four wheel drive DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 35 of 2627

A wooden crossbeam may be required for proper

connection when using the sling-type, front-end tow-

ing method.

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be

observed when towing a vehicle:

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Do not tow a heavily loaded vehicle. Damage to

the cab, cargo box or frame may result. Use a flatbed

device to transport a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain or steep rises in the road. If necessary,remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used on 4WD vehicles providedall the

wheels are lifted off the ground using tow dol-

lies.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be

transported on a flat-bed device. A Wheel-lift or

Sling-type device can be used providedall the

wheels are lifted off the ground using tow dol-

lies.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

0 - 22 LUBRICATION & MAINTENANCEDR

TOWING (Continued)

Page 55 of 2627

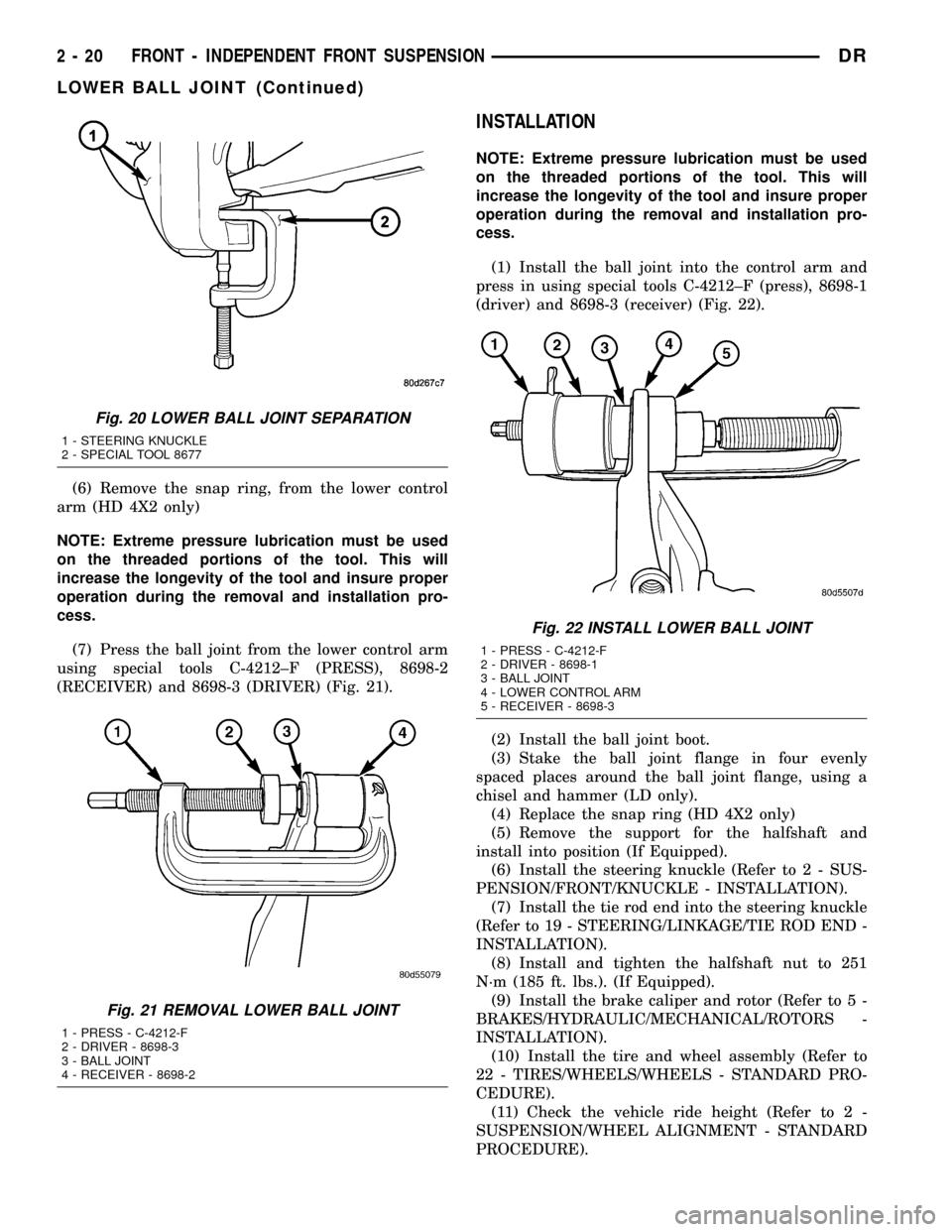

(6) Remove the snap ring, from the lower control

arm (HD 4X2 only)

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(7) Press the ball joint from the lower control arm

using special tools C-4212±F (PRESS), 8698-2

(RECEIVER) and 8698-3 (DRIVER) (Fig. 21).

INSTALLATION

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(1) Install the ball joint into the control arm and

press in using special tools C-4212±F (press), 8698-1

(driver) and 8698-3 (receiver) (Fig. 22).

(2) Install the ball joint boot.

(3) Stake the ball joint flange in four evenly

spaced places around the ball joint flange, using a

chisel and hammer (LD only).

(4) Replace the snap ring (HD 4X2 only)

(5) Remove the support for the halfshaft and

install into position (If Equipped).

(6) Install the steering knuckle (Refer to 2 - SUS-

PENSION/FRONT/KNUCKLE - INSTALLATION).

(7) Install the tie rod end into the steering knuckle

(Refer to 19 - STEERING/LINKAGE/TIE ROD END -

INSTALLATION).

(8) Install and tighten the halfshaft nut to 251

N´m (185 ft. lbs.). (If Equipped).

(9) Install the brake caliper and rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(10) Install the tire and wheel assembly (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(11) Check the vehicle ride height (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 20 LOWER BALL JOINT SEPARATION

1 - STEERING KNUCKLE

2 - SPECIAL TOOL 8677

Fig. 21 REMOVAL LOWER BALL JOINT

1 - PRESS - C-4212-F

2 - DRIVER - 8698-3

3 - BALL JOINT

4 - RECEIVER - 8698-2

Fig. 22 INSTALL LOWER BALL JOINT

1 - PRESS - C-4212-F

2 - DRIVER - 8698-1

3 - BALL JOINT

4 - LOWER CONTROL ARM

5 - RECEIVER - 8698-3

2 - 20 FRONT - INDEPENDENT FRONT SUSPENSIONDR

LOWER BALL JOINT (Continued)

Page 83 of 2627

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.1) Clean exterior of shaft and wash

with solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

and tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline

angles.

5) Rear spring center bolt not in

seat.5) Loosen spring u-bolts and seat

center bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test,

and evaluate.

10) Excessive drive pinion gear

shaft runout.10) Re-index propeller shaft and

evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as

necessary.

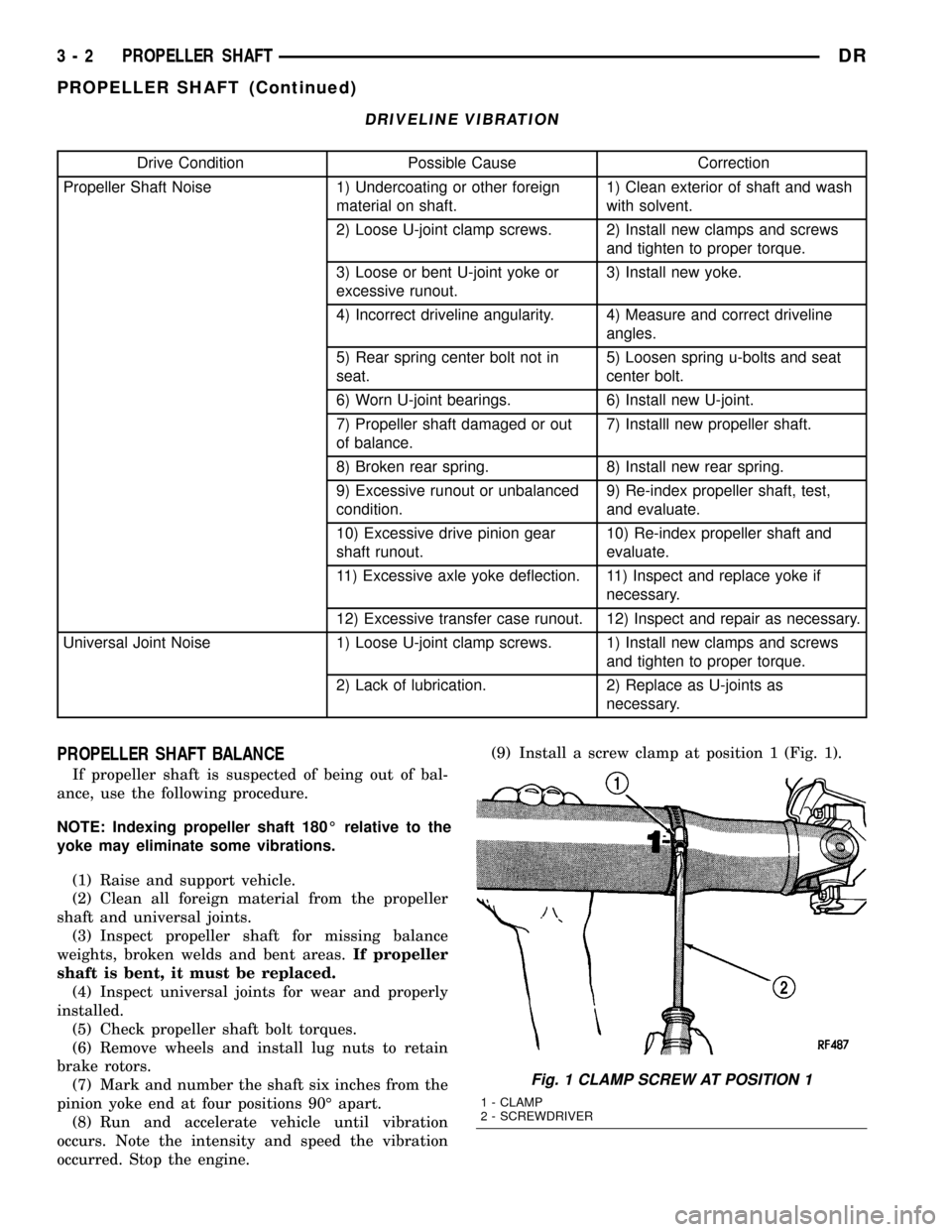

PROPELLER SHAFT BALANCE

If propeller shaft is suspected of being out of bal-

ance, use the following procedure.

NOTE: Indexing propeller shaft 180É relative to the

yoke may eliminate some vibrations.

(1) Raise and support vehicle.

(2) Clean all foreign material from the propeller

shaft and universal joints.

(3) Inspect propeller shaft for missing balance

weights, broken welds and bent areas.If propeller

shaft is bent, it must be replaced.

(4) Inspect universal joints for wear and properly

installed.

(5) Check propeller shaft bolt torques.

(6) Remove wheels and install lug nuts to retain

brake rotors.

(7) Mark and number the shaft six inches from the

pinion yoke end at four positions 90É apart.

(8) Run and accelerate vehicle until vibration

occurs. Note the intensity and speed the vibration

occurred. Stop the engine.(9) Install a screw clamp at position 1 (Fig. 1).

Fig. 1 CLAMP SCREW AT POSITION 1

1 - CLAMP

2 - SCREWDRIVER

3 - 2 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 398 of 2627

(1) Install remote radio switch to the steering

wheel.

(2) Connect the wire harness to the remote radio

switch.

(3) Install the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

INSTALLATION).

(4) Install the driver airbag

(5) Connect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in four locations. One 15.2 X 22.8 centime-

ter (6 X 9 inch) full-range speaker is located in each

front door. There is also one full-range 13.3 centime-

ter (5.25 inch) diameter full-range speaker located in

each rear door.

PREMIUM

The optional premium speaker system features

eleven Premium model speakers in seven locations.

Each of the standard speakers is replaced with Pre-

mium model speakers. One 8.8 centimeter (3.50 inch)

diameter speaker is located on each end of the

instrument panel top pad. One 6.3 centimeter (2.50

inch) diameter speaker is located in the center of the

instrument panel top pad. One 15.2 X 22.8 centime-

ter (6 X 9 inch) Premium speaker is located in each

front door. There is also one coaxial 13.3 centimeter

(5.25 inch) diameter Premium full-range speaker

located in each rear door. The premium speaker sys-

tem also includes a power amplifier mounted behind

the glove box. The total available power of the pre-

mium speaker system is 240 watts.

OPERATION

Two wires connected to each speaker, one feed cir-

cuit (+) and one return circuit (±), allow the audio

output signal electrical current to flow through the

voice coil. For complete circuit diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

DIAGNOSIS AND TESTING - SPEAKER

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Service Manual.

Refer to the appropriate wiring information.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

and/or amplifier may result.

(1) If all speakers are inoperative, check the fuses

in the Integrated Power Module (IPM). If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

IPM. If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 5.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 6. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

DRAUDIO/VIDEO 8A - 13

REMOTE SWITCHES (Continued)

Page 423 of 2627

TRANSFER CASE CONTROL

MODULE

DESCRIPTION

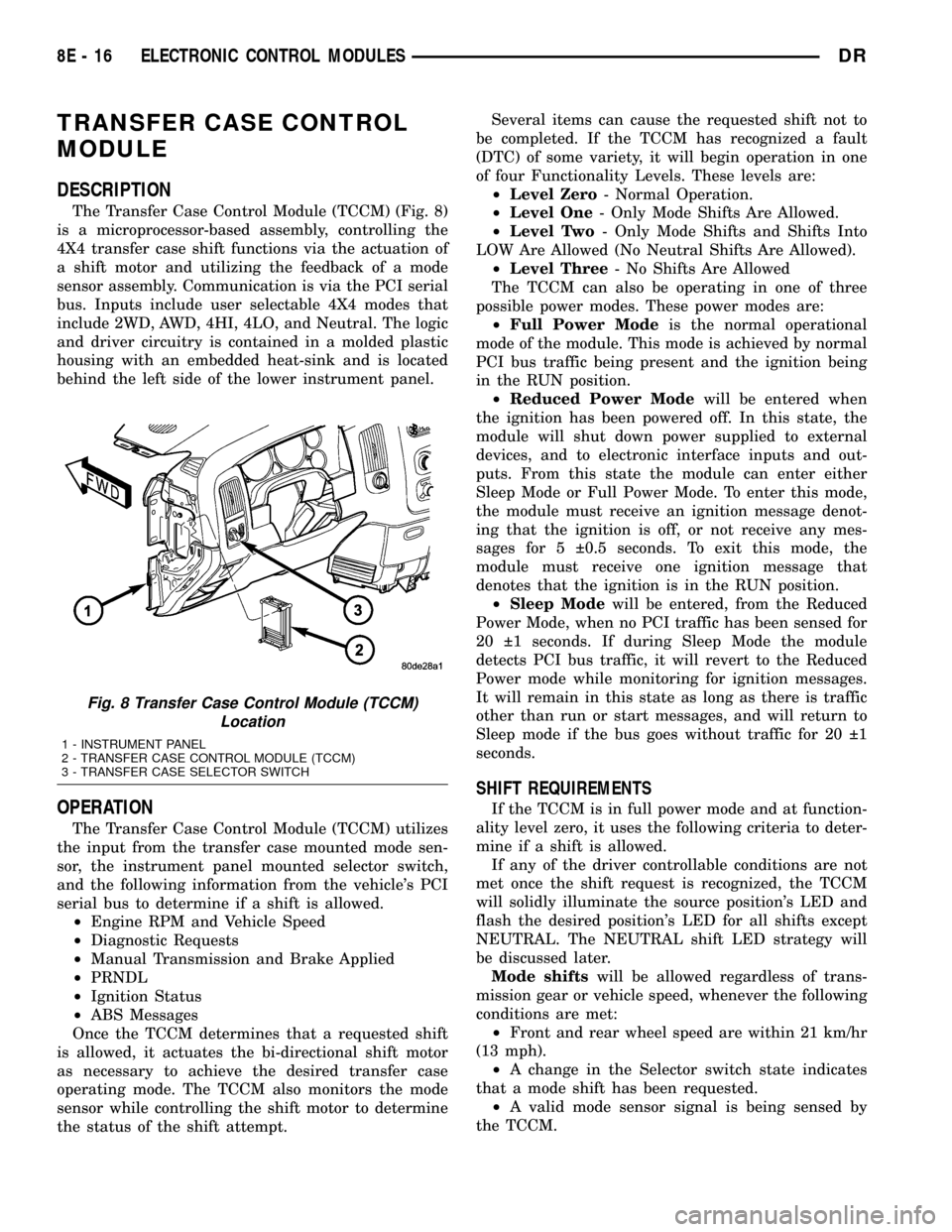

The Transfer Case Control Module (TCCM) (Fig. 8)

is a microprocessor-based assembly, controlling the

4X4 transfer case shift functions via the actuation of

a shift motor and utilizing the feedback of a mode

sensor assembly. Communication is via the PCI serial

bus. Inputs include user selectable 4X4 modes that

include 2WD, AWD, 4HI, 4LO, and Neutral. The logic

and driver circuitry is contained in a molded plastic

housing with an embedded heat-sink and is located

behind the left side of the lower instrument panel.

OPERATION

The Transfer Case Control Module (TCCM) utilizes

the input from the transfer case mounted mode sen-

sor, the instrument panel mounted selector switch,

and the following information from the vehicle's PCI

serial bus to determine if a shift is allowed.

²Engine RPM and Vehicle Speed

²Diagnostic Requests

²Manual Transmission and Brake Applied

²PRNDL

²Ignition Status

²ABS Messages

Once the TCCM determines that a requested shift

is allowed, it actuates the bi-directional shift motor

as necessary to achieve the desired transfer case

operating mode. The TCCM also monitors the mode

sensor while controlling the shift motor to determine

the status of the shift attempt.Several items can cause the requested shift not to

be completed. If the TCCM has recognized a fault

(DTC) of some variety, it will begin operation in one

of four Functionality Levels. These levels are:

²Level Zero- Normal Operation.

²Level One- Only Mode Shifts Are Allowed.

²Level Two- Only Mode Shifts and Shifts Into

LOW Are Allowed (No Neutral Shifts Are Allowed).

²Level Three- No Shifts Are Allowed

The TCCM can also be operating in one of three

possible power modes. These power modes are:

²Full Power Modeis the normal operational

mode of the module. This mode is achieved by normal

PCI bus traffic being present and the ignition being

in the RUN position.

²Reduced Power Modewill be entered when

the ignition has been powered off. In this state, the

module will shut down power supplied to external

devices, and to electronic interface inputs and out-

puts. From this state the module can enter either

Sleep Mode or Full Power Mode. To enter this mode,

the module must receive an ignition message denot-

ing that the ignition is off, or not receive any mes-

sages for 5 0.5 seconds. To exit this mode, the

module must receive one ignition message that

denotes that the ignition is in the RUN position.

²Sleep Modewill be entered, from the Reduced

Power Mode, when no PCI traffic has been sensed for

20 1 seconds. If during Sleep Mode the module

detects PCI bus traffic, it will revert to the Reduced

Power mode while monitoring for ignition messages.

It will remain in this state as long as there is traffic

other than run or start messages, and will return to

Sleep mode if the bus goes without traffic for 20 1

seconds.

SHIFT REQUIREMENTS

If the TCCM is in full power mode and at function-

ality level zero, it uses the following criteria to deter-

mine if a shift is allowed.

If any of the driver controllable conditions are not

met once the shift request is recognized, the TCCM

will solidly illuminate the source position's LED and

flash the desired position's LED for all shifts except

NEUTRAL. The NEUTRAL shift LED strategy will

be discussed later.

Mode shiftswill be allowed regardless of trans-

mission gear or vehicle speed, whenever the following

conditions are met:

²Front and rear wheel speed are within 21 km/hr

(13 mph).

²A change in the Selector switch state indicates

that a mode shift has been requested.

²A valid mode sensor signal is being sensed by

the TCCM.

Fig. 8 Transfer Case Control Module (TCCM)

Location

1 - INSTRUMENT PANEL

2 - TRANSFER CASE CONTROL MODULE (TCCM)

3 - TRANSFER CASE SELECTOR SWITCH

8E - 16 ELECTRONIC CONTROL MODULESDR

Page 514 of 2627

for more than about 1.6 kilometers (one mile) and

the vehicle speed remains greater than about twenty-

four kilometers-per-hour (fifteen miles-per-hour).

²Vacuum Fluorescent Display Synchroniza-

tion- The EMIC transmits electronic panel lamp

dimming level messages which allows all other elec-

tronic modules on the PCI data bus with Vacuum

Fluorescent Display (VFD) units to coordinate their

illumination intensity with that of the EMIC VFD

units.

²Vehicle Theft Security System- The EMIC

monitors inputs from the door cylinder lock

switch(es), the door ajar switches, the ignition

switch, and the Remote Keyless Entry (RKE) receiver

module, then provides electronic horn and lighting

request messages to the Front Control Module (FCM)

located on the Integrated Power Module (IPM) for

the appropriate VTSS alarm output features.

²Wiper/Washer System Control- The EMIC

provides electronic wiper and/or washer request mes-

sages to the Front Control Module (FCM) located on

the Integrated Power Module (IPM) for the appropri-

ate wiper and washer system features. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - DESCRIP-

TION).

The EMIC houses six analog gauges and has pro-

visions for up to twenty-three indicators (Fig. 3) or

(Fig. 4). The EMIC includes the following analog

gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

3) or (Fig. 4):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS or Rear Wheel Anti-Lock [RWAL]

brakes only)

²Brake Indicator

²Cargo Lamp Indicator

²Check Gauges Indicator

²Cruise Indicator (with Speed Control only)

²Door Ajar Indicator²Electronic Throttle Control (ETC) Indicator

(with 5.7L Gasoline Engine only)

²Gear Selector Indicator (with Automatic

Transmission only)

²High Beam Indicator

²Lamp Out Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Seatbelt Indicator

²Security Indicator (with Sentry Key Immo-

bilizer & Vehicle Theft Security Systems only)

²Service Four-Wheel Drive Indicator (with

Four-Wheel Drive only)

²Tow/Haul Indicator (with Automatic Trans-

mission only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Upshift Indicator (with Manual Transmis-

sion only)

²Washer Fluid Indicator

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC, except those located

within one of the VFD units, is illuminated by a ded-

icated LED that is soldered onto the EMIC electronic

circuit board. The LED units are not available for

service replacement and, if damaged or faulty, the

entire EMIC must be replaced. Cluster illumination

is accomplished by dimmable incandescent back

lighting, which illuminates the gauges for visibility

when the exterior lighting is turned on. Each of the

incandescent bulbs is secured by an integral bulb

holder to the electronic circuit board from the back of

the cluster housing.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator, a

VFD unit, the electronic circuit board, the circuit

DRINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 519 of 2627

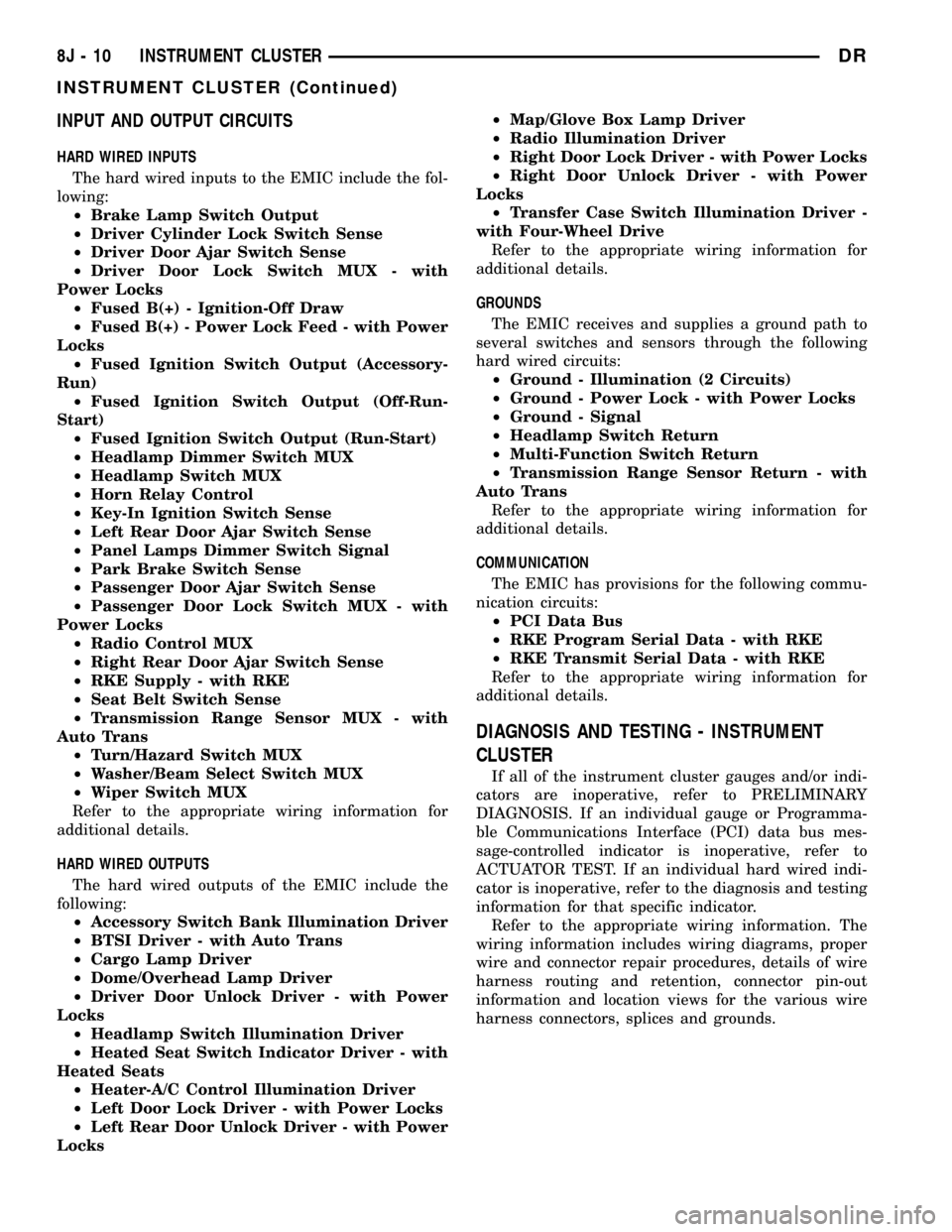

INPUT AND OUTPUT CIRCUITS

HARD WIRED INPUTS

The hard wired inputs to the EMIC include the fol-

lowing:

²Brake Lamp Switch Output

²Driver Cylinder Lock Switch Sense

²Driver Door Ajar Switch Sense

²Driver Door Lock Switch MUX - with

Power Locks

²Fused B(+) - Ignition-Off Draw

²Fused B(+) - Power Lock Feed - with Power

Locks

²Fused Ignition Switch Output (Accessory-

Run)

²Fused Ignition Switch Output (Off-Run-

Start)

²Fused Ignition Switch Output (Run-Start)

²Headlamp Dimmer Switch MUX

²Headlamp Switch MUX

²Horn Relay Control

²Key-In Ignition Switch Sense

²Left Rear Door Ajar Switch Sense

²Panel Lamps Dimmer Switch Signal

²Park Brake Switch Sense

²Passenger Door Ajar Switch Sense

²Passenger Door Lock Switch MUX - with

Power Locks

²Radio Control MUX

²Right Rear Door Ajar Switch Sense

²RKE Supply - with RKE

²Seat Belt Switch Sense

²Transmission Range Sensor MUX - with

Auto Trans

²Turn/Hazard Switch MUX

²Washer/Beam Select Switch MUX

²Wiper Switch MUX

Refer to the appropriate wiring information for

additional details.

HARD WIRED OUTPUTS

The hard wired outputs of the EMIC include the

following:

²Accessory Switch Bank Illumination Driver

²BTSI Driver - with Auto Trans

²Cargo Lamp Driver

²Dome/Overhead Lamp Driver

²Driver Door Unlock Driver - with Power

Locks

²Headlamp Switch Illumination Driver

²Heated Seat Switch Indicator Driver - with

Heated Seats

²Heater-A/C Control Illumination Driver

²Left Door Lock Driver - with Power Locks

²Left Rear Door Unlock Driver - with Power

Locks²Map/Glove Box Lamp Driver

²Radio Illumination Driver

²Right Door Lock Driver - with Power Locks

²Right Door Unlock Driver - with Power

Locks

²Transfer Case Switch Illumination Driver -

with Four-Wheel Drive

Refer to the appropriate wiring information for

additional details.

GROUNDS

The EMIC receives and supplies a ground path to

several switches and sensors through the following

hard wired circuits:

²Ground - Illumination (2 Circuits)

²Ground - Power Lock - with Power Locks

²Ground - Signal

²Headlamp Switch Return

²Multi-Function Switch Return

²Transmission Range Sensor Return - with

Auto Trans

Refer to the appropriate wiring information for

additional details.

COMMUNICATION

The EMIC has provisions for the following commu-

nication circuits:

²PCI Data Bus

²RKE Program Serial Data - with RKE

²RKE Transmit Serial Data - with RKE

Refer to the appropriate wiring information for

additional details.

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER

If all of the instrument cluster gauges and/or indi-

cators are inoperative, refer to PRELIMINARY

DIAGNOSIS. If an individual gauge or Programma-

ble Communications Interface (PCI) data bus mes-

sage-controlled indicator is inoperative, refer to

ACTUATOR TEST. If an individual hard wired indi-

cator is inoperative, refer to the diagnosis and testing

information for that specific indicator.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

8J - 10 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 520 of 2627

CAUTION: Instrument clusters used in this model

automatically configure themselves for compatibil-

ity with the features and optional equipment in the

vehicle in which they are initially installed. The

instrument cluster is programmed to do this by

embedding the Vehicle Identification Number (VIN)

and other information critical to proper cluster

operation into electronic memory. This embedded

information is learned through electronic messages

received from other electronic modules in the vehi-

cle over the Programmable Communications Inter-

face (PCI) data bus, and through certain hard wired

inputs received when the cluster is connected to

the vehicle electrically. Once configured, the instru-

ment cluster memory may be irreparably damaged

and certain irreversible configuration errors may

occur if the cluster is connected electrically to

another vehicle; or, if an electronic module from

another vehicle is connected that provides data to

the instrument cluster (including odometer values)

that conflicts with that which was previously

learned and stored. Therefore, the practice of

exchanging (swapping) instrument clusters and

other electronic modules in this vehicle with those

removed from another vehicle must always be

avoided. Failure to observe this caution may result

in instrument cluster damage, which is not reim-

bursable under the terms of the product warranty.

Service replacement instrument clusters are pro-

vided with the correct VIN, and the certified odom-

eter and engine hours values embedded into cluster

memory, but will otherwise be automatically config-

ured for compatibility with the features and optional

equipment in the vehicle in which they are initially

installed.

NOTE: Certain indicators in this instrument cluster

are automatically configured. This feature allows

those indicators to be activated or deactivated for

compatibility with certain optional equipment. If the

problem being diagnosed involves improper illumi-

nation of the cruise indicator, the electronic throttle

control indicator, the service four-wheel drive indi-

cator, the tow/haul indicator, the transmission over-

temp indicator, the upshift indicator, the security

indicator or the gear selector indicator, disconnect

and isolate the battery negative cable. After about

five minutes, reconnect the battery negative cable

and turn the ignition switch to the On position. The

instrument cluster should automatically relearn the

equipment in the vehicle and properly configure the

configurable indicators accordingly.PRELIMINARY DIAGNOSIS

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Check the fused B(+) fuse (Fuse 51 - 20

ampere) in the Integrated Power Module (IPM). If

OK, go to Step 2. If not OK, repair the shorted circuit

or component as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 51 - 20 ampere) in the IPM. If OK, go to Step

3. If not OK, repair the open fused B(+) circuit

between the IPM and the battery as required.

(3) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Reconnect the

battery negative cable. Check for battery voltage at

the fused B(+) circuit cavity of the instrument panel

wire harness connector (Connector C1) for the instru-

ment cluster. If OK, go to Step 4. If not OK, repair

the open fused B(+) circuit between the instrument

cluster and the IPM as required.

(4) Check for continuity between the signal ground

circuit cavity of the instrument panel wire harness

connector (Connector C1) for the instrument cluster

and a good ground. There should be continuity. If

OK, refer to ACTUATOR TEST. If not OK, repair the

open ground circuit to ground (G202) as required.

DRINSTRUMENT CLUSTER 8J - 11

INSTRUMENT CLUSTER (Continued)

Page 526 of 2627

NOTE: Certain indicators in this instrument cluster

are automatically configured. This feature allows

those indicators to be activated or deactivated for

compatibility with certain optional equipment. If the

problem being diagnosed involves improper illumi-

nation of the cruise indicator, the electronic throttle

control indicator, the service four-wheel drive indi-

cator, the tow/haul indicator, the transmission over-

temp indicator, the upshift indicator, the security

indicator or the gear selector indicator, disconnect

and isolate the battery negative cable. After about

five minutes, reconnect the battery negative cable

and turn the ignition switch to the On position. The

instrument cluster should automatically relearn the

equipment in the vehicle and properly configure the

configurable indicators accordingly.

ABS INDICATOR

DESCRIPTION

An Antilock Brake System (ABS) indicator is stan-

dard equipment on all instrument clusters (Fig. 8).

However, the instrument cluster can be programmed

to disable this indicator on vehicles that are not

equipped with the ABS or Rear Wheel Anti-Lock

(RWAL) brake systems, which are not available in

some markets. On vehicles equipped with a gasoline

engine, the ABS indicator is located near the lower

edge of the instrument cluster, between the tachom-

eter and the speedometer. On vehicles equipped with

a diesel engine, the ABS indicator is located on the

right side of the instrument cluster, to the right of

the engine temperature gauge. The ABS indicator

consists of a stencil-like cutout of the International

Control and Display Symbol icon for ªFailure of Anti-

lock Braking Systemº in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. An amber Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The ABS

indicator is serviced as a unit with the instrument

cluster.

OPERATION

The ABS indicator gives an indication to the vehi-

cle operator when the ABS system is faulty or inop-

erative. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the Controller Antilock Brake (CAB)

over the Programmable Communications Interface

(PCI) data bus. The ABS indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the LED will always be off when the ignition switch

is in any position except On or Start. The LED only

illuminates when it is provided a path to ground by

the instrument cluster transistor. The instrument

cluster will turn on the ABS indicator for the follow-

ing reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the ABS indicator is illu-

minated by the cluster for about two seconds as a

bulb test.

²ABS Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the CAB, the

ABS indicator will be illuminated. The indicator

remains illuminated until the cluster receives a

lamp-off message from the CAB, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Communication Error- If the cluster receives

no lamp-on or lamp-off messages from the CAB for

three consecutive seconds, the ABS indicator is illu-

minated. The indicator remains illuminated until the

cluster receives a valid message from the CAB, or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the instrument clus-

ter is put through the actuator test, the ABS indica-

tor will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

²ABS Diagnostic Test- The ABS indicator is

blinked on and off by lamp-on and lamp-off messages

from the CAB during the performance of the ABS

diagnostic tests.

The CAB continually monitors the ABS circuits

and sensors to decide whether the system is in good

operating condition. The CAB then sends the proper

lamp-on or lamp-off messages to the instrument clus-

ter. If the CAB sends a lamp-on message after the

bulb test, it indicates that the CAB has detected a

system malfunction and/or that the ABS system has

become inoperative. The CAB will store a Diagnostic

Trouble Code (DTC) for any malfunction it detects.

Fig. 8 ABS Indicator

DRINSTRUMENT CLUSTER 8J - 17

INSTRUMENT CLUSTER (Continued)

Page 545 of 2627

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The secu-

rity indicator is serviced as a unit with the instru-

ment cluster.

OPERATION

The security indicator gives an indication to the

vehicle operator when the Vehicle Theft Security Sys-

tem (VTSS) is arming or is armed. On models

equipped with the Sentry Key Immobilizer System

(SKIS), the security indicator also gives an indication

to the vehicle operator of the status of the SKIS. This

indicator is controlled by a transistor on the instru-

ment cluster circuit board based upon cluster pro-

gramming, hard wired inputs to the cluster from the

various security system components, electronic mes-

sages received by the cluster from the Remote Key-

less Entry (RKE) receiver module over a dedicated

serial bus, and electronic messages received by the

cluster from the Sentry Key Immobilizer Module

(SKIM) over the Programmable Communications

Interface (PCI) data bus. The security indicator Light

Emitting Diode (LED) is completely controlled by the

instrument cluster logic circuit, and that logic will

allow this indicator to operate whenever the instru-

ment cluster receives a battery current input on the

fused B(+) circuit. Therefore, the LED can be illumi-

nated regardless of the ignition switch position. The

LED only illuminates when it is provided a path to

ground by the instrument cluster transistor. The

instrument cluster will turn on the security indicator

for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position, the SKIM tells the cluster

to illuminate the SKIS indicator for about two sec-

onds as a bulb test.

²VTSS Indication- During the sixteen second

VTSS arming function, the cluster will flash the

security indicator on and off repeatedly at a steady,

fast rate to indicate that the VTSS is in the process

of arming. Following successful VTSS arming, the

cluster flashes the security indicator on and off con-

tinuously at a slower rate to indicate that the VTSS

is armed. The security indicator continues flashing at

the slower rate until the VTSS is disarmed or trig-

gered. If the VTSS has alarmed and rearmed, the

cluster will flash the security indicator at a steady,

slow rate for about thirty seconds after the VTSS is

disarmed.

²SKIM Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the SKIM, the

security indicator will be illuminated. The indicator

can be flashed on and off, or illuminated solid, as dic-

tated by the SKIM message. The indicator remains

illuminated solid or continues to flash until the clus-

ter receives a lamp-off message from the SKIM, oruntil the ignition switch is turned to the Off position,

whichever occurs first. For more information on the

SKIS and the security indicator control parameters,

(Refer to 8 - ELECTRICAL/VEHICLE THEFT SECU-

RITY/SENTRY KEY IMMOBILIZER SYSTEM -

OPERATION).

²Communication Error- If the cluster receives

no SKIS lamp-on or lamp-off messages from the

SKIM for twenty consecutive seconds, the SKIS indi-

cator is illuminated by the instrument cluster. The

indicator remains controlled and illuminated by the

cluster until a valid SKIS lamp-on or lamp-off mes-

sage is received from the SKIM.

²Actuator Test- Each time the instrument clus-

ter is put through the actuator test, the security indi-

cator will be turned on, then off again during the

bulb check portion of the test to confirm the function-

ality of the LED and the cluster control circuitry.

The instrument cluster circuitry controls the secu-

rity indicator whenever the ignition switch is in the

Off position and the VTSS is arming, armed, or

alarming. Whenever the ignition switch is in the On

or Start positions, the SKIM performs a self-test to

decide whether the SKIS is in good operating condi-

tion and whether a valid key is present in the igni-

tion lock cylinder. The SKIM then sends the proper

lamp-on or lamp-off messages to the instrument clus-

ter. For further diagnosis of the security indicator or

the instrument cluster circuitry that controls the

indicator, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). If the

instrument cluster flashes the SKIS indicator upon

ignition On, or turns on the SKIS indicator solid

after the bulb test, it indicates that a SKIS malfunc-

tion has occurred or that the SKIS is inoperative. For

proper diagnosis of the VTSS, the SKIS, the SKIM,

the PCI data bus, or the electronic message inputs to

the instrument cluster that control the security indi-

cator, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

SERVICE 4WD INDICATOR

DESCRIPTION

A service 4WD indicator is standard equipment on

all instrument clusters (Fig. 27). However, on vehi-

cles not equipped with the optional four-wheel drive

system and electronically shifted transfer case, this

indicator is electronically disabled. The service 4WD

indicator consists of the text ªSERV 4WDº, which

Fig. 27 Service 4WD Indicator

8J - 36 INSTRUMENT CLUSTERDR

SECURITY INDICATOR (Continued)