Clutch DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1156 of 2627

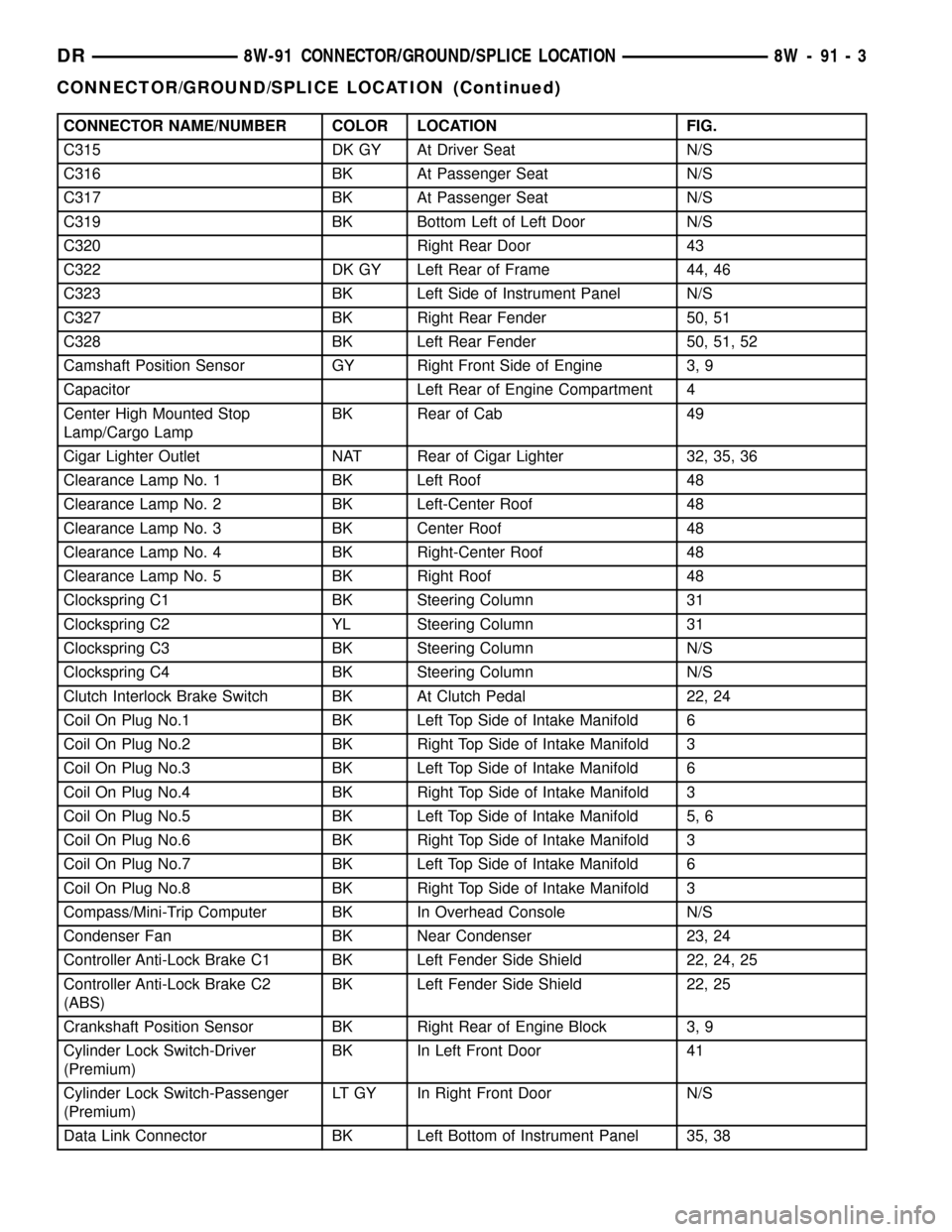

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C315 DK GY At Driver Seat N/S

C316 BK At Passenger Seat N/S

C317 BK At Passenger Seat N/S

C319 BK Bottom Left of Left Door N/S

C320 Right Rear Door 43

C322 DK GY Left Rear of Frame 44, 46

C323 BK Left Side of Instrument Panel N/S

C327 BK Right Rear Fender 50, 51

C328 BK Left Rear Fender 50, 51, 52

Camshaft Position Sensor GY Right Front Side of Engine 3, 9

Capacitor Left Rear of Engine Compartment 4

Center High Mounted Stop

Lamp/Cargo LampBK Rear of Cab 49

Cigar Lighter Outlet NAT Rear of Cigar Lighter 32, 35, 36

Clearance Lamp No. 1 BK Left Roof 48

Clearance Lamp No. 2 BK Left-Center Roof 48

Clearance Lamp No. 3 BK Center Roof 48

Clearance Lamp No. 4 BK Right-Center Roof 48

Clearance Lamp No. 5 BK Right Roof 48

Clockspring C1 BK Steering Column 31

Clockspring C2 YL Steering Column 31

Clockspring C3 BK Steering Column N/S

Clockspring C4 BK Steering Column N/S

Clutch Interlock Brake Switch BK At Clutch Pedal 22, 24

Coil On Plug No.1 BK Left Top Side of Intake Manifold 6

Coil On Plug No.2 BK Right Top Side of Intake Manifold 3

Coil On Plug No.3 BK Left Top Side of Intake Manifold 6

Coil On Plug No.4 BK Right Top Side of Intake Manifold 3

Coil On Plug No.5 BK Left Top Side of Intake Manifold 5, 6

Coil On Plug No.6 BK Right Top Side of Intake Manifold 3

Coil On Plug No.7 BK Left Top Side of Intake Manifold 6

Coil On Plug No.8 BK Right Top Side of Intake Manifold 3

Compass/Mini-Trip Computer BK In Overhead Console N/S

Condenser Fan BK Near Condenser 23, 24

Controller Anti-Lock Brake C1 BK Left Fender Side Shield 22, 24, 25

Controller Anti-Lock Brake C2

(ABS)BK Left Fender Side Shield 22, 25

Crankshaft Position Sensor BK Right Rear of Engine Block 3, 9

Cylinder Lock Switch-Driver

(Premium)BK In Left Front Door 41

Cylinder Lock Switch-Passenger

(Premium)LT GY In Right Front Door N/S

Data Link Connector BK Left Bottom of Instrument Panel 35, 38

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1280 of 2627

(5) Install fan blade assembly (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

INSTALLATION).

(6) Install radiator upper shroud and tighten fas-

teners to 11 N´m (95 in. lbs.).

(7) Connect electrical connector for shroud fan.

(8) Install radiator upper hose.

(9) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(10) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Connect negative cable to battery.

STRUCTURAL COVER

DESCRIPTION

The structural dust cover is made of die cast alu-

minum and joins the lower half of the transmission

bell housing to the engine bedplate.

OPERATION

The structural cover provides additional power-

train stiffness and reduces noise and vibration.

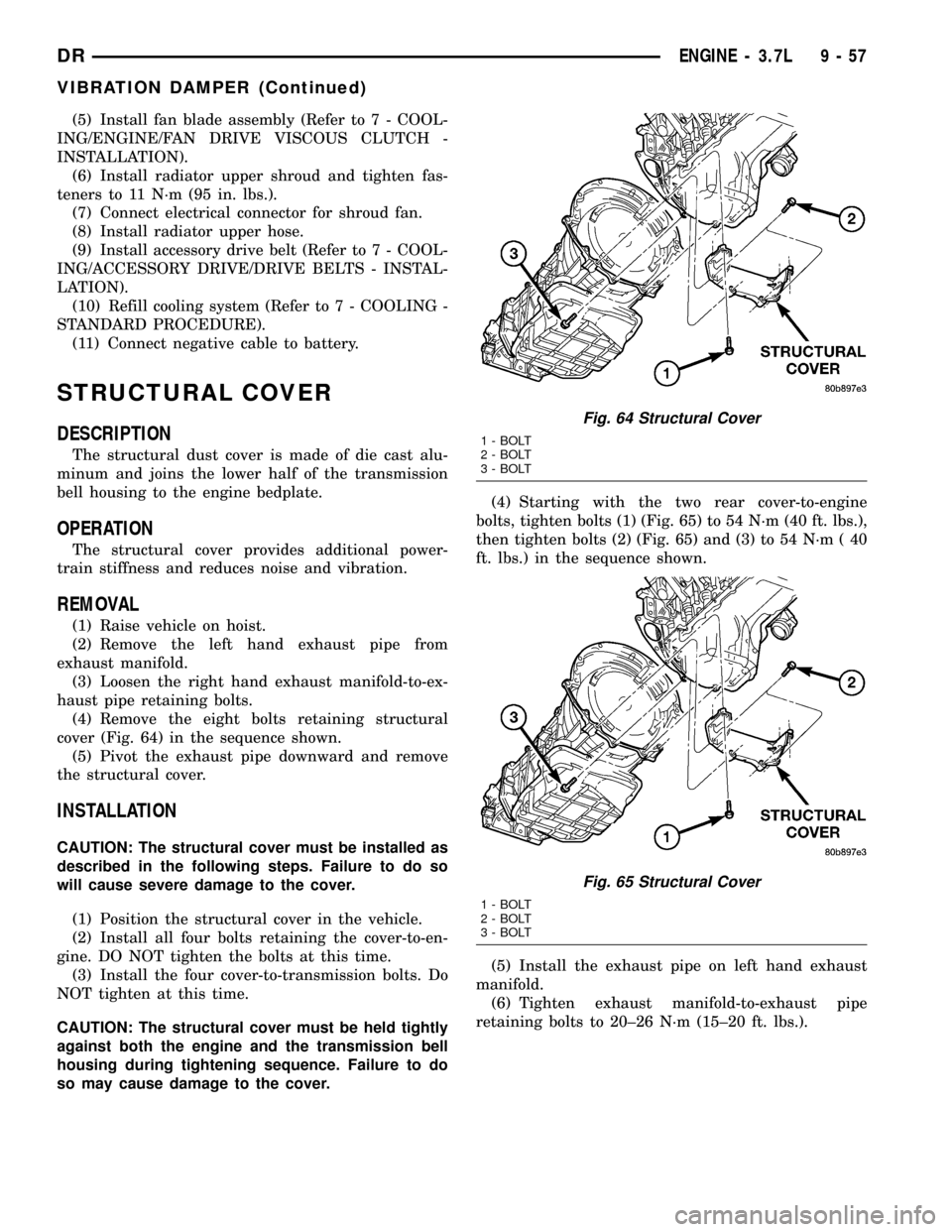

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the left hand exhaust pipe from

exhaust manifold.

(3) Loosen the right hand exhaust manifold-to-ex-

haust pipe retaining bolts.

(4) Remove the eight bolts retaining structural

cover (Fig. 64) in the sequence shown.

(5) Pivot the exhaust pipe downward and remove

the structural cover.

INSTALLATION

CAUTION: The structural cover must be installed as

described in the following steps. Failure to do so

will cause severe damage to the cover.

(1) Position the structural cover in the vehicle.

(2) Install all four bolts retaining the cover-to-en-

gine. DO NOT tighten the bolts at this time.

(3) Install the four cover-to-transmission bolts. Do

NOT tighten at this time.

CAUTION: The structural cover must be held tightly

against both the engine and the transmission bell

housing during tightening sequence. Failure to do

so may cause damage to the cover.(4) Starting with the two rear cover-to-engine

bolts, tighten bolts (1) (Fig. 65) to 54 N´m (40 ft. lbs.),

then tighten bolts (2) (Fig. 65) and (3) to 54 N´m ( 40

ft. lbs.) in the sequence shown.

(5) Install the exhaust pipe on left hand exhaust

manifold.

(6) Tighten exhaust manifold-to-exhaust pipe

retaining bolts to 20±26 N´m (15±20 ft. lbs.).

Fig. 64 Structural Cover

1 - BOLT

2 - BOLT

3 - BOLT

Fig. 65 Structural Cover

1 - BOLT

2 - BOLT

3 - BOLT

DRENGINE - 3.7L 9 - 57

VIBRATION DAMPER (Continued)

Page 1281 of 2627

FRONT MOUNT

REMOVAL

2WD

(1) Disconnect the negative cable from the battery.

CAUTION: Remove the viscous fan before raising

engine. Failure to do so may cause damage to the

fan blade, fan clutch and fan shroud.

(2) Remove the viscous fan (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(3) Raise the vehicle.

(4) Remove the engine oil filter.

(5) Remove the oil drain trough.

(6)

Support the engine with a suitable jack and a

block of wood across the full width of the engine oil pan.

(7) Support the front axle with a suitable jack.

(8) Remove the (4) bolts that attach the engine

mounts to the front axle.

(9) Remove the (3) bolts that attach the front axle

to the left engine bracket.

(10) Lower the front axle.

(11) Remove the through bolts(12) Raise the engine far enough to be able to

remove the left and right engine mounts.

(13) Remove the (8) mount to engine attaching

bolts

(14) Remove the engine mounts.

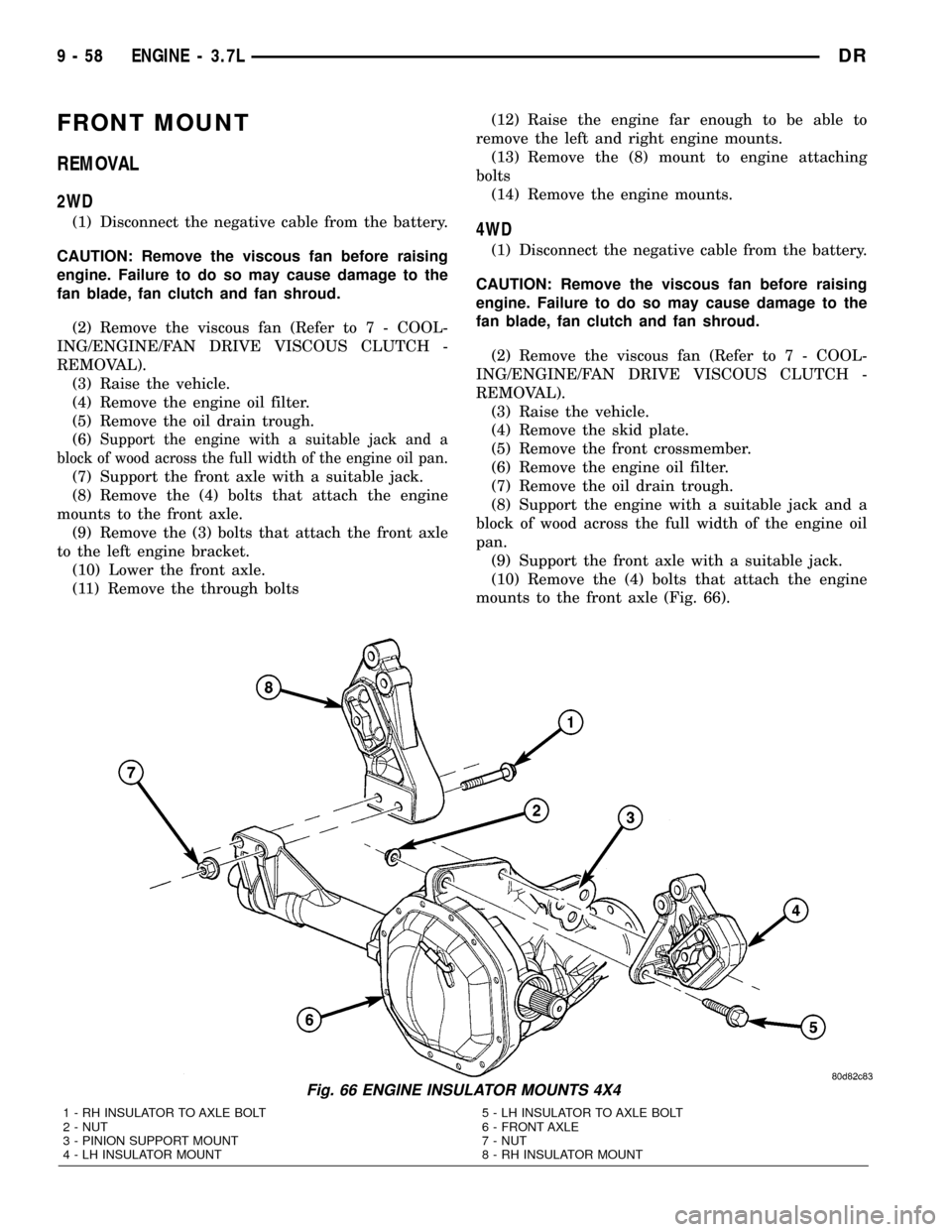

4WD

(1) Disconnect the negative cable from the battery.

CAUTION: Remove the viscous fan before raising

engine. Failure to do so may cause damage to the

fan blade, fan clutch and fan shroud.

(2) Remove the viscous fan (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(3) Raise the vehicle.

(4) Remove the skid plate.

(5) Remove the front crossmember.

(6) Remove the engine oil filter.

(7) Remove the oil drain trough.

(8) Support the engine with a suitable jack and a

block of wood across the full width of the engine oil

pan.

(9) Support the front axle with a suitable jack.

(10) Remove the (4) bolts that attach the engine

mounts to the front axle (Fig. 66).

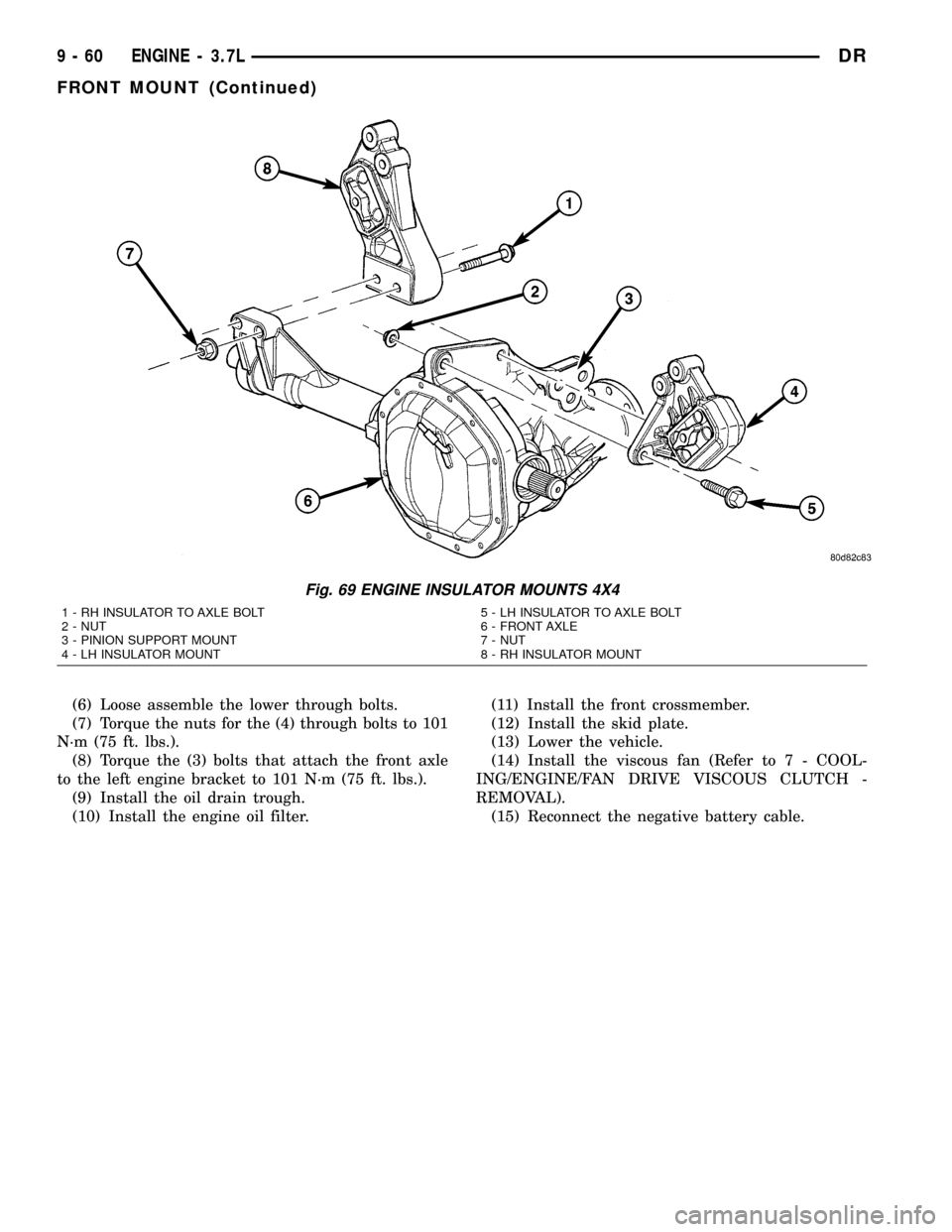

Fig. 66 ENGINE INSULATOR MOUNTS 4X4

1 - RH INSULATOR TO AXLE BOLT

2 - NUT

3 - PINION SUPPORT MOUNT

4 - LH INSULATOR MOUNT5 - LH INSULATOR TO AXLE BOLT

6 - FRONT AXLE

7 - NUT

8 - RH INSULATOR MOUNT

9 - 58 ENGINE - 3.7LDR

Page 1282 of 2627

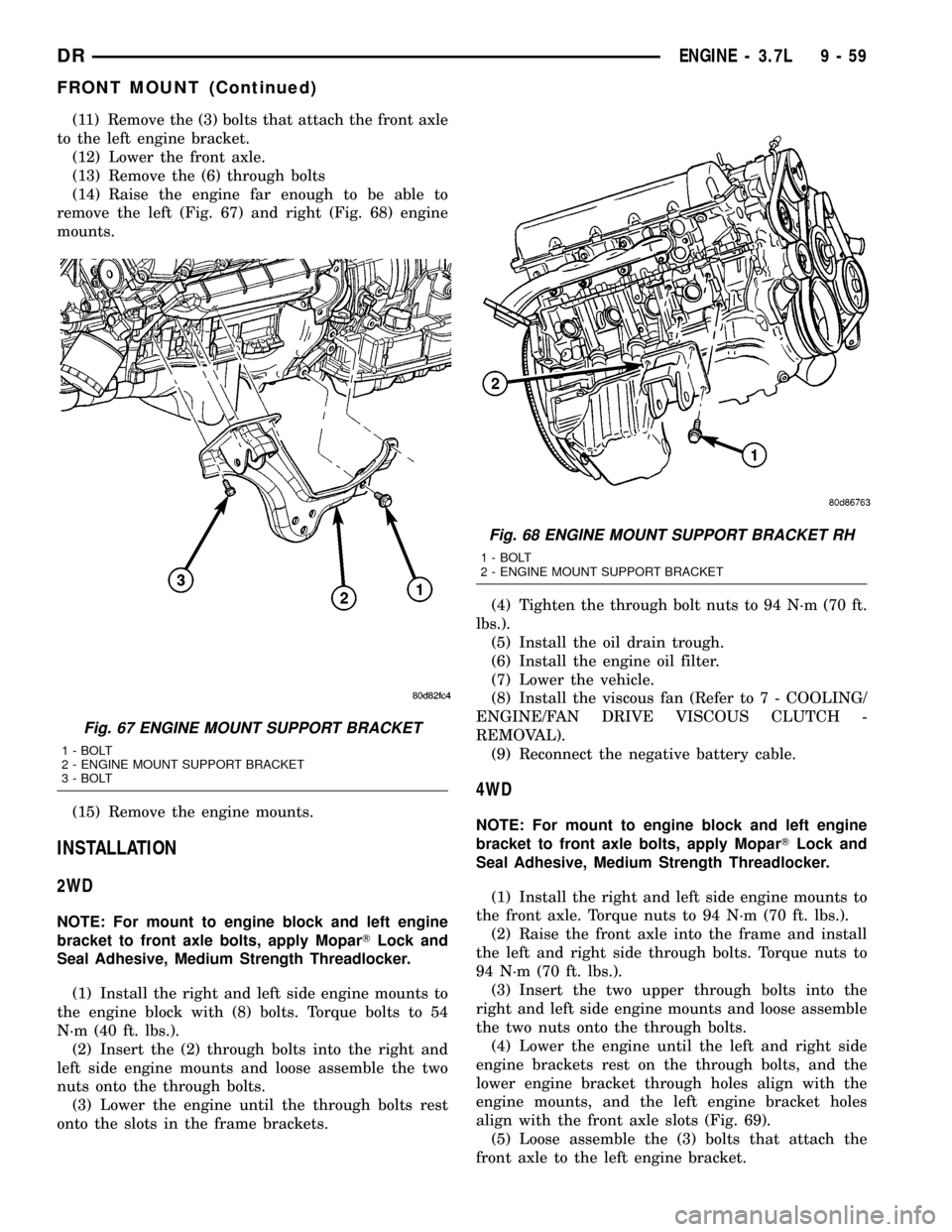

(11) Remove the (3) bolts that attach the front axle

to the left engine bracket.

(12) Lower the front axle.

(13) Remove the (6) through bolts

(14) Raise the engine far enough to be able to

remove the left (Fig. 67) and right (Fig. 68) engine

mounts.

(15) Remove the engine mounts.

INSTALLATION

2WD

NOTE: For mount to engine block and left engine

bracket to front axle bolts, apply MoparTLock and

Seal Adhesive, Medium Strength Threadlocker.

(1) Install the right and left side engine mounts to

the engine block with (8) bolts. Torque bolts to 54

N´m (40 ft. lbs.).

(2) Insert the (2) through bolts into the right and

left side engine mounts and loose assemble the two

nuts onto the through bolts.

(3) Lower the engine until the through bolts rest

onto the slots in the frame brackets.(4) Tighten the through bolt nuts to 94 N´m (70 ft.

lbs.).

(5) Install the oil drain trough.

(6) Install the engine oil filter.

(7) Lower the vehicle.

(8) Install the viscous fan (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(9) Reconnect the negative battery cable.

4WD

NOTE: For mount to engine block and left engine

bracket to front axle bolts, apply MoparTLock and

Seal Adhesive, Medium Strength Threadlocker.

(1) Install the right and left side engine mounts to

the front axle. Torque nuts to 94 N´m (70 ft. lbs.).

(2) Raise the front axle into the frame and install

the left and right side through bolts. Torque nuts to

94 N´m (70 ft. lbs.).

(3) Insert the two upper through bolts into the

right and left side engine mounts and loose assemble

the two nuts onto the through bolts.

(4) Lower the engine until the left and right side

engine brackets rest on the through bolts, and the

lower engine bracket through holes align with the

engine mounts, and the left engine bracket holes

align with the front axle slots (Fig. 69).

(5) Loose assemble the (3) bolts that attach the

front axle to the left engine bracket.

Fig. 67 ENGINE MOUNT SUPPORT BRACKET

1 - BOLT

2 - ENGINE MOUNT SUPPORT BRACKET

3 - BOLT

Fig. 68 ENGINE MOUNT SUPPORT BRACKET RH

1 - BOLT

2 - ENGINE MOUNT SUPPORT BRACKET

DRENGINE - 3.7L 9 - 59

FRONT MOUNT (Continued)

Page 1283 of 2627

(6) Loose assemble the lower through bolts.

(7) Torque the nuts for the (4) through bolts to 101

N´m (75 ft. lbs.).

(8) Torque the (3) bolts that attach the front axle

to the left engine bracket to 101 N´m (75 ft. lbs.).

(9) Install the oil drain trough.

(10) Install the engine oil filter.(11) Install the front crossmember.

(12) Install the skid plate.

(13) Lower the vehicle.

(14) Install the viscous fan (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(15) Reconnect the negative battery cable.

Fig. 69 ENGINE INSULATOR MOUNTS 4X4

1 - RH INSULATOR TO AXLE BOLT

2 - NUT

3 - PINION SUPPORT MOUNT

4 - LH INSULATOR MOUNT5 - LH INSULATOR TO AXLE BOLT

6 - FRONT AXLE

7 - NUT

8 - RH INSULATOR MOUNT

9 - 60 ENGINE - 3.7LDR

FRONT MOUNT (Continued)

Page 1287 of 2627

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.If the oil leak source is not posi-

tively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kPa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

9 - 64 ENGINE - 3.7LDR

LUBRICATION (Continued)

Page 1288 of 2627

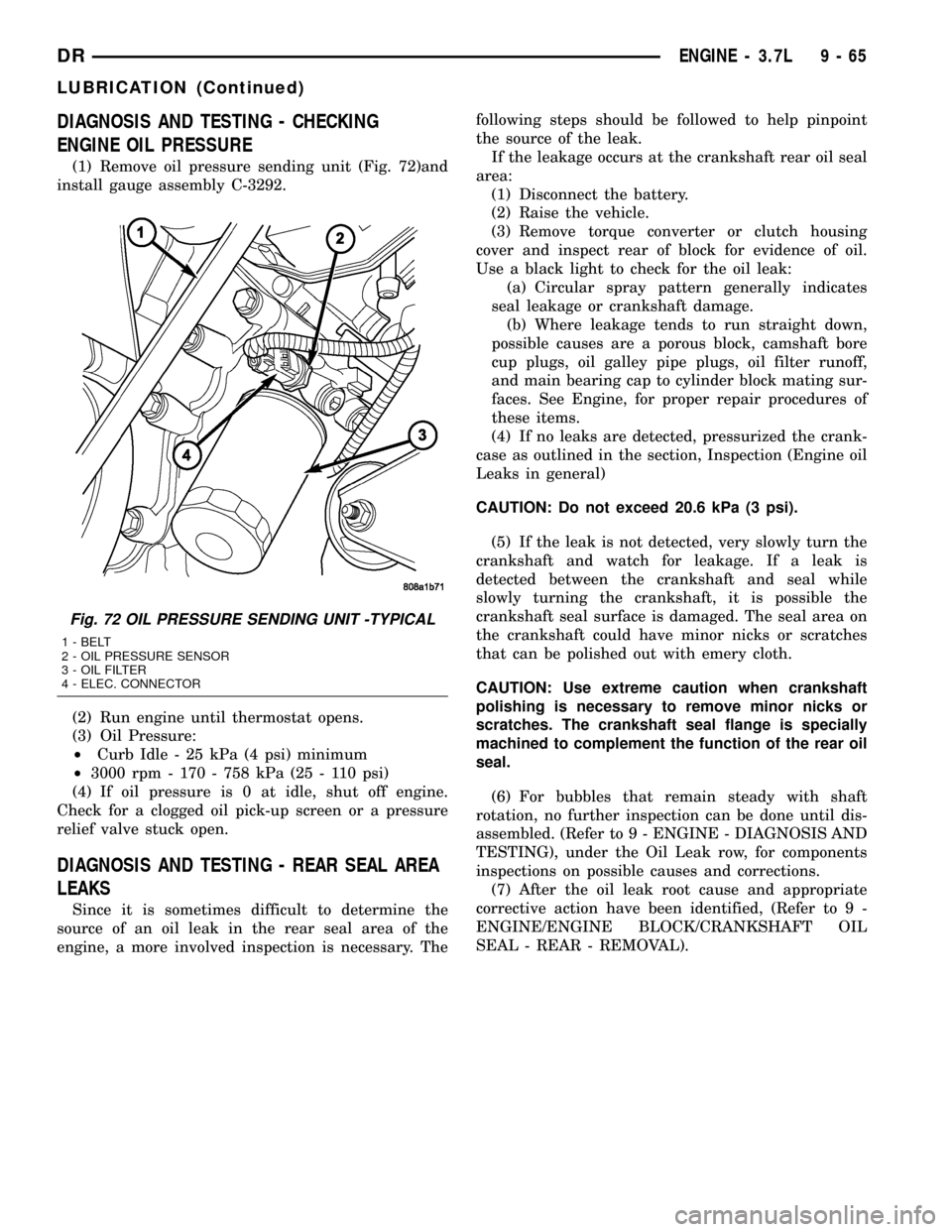

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit (Fig. 72)and

install gauge assembly C-3292.

(2) Run engine until thermostat opens.

(3) Oil Pressure:

²Curb Idle - 25 kPa (4 psi) minimum

²3000 rpm - 170 - 758 kPa (25 - 110 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

DIAGNOSIS AND TESTING - REAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. Thefollowing steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs, oil galley pipe plugs, oil filter runoff,

and main bearing cap to cylinder block mating sur-

faces. See Engine, for proper repair procedures of

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

Fig. 72 OIL PRESSURE SENDING UNIT -TYPICAL

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

DRENGINE - 3.7L 9 - 65

LUBRICATION (Continued)

Page 1304 of 2627

IDLER SHAFT

REMOVAL

(1) Remove the primary and secondary timing

chains and sprockets. Refer to procedure in this sec-

tion.

NOTE: To remove the idler shaft, it is necessary to

tap threads into the shaft, to install the removal

tool.

(2) Using a 12 mm X 1.75 tap, cut threads in the

idler shaft center bore.

(3) Cover the radiator core with a suitable cover.

CAUTION: Use care when removing the idler shaft,

Do not strike the radiator cooling fins with the slide

hammer.

(4) Using Special Tool 8517 Slide Hammer, remove

the idler shaft.

INSTALLATION

(1) Thoroughly clean the idler shaft bore.

(2) Position the idler shaft in the bore.

NOTE: The two lubrication holes in the idler shaft

do not require any special alignment.

NOTE: Before using the retaining bolt to install the

idler shaft, coat the threads and the pilot on the

idler shaft, with clean engine oil.

(3) Using the primary idler sprocket retaining bolt

and washer, carefully draw the idler shaft into the

bore until fully seated.

(4) Coat the idler shaft with clean engine oil.

(5) Install the timing chains and sprockets. Refer

to procedure in this section.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove electric cooling fan and fan shroud

assembly.

(4) Remove fan and fan drive assembly (Refer to 7

- COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(5) Disconnect both heater hoses at timing cover.

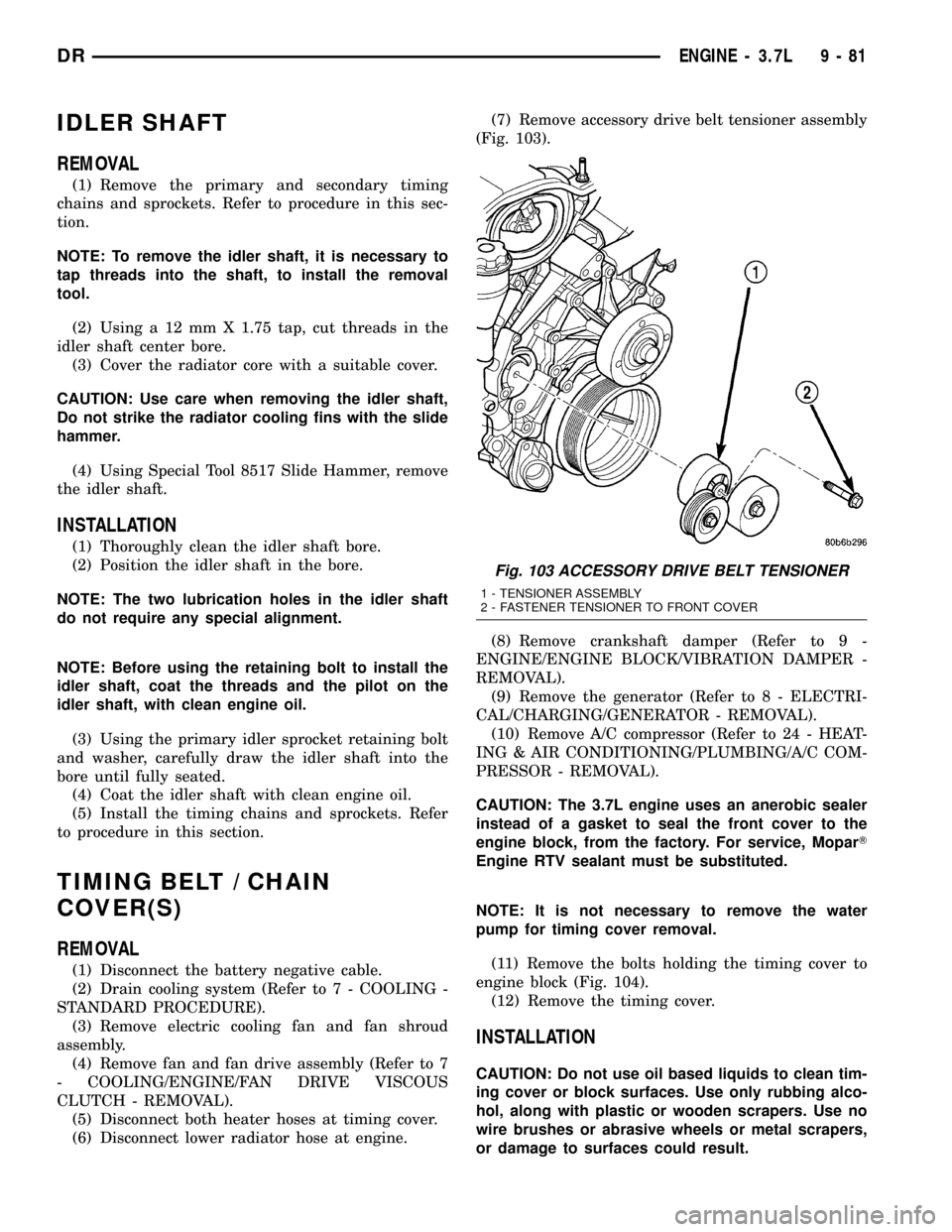

(6) Disconnect lower radiator hose at engine.(7) Remove accessory drive belt tensioner assembly

(Fig. 103).

(8) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(9) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(10) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

CAUTION: The 3.7L engine uses an anerobic sealer

instead of a gasket to seal the front cover to the

engine block, from the factory. For service, MoparT

Engine RTV sealant must be substituted.

NOTE: It is not necessary to remove the water

pump for timing cover removal.

(11) Remove the bolts holding the timing cover to

engine block (Fig. 104).

(12) Remove the timing cover.

INSTALLATION

CAUTION: Do not use oil based liquids to clean tim-

ing cover or block surfaces. Use only rubbing alco-

hol, along with plastic or wooden scrapers. Use no

wire brushes or abrasive wheels or metal scrapers,

or damage to surfaces could result.

Fig. 103 ACCESSORY DRIVE BELT TENSIONER

1 - TENSIONER ASSEMBLY

2 - FASTENER TENSIONER TO FRONT COVER

DRENGINE - 3.7L 9 - 81

Page 1305 of 2627

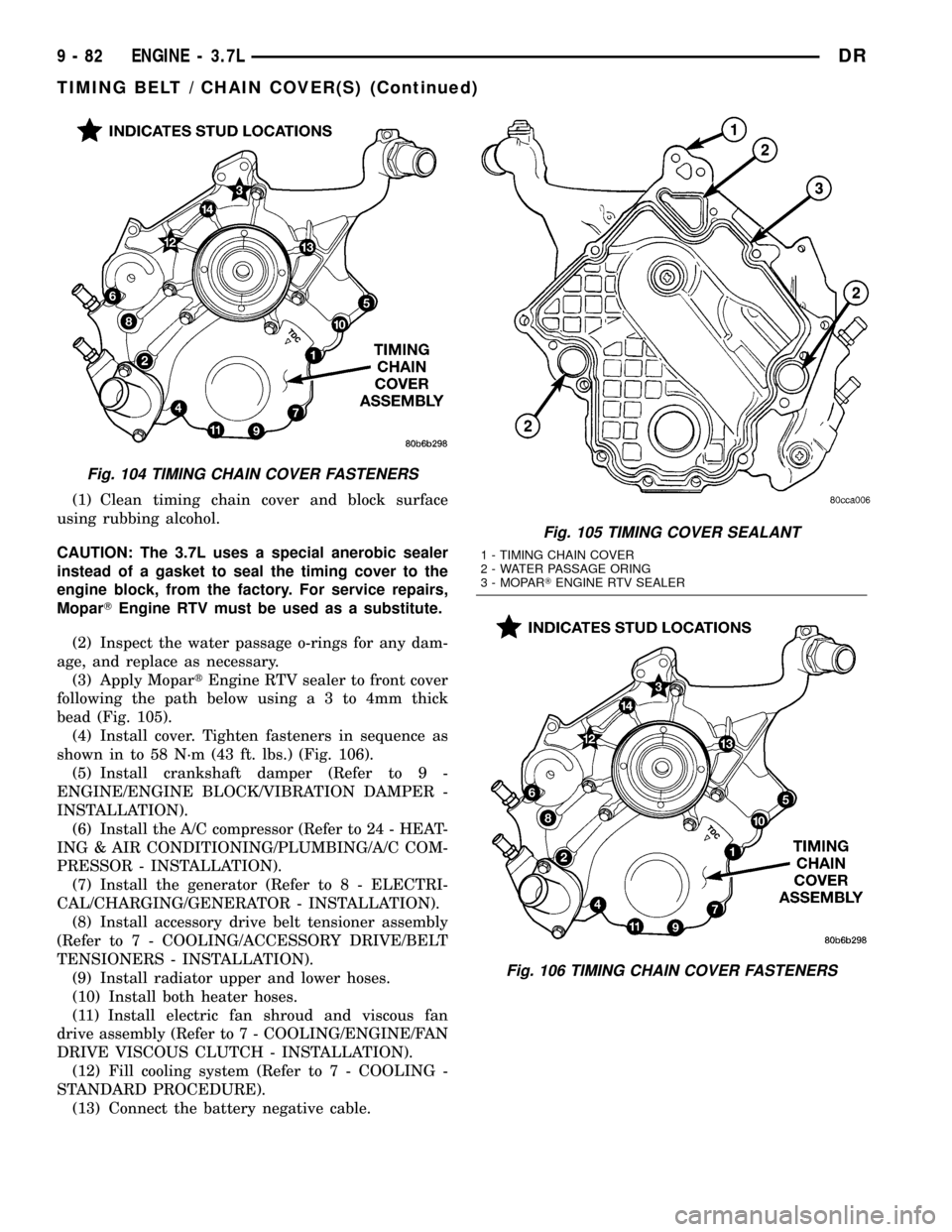

(1) Clean timing chain cover and block surface

using rubbing alcohol.

CAUTION: The 3.7L uses a special anerobic sealer

instead of a gasket to seal the timing cover to the

engine block, from the factory. For service repairs,

MoparTEngine RTV must be used as a substitute.

(2) Inspect the water passage o-rings for any dam-

age, and replace as necessary.

(3) Apply MopartEngine RTV sealer to front cover

following the path below usinga3to4mmthick

bead (Fig. 105).

(4) Install cover. Tighten fasteners in sequence as

shown in to 58 N´m (43 ft. lbs.) (Fig. 106).

(5) Install crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(6) Install the A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(7) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION).

(8) Install accessory drive belt tensioner assembly

(Refer to 7 - COOLING/ACCESSORY DRIVE/BELT

TENSIONERS - INSTALLATION).

(9) Install radiator upper and lower hoses.

(10) Install both heater hoses.

(11) Install electric fan shroud and viscous fan

drive assembly (Refer to 7 - COOLING/ENGINE/FAN

DRIVE VISCOUS CLUTCH - INSTALLATION).

(12) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect the battery negative cable.

Fig. 104 TIMING CHAIN COVER FASTENERS

Fig. 105 TIMING COVER SEALANT

1 - TIMING CHAIN COVER

2 - WATER PASSAGE ORING

3 - MOPARTENGINE RTV SEALER

Fig. 106 TIMING CHAIN COVER FASTENERS

9 - 82 ENGINE - 3.7LDR

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1319 of 2627

(19) Disconnect throttle and speed control cables.

(20) Disconnect tube from both the left and right

side crankcase breathers (Fig. 2). Remove breathers

(21) Discharge A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

(22) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

(23) Remove shroud, fan assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL) and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - REMOVAL).

(24) Disconnect transmission oil cooler lines at the

radiator.

(25) Disconnect radiator upper and lower hoses.

(26) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL), A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) and

transmission oil cooler.

(27) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(28) Disconnect the two heater hoses from the tim-

ing chain cover and heater core.

(29) Unclip and remove heater hoses and tubes

from the intake manifold.

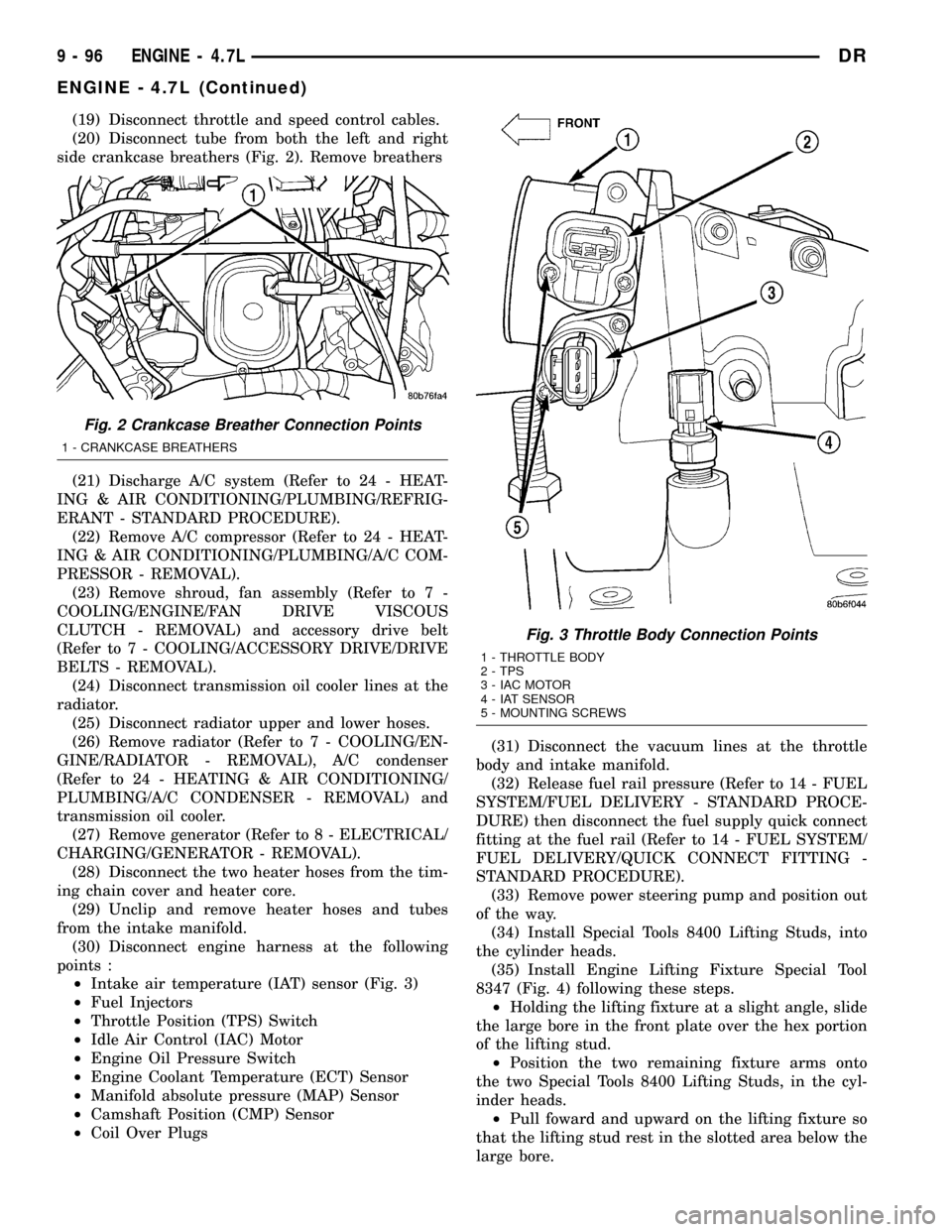

(30) Disconnect engine harness at the following

points :

²Intake air temperature (IAT) sensor (Fig. 3)

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs(31) Disconnect the vacuum lines at the throttle

body and intake manifold.

(32) Release fuel rail pressure (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - STANDARD PROCE-

DURE) then disconnect the fuel supply quick connect

fitting at the fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

(33) Remove power steering pump and position out

of the way.

(34) Install Special Tools 8400 Lifting Studs, into

the cylinder heads.

(35) Install Engine Lifting Fixture Special Tool

8347 (Fig. 4) following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.

Fig. 2 Crankcase Breather Connection Points

1 - CRANKCASE BREATHERS

Fig. 3 Throttle Body Connection Points

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

9 - 96 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)