behind the glove box lamp and switch mounting

bracket to depress the retaining tabs on the top and

bottom of the glove box lamp and switch housing.

(6) While holding the retaining tabs depressed,

push the glove box lamp and switch unit out through

the hole in the mounting bracket on the instrument

panel glove box opening upper reinforcement.

(7) Remove the glove box lamp and switch unit

from the instrument panel.

Fig. 2 Dome Lamp

1 - SLIDE LAMP

Fig. 3 Glove Box Lamp and Switch Remove/Install

1 - WIRE HARNESS CONNECTOR

2 - DASH BOARD

3 - GLOVE BOX SWITCH/LIGHT

DRLAMPS/LIGHTING - INTERIOR 8L - 27

DOME LAMP (Continued)

Page 583 of 2627

INSTALLATION

(1) Reach through the glove box opening and

behind the glove box lamp and switch mounting

bracket to feed the instrument panel wire harness

connectors out through the hole in the glove box

lamp and switch housing mounting bracket.

(2) Position the glove box lamp and switch unit to

the instrument panel.

(3) Reconnect the instrument panel wire harness

connector to the connector receptacle on the back of

the glove box lamp and switch unit.

(4) Push the glove box lamp and switch unit into

the hole in the mounting bracket on the instrument

panel glove box opening upper reinforcement.

(5) Install the glove box onto the instrument panel.

(Refer to 23 - BODY/INSTRUMENT PANEL/GLOVE

BOX - INSTALLATION) for the procedures.

(6) Close the glove box.

(7) Reconnect the battery negative cable.

READING LAMP

DESCRIPTION

The overhead console in this vehicle is equipped

with two individual reading and courtesy lamps. The

lamp lenses are the only visible components of these

lamps. Each lamp has its own switch, bulb, reflector

and lens within the overhead console.

The overhead console reading and courtesy lamps

are controlled by the instrument cluster which pro-

vides power at all times, regardless of the ignition

switch position. The ground circuit for the lamps is

switched through the integral reading and courtesy

lamp switches or through the door ajar switches.

Each lamp is designed and aimed to provide illumi-

nation that will be directed only to that side of the

vehicle on which the lamp is located.

The reading and courtesy lamp lenses and bulbs

are available for service replacement. The reading

and courtesy lamp switches, bulb holders and wiring

are only available as part of the overhead console

wire harness. If either of the lamp switches or bulb

holders is faulty or damaged, the entire overhead

console wire harness assembly must be replaced.

For service of the reading and courtesy lamp bulbs,

refer to the appropriate wiring information.

OPERATION

All reading and courtesy lamps located in the over-

head console are activated by the door ajar switches

via the instrument cluster. When all of the doors are

closed, these lamps can be individually activated by

depressing the corresponding lens. When any door is

open, depressing the lamp lenses to activate the lamp

switches will not turn the lamps off.The instrument cluster monitors the door ajar

switches. When a door is open the instrument cluster

grounds the low side drivers to turn on the lamps.

Upon closing all doors, the instrument cluster ini-

tiates a 30 second timer. If any of the doors are

opened during the ªtime outº cycle, the instrument

cluster will reset the timer until all doors are closed.

The instrument cluster will faid to off when the doors

are closed and the ignition is turned ON, the time

out expires or the power locks are activated.

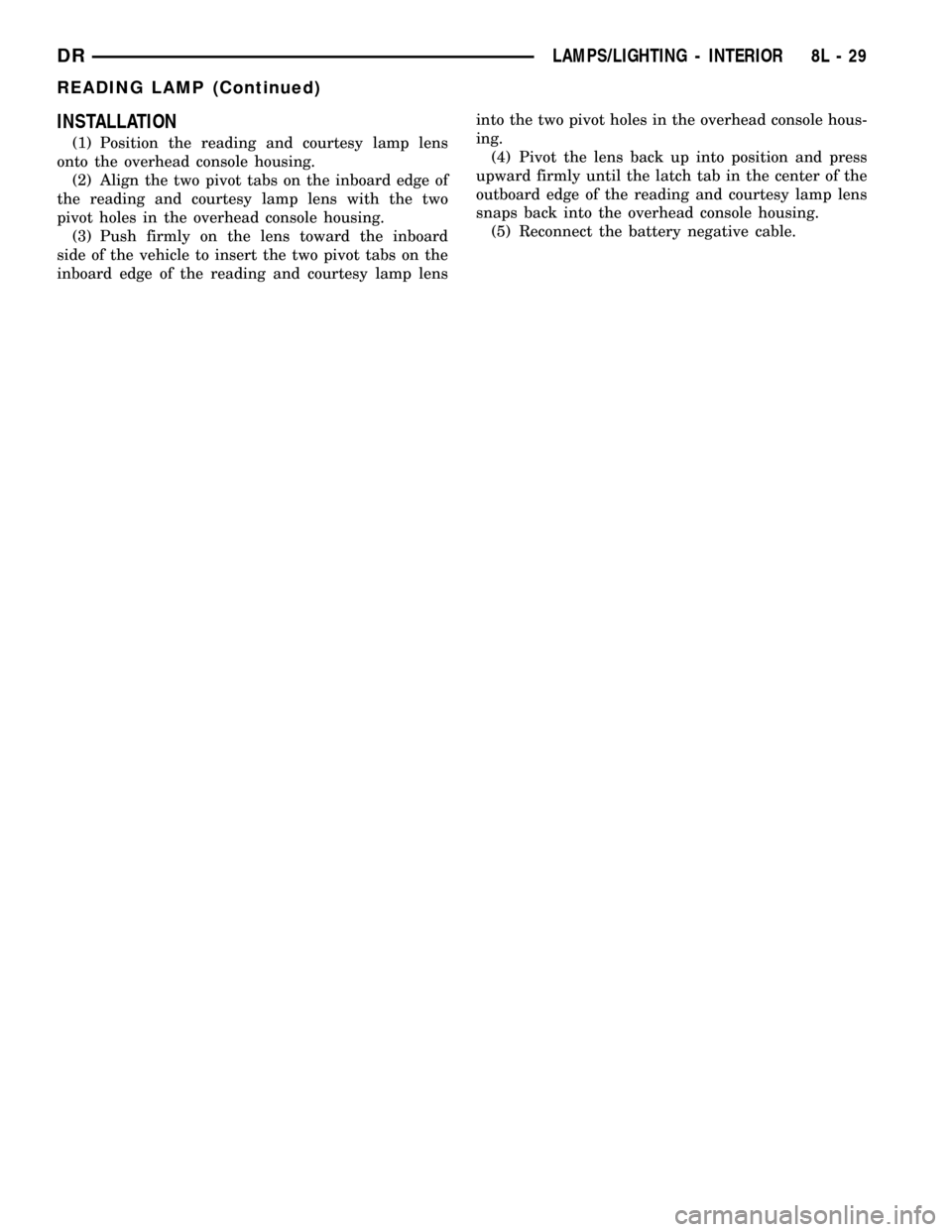

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert a long, narrow, flat-bladed tool between

the curved (outboard) edge of the reading and cour-

tesy lamp lens and the overhead console housing

(Fig. 4).

(3) Gently pry inward and downward against the

lens until the latch tab in the center of the outboard

edge of the reading and courtesy lamp lens is disen-

gaged from the overhead console housing.

(4) Pull firmly on the lens toward the outboard

side of the vehicle to disengage the two pivot tabs on

the inboard edge of the reading and courtesy lamp

lens are disengaged from the overhead console hous-

ing.

(5) Remove the reading and courtesy lamp lens

from the overhead console housing.

Fig. 4 Overhead Console Reading Lamp Bulb

Removal

1 - LENS

2 - FLAT BLADE

3 - CONSOLE

8L - 28 LAMPS/LIGHTING - INTERIORDR

GLOVE BOX LAMP/SWITCH (Continued)

Page 584 of 2627

INSTALLATION

(1) Position the reading and courtesy lamp lens

onto the overhead console housing.

(2) Align the two pivot tabs on the inboard edge of

the reading and courtesy lamp lens with the two

pivot holes in the overhead console housing.

(3) Push firmly on the lens toward the inboard

side of the vehicle to insert the two pivot tabs on the

inboard edge of the reading and courtesy lamp lensinto the two pivot holes in the overhead console hous-

ing.

(4) Pivot the lens back up into position and press

upward firmly until the latch tab in the center of the

outboard edge of the reading and courtesy lamp lens

snaps back into the overhead console housing.

(5) Reconnect the battery negative cable.

DRLAMPS/LIGHTING - INTERIOR 8L - 29

READING LAMP (Continued)

Page 586 of 2627

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT.........3

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT.......................3

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT.......................3

STANDARD PROCEDURE - COMPASS

CALIBRATION.........................3

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING......................4

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................5

REMOVAL

OVERHEAD CONSOLE REMOVAL.........6

INSTALLATION..........................6

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER..................6

REMOVAL.............................6

INSTALLATION..........................6

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION..........................7OPERATION............................7

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER.........8

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING.......................8

REMOVAL.............................9

INSTALLATION..........................9

AMBIENT TEMP SENSOR

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR...............10

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT........10

REMOVAL.............................11

INSTALLATION.........................11

UNIVERSAL TRANSMITTER

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER.......................11

STANDARD PROCEDURE

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES.................12

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES.................12

REMOVAL.............................12

OVERHEAD CONSOLE

DESCRIPTION

Two different overhead consoles are available on

DR models. The Electronic Vehicle Information Cen-

ter (EVIC) (Fig. 1) or Compass Mini-Trip Computer

(CMTC). All consoles are equipped with two reading/

courtesy lamps. The overhead console is mounted

with screws and two snap clips to a molded plastic

retainer bracket located above the headliner.

COMPASS DISPLAY

All the available overhead consoles on this model

include Compass information. While in the compass/

temperature mode, the compass will display the

direction in which the vehicle is pointed using the

eight major compass headings (Examples: north is N,

northeast is NE). The self-calibrating compass unit

requires no adjusting in normal use. The only cali-

bration that may prove necessary is to drive the vehi-

cle at 5 to 8 kilometers-per-hour (3 to 5 miles-per-

hour), on level ground in a square shaped pattern.

This will reorient the compass unit to its vehicle.

DRMESSAGE SYSTEMS 8M - 1

Page 588 of 2627

SELF-DIAGNOSTIC TEST

A self-diagnostic test is built-in to the module to

determine that the electronics module is operating

properly, and that all the J1850 PCI data bus mes-

sages are being received for proper operation. To per-

form the self-diagnostic test proceed as follows:

(1) With the ignition switch in the Off position,

simultaneously depress and hold theSTEP and

RESET buttons.

(2) Turn the ignition switch to the On position.

(3) Following completion of the test, the electronics

module will display one of the following messages:

a.Pass Self Test (EVIC only), PASS (CMTC)-

The electronics module is working properly.

b.Failed Self Test (EVIC only), FAIL (CMTC)-

The electronics module has an internal failure. The

electronics module is faulty and must be replaced.

c.Failed J1850 Communication (EVIC only),

BUS (CMTC)- The electronics module is not receiv-

ing proper message input through the J1850 PCI

data bus circuit. This can result from one or more

faulty electronic modules in the vehicle, or from a

faulty PCI data bus. The use of a DRB IIItscan tool

and the proper Diagnostic Procedures manual are

required for further diagnosis.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Stan-

dard Procedures section of this group.

NOTE: If the compass reading displays dashes, and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Standard Procedures section

of this group.

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable.

(2) Remove the reading/courtesy lamp lens. Using

a trim stick, gently pry the forward edge of the read-

ing/courtesy lamp lens outward.

(3) Remove the reading/courtesy lamp socket from

the overhead console. Rotate the reading/courtesy

lamp socket one quarter turn counter clockwise.

(4) Remove the lamp and socket assembly.(5) Reverse the above procedure to install.

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

(2) Remove the electronics module from the over-

head console. Refer to the procedure later in this sec-

tion.

(3) Unsnap the lens from the module and replace

lens as necessary.

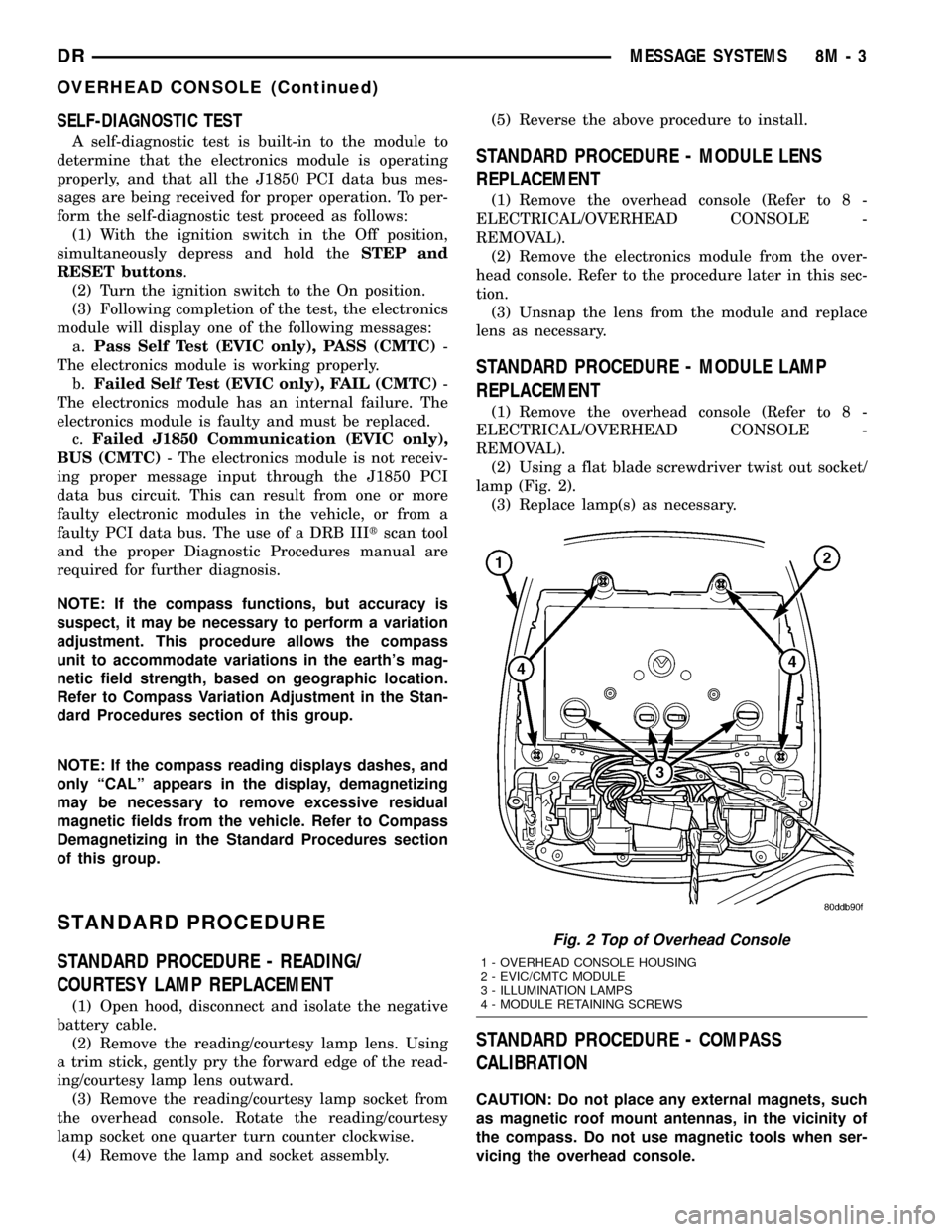

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 2).

(3) Replace lamp(s) as necessary.

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.

Fig. 2 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC/CMTC MODULE

3 - ILLUMINATION LAMPS

4 - MODULE RETAINING SCREWS

DRMESSAGE SYSTEMS 8M - 3

OVERHEAD CONSOLE (Continued)

Page 591 of 2627

(6) Depress and release theRESETpush button

to enter the displayed zone number into the EVIC/

CMTC module memory.

(7) Confirm that the correct directions are now

indicated by the compass.

REMOVAL

OVERHEAD CONSOLE REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the overhead console retaining screws,

located in the sunglass storage bin.

(3) Using your fingertips, grasp the sides of the

overhead console and pull straight down evenly to

disengage the two snap clips at the front of the unit.

(4) Lower the overhead console far enough to

access the wire harness connectors.

(5) Disconnect the EVIC, CMTC electronic module

and the reading/courtesy lamps electrical connectors.

(6) Remove the overhead console from the vehicle.

INSTALLATION

(1) Position the overhead console in the vehicle.

(2) Connect the EVIC, CMTC electronic module

and the reading/courtesy lamps electrical connectors.

(3) Grasp the sides of the overhead console and

push straight up evenly to engage the two snap clips

at the rear of the unit.

(4) Install the overhead console retaining screw,

located in the front of console. Torque the screw to

1.2 N´m (10 in. lbs.).

(5) Connect the negative battery cable.

COMPASS/MINI-TRIP

COMPUTER

DESCRIPTION

The Compass Mini-Trip Computer (CMTC) is a

module located in the overhead console. The CMTC is

equipped with a mini-trip feature. The CMTC con-

sists of a electronic control module with a vacuum

fluorescent display (VFD) and function switches. The

CMTC consists of a electronic module that displays

compass, trip computer, and temperature features.

Actuating the STEP push button will cause the

CMTC to change mode of operation when the ignition

is ON. Example:

²Average miles per gallon (ECO)

²Distance to empty (DTE)

²Trip odometer (ODO)

²Elapsed time (ET)

²OffActuating the C/T push button will cause the

CMTC to change to Compass/Temperature display.

OPERATION

The Compass Mini-Trip Computer module in the

overhead console has buttons used to select various

functions. The CMTC selector buttons will not oper-

ate until the ignition is in the RUN position.

When the ignition switch is first turned to the

RUN position the CMTC display;

²Returns to the last mode setting selected before

the ignition was last switched OFF.

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER

Compass Mini-Trip Computer (CMTC) data is

obtained from other electronic modules (CCN, FCM

and JTEC) on the J1850 Data Bus circuit. The

CMTC will display dashes (- -) for any of the screens

it did not receive the bus messages. The label corre-

sponding to the missing information will be lit. If no

compass mini-trip computer data is displayed, check

the J1850 Data Bus circuit communications and the

other modules.

Refer to Overhead Console Diagnosis and Testing

for instructions on performing a CMTC module Self-

Diagnostic Test. The DRB IIItis recommended for

checking the J1850 Data Bus circuit and the other

modules. Perform the CMTC self diagnosis before

replacing the CMTC module.

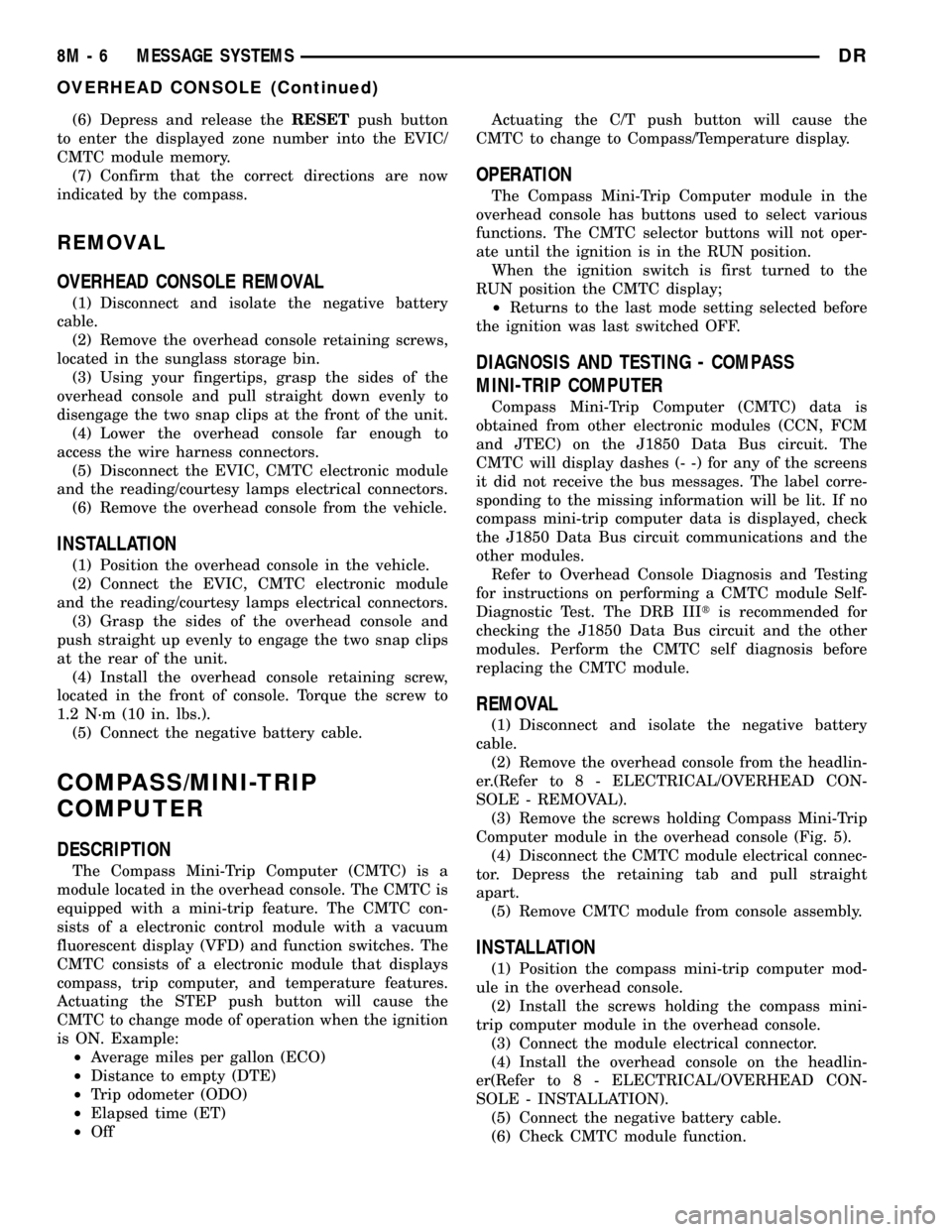

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the overhead console from the headlin-

er.(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(3) Remove the screws holding Compass Mini-Trip

Computer module in the overhead console (Fig. 5).

(4) Disconnect the CMTC module electrical connec-

tor. Depress the retaining tab and pull straight

apart.

(5) Remove CMTC module from console assembly.

INSTALLATION

(1) Position the compass mini-trip computer mod-

ule in the overhead console.

(2) Install the screws holding the compass mini-

trip computer module in the overhead console.

(3) Connect the module electrical connector.

(4) Install the overhead console on the headlin-

er(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - INSTALLATION).

(5) Connect the negative battery cable.

(6) Check CMTC module function.

8M - 6 MESSAGE SYSTEMSDR

OVERHEAD CONSOLE (Continued)

Page 594 of 2627

appears,AUTO UNLOCK ON EXIT?- The options

again include Yes and No. The default is No. When

Yes is selected, following each Auto Door Lock event

all doors will automatically unlock when the driver

door is opened, if the vehicle is stopped and the

transmission gear selector is in Park or Neutral. The

Auto Door Unlock event will only occur once follow-

ing each Auto Door Lock event.

²REMOTE UNLOCK- The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

²SOUND HORN ON LOCK?- The options

include On and Off. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²TRAIN REMOTE- When this feature is

selected the driver can choose to train up to four

remote keyless entry transmitters. The options

include Yes and No. The default is No. When Yes is

selected and the MENU button is pressed the EVIC

will display ªPRESS REMOTE LOCK & UNLOCK

THEN PRESS UNLOCKº, followed by a chime to

indicate the training sequence can commence. You

have approximately 30 seconds to train up to fourtransmitters, after each transmitter is trained a

chime will sound indicating that the training was

successful. If remote link to memory is ªYESº , the

first transmitter trained will be associated with

memory setting 1 and the second transmitter trained

will be associated with memory setting 2. Additional

transmitters will not be associated with a memory

setting. When you have finished training the trans-

mitters, press the menu button again and the EVIC

will display ªTRAIN DONE ªXº TRAINED. If no

transmitters are trained within approximately 30

seconds the EVIC will display ªTRAIN TIMEOUTº.

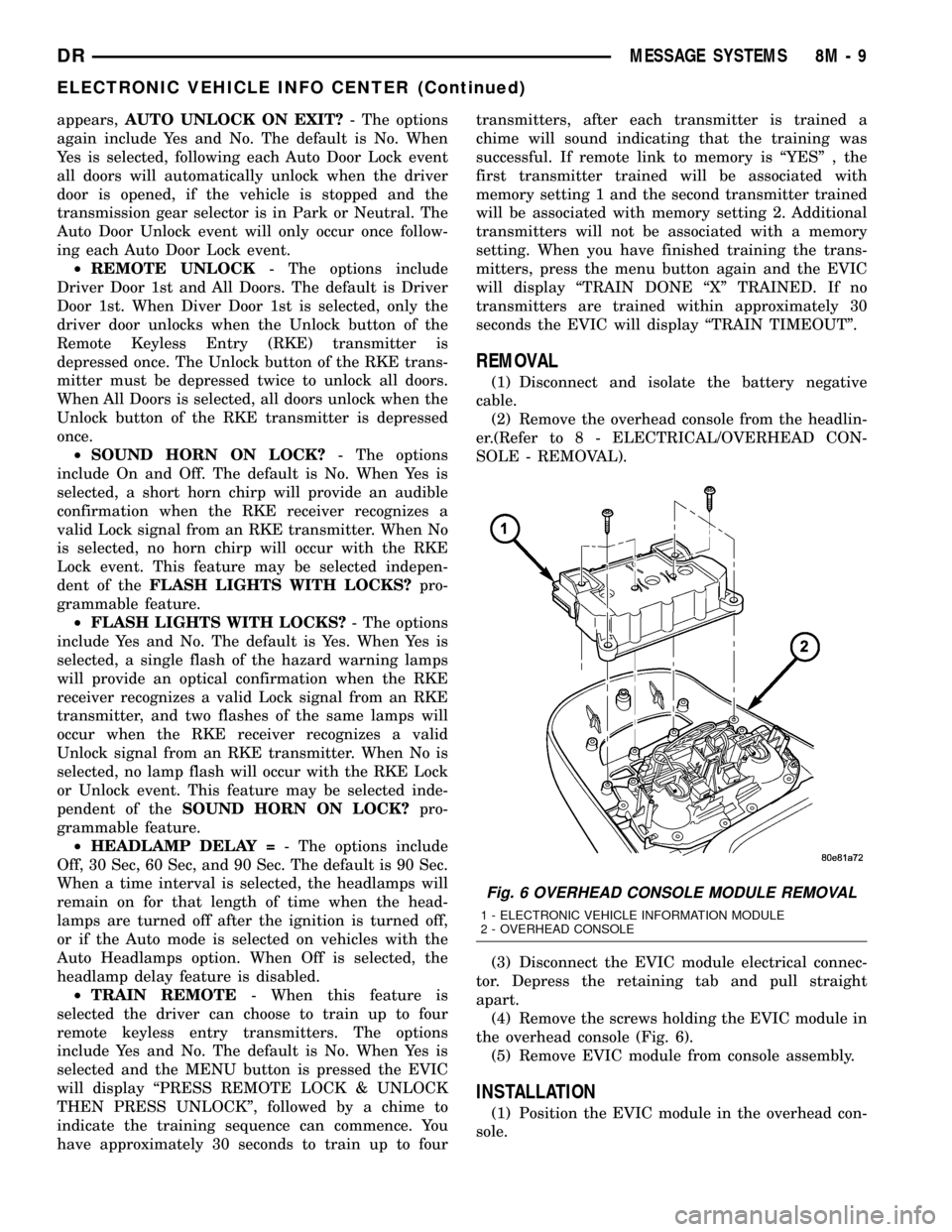

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the overhead console from the headlin-

er.(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(3) Disconnect the EVIC module electrical connec-

tor. Depress the retaining tab and pull straight

apart.

(4) Remove the screws holding the EVIC module in

the overhead console (Fig. 6).

(5) Remove EVIC module from console assembly.

INSTALLATION

(1) Position the EVIC module in the overhead con-

sole.

Fig. 6 OVERHEAD CONSOLE MODULE REMOVAL

1 - ELECTRONIC VEHICLE INFORMATION MODULE

2 - OVERHEAD CONSOLE

DRMESSAGE SYSTEMS 8M - 9

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 599 of 2627

Certain functions and features of the power lock

system rely upon resources shared with other elec-

tronic modules in the vehicle over the Programmable

Communications Interface (PCI) data bus network.

For proper diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRB IIIt

scan tool and the appropriate diagnostic information

are required.

CENTRAL LOCKING/UNLOCKING

The instrument cluster will lock all doors when a

cylinder lock switch is activated in the ªlockº posi-

tion. When the instrument cluster receives an unlock

command from one of the cylinder lock switches, it

will unlock only that door. If the instrument cluster

receives a second command within a 5 second period,

it will unlock all the remaining doors. The illumi-

nated entry will activate during door unlock.

ENHANCED ACCIDENT RESPONSE

Upon detection of an airbag deployment by way of

the PCI bus, the instrument cluster will:

²Immediately disable the power door lock output.

²Unlock all doors by activating the door unlock

output for approximately 300 milliseconds.

²After actuating the door unlock output, allow

the door lock motors to be activated if the door lock

input has been inactive (not erratic) for 2 seconds

since the reception of the airbag deployment mes-

sage.

REMOTE KEYLESS ENTRY

A Radio Frequency (RF) type Remote Keyless

Entry (RKE) system is an available factory-installed

option on this model. The RKE system allows the use

of a remote battery-powered radio transmitter to sig-

nal the instrument cluster to actuate the power lock

system. The RKE receiver operates on non-switched

battery current through a fuse in the Integrated

Power Module (IPM), so that the system remains

operational, regardless of the ignition switch position.

The RKE transmitters are also equipped with a

Panic button. If the Panic button on the RKE trans-

mitter is depressed, the horn will sound and the

exterior lights will flash on the vehicle for about

three minutes, or until the Panic button is depressed

a second time. A vehicle speed of about 25.7 kilome-

ters-per-hour (15 miles-per-hour) will also cancel the

panic event.

The RKE system can also perform other functions

on this vehicle. If the vehicle is equipped with the

optional Vehicle Theft Security System (VTSS), the

RKE transmitter will arm the VTSS when the Lock

button is depressed, and disarm the VTSS when the

Unlock button is depressed.

The RKE system includes two transmitters when

the vehicle is shipped from the factory, but the system

can retain the vehicle access codes of up to a total of

four transmitters. The transmitter codes are retained

in the RKE module memory, even if the battery is dis-

connected. If an RKE transmitter is faulty or lost,

new transmitter vehicle access codes can be pro-

grammed into the system using a DRB IIItscan tool.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. Customer programmable feature options

affecting the RKE system include:

²Remote Unlock Sequence- Allows the option

of having only the driver side front door unlock when

the RKE transmitter Unlock button is depressed the

first time. The remaining doors unlock when the but-

ton is depressed a second time within 5 seconds of

the first unlock press. Another option is having all

doors unlock upon the first depression of the RKE

transmitter Unlock button.

²Sound Horn on Lock- Allows the option of

having the horn sound a short chirp as an audible

verification that the RKE system received a valid

Lock request from the RKE transmitter, or having no

audible verification.

²Flash Lights with Lock and Unlock- Allows

the option of having the park lamps flash as an opti-

cal verification that the RKE system received a valid

Lock request or Unlock request from the RKE trans-

mitter, or having no optical verification.

²Programming Additional Transmitters-

Allows up to a total of four transmitter vehicle access

codes to be stored in the receiver memory.

Certain functions and features of the RKE system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. For

diagnosis of these electronic modules or of the PCI

data bus network, the use of a DRB IIItscan tool

and the appropriate diagnostic information are

required.

OPERATION

POWER LOCKS

The instrument cluster locks or unlocks the doors

when an actuation input signal from a door lock

switch or Remote Keyless Entry Module (RKE) is

received. The instrument cluster turns on the output

drivers and provides a voltage level to the door lock

motor for a specified time. All passenger doors can be

locked or unlocked using a mechanical button

mounted on the door trim panel. The front passenger

doors can be locked or unlocked by using the key cyl-

inder.

8N - 2 POWER LOCKSDR

POWER LOCKS (Continued)

Page 600 of 2627

AUTOMATIC DOOR LOCKS

When the automatic door locks are ENABLED the

door locks will lock when the vehicle is moving at

about 25.7 Km/h (15 mph), all doors are closed and

the accelerator pedal is depressed. This feature can

be switched ON or OFF as desired. When the system

is DISABLED the door locks will operate normally,

but will not lock automatically when the vehicle is

rolling. Once the automatic door locks have been

actuated, they will not try to lock the doors again

until a door is opened.

DOOR LOCK INHIBIT

If the key is in the ignition, in any position, and

either front door is ajar, the doors can not be locked,

but the unlock function still operates. Pressing the

RKE lock/unlock button under these conditions will

result in a normal lock/unlock activation.

After the key is removed from the ignition switch,

or the doors are closed, the power door locks will

operate normally.

DOOR LOCK CIRCUIT PROTECTION

If the door lock switch is actuated continuously for

more than five seconds the instrument cluster will

turn the output driver OFF (the instrument cluster

would consider the switch stuck). Each lock motor is

protected with a Positive Temperature Coefficient

device that prevents motor burn out.

REMOTE KEYLESS ENTRY

²LOCK: Pressing the LOCK button locks all

doors, sounds horn (chirp) once if enabled, flashes the

park lamps once if enabled, and arms the Vehicle

Theft Security System (VTSS), if enabled. The chirp

verifies that the RKE module has sent a message to

the instrument cluster for door lock operation. If a

door has not been closed before pressing the LOCK

button, the vehicle may not be secured and the VTSS

(if equipped) will not arm until the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's door first if enabled, flashes

the park lamps twice if enabled, activates the illumi-

nated entry system, and disarms the Vehicle Theft

Security System (VTSS), if equipped. Pressing the

UNLOCK button twice within five seconds will

unlock all doors, if driver's door first is enabled.

²PANIC:

Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the vehicle speed

exceeds 25.7 Km/h (15 mph) will cancel the panic event.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s) in its

memory even after vehicle power has been interrupted.

DIAGNOSIS AND TESTING - POWER LOCKS

The most reliable, efficient, and accurate

means to diagnose the power lock system

requires the use of a DRBIIItscan tool and the

proper Diagnostic Procedures manual.

Following are tests that will help to diagnose the

hard wired components and circuits of the power lock

system. However, these tests may not prove conclu-

sive in the diagnosis of this system. In order to

obtain conclusive testing of the power lock system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power lock system components must be checked.

The instrument cluster will set Diagnostic Trouble

Codes (DTC) for the power lock system.

Refer to the appropriate wiring information.

PRELIMINARY DIAGNOSIS

As a preliminary diagnosis for the power lock sys-

tem, note the system operation while you actuate

both the Lock and Unlock functions with the power

lock switches and with the Remote Keyless Entry

(RKE) transmitter. Then, proceed as follows:

²If the entire power lock system fails to function

with either the power lock switches or the RKE

transmitter, check the fused B(+) fuse in the Inte-

grated Power Module (IPM).

²If the power lock system functions with both

power lock switches, but not with the RKE transmit-

ter, proceed to diagnosis of the Remote Keyless Entry

(RKE) system. (Refer to 8 - ELECTRICAL/POWER

LOCKS/KEYLESS ENTRY TRANSMITTER - DIAG-

NOSIS AND TESTING) or (Refer to 8 - ELECTRI-

CAL/POWER LOCKS/REMOTE KEYLESS ENTRY

MODULE - DIAGNOSIS AND TESTING).

²If the power lock system functions with the RKE

transmitter, but not with one or both power lock

switches, proceed to diagnosis of the door lock

switches. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK SWITCH - DIAGNOSIS AND

TESTING).

²If the driver side power lock switch operates

only the driver side front door power lock motor, but

all other power lock motors operate with the passen-

ger side power lock switch or the RKE transmitter,

use a DRBIIItscan tool and the appropriate diagnos-

tic information to diagnose the Programmable Com-

munications Interface (PCI) data bus.

²If only one power lock motor fails to operate

with both power lock switches and the RKE trans-

mitter, proceed to diagnosis of the power lock motor.

(Refer to 8 - ELECTRICAL/POWER LOCKS/POWER

LOCK MOTOR - DIAGNOSIS AND TESTING).

DRPOWER LOCKS 8N - 3

POWER LOCKS (Continued)