Transmission install DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1565 of 2627

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Cab mount bolts 81 60 Ð

Cargo box bolts 108 80 Ð

Front crossmember bolts - 2WD (light duty only) 61 45 Ð

Front crossmember bolts - 2WD (heavy duty only) 75 55 Ð

Front crossmember bolts - 4WD (light duty only) 102 75 Ð

Front skid plate bolts 34 25 Ð

Lower bumper support bracket bolt 54 40 Ð

Radiator crossmember bolts - lower 28 21 Ð

Radiator crossmember bolts - upper 28 21 Ð

Rear crossmember (light duty only) 102 75 Ð

Rear crossmember (heavy duty only) 115 85 Ð

Rear spring shackle bolts 163 120 Ð

Spare tire winch bolts 41 30 Ð

Trailer hitch reinforcement bracket bolt 170 125 Ð

Transfercase skid plate bolts 34 25 Ð

Transercase skid plate crossmember bolts 34 25 Ð

Transmission mount to crossmember nuts 54 40 Ð

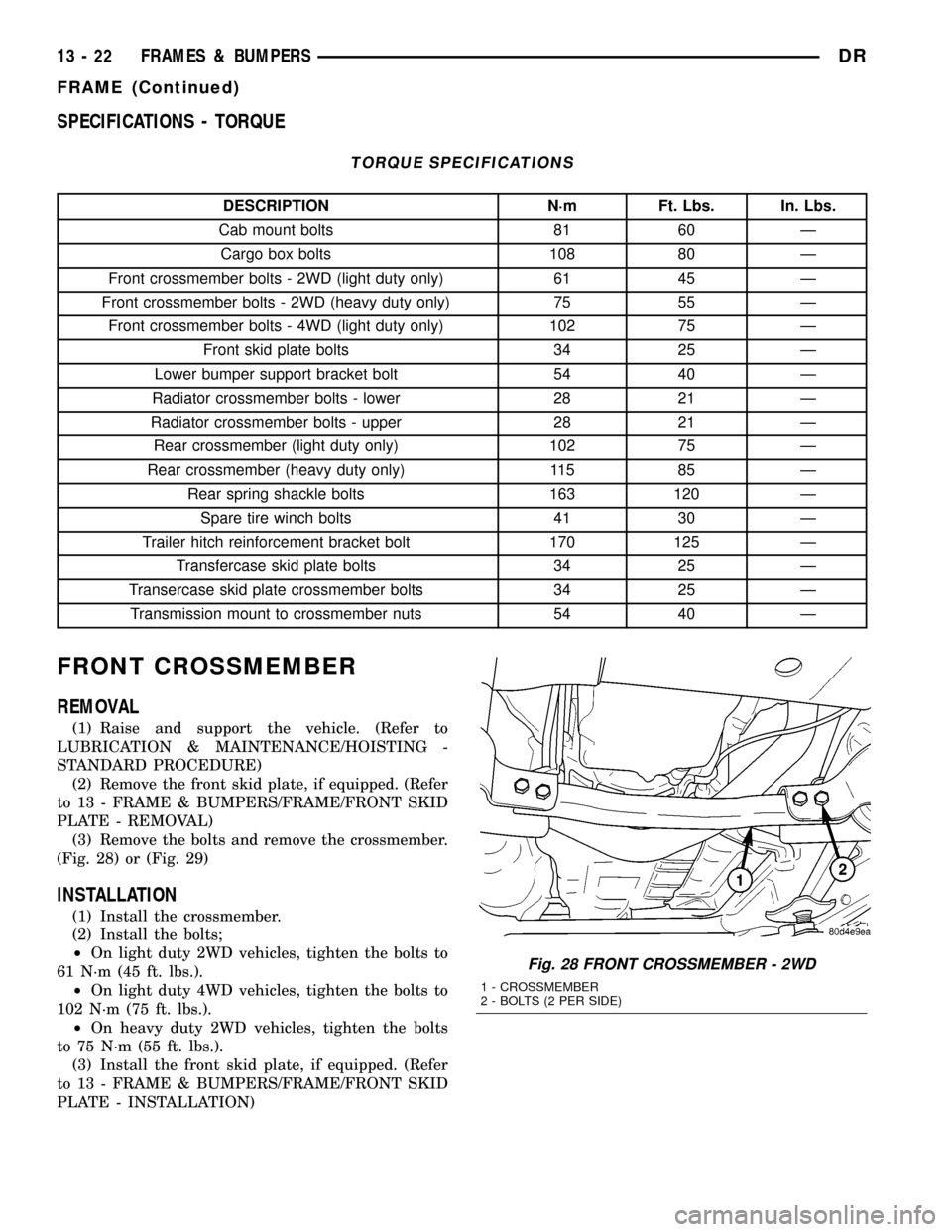

FRONT CROSSMEMBER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the front skid plate, if equipped. (Refer

to 13 - FRAME & BUMPERS/FRAME/FRONT SKID

PLATE - REMOVAL)

(3) Remove the bolts and remove the crossmember.

(Fig. 28) or (Fig. 29)

INSTALLATION

(1) Install the crossmember.

(2) Install the bolts;

²On light duty 2WD vehicles, tighten the bolts to

61 N´m (45 ft. lbs.).

²On light duty 4WD vehicles, tighten the bolts to

102 N´m (75 ft. lbs.).

²On heavy duty 2WD vehicles, tighten the bolts

to 75 N´m (55 ft. lbs.).

(3) Install the front skid plate, if equipped. (Refer

to 13 - FRAME & BUMPERS/FRAME/FRONT SKID

PLATE - INSTALLATION)

Fig. 28 FRONT CROSSMEMBER - 2WD

1 - CROSSMEMBER

2 - BOLTS (2 PER SIDE)

13 - 22 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1567 of 2627

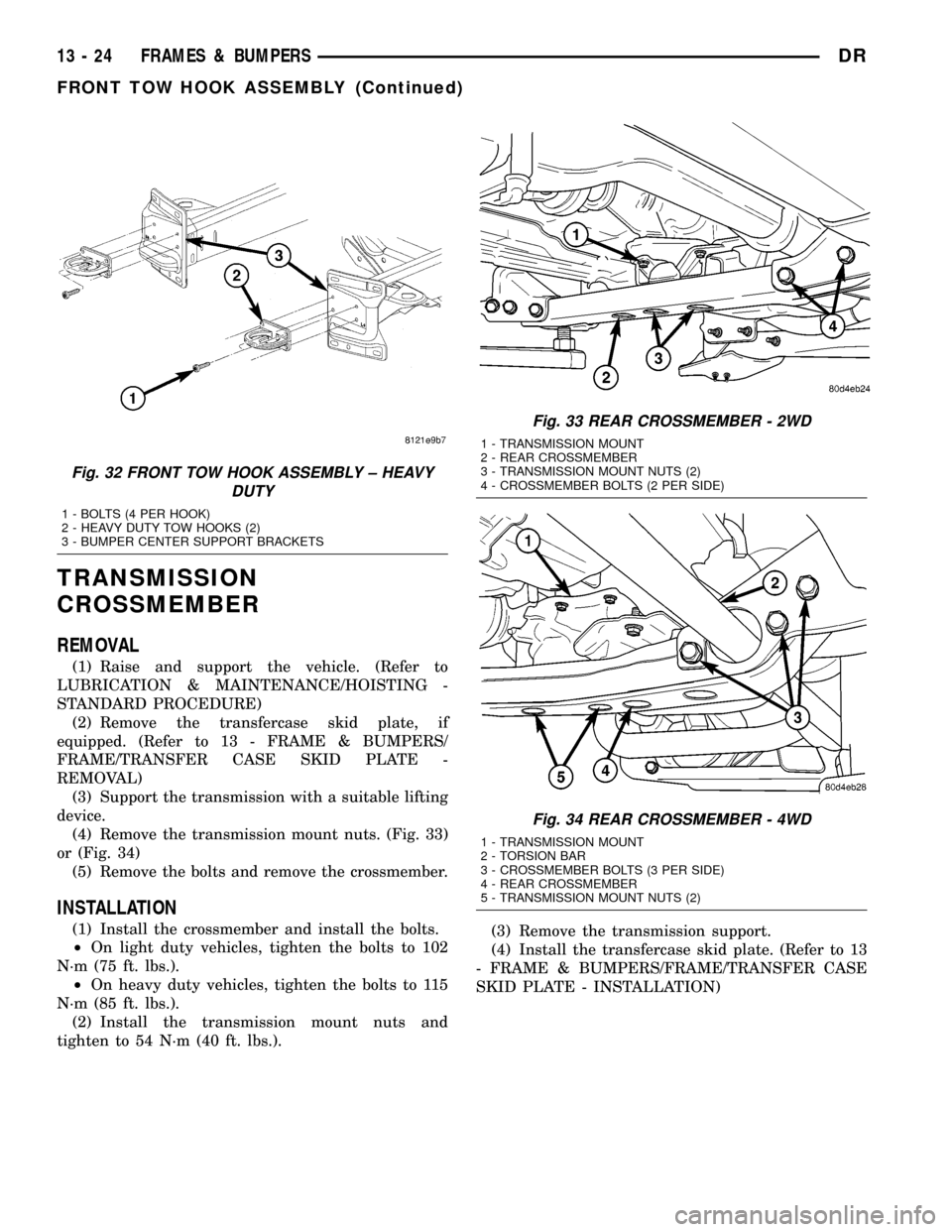

TRANSMISSION

CROSSMEMBER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the transfercase skid plate, if

equipped. (Refer to 13 - FRAME & BUMPERS/

FRAME/TRANSFER CASE SKID PLATE -

REMOVAL)

(3) Support the transmission with a suitable lifting

device.

(4) Remove the transmission mount nuts. (Fig. 33)

or (Fig. 34)

(5) Remove the bolts and remove the crossmember.

INSTALLATION

(1) Install the crossmember and install the bolts.

²On light duty vehicles, tighten the bolts to 102

N´m (75 ft. lbs.).

²On heavy duty vehicles, tighten the bolts to 115

N´m (85 ft. lbs.).

(2) Install the transmission mount nuts and

tighten to 54 N´m (40 ft. lbs.).(3) Remove the transmission support.

(4) Install the transfercase skid plate. (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

Fig. 32 FRONT TOW HOOK ASSEMBLY ± HEAVY

DUTY

1 - BOLTS (4 PER HOOK)

2 - HEAVY DUTY TOW HOOKS (2)

3 - BUMPER CENTER SUPPORT BRACKETS

Fig. 33 REAR CROSSMEMBER - 2WD

1 - TRANSMISSION MOUNT

2 - REAR CROSSMEMBER

3 - TRANSMISSION MOUNT NUTS (2)

4 - CROSSMEMBER BOLTS (2 PER SIDE)

Fig. 34 REAR CROSSMEMBER - 4WD

1 - TRANSMISSION MOUNT

2 - TORSION BAR

3 - CROSSMEMBER BOLTS (3 PER SIDE)

4 - REAR CROSSMEMBER

5 - TRANSMISSION MOUNT NUTS (2)

13 - 24 FRAMES & BUMPERSDR

FRONT TOW HOOK ASSEMBLY (Continued)

Page 1605 of 2627

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

threads of a new oxygen sensor.

(1) Install O2S sensor. Tighten to 30 N´m (22 ft.

lbs.) torque.

(2) Connect O2S sensor wire connector.

(3) Lower vehicle.

PTO SWITCH

DESCRIPTION

This Powertrain Control Module (PCM) input is

used only on models equipped with aftermarket

Power Take Off (PTO) units.

OPERATION

The input is used only to tell the PCM (or ECM-

Diesel) that the PTO has been engaged. The PCM (or

ECM) will disable (temporarily shut down) certain

OBD II diagnostic trouble codes when the PTO is

engaged.

JTEC and NGC Engine Controllers:When the

aftermarket PTO switch has been engaged, a 12V +

signal is sent through circuit G113 to PCM pin A13.

The PCM will then sense and determine that the

PTO has been activated.

CM 845 or CM 848 Diesel Engine Controllers:

When the aftermarket PTO switch has been engaged,

a 12V + signal is sent through circuit G113 to ECM

pin B38. The ECM will then sense and determine

that the PTO has been activated.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

5.7L V-8 Engine:

The throttle body on the 5.7L engine is an electri-

cally controlled unit. A mechanical cable is not used

to connect the throttle body to the accelerator pedal.

The Accelerator Pedal Position Sensor (APPS) alongwith inputs from other sensors sets the throttle blade

to pre-determined positions.

Except 5.7L V-8 Engine:

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

3.7L V-6

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner tube at throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS.

(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section for removal/installation procedures.

(4) Disconnect necessary vacuum lines at throttle

body.

(5) Remove 3 throttle body mounting bolts (Fig.

28).

(6) Remove throttle body from intake manifold.

(7) Check condition of old throttle body-to-intake

manifold o-ring (Fig. 29).

4.7L V-8

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS (Fig. 30).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(5) Remove three throttle body mounting bolts

(Fig. 30).

(6) Remove throttle body from intake manifold.

5.7L V-8

CAUTION: Do not use spray (carb) cleaners on any

part of the throttle body. Do not apply silicone lubri-

cants to any part of the throttle body.

(1) Remove air duct and air resonator box at throt-

tle body.

14 - 36 FUEL INJECTION - GASDR

OXYGEN SENSOR (Continued)

Page 1638 of 2627

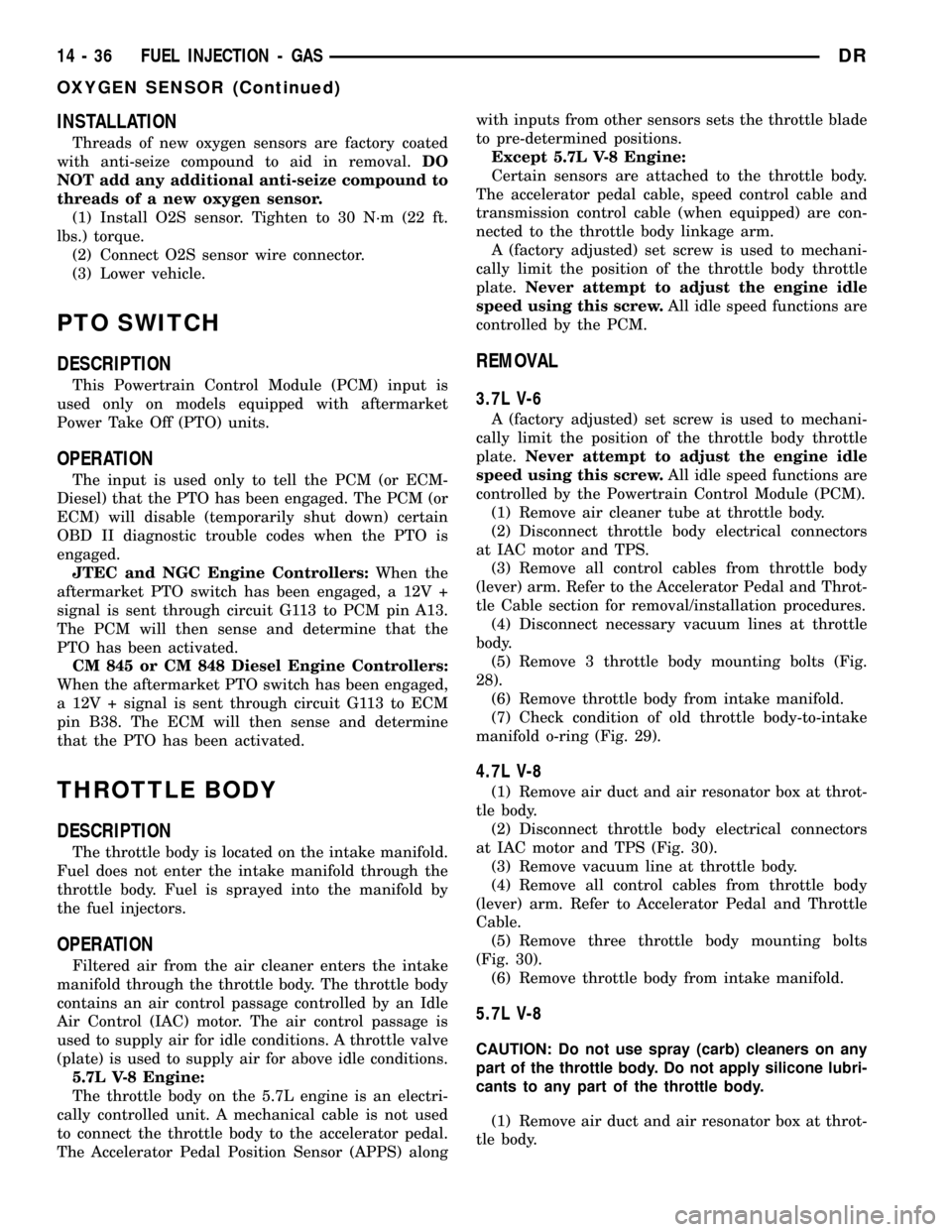

CAUTION: Do not attempt to remove sensor from

its mounting bracket as electronic calibration will

be destroyed (sensor-to-bracket mounting screws

are permanently attached). Two accelerator lever

set screws (Fig. 3) are used to position lever. Do

not attempt to alter positions of these set screws as

electronic calibration will be destroyed.

(1) Disconnect both negative battery cables at both

batteries.

(2) Remove cable cover (Fig. 1). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 1). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.

(3) Using finger pressure only, disconnect end of

speed control servo cable from throttle lever pin by

pulling forward on connector while holding lever

rearward (Fig. 2).DO NOT try to pull connector

off perpendicular to lever pin. Connector will

be broken.

(4) Using two small screwdrivers, pry throttle

cable connector socket from throttle lever ball (Fig.

2).Be very careful not to bend throttle lever

arm.

(5) Disconnect transmission control cable at lever

arm (if equipped). Refer to 21, Transmission.

(6) Squeeze pinch tabs on speed control cable (Fig.

2) and pull cable rearward to remove from cable

mounting bracket.

(7) Squeeze pinch tabs on throttle cable (Fig. 2)

and pull cable rearward to remove from cable mount-

ing bracket.

(8) Refer to 21, Transmission for transmission con-

trol cable removal procedures.

(9) Disconnect wiring harness clip (Fig. 3) at bot-

tom of bracket.

(10) Remove 6 mounting bolts (Fig. 3) and par-

tially remove APPS assembly from engine. After

assembly is partially removed, disconnect electrical

connector from bottom of sensor by pushing on con-

nector tab (Fig. 4).

(11) Remove APPS assembly from engine.

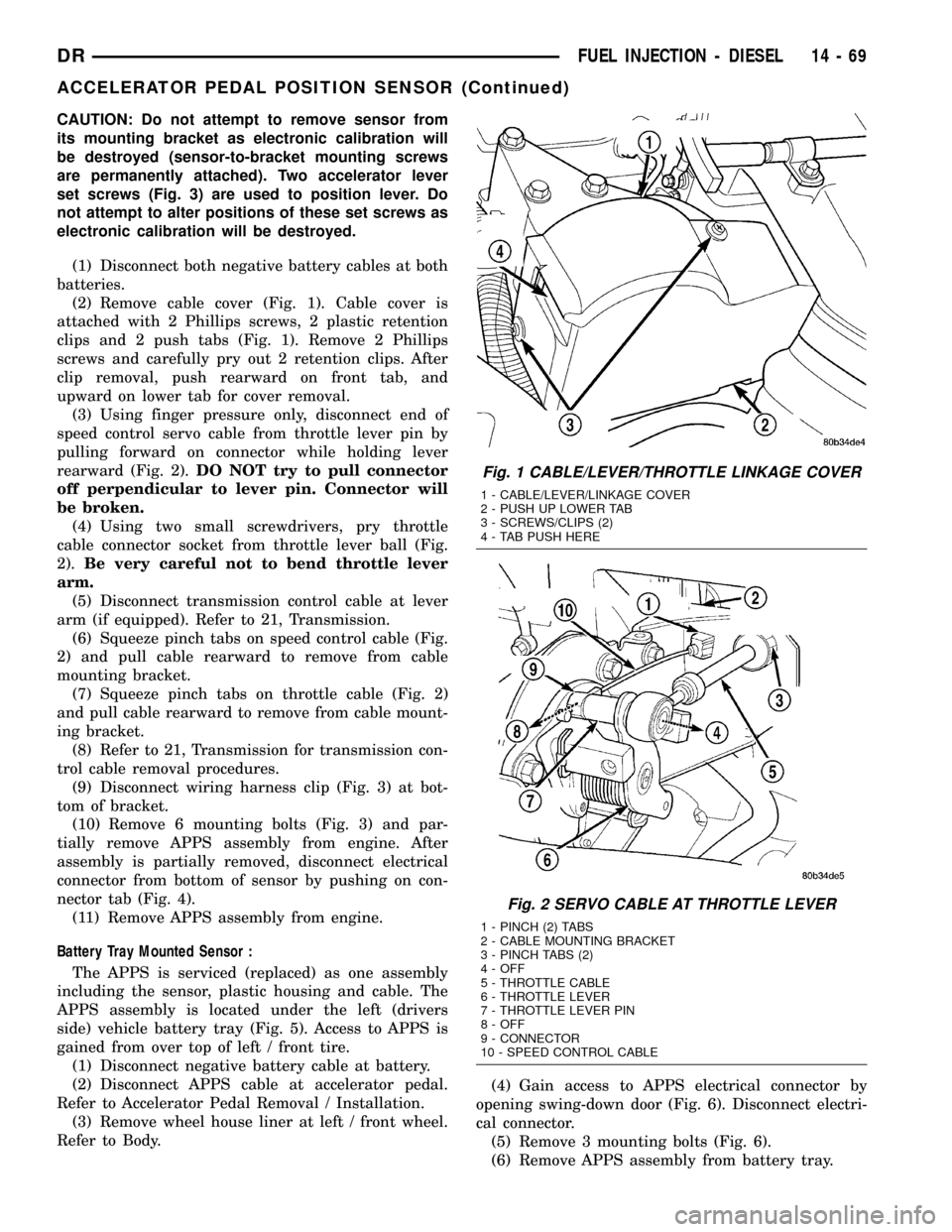

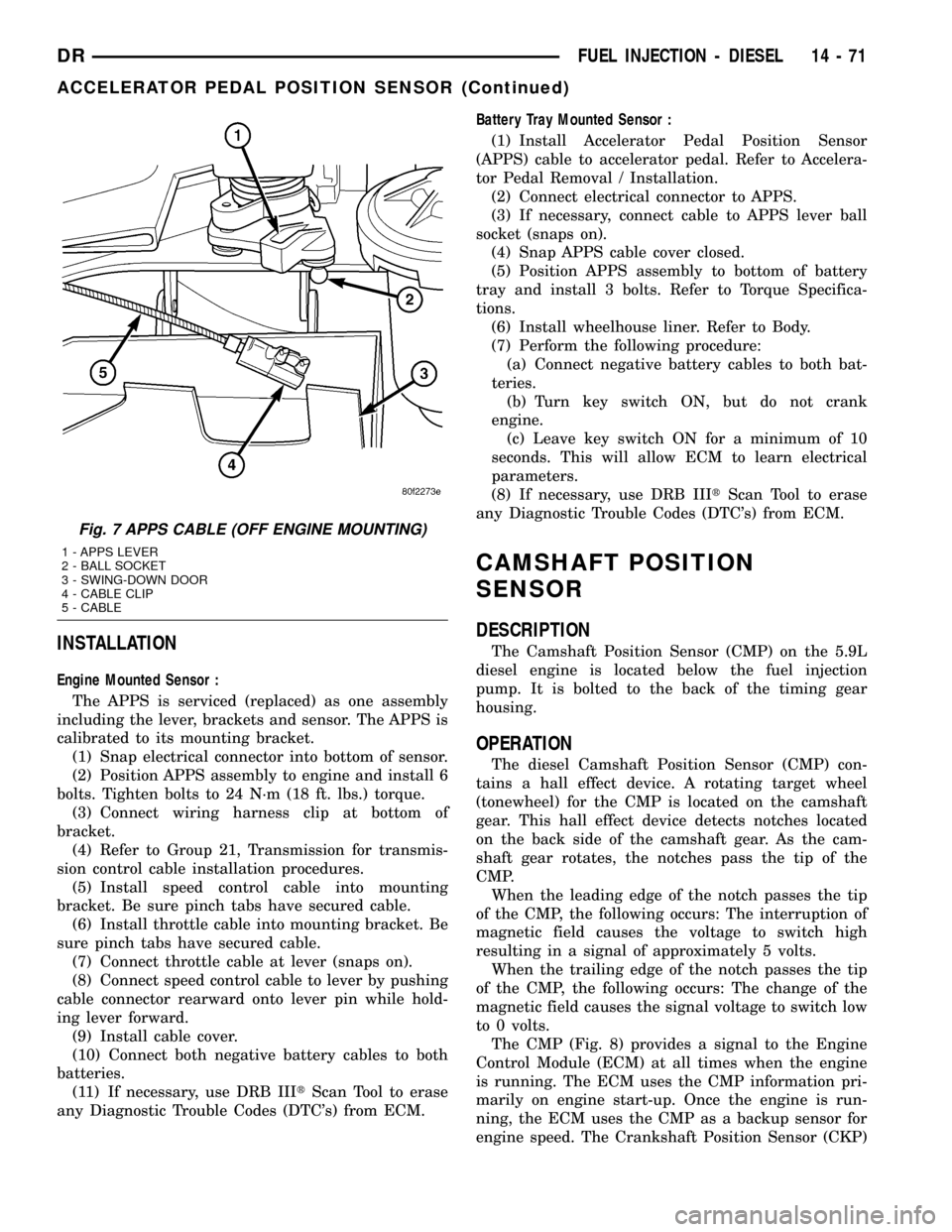

Battery Tray Mounted Sensor :

The APPS is serviced (replaced) as one assembly

including the sensor, plastic housing and cable. The

APPS assembly is located under the left (drivers

side) vehicle battery tray (Fig. 5). Access to APPS is

gained from over top of left / front tire.

(1) Disconnect negative battery cable at battery.

(2) Disconnect APPS cable at accelerator pedal.

Refer to Accelerator Pedal Removal / Installation.

(3) Remove wheel house liner at left / front wheel.

Refer to Body.(4) Gain access to APPS electrical connector by

opening swing-down door (Fig. 6). Disconnect electri-

cal connector.

(5) Remove 3 mounting bolts (Fig. 6).

(6) Remove APPS assembly from battery tray.

Fig. 1 CABLE/LEVER/THROTTLE LINKAGE COVER

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

Fig. 2 SERVO CABLE AT THROTTLE LEVER

1 - PINCH (2) TABS

2 - CABLE MOUNTING BRACKET

3 - PINCH TABS (2)

4 - OFF

5 - THROTTLE CABLE

6 - THROTTLE LEVER

7 - THROTTLE LEVER PIN

8 - OFF

9 - CONNECTOR

10 - SPEED CONTROL CABLE

DRFUEL INJECTION - DIESEL 14 - 69

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1640 of 2627

INSTALLATION

Engine Mounted Sensor :

The APPS is serviced (replaced) as one assembly

including the lever, brackets and sensor. The APPS is

calibrated to its mounting bracket.

(1) Snap electrical connector into bottom of sensor.

(2) Position APPS assembly to engine and install 6

bolts. Tighten bolts to 24 N´m (18 ft. lbs.) torque.

(3) Connect wiring harness clip at bottom of

bracket.

(4) Refer to Group 21, Transmission for transmis-

sion control cable installation procedures.

(5) Install speed control cable into mounting

bracket. Be sure pinch tabs have secured cable.

(6) Install throttle cable into mounting bracket. Be

sure pinch tabs have secured cable.

(7) Connect throttle cable at lever (snaps on).

(8) Connect speed control cable to lever by pushing

cable connector rearward onto lever pin while hold-

ing lever forward.

(9) Install cable cover.

(10) Connect both negative battery cables to both

batteries.

(11) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from ECM.Battery Tray Mounted Sensor :

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelera-

tor Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cables to both bat-

teries.

(b) Turn key switch ON, but do not crank

engine.

(c) Leave key switch ON for a minimum of 10

seconds. This will allow ECM to learn electrical

parameters.

(8) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from ECM.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

housing.

OPERATION

The diesel Camshaft Position Sensor (CMP) con-

tains a hall effect device. A rotating target wheel

(tonewheel) for the CMP is located on the camshaft

gear. This hall effect device detects notches located

on the back side of the camshaft gear. As the cam-

shaft gear rotates, the notches pass the tip of the

CMP.

When the leading edge of the notch passes the tip

of the CMP, the following occurs: The interruption of

magnetic field causes the voltage to switch high

resulting in a signal of approximately 5 volts.

When the trailing edge of the notch passes the tip

of the CMP, the following occurs: The change of the

magnetic field causes the signal voltage to switch low

to 0 volts.

The CMP (Fig. 8) provides a signal to the Engine

Control Module (ECM) at all times when the engine

is running. The ECM uses the CMP information pri-

marily on engine start-up. Once the engine is run-

ning, the ECM uses the CMP as a backup sensor for

engine speed. The Crankshaft Position Sensor (CKP)

Fig. 7 APPS CABLE (OFF ENGINE MOUNTING)

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

DRFUEL INJECTION - DIESEL 14 - 71

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1661 of 2627

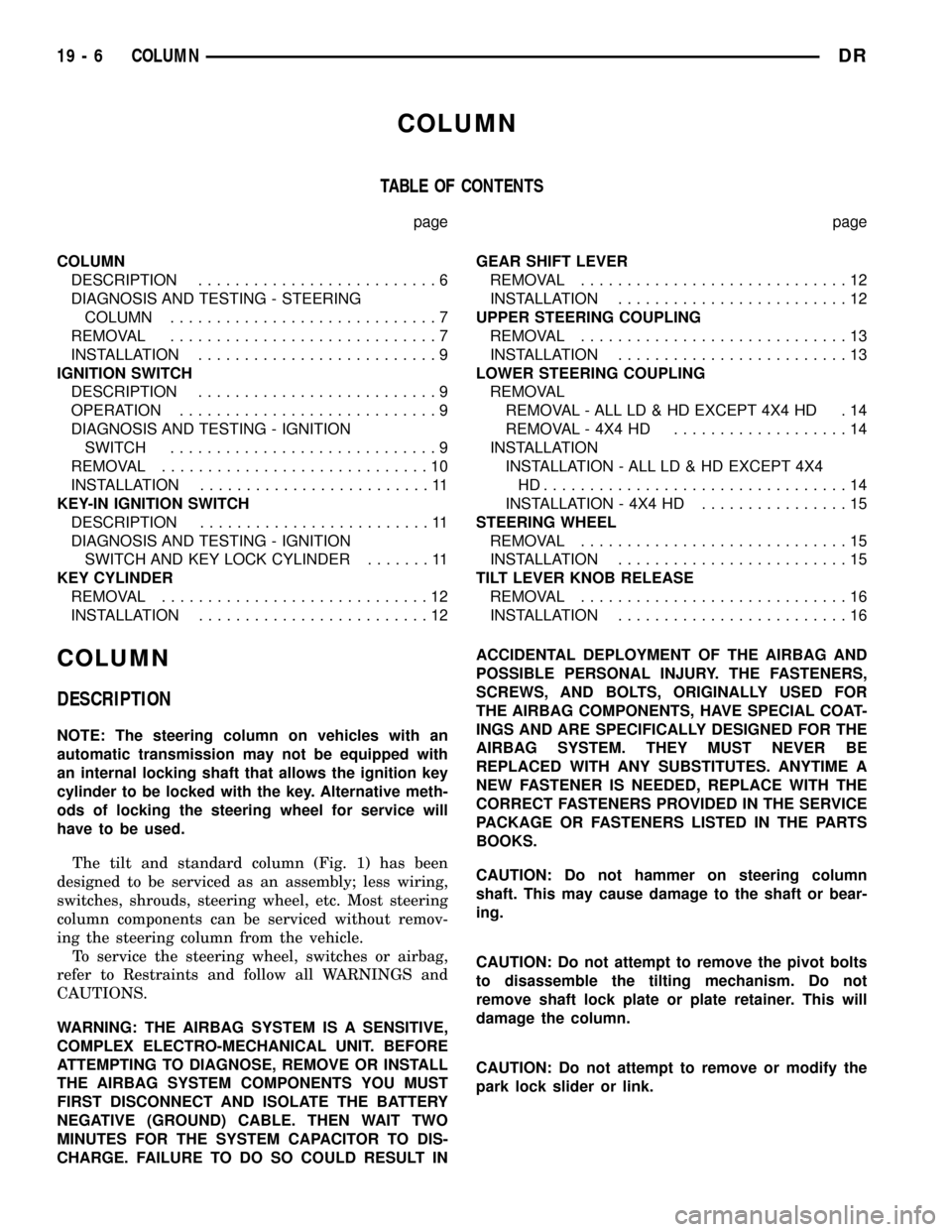

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION..........................6

DIAGNOSIS AND TESTING - STEERING

COLUMN.............................7

REMOVAL.............................7

INSTALLATION..........................9

IGNITION SWITCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - IGNITION

SWITCH.............................9

REMOVAL.............................10

INSTALLATION.........................11

KEY-IN IGNITION SWITCH

DESCRIPTION.........................11

DIAGNOSIS AND TESTING - IGNITION

SWITCH AND KEY LOCK CYLINDER.......11

KEY CYLINDER

REMOVAL.............................12

INSTALLATION.........................12GEAR SHIFT LEVER

REMOVAL.............................12

INSTALLATION.........................12

UPPER STEERING COUPLING

REMOVAL.............................13

INSTALLATION.........................13

LOWER STEERING COUPLING

REMOVAL

REMOVAL - ALL LD & HD EXCEPT 4X4 HD . 14

REMOVAL - 4X4 HD...................14

INSTALLATION

INSTALLATION - ALL LD & HD EXCEPT 4X4

HD.................................14

INSTALLATION - 4X4 HD................15

STEERING WHEEL

REMOVAL.............................15

INSTALLATION.........................15

TILT LEVER KNOB RELEASE

REMOVAL.............................16

INSTALLATION.........................16

COLUMN

DESCRIPTION

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

The tilt and standard column (Fig. 1) has been

designed to be serviced as an assembly; less wiring,

switches, shrouds, steering wheel, etc. Most steering

column components can be serviced without remov-

ing the steering column from the vehicle.

To service the steering wheel, switches or airbag,

refer to Restraints and follow all WARNINGS and

CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT INACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COAT-

INGS AND ARE SPECIFICALLY DESIGNED FOR THE

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.

CAUTION: Do not hammer on steering column

shaft. This may cause damage to the shaft or bear-

ing.

CAUTION: Do not attempt to remove the pivot bolts

to disassemble the tilting mechanism. Do not

remove shaft lock plate or plate retainer. This will

damage the column.

CAUTION: Do not attempt to remove or modify the

park lock slider or link.

19 - 6 COLUMNDR

Page 1664 of 2627

(17) Remove the steering column assembly from

the vehicle. (Fig. 7)

INSTALLATION

WARNING: BEFORE SERVICING THE STEERING

COLUMN THE AIRBAG SYSTEM MUST BE DIS-

ARMED. REFER TO ELECTRICAL RESTRAINT SYS-

TEM FOR SERVICE PROCEDURES. FAILURE TO DO

SO MAY RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIRBAG AND POSSIBLE PERSONAL INJURY.

CAUTION: All fasteners must be torqued to specifi-

cation to ensure proper operation of the steering

column.

(1) Position the steering column on the dash panel

support and loosely install the mounting nuts.

(2) Firmly slide the steering column upward

against the studs in dash panel and hand tighten the

nuts.

(3) Install the steering shaft coupler on the steer-

ing shaft and loosely install anewbolt.

(4) Center steering column in dash opening and

tighten mounting nuts to 28 N´m (250 in. lbs.).

NOTE: Torque the upper left nut first then the lower

right nut. Then torque the lower left nut then the

upper right nut.

NOTE: A new bolt must be used for reinstallation.

(5) Tighten the coupler bolt to 57 N´m (42 ft. lbs.).(6) Install a new brake light switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

(7) Install the shifter cable. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 32RH/GEAR

SHIFT CABLE - INSTALLATION)

(8) Connect the wiring harness to the column.

(9) Install the SKIM module.

(10) Install the clockspring(Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

(11) Install the shrouds.

(12) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(13) Align the spline on the wheel hub to shaft.

(14) Then install the steering wheel and install a

newbolt. Tighten the bolt to 61 N´m (45 ft. lbs.).

(15) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(16) Install the two steering wheel switches.

(17) Install the tilt lever handle.

(18) Install the negative battery terminal.

(19) Test the operation of the horn, Electronic

PRNDL Indicator, lights and any other functions that

are steering column operated.

IGNITION SWITCH

DESCRIPTION

The ignition switch is located on the steering col-

umn. It is used as the main on/off switching device

for most electrical components. The mechanical key

cylinder is used to engage/disengage the electrical

ignition switch.

OPERATION

Vehicles equipped with an automatic trans-

mission and a steering column mounted shifter:

an interlock device is located within the shift cable.

This interlock device is used to lock the transmission

shifter in the PARK position when the key cylinder is

in any position and the brake pedal is not depressed.

DIAGNOSIS AND TESTING - IGNITION SWITCH

TEST AND REPAIR

If the key removal effort is excessive on a vehicle

with a automatic transmission first adjust the shift

linkage, (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 46RE/GEAR SHIFT CABLE -

ADJUSTMENTS).

If the ignition switch effort is excessive remove the

ignition key cylinder from the steering column. (Refer

to 19 - STEERING/COLUMN/LOCK CYLINDER

Fig. 7 STEERING COLUMN

1 - Steering Wheel

2 - Key Cylinder

3 - Gear Shift Lever

4 - Steering Column

5 - Tilt Lever Cable

DRCOLUMN 19 - 9

COLUMN (Continued)

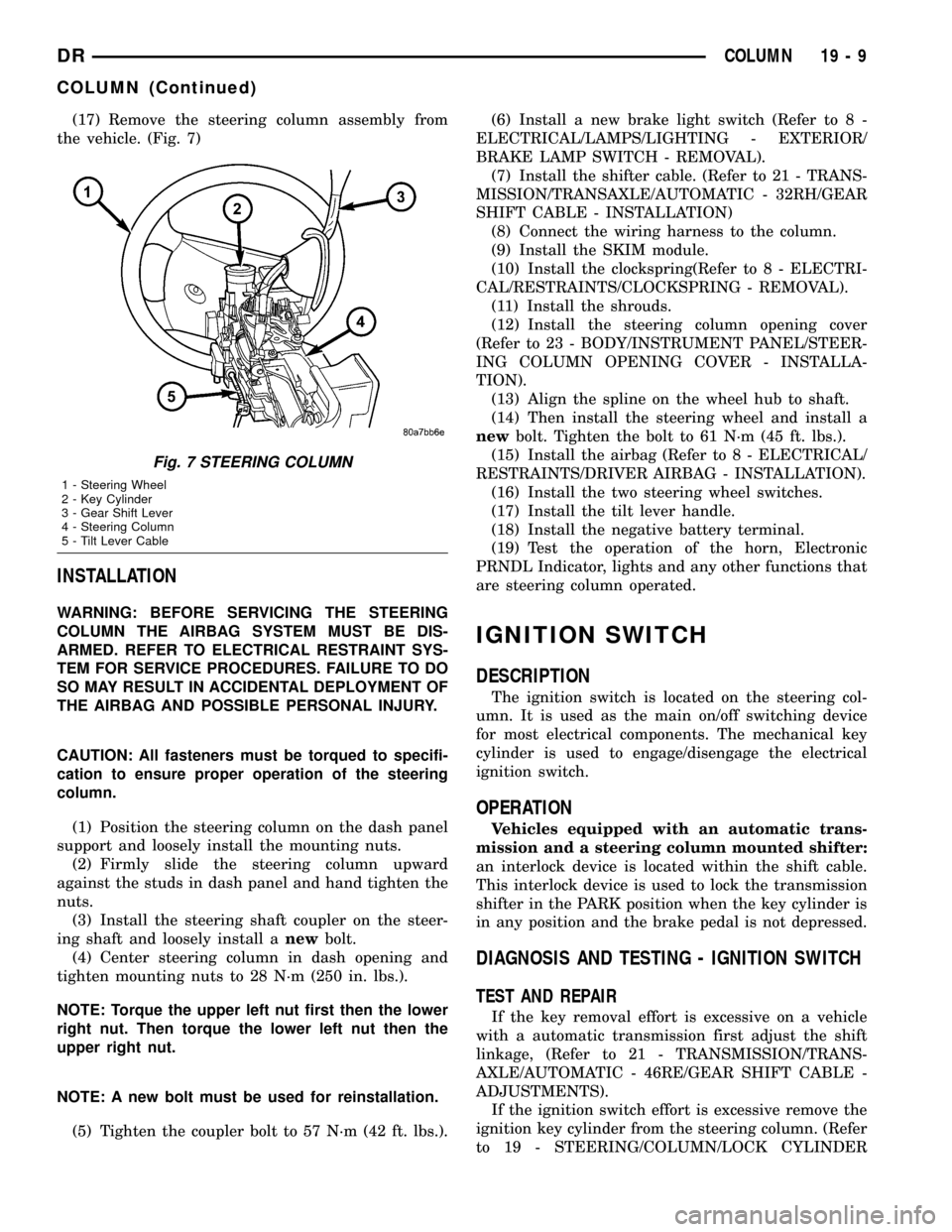

Page 1665 of 2627

HOUSING - REMOVAL). Check the turning effort of

the key cylinder. If the ignition key cylinder effort is

excessive replace the key cylinder.

REMOVAL

SERVICE PRECAUTIONS

NOTE: The steering column on vehicles equipped

with an automatic transmission is not equipped

with an internal locking shaft with the ignition cyl-

inder. Alternative methods of locking the steering

wheel for service will have to be used.

The tilt and standard column (Fig. 8) have been

designed to be serviced as an assembly; without wir-

ing, switches, shrouds, steering wheel, etc. Most

steering column components can be serviced without

removing the steering column from the vehicle.

Safety goggles should be worn at all times when

working on steering columns.

To service the steering wheel, switches or airbag,

Refer to Electrical Restraints and follow all WARN-

INGS and CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIRBAG ANDPOSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COAT-

INGS AND ARE SPECIFICALLY DESIGNED FOR THE

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.

CAUTION: Do not hammer on steering column

shaft. This may cause damage to the shaft or bear-

ing.

CAUTION: Do not attempt to remove the pivot bolts

to disassemble the tilting mechanism.

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Remove the negative (ground) cable from the

battery.

(2) Disable the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(3) Remove the lower and upper shrouds.

(4) Remove key cylinder. (Refer to 19 - STEER-

ING/COLUMN/LOCK CYLINDER HOUSING -

REMOVAL).

(5) Disconnect the lower clockspring connectors.

(6) Remove the wire retainer from the tilt lever

bracket.

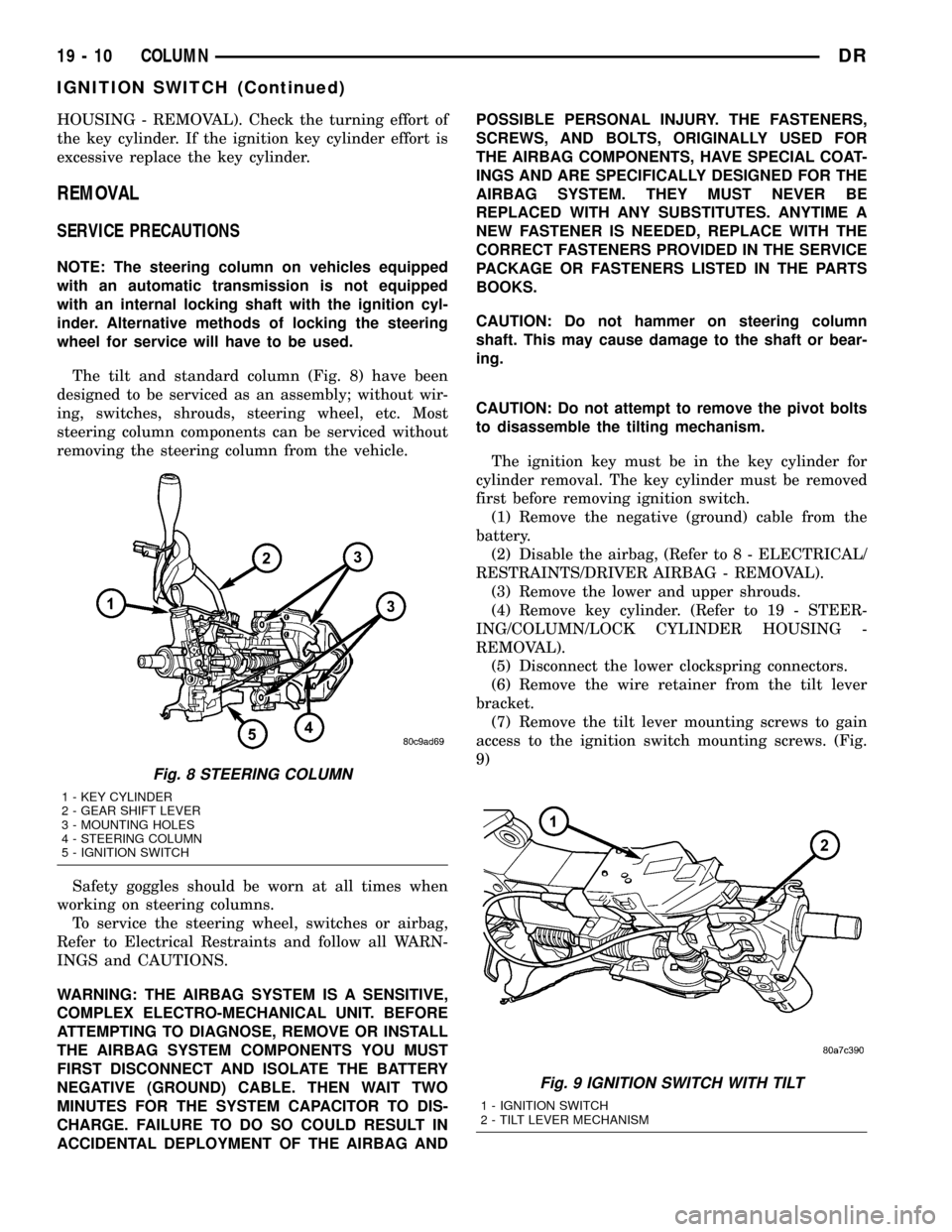

(7) Remove the tilt lever mounting screws to gain

access to the ignition switch mounting screws. (Fig.

9)

Fig. 8 STEERING COLUMN

1 - KEY CYLINDER

2 - GEAR SHIFT LEVER

3 - MOUNTING HOLES

4 - STEERING COLUMN

5 - IGNITION SWITCH

Fig. 9 IGNITION SWITCH WITH TILT

1 - IGNITION SWITCH

2 - TILT LEVER MECHANISM

19 - 10 COLUMNDR

IGNITION SWITCH (Continued)

Page 1668 of 2627

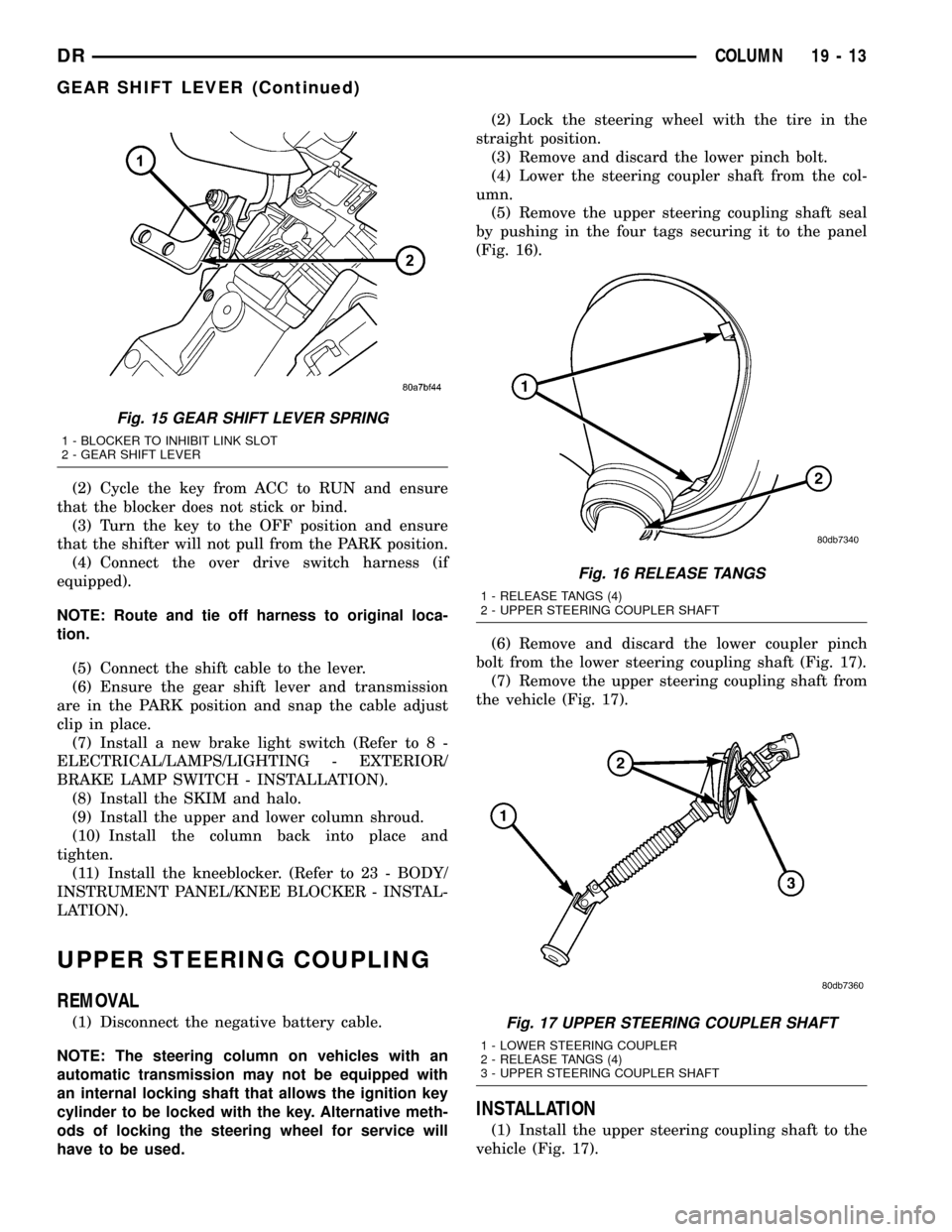

(2) Cycle the key from ACC to RUN and ensure

that the blocker does not stick or bind.

(3) Turn the key to the OFF position and ensure

that the shifter will not pull from the PARK position.

(4) Connect the over drive switch harness (if

equipped).

NOTE: Route and tie off harness to original loca-

tion.

(5) Connect the shift cable to the lever.

(6) Ensure the gear shift lever and transmission

are in the PARK position and snap the cable adjust

clip in place.

(7) Install a new brake light switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION).

(8) Install the SKIM and halo.

(9) Install the upper and lower column shroud.

(10) Install the column back into place and

tighten.

(11) Install the kneeblocker. (Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

UPPER STEERING COUPLING

REMOVAL

(1) Disconnect the negative battery cable.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.(2) Lock the steering wheel with the tire in the

straight position.

(3) Remove and discard the lower pinch bolt.

(4) Lower the steering coupler shaft from the col-

umn.

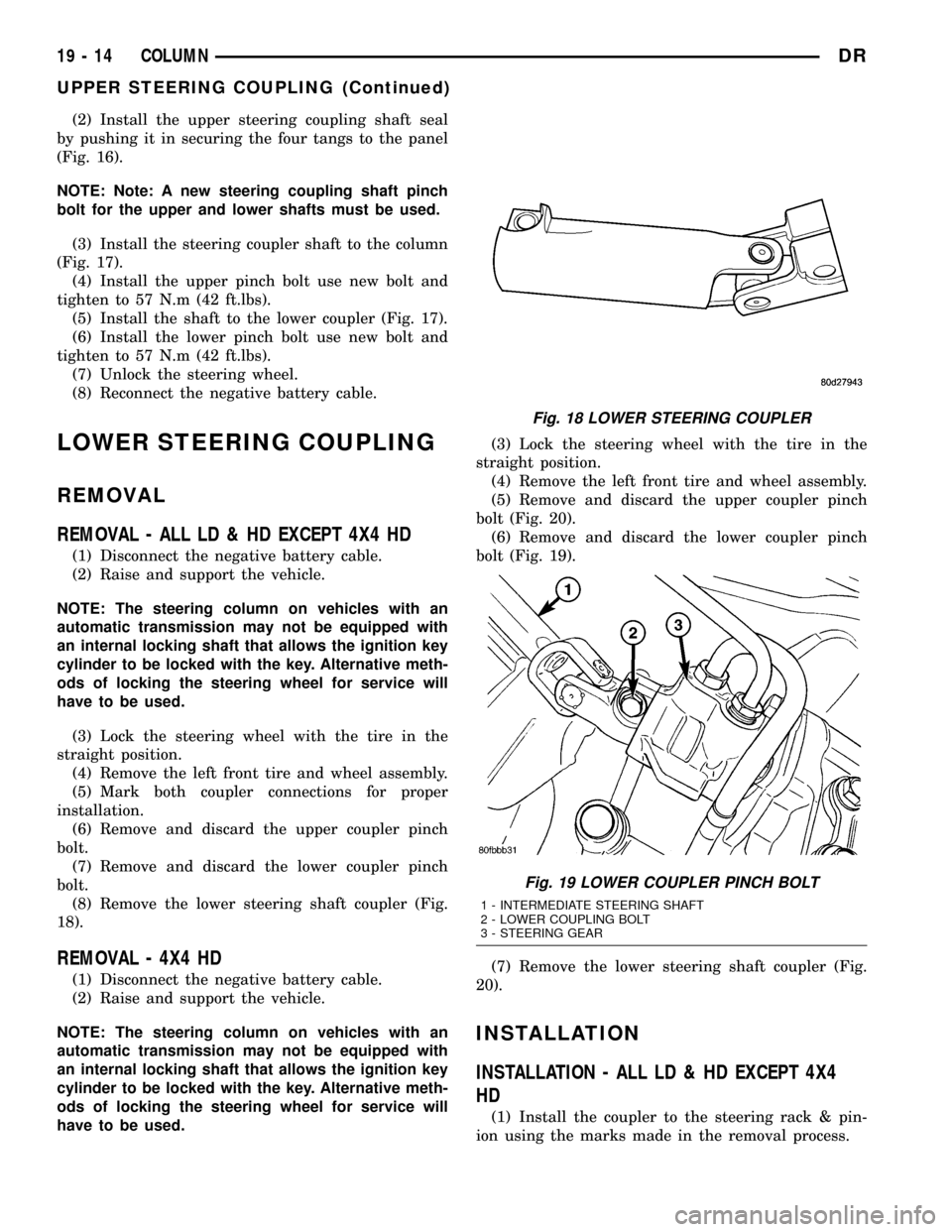

(5) Remove the upper steering coupling shaft seal

by pushing in the four tags securing it to the panel

(Fig. 16).

(6) Remove and discard the lower coupler pinch

bolt from the lower steering coupling shaft (Fig. 17).

(7) Remove the upper steering coupling shaft from

the vehicle (Fig. 17).

INSTALLATION

(1) Install the upper steering coupling shaft to the

vehicle (Fig. 17).

Fig. 15 GEAR SHIFT LEVER SPRING

1 - BLOCKER TO INHIBIT LINK SLOT

2 - GEAR SHIFT LEVER

Fig. 16 RELEASE TANGS

1 - RELEASE TANGS (4)

2 - UPPER STEERING COUPLER SHAFT

Fig. 17 UPPER STEERING COUPLER SHAFT

1 - LOWER STEERING COUPLER

2 - RELEASE TANGS (4)

3 - UPPER STEERING COUPLER SHAFT

DRCOLUMN 19 - 13

GEAR SHIFT LEVER (Continued)

Page 1669 of 2627

(2) Install the upper steering coupling shaft seal

by pushing it in securing the four tangs to the panel

(Fig. 16).

NOTE: Note: A new steering coupling shaft pinch

bolt for the upper and lower shafts must be used.

(3) Install the steering coupler shaft to the column

(Fig. 17).

(4) Install the upper pinch bolt use new bolt and

tighten to 57 N.m (42 ft.lbs).

(5) Install the shaft to the lower coupler (Fig. 17).

(6) Install the lower pinch bolt use new bolt and

tighten to 57 N.m (42 ft.lbs).

(7) Unlock the steering wheel.

(8) Reconnect the negative battery cable.

LOWER STEERING COUPLING

REMOVAL

REMOVAL - ALL LD & HD EXCEPT 4X4 HD

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

(3) Lock the steering wheel with the tire in the

straight position.

(4) Remove the left front tire and wheel assembly.

(5) Mark both coupler connections for proper

installation.

(6) Remove and discard the upper coupler pinch

bolt.

(7) Remove and discard the lower coupler pinch

bolt.

(8) Remove the lower steering shaft coupler (Fig.

18).

REMOVAL - 4X4 HD

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.(3) Lock the steering wheel with the tire in the

straight position.

(4) Remove the left front tire and wheel assembly.

(5) Remove and discard the upper coupler pinch

bolt (Fig. 20).

(6) Remove and discard the lower coupler pinch

bolt (Fig. 19).

(7) Remove the lower steering shaft coupler (Fig.

20).

INSTALLATION

INSTALLATION - ALL LD & HD EXCEPT 4X4

HD

(1) Install the coupler to the steering rack & pin-

ion using the marks made in the removal process.

Fig. 18 LOWER STEERING COUPLER

Fig. 19 LOWER COUPLER PINCH BOLT

1 - INTERMEDIATE STEERING SHAFT

2 - LOWER COUPLING BOLT

3 - STEERING GEAR

19 - 14 COLUMNDR

UPPER STEERING COUPLING (Continued)