Motor mount DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2523 of 2627

ING/CONTROLS/BLOWER MOTOR RESISTOR

BLOCK - INSTALLATION).

(5) If removed, install the blower motor (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION/BLOWER MOTOR - INSTALLATION).

(6) Install the HVAC wire harness. Make sure the

wires are routed through all wiring retainers.

(7) Connect the wire harness to the blower motor,

blower motor resistor block, evaporator temperature

sensor and each actuator.

(8) Install the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION).

INSTALLATION

WARNING: IF THE VEHICLE IS EQUIPPED WITH AIR

CONDITIONING, REVIEW THE WARNINGS AND

CAUTIONS IN PLUMBING BEFORE PERFORMING

THE FOLLOWING OPERATION. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - WARNING)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION -

REFRIGERANT HOSES/LINES/TUBES PRECAU-

TIONS)

(1) Position the HVAC housing into the vehicle. Be

certain that the evaporator condensate drain tube

and the housing mounting studs are inserted into

their correct locations.

(2) Install the two nuts that secure the HVAC

housing to the mounting studs in the passenger com-

partment. Tighten the nuts to 6.2 N´m (55 in. lbs.).

(3) Install the bolt that secures the HVAC housing

to the floor bracket in the passenger compartment.

Tighten the bolt to 6.2 N´m (55 in. lbs.).

(4) Install the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL - INSTALLATION).

(5) Install the two nuts that secure the HVAC

housing to the mounting studs in the engine com-

partment. Tighten the nuts to 6.2 N´m (55 in. lbs.).

(6) Install the powertrain control module (PCM)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/POWERTRAIN CONTROL MOD-

ULE - INSTALLATION).

(7) Unplug or remove the tape from the heater

core tubes and connect the heater hoses to the heater

core tubes.

(8) Unplug or remove the tape from the opened

refrigerant line fittings and the evaporator outlet

tube and install the accumulator (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR - INSTALLATION).

(9) Unplug or remove the tape from the liquid line

and the evaporator inlet tube fittings. Connect the

liquid line coupler to the evaporator inlet tube (Referto 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-

PLERS).

(10) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(11) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(12) Fill the engine cooling system (Refer to 7 -

COOLING/ENGINE - STANDARD PROCEDURE).

(13) Connect the battery negative cable.

(14) Start the engine and check for proper opera-

tion of the heating and air conditioning systems.

INSTRUMENT PANEL

DEMISTER DUCTS

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the defroster ducts (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

DEFROSTER DUCTS - REMOVAL).

(2) Remove the two screws that secure the center

distribution duct to the instrument panel support.

(3) Remove the center distribution duct from

instrument panel support, panel ducts and demister

ducts.

(4) Remove the right side panel duct adapter (Fig.

11).

(5) Remove the right side intermediate demister

duct.

(6) Remove the left side intermediate demister

duct.

(7) Remove the left side panel duct adapter.

(8) Remove the instrument panel cover (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - REMOVAL).

24 - 36 DISTRIBUTIONDR

HVAC HOUSING (Continued)

Page 2535 of 2627

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports.

NOTE: Always refer to the underhood HVAC Speci-

fication label for the refrigerant fill level of the vehi-

cle being serviced.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transmission in park or manual

transmission in neutral

²Engine at idle

²A/C mode control set to outside air

²A/C mode control set to panel mode

²A/C temperature control set to full cool

²Blower motor control set on highest speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure (Refer to 8 - ELECTRICAL/WIRING DIAGRAM

INFORMATION - DIAGNOSIS AND TESTING).

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood HVAC

specfication tag.

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

The A/C system on models equipped with the 5.9L

engine use a Sanden SD-7 reciprocating swash plate-

type compressor. This compressor has a fixed dis-

placement of 165 cubic centimeter (10.068 cubic

inches) and has both the suction and discharge ports

located on the cylinder head.

The A/C system on models equipped with the 3.7L,

4.7L and 5.7L engines use a Denso 10S17 reciprocat-

ing swash plate-type compressor. This compressor

has a fixed displacement of 170 cubic centimeter and

has both the suction and discharge ports located on

the cylinder head.

A label identifying the use of R-134a refrigerant is

located on both A/C compressors.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is on the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

24 - 48 PLUMBINGDR

PLUMBING (Continued)

Page 2539 of 2627

(11) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Reconnect the battery negative cable.

(13) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(14) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow next to the

engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When air passes through the condenser fins, the

high-pressure refrigerant gas within the A/C con-

denser gives up its heat. The refrigerant then con-

denses as it leaves the A/C condenser and becomes a

high-pressure liquid. The volume of air flowing over

the condenser fins is critical to the proper cooling

performance of the air conditioning system. There-fore, it is important that there are no objects placed

in front of the radiator grille openings at the front of

the vehicle or foreign material on the condenser fins

that might obstruct proper air flow. Also, any factory-

installed air seals or shrouds must be properly rein-

stalled following radiator or A/C condenser service.

The A/C condenser cannot be repaired and, if

faulty or damaged, it must be replaced.

REMOVAL

REMOVAL - 3.7, 4.7 AND 5.7L ENGINES

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

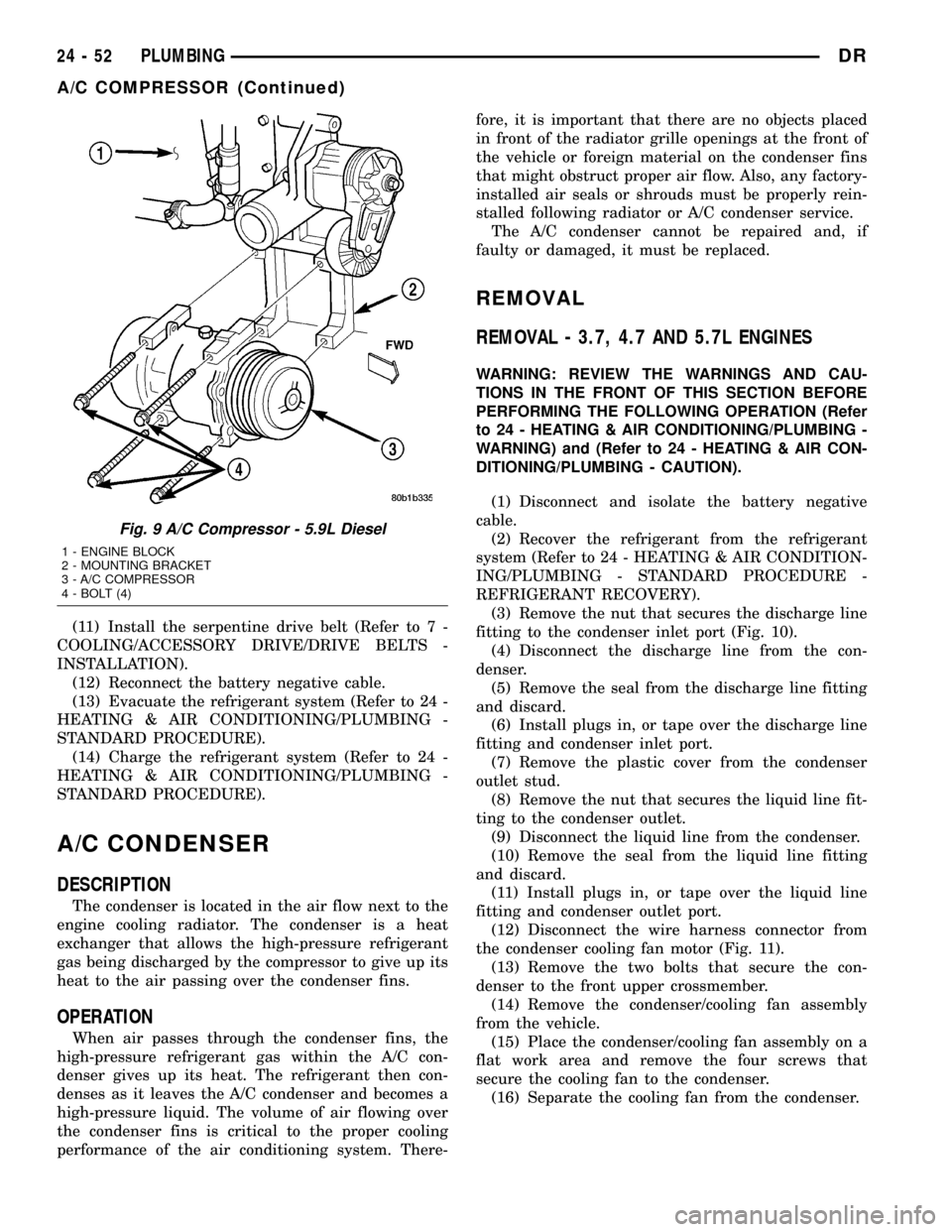

(3) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 10).

(4) Disconnect the discharge line from the con-

denser.

(5) Remove the seal from the discharge line fitting

and discard.

(6) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(7) Remove the plastic cover from the condenser

outlet stud.

(8) Remove the nut that secures the liquid line fit-

ting to the condenser outlet.

(9) Disconnect the liquid line from the condenser.

(10) Remove the seal from the liquid line fitting

and discard.

(11) Install plugs in, or tape over the liquid line

fitting and condenser outlet port.

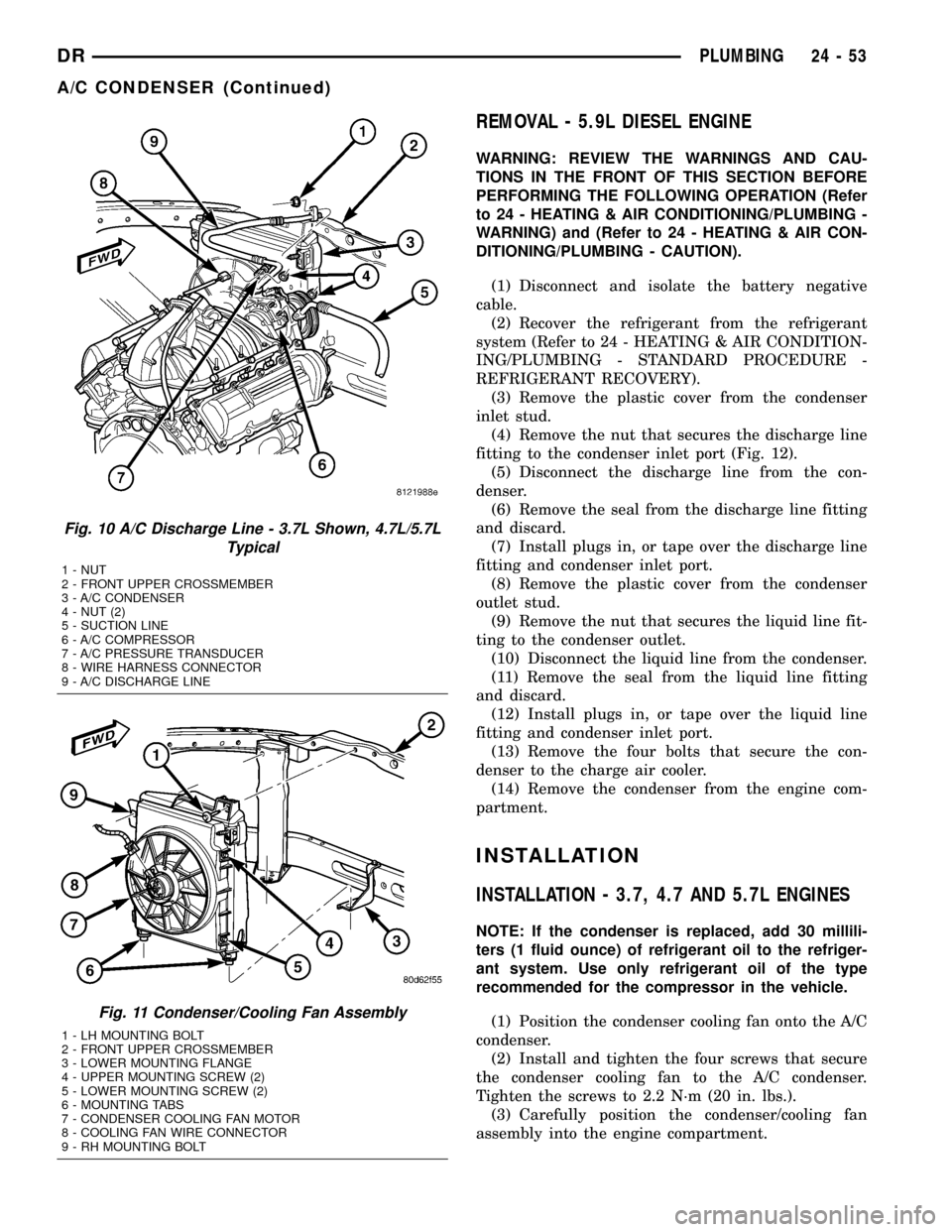

(12) Disconnect the wire harness connector from

the condenser cooling fan motor (Fig. 11).

(13) Remove the two bolts that secure the con-

denser to the front upper crossmember.

(14) Remove the condenser/cooling fan assembly

from the vehicle.

(15) Place the condenser/cooling fan assembly on a

flat work area and remove the four screws that

secure the cooling fan to the condenser.

(16) Separate the cooling fan from the condenser.

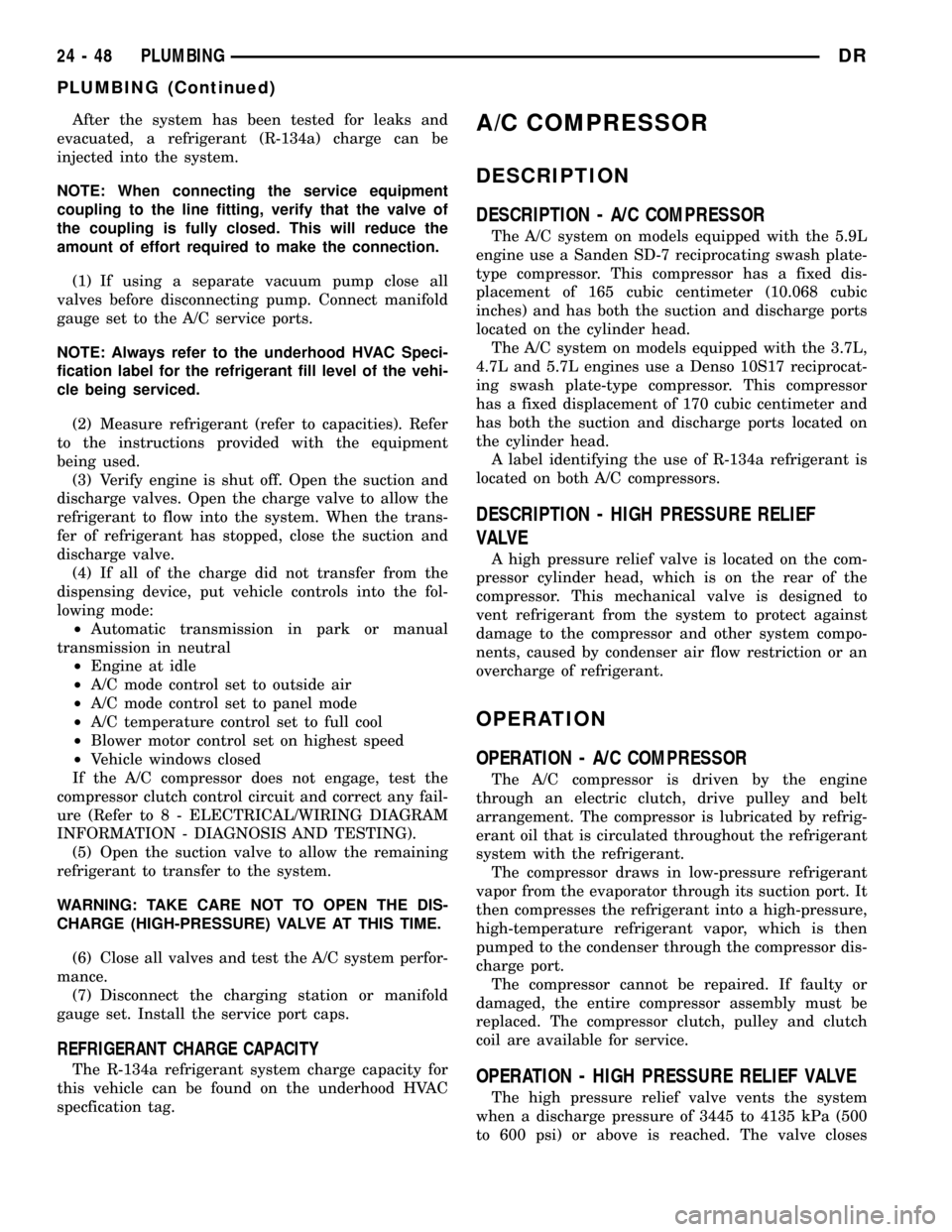

Fig. 9 A/C Compressor - 5.9L Diesel

1 - ENGINE BLOCK

2 - MOUNTING BRACKET

3 - A/C COMPRESSOR

4 - BOLT (4)

24 - 52 PLUMBINGDR

A/C COMPRESSOR (Continued)

Page 2540 of 2627

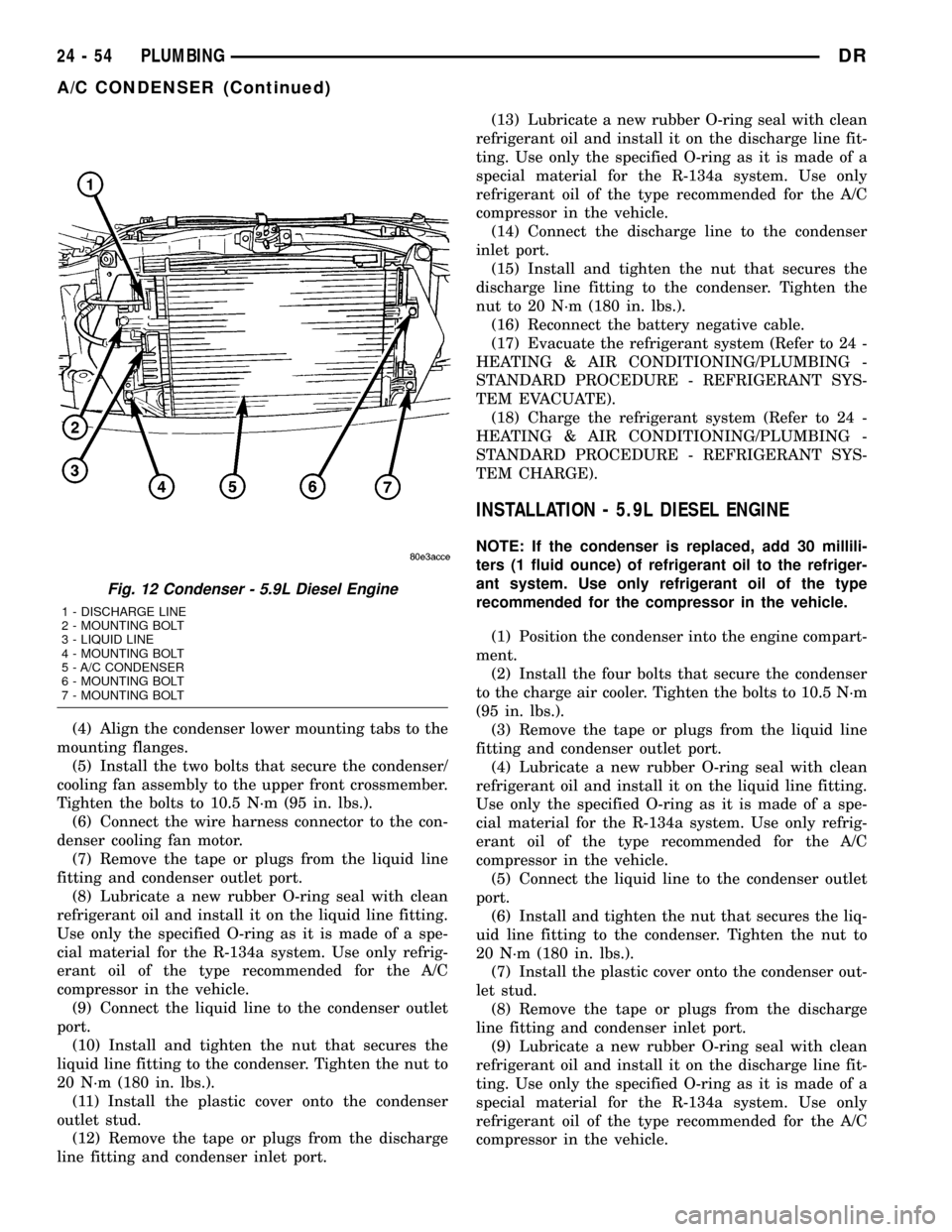

REMOVAL - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Remove the plastic cover from the condenser

inlet stud.

(4) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 12).

(5) Disconnect the discharge line from the con-

denser.

(6) Remove the seal from the discharge line fitting

and discard.

(7) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(8) Remove the plastic cover from the condenser

outlet stud.

(9) Remove the nut that secures the liquid line fit-

ting to the condenser outlet.

(10) Disconnect the liquid line from the condenser.

(11) Remove the seal from the liquid line fitting

and discard.

(12) Install plugs in, or tape over the liquid line

fitting and condenser inlet port.

(13) Remove the four bolts that secure the con-

denser to the charge air cooler.

(14) Remove the condenser from the engine com-

partment.

INSTALLATION

INSTALLATION - 3.7, 4.7 AND 5.7L ENGINES

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(1) Position the condenser cooling fan onto the A/C

condenser.

(2) Install and tighten the four screws that secure

the condenser cooling fan to the A/C condenser.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Carefully position the condenser/cooling fan

assembly into the engine compartment.

Fig. 10 A/C Discharge Line - 3.7L Shown, 4.7L/5.7L

Typical

1 - NUT

2 - FRONT UPPER CROSSMEMBER

3 - A/C CONDENSER

4 - NUT (2)

5 - SUCTION LINE

6 - A/C COMPRESSOR

7 - A/C PRESSURE TRANSDUCER

8 - WIRE HARNESS CONNECTOR

9 - A/C DISCHARGE LINE

Fig. 11 Condenser/Cooling Fan Assembly

1 - LH MOUNTING BOLT

2 - FRONT UPPER CROSSMEMBER

3 - LOWER MOUNTING FLANGE

4 - UPPER MOUNTING SCREW (2)

5 - LOWER MOUNTING SCREW (2)

6 - MOUNTING TABS

7 - CONDENSER COOLING FAN MOTOR

8 - COOLING FAN WIRE CONNECTOR

9 - RH MOUNTING BOLT

DRPLUMBING 24 - 53

A/C CONDENSER (Continued)

Page 2541 of 2627

(4) Align the condenser lower mounting tabs to the

mounting flanges.

(5) Install the two bolts that secure the condenser/

cooling fan assembly to the upper front crossmember.

Tighten the bolts to 10.5 N´m (95 in. lbs.).

(6) Connect the wire harness connector to the con-

denser cooling fan motor.

(7) Remove the tape or plugs from the liquid line

fitting and condenser outlet port.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

Use only the specified O-ring as it is made of a spe-

cial material for the R-134a system. Use only refrig-

erant oil of the type recommended for the A/C

compressor in the vehicle.

(9) Connect the liquid line to the condenser outlet

port.

(10) Install and tighten the nut that secures the

liquid line fitting to the condenser. Tighten the nut to

20 N´m (180 in. lbs.).

(11) Install the plastic cover onto the condenser

outlet stud.

(12) Remove the tape or plugs from the discharge

line fitting and condenser inlet port.(13) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(14) Connect the discharge line to the condenser

inlet port.

(15) Install and tighten the nut that secures the

discharge line fitting to the condenser. Tighten the

nut to 20 N´m (180 in. lbs.).

(16) Reconnect the battery negative cable.

(17) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(18) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

INSTALLATION - 5.9L DIESEL ENGINE

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(1) Position the condenser into the engine compart-

ment.

(2) Install the four bolts that secure the condenser

to the charge air cooler. Tighten the bolts to 10.5 N´m

(95 in. lbs.).

(3) Remove the tape or plugs from the liquid line

fitting and condenser outlet port.

(4) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

Use only the specified O-ring as it is made of a spe-

cial material for the R-134a system. Use only refrig-

erant oil of the type recommended for the A/C

compressor in the vehicle.

(5) Connect the liquid line to the condenser outlet

port.

(6) Install and tighten the nut that secures the liq-

uid line fitting to the condenser. Tighten the nut to

20 N´m (180 in. lbs.).

(7) Install the plastic cover onto the condenser out-

let stud.

(8) Remove the tape or plugs from the discharge

line fitting and condenser inlet port.

(9) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

Fig. 12 Condenser - 5.9L Diesel Engine

1 - DISCHARGE LINE

2 - MOUNTING BOLT

3 - LIQUID LINE

4 - MOUNTING BOLT

5 - A/C CONDENSER

6 - MOUNTING BOLT

7 - MOUNTING BOLT

24 - 54 PLUMBINGDR

A/C CONDENSER (Continued)

Page 2542 of 2627

(10) Connect the discharge line to the condenser

inlet port.

(11) Install and tighten the nut that secures the

discharge line fitting to the condenser. Tighten the

nut to 20 N´m (180 in. lbs.).

(12) Install the plastic cover onto the condenser

inlet stud.

(13) Reconnect the battery negative cable.

(14) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(15) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

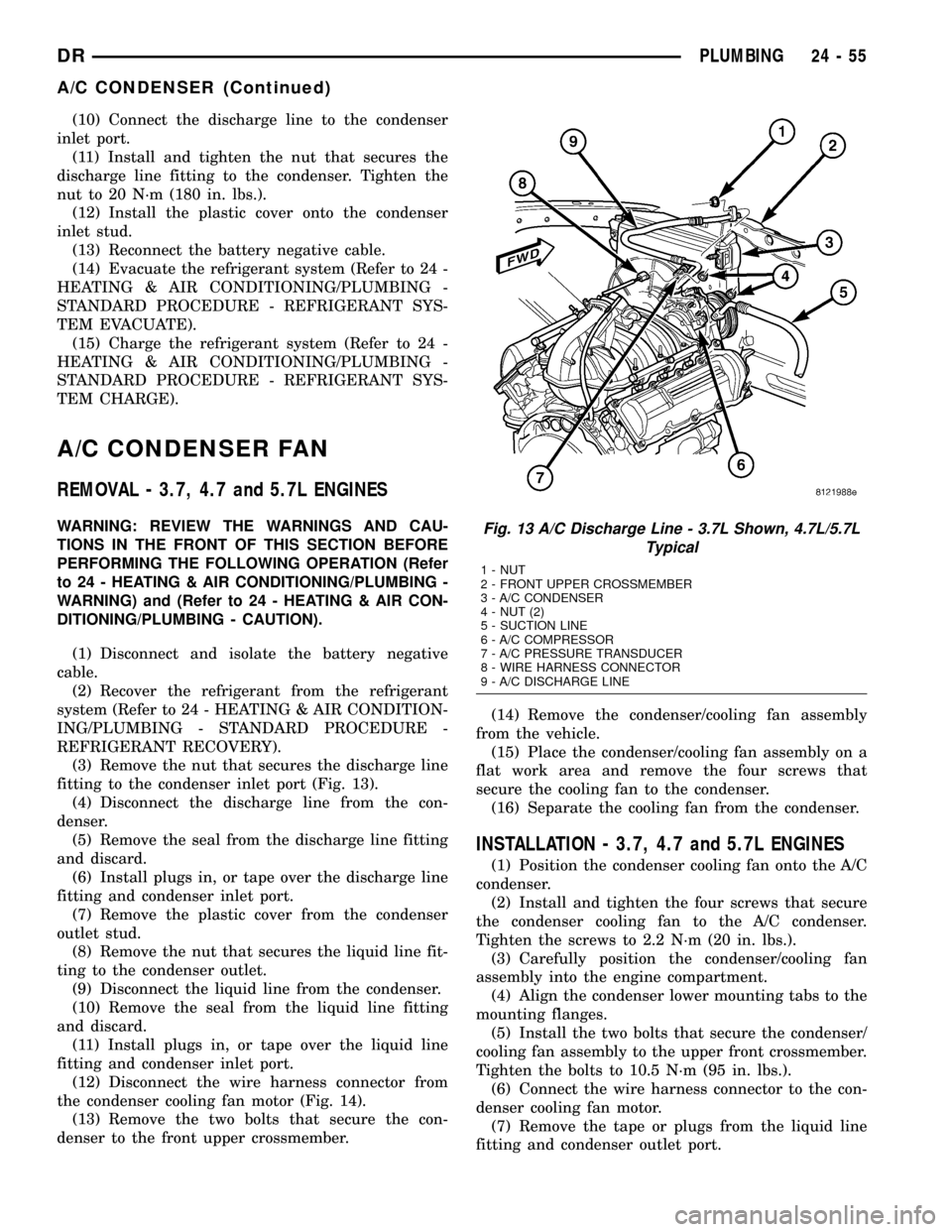

A/C CONDENSER FAN

REMOVAL - 3.7, 4.7 and 5.7L ENGINES

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 13).

(4) Disconnect the discharge line from the con-

denser.

(5) Remove the seal from the discharge line fitting

and discard.

(6) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(7) Remove the plastic cover from the condenser

outlet stud.

(8) Remove the nut that secures the liquid line fit-

ting to the condenser outlet.

(9) Disconnect the liquid line from the condenser.

(10) Remove the seal from the liquid line fitting

and discard.

(11) Install plugs in, or tape over the liquid line

fitting and condenser inlet port.

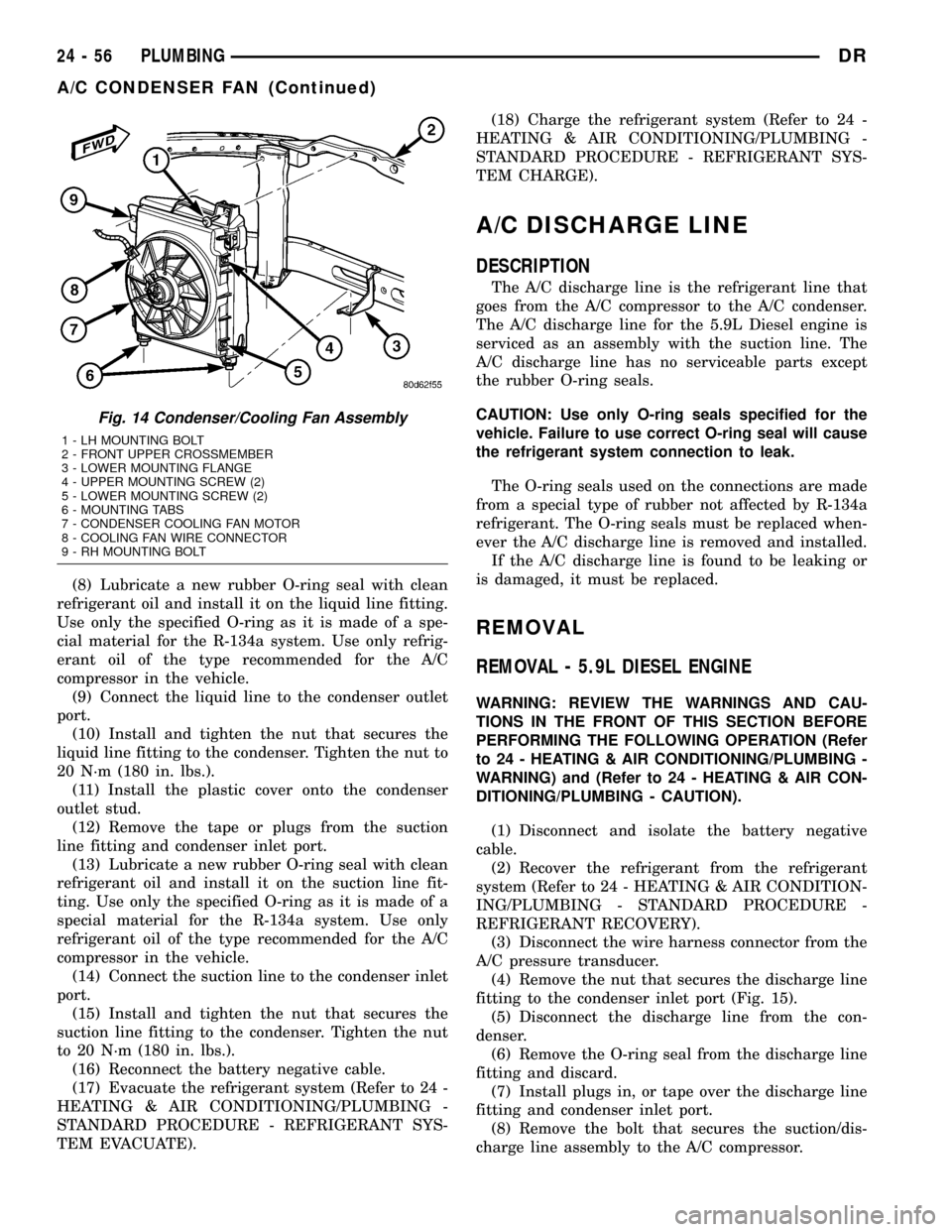

(12) Disconnect the wire harness connector from

the condenser cooling fan motor (Fig. 14).

(13) Remove the two bolts that secure the con-

denser to the front upper crossmember.(14) Remove the condenser/cooling fan assembly

from the vehicle.

(15) Place the condenser/cooling fan assembly on a

flat work area and remove the four screws that

secure the cooling fan to the condenser.

(16) Separate the cooling fan from the condenser.

INSTALLATION - 3.7, 4.7 and 5.7L ENGINES

(1) Position the condenser cooling fan onto the A/C

condenser.

(2) Install and tighten the four screws that secure

the condenser cooling fan to the A/C condenser.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Carefully position the condenser/cooling fan

assembly into the engine compartment.

(4) Align the condenser lower mounting tabs to the

mounting flanges.

(5) Install the two bolts that secure the condenser/

cooling fan assembly to the upper front crossmember.

Tighten the bolts to 10.5 N´m (95 in. lbs.).

(6) Connect the wire harness connector to the con-

denser cooling fan motor.

(7) Remove the tape or plugs from the liquid line

fitting and condenser outlet port.

Fig. 13 A/C Discharge Line - 3.7L Shown, 4.7L/5.7L

Typical

1 - NUT

2 - FRONT UPPER CROSSMEMBER

3 - A/C CONDENSER

4 - NUT (2)

5 - SUCTION LINE

6 - A/C COMPRESSOR

7 - A/C PRESSURE TRANSDUCER

8 - WIRE HARNESS CONNECTOR

9 - A/C DISCHARGE LINE

DRPLUMBING 24 - 55

A/C CONDENSER (Continued)

Page 2543 of 2627

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

Use only the specified O-ring as it is made of a spe-

cial material for the R-134a system. Use only refrig-

erant oil of the type recommended for the A/C

compressor in the vehicle.

(9) Connect the liquid line to the condenser outlet

port.

(10) Install and tighten the nut that secures the

liquid line fitting to the condenser. Tighten the nut to

20 N´m (180 in. lbs.).

(11) Install the plastic cover onto the condenser

outlet stud.

(12) Remove the tape or plugs from the suction

line fitting and condenser inlet port.

(13) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the suction line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(14) Connect the suction line to the condenser inlet

port.

(15) Install and tighten the nut that secures the

suction line fitting to the condenser. Tighten the nut

to 20 N´m (180 in. lbs.).

(16) Reconnect the battery negative cable.

(17) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).(18) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

A/C DISCHARGE LINE

DESCRIPTION

The A/C discharge line is the refrigerant line that

goes from the A/C compressor to the A/C condenser.

The A/C discharge line for the 5.9L Diesel engine is

serviced as an assembly with the suction line. The

A/C discharge line has no serviceable parts except

the rubber O-ring seals.

CAUTION: Use only O-ring seals specified for the

vehicle. Failure to use correct O-ring seal will cause

the refrigerant system connection to leak.

The O-ring seals used on the connections are made

from a special type of rubber not affected by R-134a

refrigerant. The O-ring seals must be replaced when-

ever the A/C discharge line is removed and installed.

If the A/C discharge line is found to be leaking or

is damaged, it must be replaced.

REMOVAL

REMOVAL - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Disconnect the wire harness connector from the

A/C pressure transducer.

(4) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 15).

(5) Disconnect the discharge line from the con-

denser.

(6) Remove the O-ring seal from the discharge line

fitting and discard.

(7) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(8) Remove the bolt that secures the suction/dis-

charge line assembly to the A/C compressor.

Fig. 14 Condenser/Cooling Fan Assembly

1 - LH MOUNTING BOLT

2 - FRONT UPPER CROSSMEMBER

3 - LOWER MOUNTING FLANGE

4 - UPPER MOUNTING SCREW (2)

5 - LOWER MOUNTING SCREW (2)

6 - MOUNTING TABS

7 - CONDENSER COOLING FAN MOTOR

8 - COOLING FAN WIRE CONNECTOR

9 - RH MOUNTING BOLT

24 - 56 PLUMBINGDR

A/C CONDENSER FAN (Continued)

Page 2550 of 2627

(12) Reconnect the battery negative cable.

(13) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(14) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

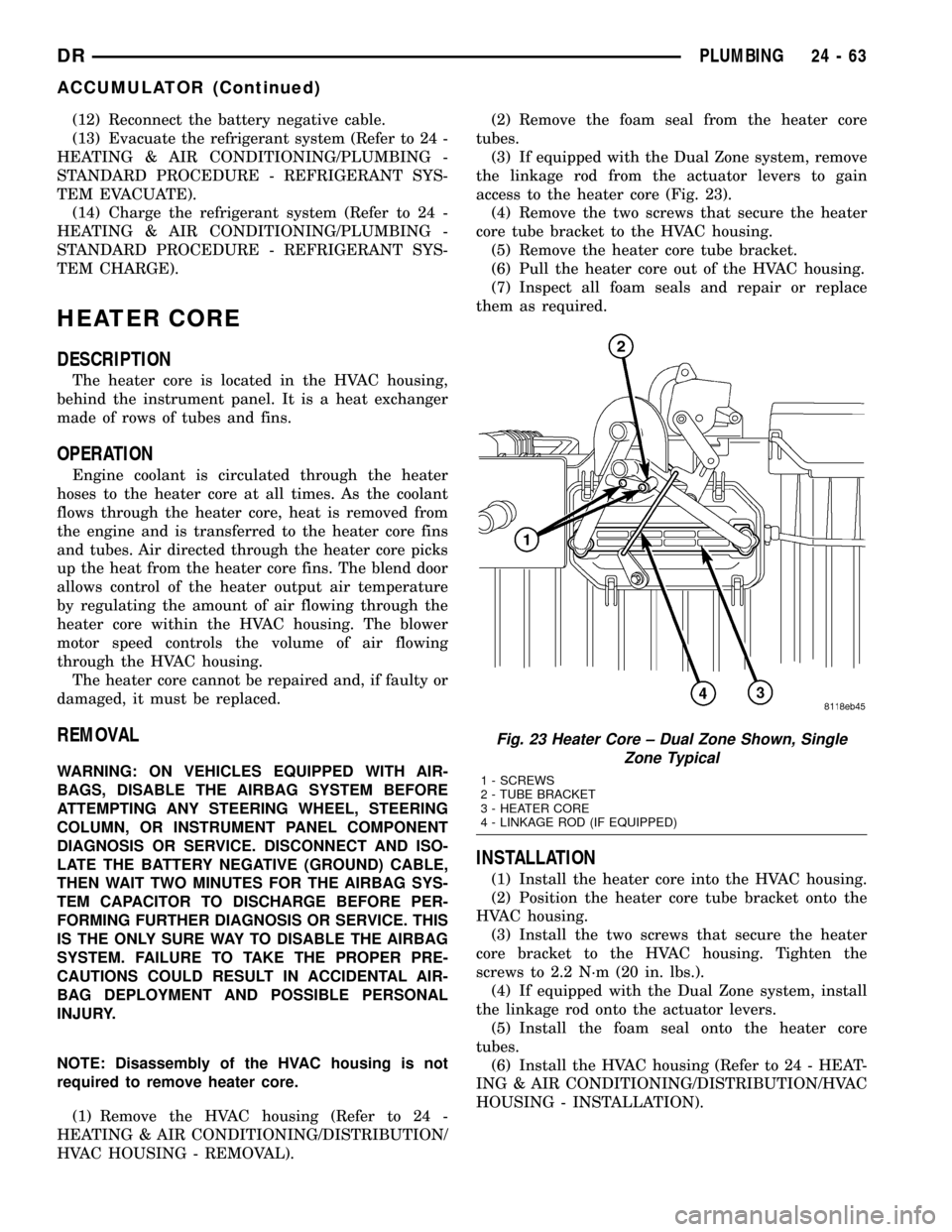

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

behind the instrument panel. It is a heat exchanger

made of rows of tubes and fins.

OPERATION

Engine coolant is circulated through the heater

hoses to the heater core at all times. As the coolant

flows through the heater core, heat is removed from

the engine and is transferred to the heater core fins

and tubes. Air directed through the heater core picks

up the heat from the heater core fins. The blend door

allows control of the heater output air temperature

by regulating the amount of air flowing through the

heater core within the HVAC housing. The blower

motor speed controls the volume of air flowing

through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: Disassembly of the HVAC housing is not

required to remove heater core.

(1) Remove the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).(2) Remove the foam seal from the heater core

tubes.

(3) If equipped with the Dual Zone system, remove

the linkage rod from the actuator levers to gain

access to the heater core (Fig. 23).

(4) Remove the two screws that secure the heater

core tube bracket to the HVAC housing.

(5) Remove the heater core tube bracket.

(6) Pull the heater core out of the HVAC housing.

(7) Inspect all foam seals and repair or replace

them as required.

INSTALLATION

(1) Install the heater core into the HVAC housing.

(2) Position the heater core tube bracket onto the

HVAC housing.

(3) Install the two screws that secure the heater

core bracket to the HVAC housing. Tighten the

screws to 2.2 N´m (20 in. lbs.).

(4) If equipped with the Dual Zone system, install

the linkage rod onto the actuator levers.

(5) Install the foam seal onto the heater core

tubes.

(6) Install the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION).

Fig. 23 Heater Core ± Dual Zone Shown, Single

Zone Typical

1 - SCREWS

2 - TUBE BRACKET

3 - HEATER CORE

4 - LINKAGE ROD (IF EQUIPPED)

DRPLUMBING 24 - 63

ACCUMULATOR (Continued)

Page 2588 of 2627

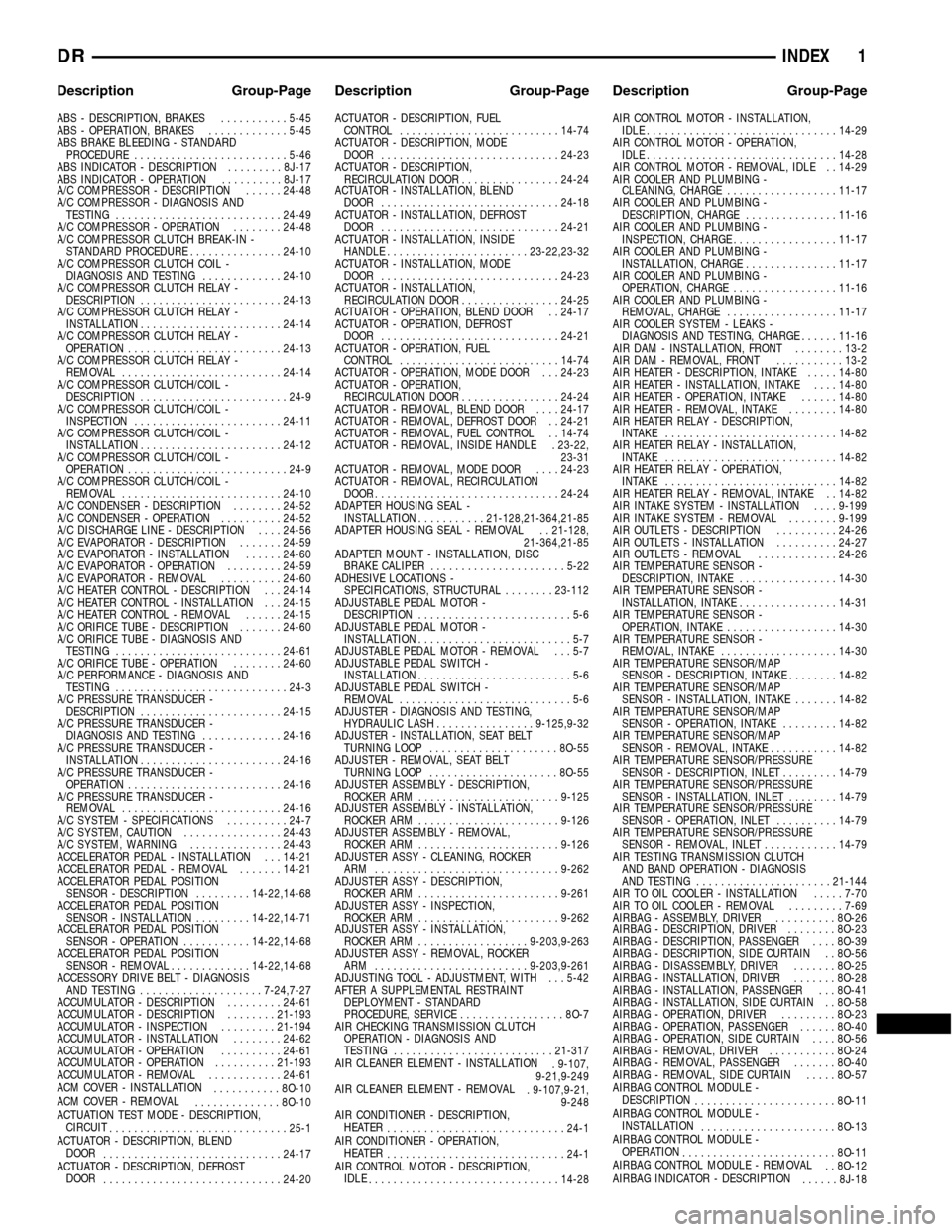

INDEX

ABS - DESCRIPTION, BRAKES...........5-45

ABS - OPERATION, BRAKES.............5-45

ABS BRAKE BLEEDING - STANDARD

PROCEDURE.........................5-46

ABS INDICATOR - DESCRIPTION.........8J-17

ABS INDICATOR - OPERATION..........8J-17

A/C COMPRESSOR - DESCRIPTION......24-48

A/C COMPRESSOR - DIAGNOSIS AND

TESTING...........................24-49

A/C COMPRESSOR - OPERATION........24-48

A/C COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-10

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-10

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-13

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-14

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-13

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-14

A/C COMPRESSOR CLUTCH/COIL -

DESCRIPTION........................24-9

A/C COMPRESSOR CLUTCH/COIL -

INSPECTION........................24-11

A/C COMPRESSOR CLUTCH/COIL -

INSTALLATION.......................24-12

A/C COMPRESSOR CLUTCH/COIL -

OPERATION..........................24-9

A/C COMPRESSOR CLUTCH/COIL -

REMOVAL..........................24-10

A/C CONDENSER - DESCRIPTION........24-52

A/C CONDENSER - OPERATION..........24-52

A/C DISCHARGE LINE - DESCRIPTION....24-56

A/C EVAPORATOR - DESCRIPTION.......24-59

A/C EVAPORATOR - INSTALLATION......24-60

A/C EVAPORATOR - OPERATION.........24-59

A/C EVAPORATOR - REMOVAL..........24-60

A/C HEATER CONTROL - DESCRIPTION . . . 24-14

A/C HEATER CONTROL - INSTALLATION . . . 24-15

A/C HEATER CONTROL - REMOVAL......24-15

A/C ORIFICE TUBE - DESCRIPTION.......24-60

A/C ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-61

A/C ORIFICE TUBE - OPERATION........24-60

A/C PERFORMANCE - DIAGNOSIS AND

TESTING............................24-3

A/C PRESSURE TRANSDUCER -

DESCRIPTION.......................24-15

A/C PRESSURE TRANSDUCER -

DIAGNOSIS AND TESTING.............24-16

A/C PRESSURE TRANSDUCER -

INSTALLATION.......................24-16

A/C PRESSURE TRANSDUCER -

OPERATION.........................24-16

A/C PRESSURE TRANSDUCER -

REMOVAL..........................24-16

A/C SYSTEM - SPECIFICATIONS..........24-7

A/C SYSTEM, CAUTION................24-43

A/C SYSTEM, WARNING...............24-43

ACCELERATOR PEDAL - INSTALLATION . . . 14-21

ACCELERATOR PEDAL - REMOVAL.......14-21

ACCELERATOR PEDAL POSITION

SENSOR - DESCRIPTION.........14-22,14-68

ACCELERATOR PEDAL POSITION

SENSOR - INSTALLATION.........14-22,14-71

ACCELERATOR PEDAL POSITION

SENSOR - OPERATION...........14-22,14-68

ACCELERATOR PEDAL POSITION

SENSOR - REMOVAL.............14-22,14-68

ACCESSORY DRIVE BELT - DIAGNOSIS

AND TESTING....................7-24,7-27

ACCUMULATOR - DESCRIPTION.........24-61

ACCUMULATOR - DESCRIPTION........21-193

ACCUMULATOR - INSPECTION.........21-194

ACCUMULATOR - INSTALLATION........24-62

ACCUMULATOR - OPERATION..........24-61

ACCUMULATOR - OPERATION..........21-193

ACCUMULATOR - REMOVAL............24-61

ACM COVER - INSTALLATION

...........8O-10

ACM COVER - REMOVAL

..............8O-10

ACTUATION TEST MODE - DESCRIPTION,

CIRCUIT

.............................25-1

ACTUATOR - DESCRIPTION, BLEND

DOOR

.............................24-17

ACTUATOR - DESCRIPTION, DEFROST

DOOR

.............................24-20ACTUATOR - DESCRIPTION, FUEL

CONTROL..........................14-74

ACTUATOR - DESCRIPTION, MODE

DOOR.............................24-23

ACTUATOR - DESCRIPTION,

RECIRCULATION DOOR................24-24

ACTUATOR - INSTALLATION, BLEND

DOOR.............................24-18

ACTUATOR - INSTALLATION, DEFROST

DOOR.............................24-21

ACTUATOR - INSTALLATION, INSIDE

HANDLE.......................23-22,23-32

ACTUATOR - INSTALLATION, MODE

DOOR.............................24-23

ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-25

ACTUATOR - OPERATION, BLEND DOOR . . 24-17

ACTUATOR - OPERATION, DEFROST

DOOR.............................24-21

ACTUATOR - OPERATION, FUEL

CONTROL..........................14-74

ACTUATOR - OPERATION, MODE DOOR . . . 24-23

ACTUATOR - OPERATION,

RECIRCULATION DOOR................24-24

ACTUATOR - REMOVAL, BLEND DOOR....24-17

ACTUATOR - REMOVAL, DEFROST DOOR . . 24-21

ACTUATOR - REMOVAL, FUEL CONTROL . . 14-74

ACTUATOR - REMOVAL, INSIDE HANDLE . 23-22,

23-31

ACTUATOR - REMOVAL, MODE DOOR....24-23

ACTUATOR - REMOVAL, RECIRCULATION

DOOR...............................24-24

ADAPTER HOUSING SEAL -

INSTALLATION...........21-128,21-364,21-85

ADAPTER HOUSING SEAL - REMOVAL . . 21-128,

21-364,21-85

ADAPTER MOUNT - INSTALLATION, DISC

BRAKE CALIPER......................5-22

ADHESIVE LOCATIONS -

SPECIFICATIONS, STRUCTURAL........23-112

ADJUSTABLE PEDAL MOTOR -

DESCRIPTION.........................5-6

ADJUSTABLE PEDAL MOTOR -

INSTALLATION.........................5-7

ADJUSTABLE PEDAL MOTOR - REMOVAL . . . 5-7

ADJUSTABLE PEDAL SWITCH -

INSTALLATION.........................5-6

ADJUSTABLE PEDAL SWITCH -

REMOVAL............................5-6

ADJUSTER - DIAGNOSIS AND TESTING,

HYDRAULIC LASH................9-125,9-32

ADJUSTER - INSTALLATION, SEAT BELT

TURNING LOOP.....................8O-55

ADJUSTER - REMOVAL, SEAT BELT

TURNING LOOP.....................8O-55

ADJUSTER ASSEMBLY - DESCRIPTION,

ROCKER ARM.......................9-125

ADJUSTER ASSEMBLY - INSTALLATION,

ROCKER ARM.......................9-126

ADJUSTER ASSEMBLY - REMOVAL,

ROCKER ARM.......................9-126

ADJUSTER ASSY - CLEANING, ROCKER

ARM ..............................9-262

ADJUSTER ASSY - DESCRIPTION,

ROCKER ARM.......................9-261

ADJUSTER ASSY - INSPECTION,

ROCKER ARM.......................9-262

ADJUSTER ASSY - INSTALLATION,

ROCKER ARM..................9-203,9-263

ADJUSTER ASSY - REMOVAL, ROCKER

ARM .........................9-203,9-261

ADJUSTING TOOL - ADJUSTMENT, WITH . . . 5-42

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE.................8O-7

AIR CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING..........................21-317

AIR CLEANER ELEMENT - INSTALLATION

. 9-107,

9-21,9-249

AIR CLEANER ELEMENT - REMOVAL

. 9-107,9-21,

9-248

AIR CONDITIONER - DESCRIPTION,

HEATER

.............................24-1

AIR CONDITIONER - OPERATION,

HEATER

.............................24-1

AIR CONTROL MOTOR - DESCRIPTION,

IDLE

...............................14-28AIR CONTROL MOTOR - INSTALLATION,

IDLE...............................14-29

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-28

AIR CONTROL MOTOR - REMOVAL, IDLE . . 14-29

AIR COOLER AND PLUMBING -

CLEANING, CHARGE..................11-17

AIR COOLER AND PLUMBING -

DESCRIPTION, CHARGE...............11-16

AIR COOLER AND PLUMBING -

INSPECTION, CHARGE.................11-17

AIR COOLER AND PLUMBING -

INSTALLATION, CHARGE...............11-17

AIR COOLER AND PLUMBING -

OPERATION, CHARGE.................11-16

AIR COOLER AND PLUMBING -

REMOVAL, CHARGE..................11-17

AIR COOLER SYSTEM - LEAKS -

DIAGNOSIS AND TESTING, CHARGE......11-16

AIR DAM - INSTALLATION, FRONT........13-2

AIR DAM - REMOVAL, FRONT...........13-2

AIR HEATER - DESCRIPTION, INTAKE.....14-80

AIR HEATER - INSTALLATION, INTAKE....14-80

AIR HEATER - OPERATION, INTAKE......14-80

AIR HEATER - REMOVAL, INTAKE........14-80

AIR HEATER RELAY - DESCRIPTION,

INTAKE ............................14-82

AIR HEATER RELAY - INSTALLATION,

INTAKE ............................14-82

AIR HEATER RELAY - OPERATION,

INTAKE ............................14-82

AIR HEATER RELAY - REMOVAL, INTAKE . . 14-82

AIR INTAKE SYSTEM - INSTALLATION....9-199

AIR INTAKE SYSTEM - REMOVAL........9-199

AIR OUTLETS - DESCRIPTION..........24-26

AIR OUTLETS - INSTALLATION..........24-27

AIR OUTLETS - REMOVAL.............24-26

AIR TEMPERATURE SENSOR -

DESCRIPTION, INTAKE................14-30

AIR TEMPERATURE SENSOR -

INSTALLATION, INTAKE................14-31

AIR TEMPERATURE SENSOR -

OPERATION, INTAKE..................14-30

AIR TEMPERATURE SENSOR -

REMOVAL, INTAKE...................14-30

AIR TEMPERATURE SENSOR/MAP

SENSOR - DESCRIPTION, INTAKE........14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - INSTALLATION, INTAKE.......14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - OPERATION, INTAKE.........14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - REMOVAL, INTAKE...........14-82

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET.........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET..........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET............14-79

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING......................21-144

AIR TO OIL COOLER - INSTALLATION.....7-70

AIR TO OIL COOLER - REMOVAL.........7-69

AIRBAG - ASSEMBLY, DRIVER..........8O-26

AIRBAG - DESCRIPTION, DRIVER........8O-23

AIRBAG - DESCRIPTION, PASSENGER....8O-39

AIRBAG - DESCRIPTION, SIDE CURTAIN . . 8O-56

AIRBAG - DISASSEMBLY, DRIVER.......8O-25

AIRBAG - INSTALLATION, DRIVER.......8O-28

AIRBAG - INSTALLATION, PASSENGER . . . 8O-41

AIRBAG - INSTALLATION, SIDE CURTAIN . . 8O-58

AIRBAG - OPERATION, DRIVER.........8O-23

AIRBAG - OPERATION, PASSENGER......8O-40

AIRBAG - OPERATION, SIDE CURTAIN....8O-56

AIRBAG - REMOVAL, DRIVER...........8O-24

AIRBAG - REMOVAL, PASSENGER.......8O-40

AIRBAG - REMOVAL, SIDE CURTAIN.....8O-57

AIRBAG CONTROL MODULE -

DESCRIPTION

.......................8O-11

AIRBAG CONTROL MODULE -

INSTALLATION

......................8O-13

AIRBAG CONTROL MODULE -

OPERATION

.........................8O-11

AIRBAG CONTROL MODULE - REMOVAL

. . 8O-12

AIRBAG INDICATOR - DESCRIPTION

......8J-18

DRINDEX 1

Description Group-Page Description Group-Page Description Group-Page

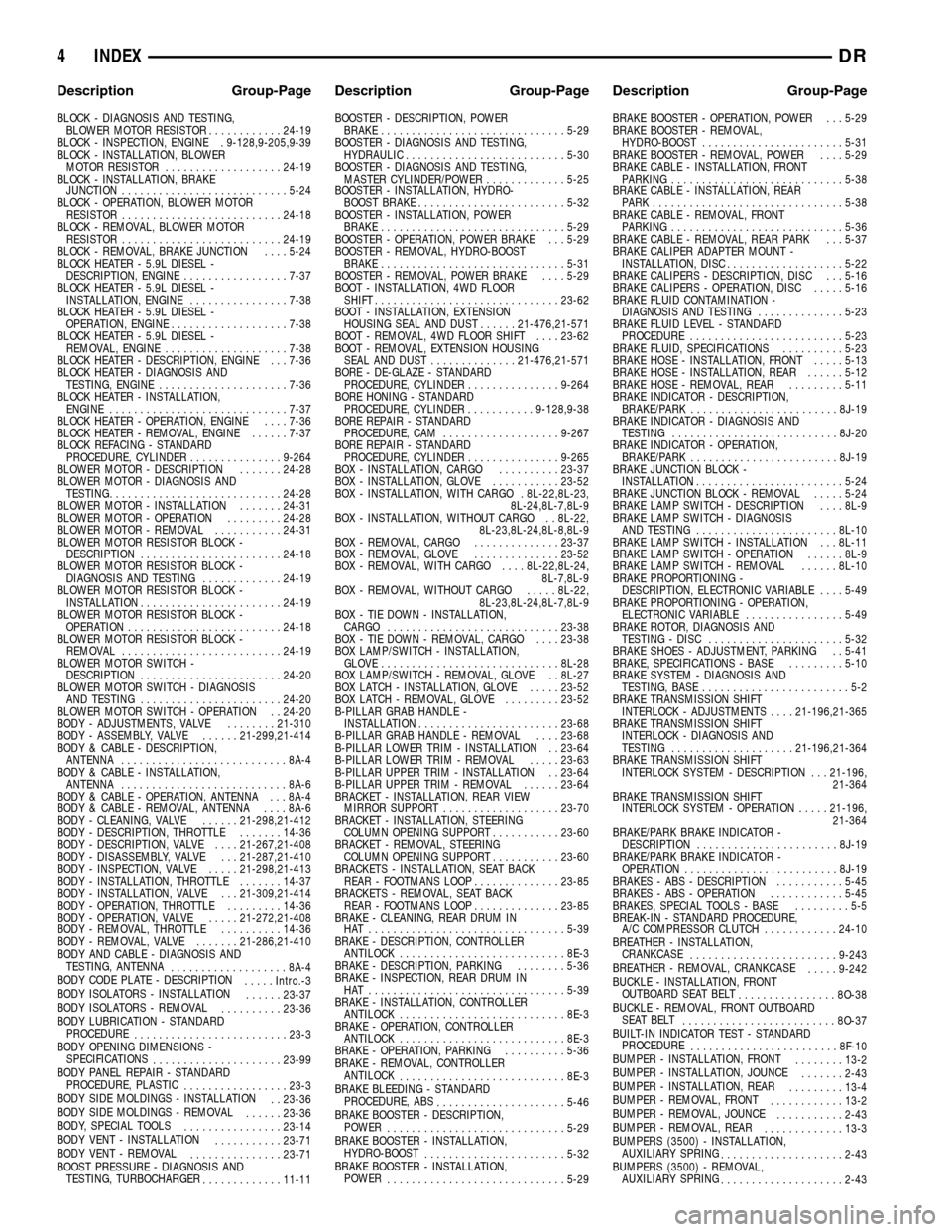

Page 2591 of 2627

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR............24-19

BLOCK - INSPECTION, ENGINE . 9-128,9-205,9-39

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR...................24-19

BLOCK - INSTALLATION, BRAKE

JUNCTION...........................5-24

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR..........................24-18

BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR..........................24-19

BLOCK - REMOVAL, BRAKE JUNCTION....5-24

BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-37

BLOCK HEATER - 5.9L DIESEL -

INSTALLATION, ENGINE................7-38

BLOCK HEATER - 5.9L DIESEL -

OPERATION, ENGINE...................7-38

BLOCK HEATER - 5.9L DIESEL -

REMOVAL, ENGINE....................7-38

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-36

BLOCK HEATER - DIAGNOSIS AND

TESTING, ENGINE.....................7-36

BLOCK HEATER - INSTALLATION,

ENGINE.............................7-37

BLOCK HEATER - OPERATION, ENGINE....7-36

BLOCK HEATER - REMOVAL, ENGINE......7-37

BLOCK REFACING - STANDARD

PROCEDURE, CYLINDER...............9-264

BLOWER MOTOR - DESCRIPTION.......24-28

BLOWER MOTOR - DIAGNOSIS AND

TESTING.............................24-28

BLOWER MOTOR - INSTALLATION.......24-31

BLOWER MOTOR - OPERATION.........24-28

BLOWER MOTOR - REMOVAL...........24-31

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION.......................24-18

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING.............24-19

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION.......................24-19

BLOWER MOTOR RESISTOR BLOCK -

OPERATION.........................24-18

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL..........................24-19

BLOWER MOTOR SWITCH -

DESCRIPTION.......................24-20

BLOWER MOTOR SWITCH - DIAGNOSIS

AND TESTING.......................24-20

BLOWER MOTOR SWITCH - OPERATION . . 24-20

BODY - ADJUSTMENTS, VALVE........21-310

BODY - ASSEMBLY, VALVE......21-299,21-414

BODY & CABLE - DESCRIPTION,

ANTENNA...........................8A-4

BODY & CABLE - INSTALLATION,

ANTENNA...........................8A-6

BODY & CABLE - OPERATION, ANTENNA . . . 8A-4

BODY & CABLE - REMOVAL, ANTENNA....8A-6

BODY - CLEANING, VALVE......21-298,21-412

BODY - DESCRIPTION, THROTTLE.......14-36

BODY - DESCRIPTION, VALVE....21-267,21-408

BODY - DISASSEMBLY, VALVE . . . 21-287,21-410

BODY - INSPECTION, VALVE.....21-298,21-413

BODY - INSTALLATION, THROTTLE.......14-37

BODY - INSTALLATION, VALVE . . . 21-309,21-414

BODY - OPERATION, THROTTLE.........14-36

BODY - OPERATION, VALVE.....21-272,21-408

BODY - REMOVAL, THROTTLE..........14-36

BODY - REMOVAL, VALVE.......21-286,21-410

BODY AND CABLE - DIAGNOSIS AND

TESTING, ANTENNA

...................8A-4

BODY CODE PLATE - DESCRIPTION

.....Intro.-3

BODY ISOLATORS - INSTALLATION

......23-37

BODY ISOLATORS - REMOVAL

..........23-36

BODY LUBRICATION - STANDARD

PROCEDURE

.........................23-3

BODY OPENING DIMENSIONS -

SPECIFICATIONS

.....................23-99

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC

.................23-3

BODY SIDE MOLDINGS - INSTALLATION

. . 23-36

BODY SIDE MOLDINGS - REMOVAL

......23-36

BODY, SPECIAL TOOLS

................23-14

BODY VENT - INSTALLATION

...........23-71

BODY VENT - REMOVAL

...............23-71

BOOST PRESSURE - DIAGNOSIS AND

TESTING, TURBOCHARGER

.............11-11BOOSTER - DESCRIPTION, POWER

BRAKE..............................5-29

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-30

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-25

BOOSTER - INSTALLATION, HYDRO-

BOOST BRAKE........................5-32

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-29

BOOSTER - OPERATION, POWER BRAKE . . . 5-29

BOOSTER - REMOVAL, HYDRO-BOOST

BRAKE..............................5-31

BOOSTER - REMOVAL, POWER BRAKE....5-29

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-62

BOOT - INSTALLATION, EXTENSION

HOUSING SEAL AND DUST......21-476,21-571

BOOT - REMOVAL, 4WD FLOOR SHIFT....23-62

BOOT - REMOVAL, EXTENSION HOUSING

SEAL AND DUST..............21-476,21-571

BORE - DE-GLAZE - STANDARD

PROCEDURE, CYLINDER...............9-264

BORE HONING - STANDARD

PROCEDURE, CYLINDER...........9-128,9-38

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-267

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-265

BOX - INSTALLATION, CARGO..........23-37

BOX - INSTALLATION, GLOVE...........23-52

BOX - INSTALLATION, WITH CARGO . 8L-22,8L-23,

8L-24,8L-7,8L-9

BOX - INSTALLATION, WITHOUT CARGO . . 8L-22,

8L-23,8L-24,8L-8,8L-9

BOX - REMOVAL, CARGO..............23-37

BOX - REMOVAL, GLOVE..............23-52

BOX - REMOVAL, WITH CARGO....8L-22,8L-24,

8L-7,8L-9

BOX - REMOVAL, WITHOUT CARGO.....8L-22,

8L-23,8L-24,8L-7,8L-9

BOX - TIE DOWN - INSTALLATION,

CARGO............................23-38

BOX - TIE DOWN - REMOVAL, CARGO....23-38

BOX LAMP/SWITCH - INSTALLATION,

GLOVE.............................8L-28

BOX LAMP/SWITCH - REMOVAL, GLOVE . . 8L-27

BOX LATCH - INSTALLATION, GLOVE.....23-52

BOX LATCH - REMOVAL, GLOVE.........23-52

B-PILLAR GRAB HANDLE -

INSTALLATION.......................23-68

B-PILLAR GRAB HANDLE - REMOVAL....23-68

B-PILLAR LOWER TRIM - INSTALLATION . . 23-64

B-PILLAR LOWER TRIM - REMOVAL.....23-63

B-PILLAR UPPER TRIM - INSTALLATION . . 23-64

B-PILLAR UPPER TRIM - REMOVAL......23-64

BRACKET - INSTALLATION, REAR VIEW

MIRROR SUPPORT...................23-70

BRACKET - INSTALLATION, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKET - REMOVAL, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKETS - INSTALLATION, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRACKETS - REMOVAL, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRAKE - CLEANING, REAR DRUM IN

HAT ................................5-39

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - DESCRIPTION, PARKING........5-36

BRAKE - INSPECTION, REAR DRUM IN

HAT ................................5-39

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, PARKING..........5-36

BRAKE - REMOVAL, CONTROLLER

ANTILOCK

...........................8E-3

BRAKE BLEEDING - STANDARD

PROCEDURE, ABS

.....................5-46

BRAKE BOOSTER - DESCRIPTION,

POWER

.............................5-29

BRAKE BOOSTER - INSTALLATION,

HYDRO-BOOST

.......................5-32

BRAKE BOOSTER - INSTALLATION,

POWER

.............................5-29BRAKE BOOSTER - OPERATION, POWER . . . 5-29

BRAKE BOOSTER - REMOVAL,

HYDRO-BOOST.......................5-31

BRAKE BOOSTER - REMOVAL, POWER....5-29

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-38

BRAKE CABLE - INSTALLATION, REAR

PARK...............................5-38

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-36

BRAKE CABLE - REMOVAL, REAR PARK . . . 5-37

BRAKE CALIPER ADAPTER MOUNT -

INSTALLATION, DISC...................5-22

BRAKE CALIPERS - DESCRIPTION, DISC . . . 5-16

BRAKE CALIPERS - OPERATION, DISC.....5-16

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-23

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-23

BRAKE FLUID, SPECIFICATIONS..........5-23

BRAKE HOSE - INSTALLATION, FRONT.....5-13

BRAKE HOSE - INSTALLATION, REAR......5-12

BRAKE HOSE - REMOVAL, REAR.........5-11

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-19

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-20

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-19

BRAKE JUNCTION BLOCK -

INSTALLATION.........................5-24

BRAKE JUNCTION BLOCK - REMOVAL.....5-24

BRAKE LAMP SWITCH - DESCRIPTION....8L-9

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-10

BRAKE LAMP SWITCH - INSTALLATION . . . 8L-11

BRAKE LAMP SWITCH - OPERATION......8L-9

BRAKE LAMP SWITCH - REMOVAL......8L-10

BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC VARIABLE....5-49

BRAKE PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE................5-49

BRAKE ROTOR, DIAGNOSIS AND

TESTING - DISC......................5-32

BRAKE SHOES - ADJUSTMENT, PARKING . . 5-41

BRAKE, SPECIFICATIONS - BASE.........5-10

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-2

BRAKE TRANSMISSION SHIFT

INTERLOCK - ADJUSTMENTS....21-196,21-365

BRAKE TRANSMISSION SHIFT

INTERLOCK - DIAGNOSIS AND

TESTING....................21-196,21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DESCRIPTION . . . 21-196,

21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - OPERATION.....21-196,

21-364

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION.......................8J-19

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-19

BRAKES - ABS - DESCRIPTION...........5-45

BRAKES - ABS - OPERATION............5-45

BRAKES, SPECIAL TOOLS - BASE.........5-5

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH............24-10

BREATHER - INSTALLATION,

CRANKCASE

........................9-243

BREATHER - REMOVAL, CRANKCASE

.....9-242

BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT BELT

................8O-38

BUCKLE - REMOVAL, FRONT OUTBOARD

SEAT BELT

.........................8O-37

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE

........................8F-10

BUMPER - INSTALLATION, FRONT

........13-2

BUMPER - INSTALLATION, JOUNCE

.......2-43

BUMPER - INSTALLATION, REAR

.........13-4

BUMPER - REMOVAL, FRONT

............13-2

BUMPER - REMOVAL, JOUNCE

...........2-43

BUMPER - REMOVAL, REAR

.............13-3

BUMPERS (3500) - INSTALLATION,

AUXILIARY SPRING

....................2-43

BUMPERS (3500) - REMOVAL,

AUXILIARY SPRING

....................2-43

4 INDEXDR

Description Group-Page Description Group-Page Description Group-Page