section 5 DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1466 of 2627

(8) Replace injector o-ring and sealing washer on

injectors #5 and #6. Install injectors and torque using

the following steps:

²Step 1ÐInstall injector hold-down capscrews

and torque to 5 N´m (44 in. lbs.) torque.

²Step 2ÐLoosen injector hold-down capscrews.

²Step 3ÐInstall HPC connector tube and nut.

Torque nut to 15 N´m (11 ft. lbs.) torque.

²Step 4ÐTorque injector hold-down capscrews to

10 N´m (89 in. lbs.) torque.

²Step 5ÐTorque HPC connector tube nut to 50

N´m (37 ft. lbs.) torque.

(9) Install #5 and #6 high pressure fuel lines. Fol-

low correct torque sequence per section 14. Torque

fuel line fittings to 30 N-m (22 ft-lb). Torque brace

capscrew to 24 N-m (18 ft-lb).

(10) Install rear engine lift bracket. Torque to 77

N-m (57 ft-lb).

(11) Install push tubes, rocker arms, and pedestals

for cylinders #4, #5, and #6. Torque the mounting

bolts to 36 N-m (27 ft-lbs).

(12) Reset valve lash on cylinders #4, #5, and #6.

Torque adjusting nuts to 24 N-m (18 ft-lbs).

(13) Install cylinder head cover. Torque to 24 N-m

(18 ft-lbs).(Refer to 9 - ENGINE/CYLINDER HEAD -

INSTALLATION).

(14) Connect breather tube and lube oil drain tube

to breather housing cover. Install breather housing.

Torque capscrews to 24 N-m (18 ft-lbs)

(15) Connect fuel supply and return hoses.

(16) Connect ECM ground to hydroform screw.

Connect ECM power connector.

(17) Install the APPS cable(s) to the APPS. Install

the throttle linkage cover.

(18) Install the power steering pump.

(19) Install the damper and speed indicator ring.

Torque to 40 N-m (30 ft-lb) plus 60 degrees.

(20) Connect the engine block heater connection.

(21) Connect the A/C compressor and pressure sen-

sor connectors

(22) Install the charge air cooler and a/c condenser

(if equipped). Install and tighten the charge air

cooler mounting bolts to 2 N-m (17 in-lbs).

(23) Connect the charge air cooler piping. Torque

all clamps to 8 N-m (72 in-lbs).

(24) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(25) Install the radiator upper support panel.

(26) Install radiator.

(27) Connect the transmission quick-connect oil

cooler lines.(28) Raise vehicle.

(29) Connect a/c compressor suction/discharge hose

(if equipped).

(30) Install the radiator lower hose and clamps.

(31) Install the battery negative cables to the

engine block on the driver and passenger side.

(32) Install the transmission adapter with a new

camshaft rectangular ring seal. Torque to 77 N-m (57

ft-lb).

(33) Install the flywheel/flexplate. Torque to 137

N-m (101 ft-lb).

(34) Install the starter motor. Torque to 43 N-m

(32 ft-lb). (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(35) Connect engine to vehicle harness connectors.

(36) Install transmission and transfer case (if

equipped).

(37) Connect the exhaust pipe to the turbocharger

elbow.

(38) Connect the transmission auxiliary oil cooler

lines (if equipped).

(39) Lower the vehicle.

(40) Connect the heater core supply and return

hoses.

(41) Install the cooling fan and upper fan shroud

at the same time. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION).

(42) Install the coolant recovery bottle.

(43) Install the windshield washer bottle.

(44) Install the upper radiator hose and clamps.

(45) Raise vehicle.

(46) Connect electronically controlled fan drive

wire harness. Install lower radiator fan shroud.

(47) Change oil filter and install new engine oil.

(48) Fill the cooling system with coolant. (Refer to

7 - COOLING - STANDARD PROCEDURE).

(49) Connect grid heater harness at grid heater

relays.

(50) Connect electrical connections to rear of alter-

nator.

(51) Start the engine and inspect for engine oil,

coolant, and fuel leaks.

INSTALLATIONÐCRANKCASE BREATHER

(1) Install a new o-ring onto the breather element.

(2) Lubricate o-ring and install into cylinder head

cover. Torque capscrews to 10 N´m (89 in. lbs.).

(3) Connect breather tube and lube oil drain tube.

(4) Install breather cover (Fig. 4). Torque to 24

N´m (18 ft. lbs.)

(5) Install oil fill cap.

DRENGINE 5.9L DIESEL 9 - 243

ENGINE 5.9L DIESEL (Continued)

Page 1478 of 2627

(37) Rotate generator into position. Install upper

bolt and torque upper and lower bolts.

(38)

Install wire harness push-on clip below bracket.

(39) Install wire harness P-clip to top of bracket.

(40) Install fan support and torque to 32 N´m (24

ft. lbs.).

(41) Install cooling fan/drive refer to (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(42) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(43) Install exhaust manifold/turbocharger assem-

bly, using new gaskets. Start all bolts/spacers by

hand. Torque bolts to 43 N´m (32 ft. lbs.).

(44) Install exhaust manifold heat shield to

exhaust manifold studs. Install retaining nuts.Torque

to 15 N´m (11 ft. lbs.).

(45) Install exhaust bolt retention straps across

cylinders5&6.

(46) Connect turbocharger oil drain tube. Torque

clamp to 8 N´m (71 in. lbs.).

(47) Perform the turbocharger pre-lube procedure.

Refer to Group 11, Exhaust System and Turbo-

charger for the correct procedure.

(48) Connect the turbocharger oil supply line.

Torque to 24 N´m (18 ft. lbs.).

(49) Install air cleaner housing and duct.

(50) Connect air inlet temperature/pressure sensor.

(51) Raise vehicle on hoist.

(52) Install exhaust pipe to turbocharger elbow.

Torque bolts to 11 N´m (100 in. lbs.).

(53) Lower vehicle.

(54) Fill engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(55) Start engine and check for leaks.

CYLINDER HEAD COVER(S)

REMOVAL

REMOVALÐCYLINDER HEAD COVER

(1) Disconnect both battery negative cables.

(2) Remove oil fill cap.

(3) Remove the breather cover.

(4) Disconnect the breather hose and breather

drain tube from the breather housing.

(5) Remove cylinder head cover bolts.

(6) Remove the cylinder head cover.

REMOVALÐROCKER HOUSING

(1) Remove cylinder head cover as outlined in this

section.

(2) Disconnect rocker housing injector harness con-

nectors.(3) Remove injector harness nuts from injectors.

(4) Remove rocker housing bolts.

(5) Remove rocker housing and gasket.

CLEANING

Using a suitable solvent, Clean and dry gasket

mating surfaces on cylinder head and rocker housing.

Wipe gasket dry and inspect for re-use.

INSPECTION

The cylinder head cover gasket and rocker hous-

ing gasket, are reusable.However, should cracks,

nicks, or tears be present in the rubber/silicone construc-

tion, the defective components should be replaced. Also

replace gasket if it is no longer flexible. Inspect o-rings

on cylinder head cover bolts.Do not reuse gasket if it

has been removed from the groove in the rocker

housing or cylinder head cover.

INSTALLATION

INSTALLATIONÐCYLINDER HEAD COVER

(1) Inspect cylinder head cover gasket for cuts and

proper installation in groove. Replace if damaged.

(2)

Position cylinder cover on top of rocker housing.

(3) Install bolts.

(4) Starting with the center bolt, torque to 24 N´m

(18 ft. lbs.).

(5) Install breather hose to breather.

(6) Install breather drain hose to breather.

(7) Install breather cover and wire harness clip.

Torque to 24 N´m (18 ft. lbs.).

INSTALLATION - ROCKER HOUSING

(1) Inspect rocker housing gasket for cuts, nicks,

or tears. Replace if damaged or if gasket has come

out of groove.

(2) Inspect rocker housing gasket for proper instal-

lation in groove. Gasket bead must be centered in

groove. A gasket bead that is tilted to the side will

cause an oil leak.

CAUTION: When installing rocker housing onto cyl-

inder head, do not slide housing from side to side,

The gasket could fall out or be damaged.

(3) Install the rocker housing. Carefully guide the

rocker housing evenly down onto the cylinder head.

(4) Install rocker housing bolts and tighten finger

tight.

(5) Torque bolts, working from center out, to 24

Nm (18ft. lbs.).

(6) Install injector harness nuts to injector sole-

noid. Torque to 1.25 Nm (11 in. lbs.).

(7) Connect rocker housing injector harness con-

nections.

DRENGINE 5.9L DIESEL 9 - 255

CYLINDER HEAD (Continued)

Page 1506 of 2627

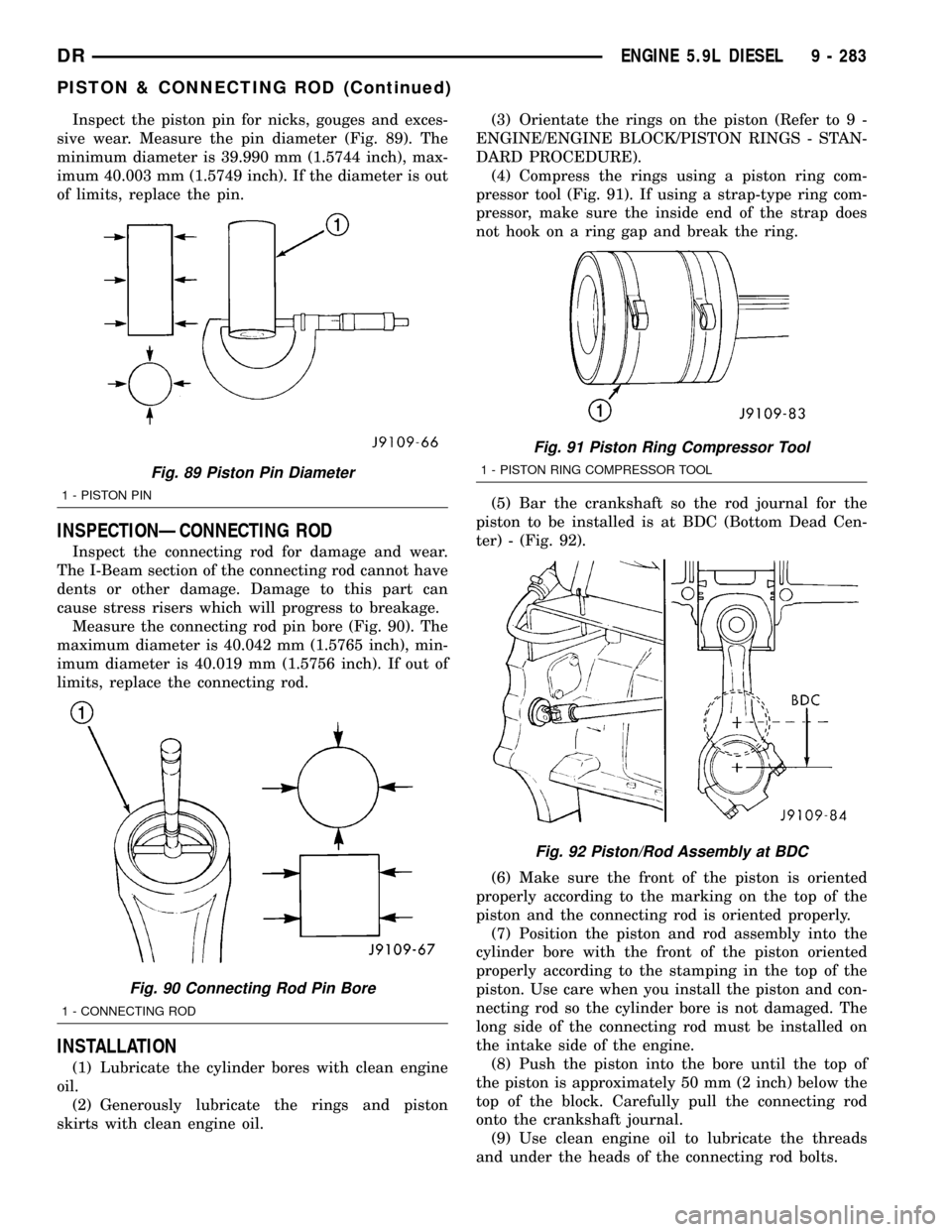

Inspect the piston pin for nicks, gouges and exces-

sive wear. Measure the pin diameter (Fig. 89). The

minimum diameter is 39.990 mm (1.5744 inch), max-

imum 40.003 mm (1.5749 inch). If the diameter is out

of limits, replace the pin.

INSPECTIONÐCONNECTING ROD

Inspect the connecting rod for damage and wear.

The I-Beam section of the connecting rod cannot have

dents or other damage. Damage to this part can

cause stress risers which will progress to breakage.

Measure the connecting rod pin bore (Fig. 90). The

maximum diameter is 40.042 mm (1.5765 inch), min-

imum diameter is 40.019 mm (1.5756 inch). If out of

limits, replace the connecting rod.

INSTALLATION

(1) Lubricate the cylinder bores with clean engine

oil.

(2) Generously lubricate the rings and piston

skirts with clean engine oil.(3) Orientate the rings on the piston (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON RINGS - STAN-

DARD PROCEDURE).

(4) Compress the rings using a piston ring com-

pressor tool (Fig. 91). If using a strap-type ring com-

pressor, make sure the inside end of the strap does

not hook on a ring gap and break the ring.

(5) Bar the crankshaft so the rod journal for the

piston to be installed is at BDC (Bottom Dead Cen-

ter) - (Fig. 92).

(6) Make sure the front of the piston is oriented

properly according to the marking on the top of the

piston and the connecting rod is oriented properly.

(7) Position the piston and rod assembly into the

cylinder bore with the front of the piston oriented

properly according to the stamping in the top of the

piston. Use care when you install the piston and con-

necting rod so the cylinder bore is not damaged. The

long side of the connecting rod must be installed on

the intake side of the engine.

(8) Push the piston into the bore until the top of

the piston is approximately 50 mm (2 inch) below the

top of the block. Carefully pull the connecting rod

onto the crankshaft journal.

(9) Use clean engine oil to lubricate the threads

and under the heads of the connecting rod bolts.

Fig. 89 Piston Pin Diameter

1 - PISTON PIN

Fig. 90 Connecting Rod Pin Bore

1 - CONNECTING ROD

Fig. 91 Piston Ring Compressor Tool

1 - PISTON RING COMPRESSOR TOOL

Fig. 92 Piston/Rod Assembly at BDC

DRENGINE 5.9L DIESEL 9 - 283

PISTON & CONNECTING ROD (Continued)

Page 1537 of 2627

(6) Full load boost pressure at rated speed will be

158 - 186 kPa (23 - 27 psi.) depending on engine hp

rating.. If pressure readings are are not within this

range inspect for the following:

²Restricted air inlet system

²Leak in the charge air cooler system (Refer to 11

- EXHAUST SYSTEM/TURBOCHARGER SYSTEM/

CHARGE AIR COOLER AND PLUMBING - DIAG-

NOSIS AND TESTING)

²Turbocharger wastegate broken or misadjusted

²Restricted/high pressure drop across charge air

cooler

²Turbocharger damaged (Refer to 11 - EXHAUST

SYSTEM/TURBOCHARGER SYSTEM/TURBO-

CHARGER - INSPECTION)

TURBOCHARGER

DESCRIPTION

The turbocharger is an exhaust-driven super-

charger which increases the pressure and density of

the air entering the engine. With the increase of air

entering the engine, more fuel can be injected into

the cylinders, which creates more power during com-

bustion.

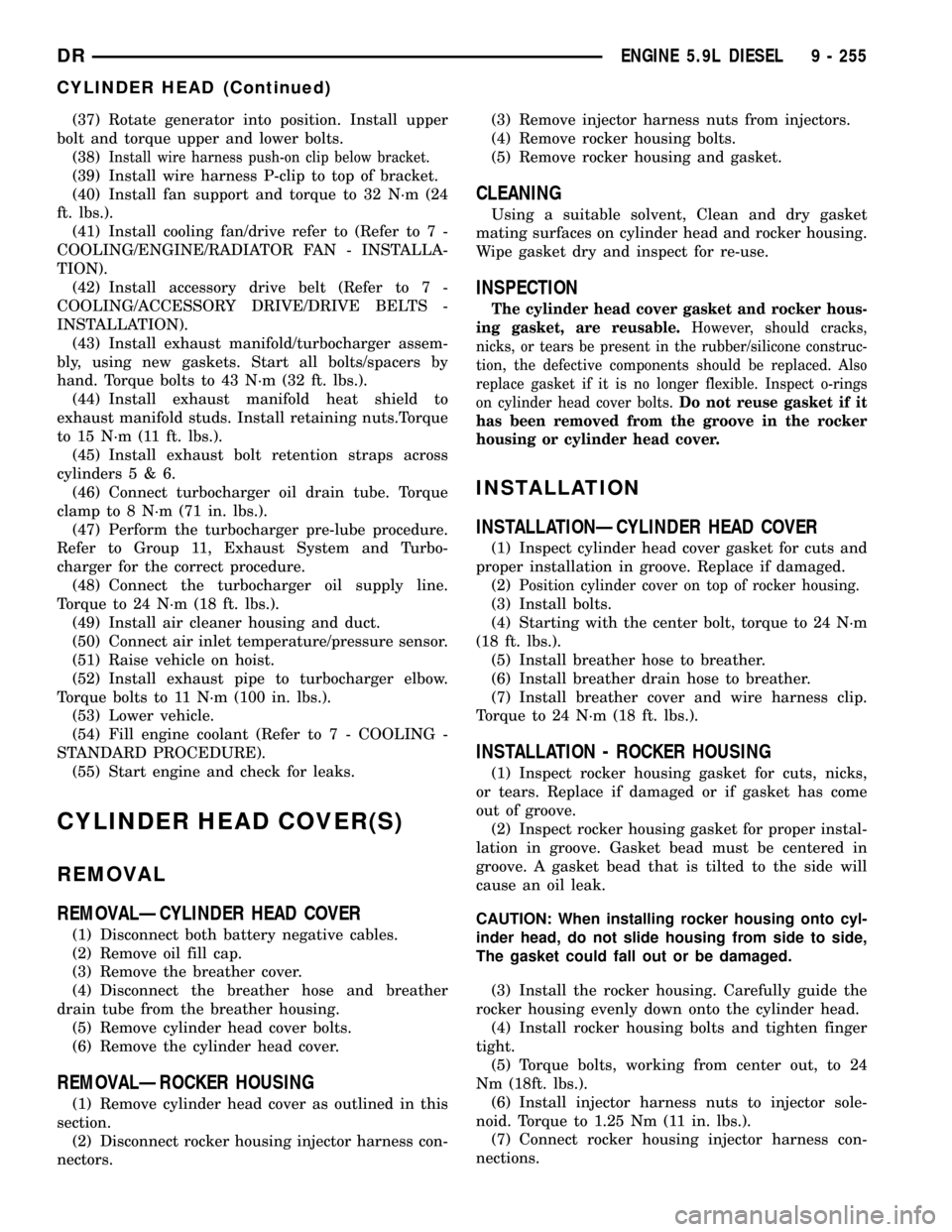

The turbocharger assembly consists of four (4)

major component systems (Fig. 14) (Fig. 15) :²Turbine section

²Compressor section

²Bearing housing

²Wastegate

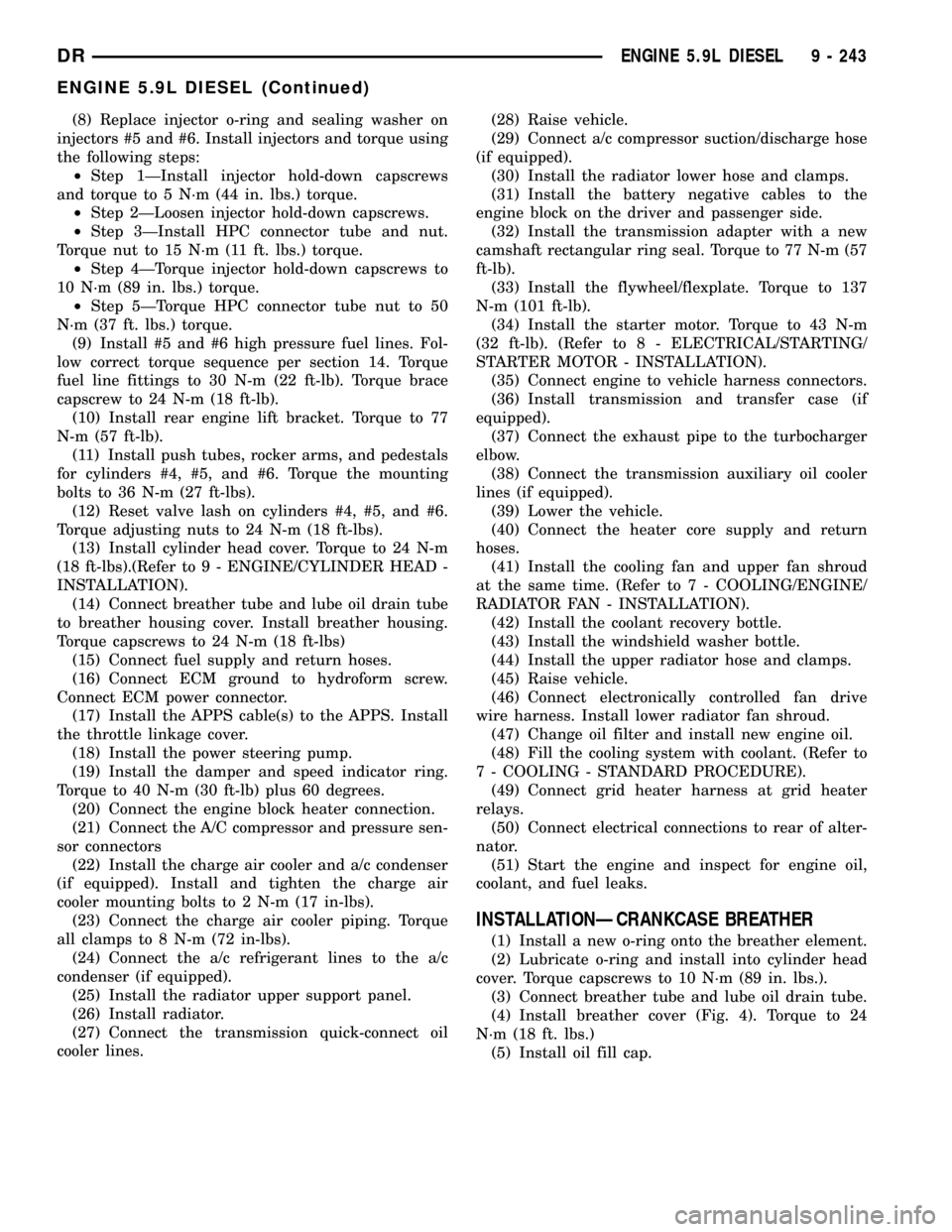

Fig. 13 INTAKE MANIFOLD TO AIR INLET DUCT

RUBBER SLEEVE

1 - INTAKE MANIFOLD AIR INLET

2 - CLAMPS

3 - AIR INLET DUCT

4 - AIR INLET DUCT RUBBER SLEEVE

Fig. 14 Turbocharger Operation

1 - TURBINE SECTION

2 - EXHAUST GAS

3 - BEARING HOUSING

4 - COMPRESSOR SECTION

5 - INLET AIR

6 - COMPRESSED AIR TO ENGINE

7 - EXHAUST GAS

8 - EXHAUST GAS TO EXHAUST PIPE

Fig. 15 Turbocharger Wastegate Actuator

1 - TURBOCHARGER

2 - DIAPHRAGM

3 - WASTE GATE ACTUATOR

11 - 12 EXHAUST SYSTEMDR

TURBOCHARGER SYSTEM (Continued)

Page 1538 of 2627

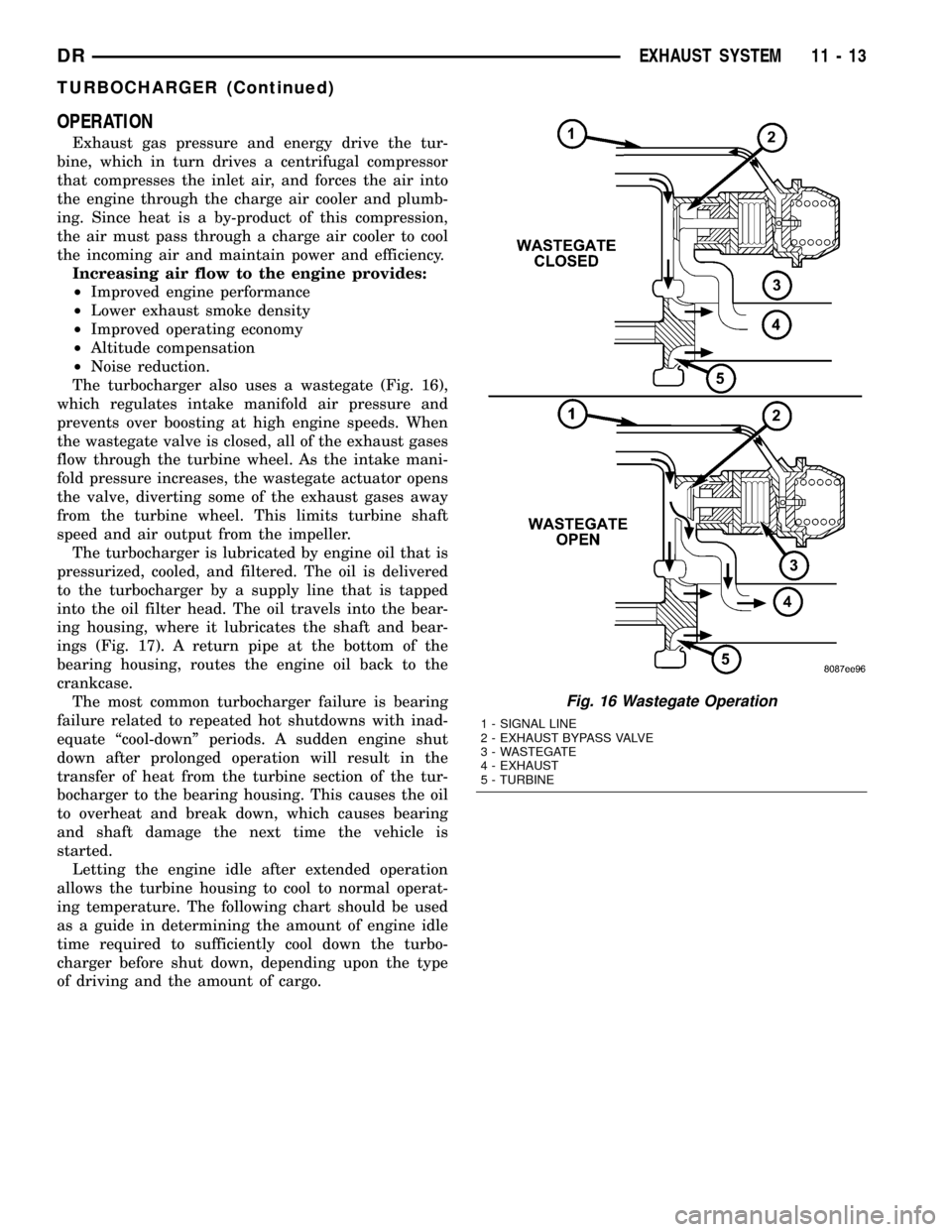

OPERATION

Exhaust gas pressure and energy drive the tur-

bine, which in turn drives a centrifugal compressor

that compresses the inlet air, and forces the air into

the engine through the charge air cooler and plumb-

ing. Since heat is a by-product of this compression,

the air must pass through a charge air cooler to cool

the incoming air and maintain power and efficiency.

Increasing air flow to the engine provides:

²Improved engine performance

²Lower exhaust smoke density

²Improved operating economy

²Altitude compensation

²Noise reduction.

The turbocharger also uses a wastegate (Fig. 16),

which regulates intake manifold air pressure and

prevents over boosting at high engine speeds. When

the wastegate valve is closed, all of the exhaust gases

flow through the turbine wheel. As the intake mani-

fold pressure increases, the wastegate actuator opens

the valve, diverting some of the exhaust gases away

from the turbine wheel. This limits turbine shaft

speed and air output from the impeller.

The turbocharger is lubricated by engine oil that is

pressurized, cooled, and filtered. The oil is delivered

to the turbocharger by a supply line that is tapped

into the oil filter head. The oil travels into the bear-

ing housing, where it lubricates the shaft and bear-

ings (Fig. 17). A return pipe at the bottom of the

bearing housing, routes the engine oil back to the

crankcase.

The most common turbocharger failure is bearing

failure related to repeated hot shutdowns with inad-

equate ªcool-downº periods. A sudden engine shut

down after prolonged operation will result in the

transfer of heat from the turbine section of the tur-

bocharger to the bearing housing. This causes the oil

to overheat and break down, which causes bearing

and shaft damage the next time the vehicle is

started.

Letting the engine idle after extended operation

allows the turbine housing to cool to normal operat-

ing temperature. The following chart should be used

as a guide in determining the amount of engine idle

time required to sufficiently cool down the turbo-

charger before shut down, depending upon the type

of driving and the amount of cargo.

Fig. 16 Wastegate Operation

1 - SIGNAL LINE

2 - EXHAUST BYPASS VALVE

3 - WASTEGATE

4 - EXHAUST

5 - TURBINE

DREXHAUST SYSTEM 11 - 13

TURBOCHARGER (Continued)

Page 1544 of 2627

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT BUMPER

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................2

INSTALLATION..........................3

REAR BUMPER

REMOVAL.............................3

INSTALLATION..........................4

FRAME

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR.................11

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT.............13SPECIFICATIONS

SPECIFICATIONS - WELD PROCESS......15

SPECIFICATIONS - FRAME DIMENSIONS . . . 16

SPECIFICATIONS - TORQUE............22

FRONT CROSSMEMBER

REMOVAL.............................22

INSTALLATION.........................22

FRONT SKID PLATE

REMOVAL.............................23

INSTALLATION.........................23

FRONT TOW HOOK ASSEMBLY

REMOVAL.............................23

INSTALLATION.........................23

TRANSMISSION CROSSMEMBER

REMOVAL.............................24

INSTALLATION.........................24

TRAILER HITCH

REMOVAL.............................25

INSTALLATION.........................25

TRANSFER CASE SKID PLATE

REMOVAL.............................26

INSTALLATION.........................26

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 Ð

Front bumper stud plate nuts 95 70 Ð

License plate hitch reinforcement bolts 54 40 Ð

Rear bumper support bracket stud plate nuts 54 40 Ð

Rear bumper support bracket to hitch bolts 54 40 Ð

Rear bumper to hitch bolts 54 40 Ð

DRFRAMES & BUMPERS 13 - 1

Page 1549 of 2627

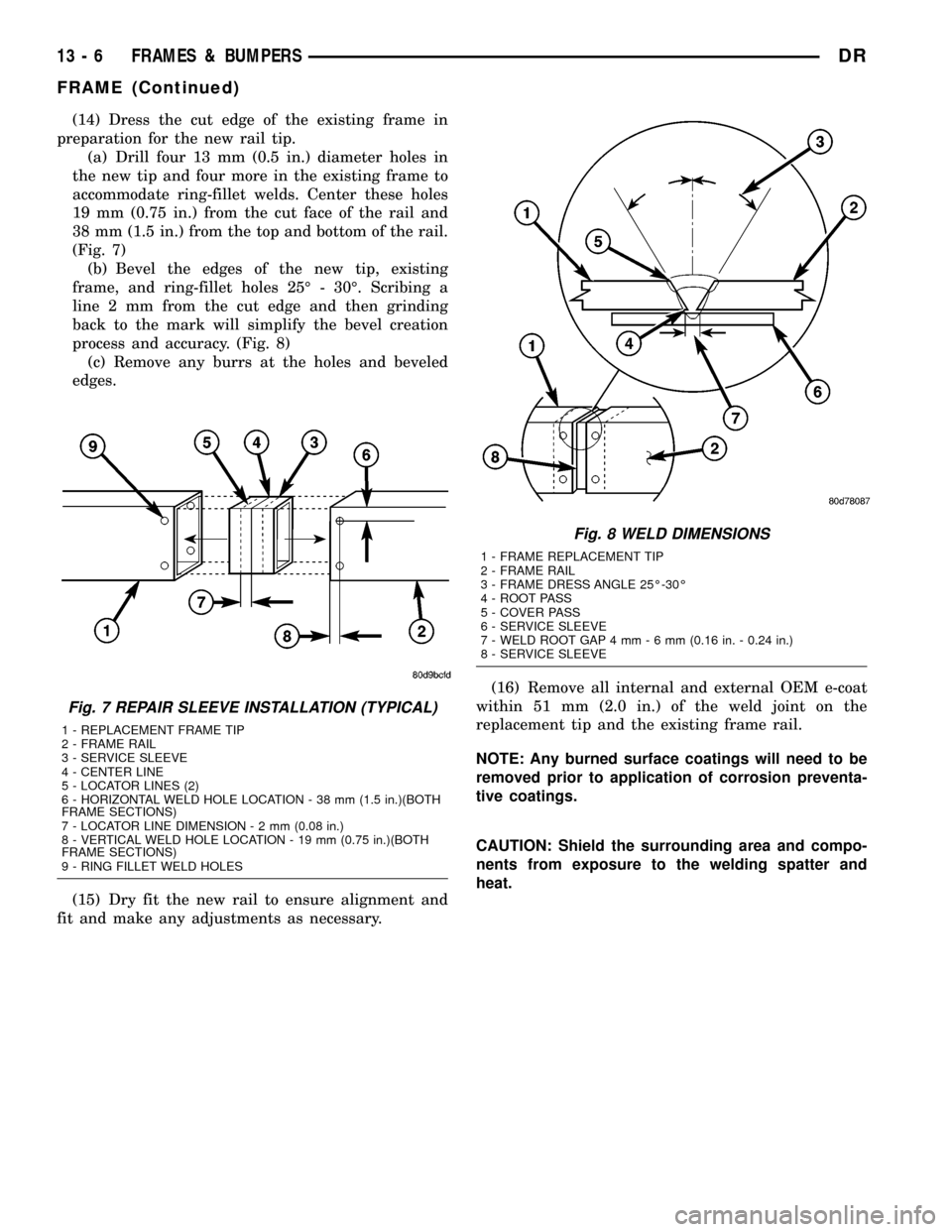

(14) Dress the cut edge of the existing frame in

preparation for the new rail tip.

(a) Drill four 13 mm (0.5 in.) diameter holes in

the new tip and four more in the existing frame to

accommodate ring-fillet welds. Center these holes

19 mm (0.75 in.) from the cut face of the rail and

38 mm (1.5 in.) from the top and bottom of the rail.

(Fig. 7)

(b) Bevel the edges of the new tip, existing

frame, and ring-fillet holes 25É - 30É. Scribing a

line 2 mm from the cut edge and then grinding

back to the mark will simplify the bevel creation

process and accuracy. (Fig. 8)

(c) Remove any burrs at the holes and beveled

edges.

(15) Dry fit the new rail to ensure alignment and

fit and make any adjustments as necessary.(16) Remove all internal and external OEM e-coat

within 51 mm (2.0 in.) of the weld joint on the

replacement tip and the existing frame rail.

NOTE: Any burned surface coatings will need to be

removed prior to application of corrosion preventa-

tive coatings.

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

Fig. 7 REPAIR SLEEVE INSTALLATION (TYPICAL)

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - CENTER LINE

5 - LOCATOR LINES (2)

6 - HORIZONTAL WELD HOLE LOCATION - 38 mm (1.5 in.)(BOTH

FRAME SECTIONS)

7 - LOCATOR LINE DIMENSION-2mm(0.08 in.)

8 - VERTICAL WELD HOLE LOCATION - 19 mm (0.75 in.)(BOTH

FRAME SECTIONS)

9 - RING FILLET WELD HOLES

Fig. 8 WELD DIMENSIONS

1 - FRAME REPLACEMENT TIP

2 - FRAME RAIL

3 - FRAME DRESS ANGLE 25É-30É

4 - ROOT PASS

5 - COVER PASS

6 - SERVICE SLEEVE

7 - WELD ROOT GAP 4 mm-6mm(0.16 in. - 0.24 in.)

8 - SERVICE SLEEVE

13 - 6 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1552 of 2627

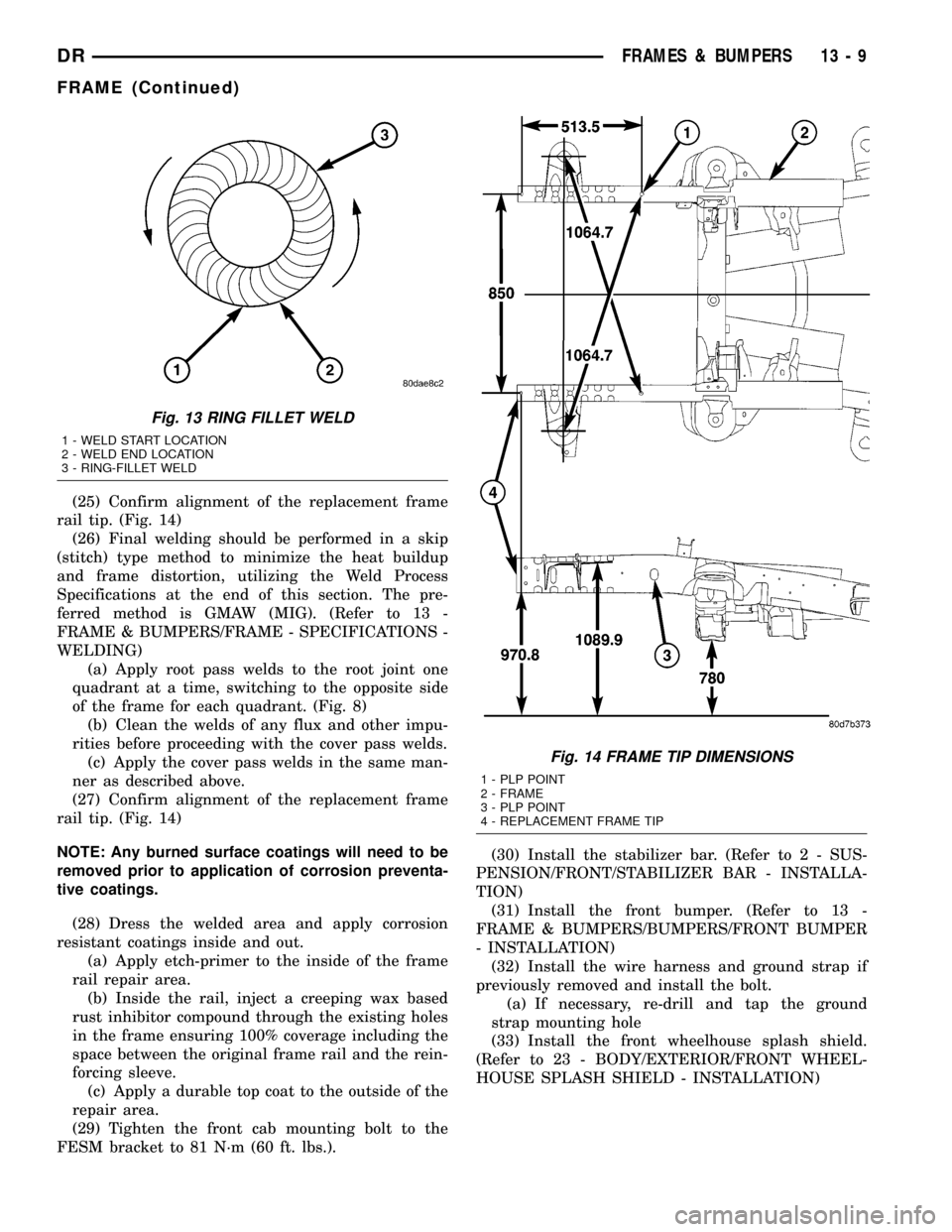

(25) Confirm alignment of the replacement frame

rail tip. (Fig. 14)

(26) Final welding should be performed in a skip

(stitch) type method to minimize the heat buildup

and frame distortion, utilizing the Weld Process

Specifications at the end of this section. The pre-

ferred method is GMAW (MIG). (Refer to 13 -

FRAME & BUMPERS/FRAME - SPECIFICATIONS -

WELDING)

(a) Apply root pass welds to the root joint one

quadrant at a time, switching to the opposite side

of the frame for each quadrant. (Fig. 8)

(b) Clean the welds of any flux and other impu-

rities before proceeding with the cover pass welds.

(c) Apply the cover pass welds in the same man-

ner as described above.

(27) Confirm alignment of the replacement frame

rail tip. (Fig. 14)

NOTE: Any burned surface coatings will need to be

removed prior to application of corrosion preventa-

tive coatings.

(28) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Apply etch-primer to the inside of the frame

rail repair area.

(b) Inside the rail, inject a creeping wax based

rust inhibitor compound through the existing holes

in the frame ensuring 100% coverage including the

space between the original frame rail and the rein-

forcing sleeve.

(c) Apply a durable top coat to the outside of the

repair area.

(29) Tighten the front cab mounting bolt to the

FESM bracket to 81 N´m (60 ft. lbs.).(30) Install the stabilizer bar. (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER BAR - INSTALLA-

TION)

(31) Install the front bumper. (Refer to 13 -

FRAME & BUMPERS/BUMPERS/FRONT BUMPER

- INSTALLATION)

(32) Install the wire harness and ground strap if

previously removed and install the bolt.

(a) If necessary, re-drill and tap the ground

strap mounting hole

(33) Install the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION)

Fig. 13 RING FILLET WELD

1 - WELD START LOCATION

2 - WELD END LOCATION

3 - RING-FILLET WELD

Fig. 14 FRAME TIP DIMENSIONS

1 - PLP POINT

2 - FRAME

3 - PLP POINT

4 - REPLACEMENT FRAME TIP

DRFRAMES & BUMPERS 13 - 9

FRAME (Continued)

Page 1554 of 2627

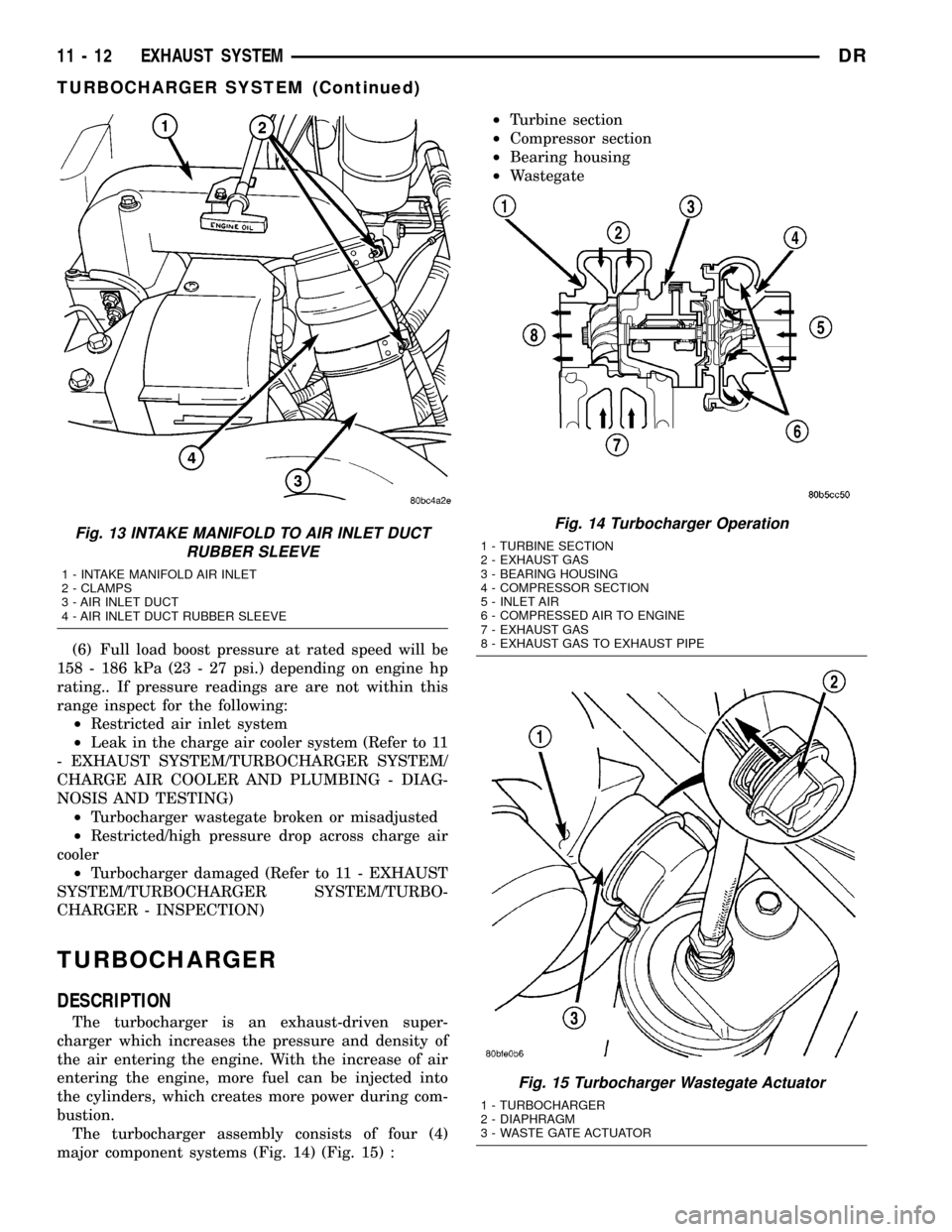

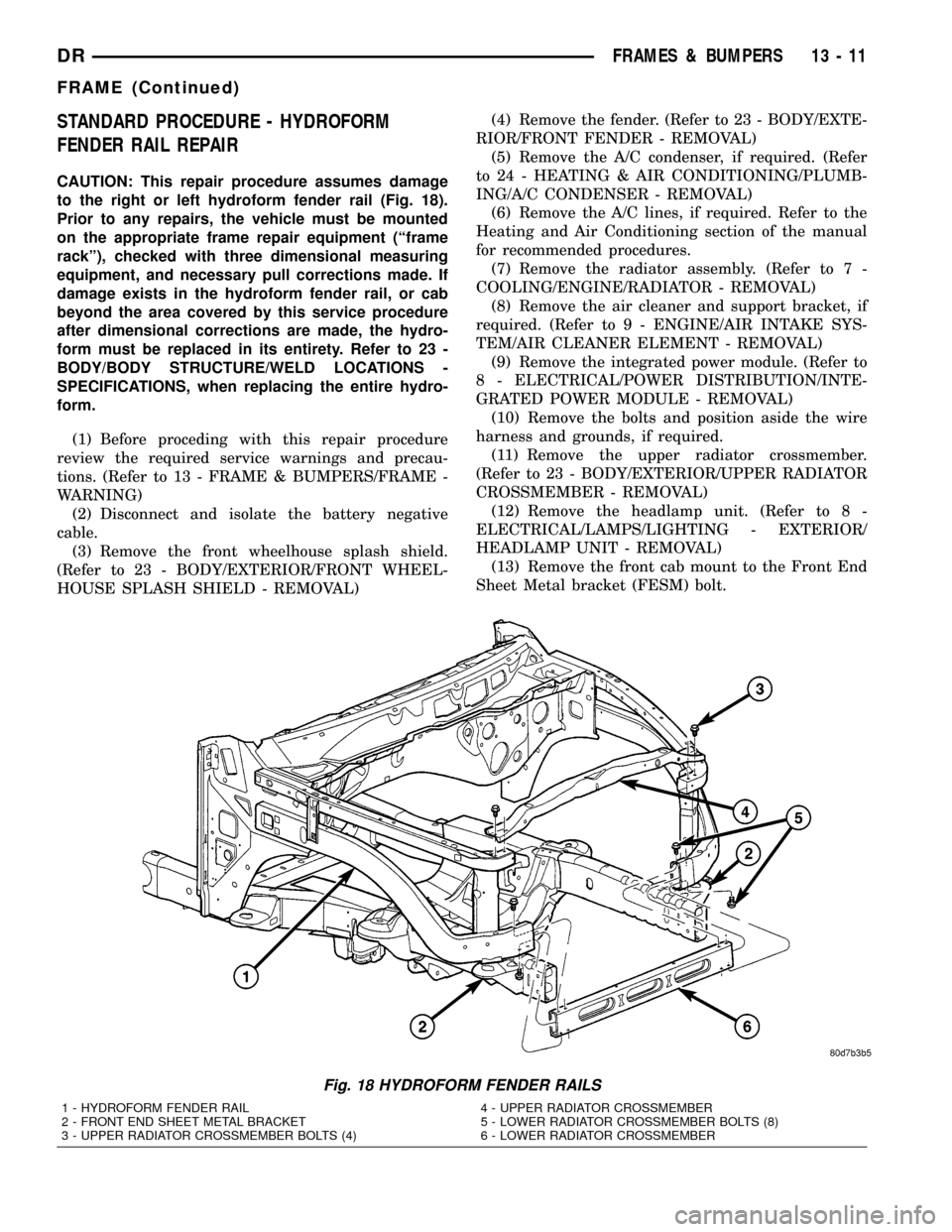

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR

CAUTION: This repair procedure assumes damage

to the right or left hydroform fender rail (Fig. 18).

Prior to any repairs, the vehicle must be mounted

on the appropriate frame repair equipment (ªframe

rackº), checked with three dimensional measuring

equipment, and necessary pull corrections made. If

damage exists in the hydroform fender rail, or cab

beyond the area covered by this service procedure

after dimensional corrections are made, the hydro-

form must be replaced in its entirety. Refer to 23 -

BODY/BODY STRUCTURE/WELD LOCATIONS -

SPECIFICATIONS, when replacing the entire hydro-

form.

(1) Before proceding with this repair procedure

review the required service warnings and precau-

tions. (Refer to 13 - FRAME & BUMPERS/FRAME -

WARNING)

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - REMOVAL)(4) Remove the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - REMOVAL)

(5) Remove the A/C condenser, if required. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - REMOVAL)

(6) Remove the A/C lines, if required. Refer to the

Heating and Air Conditioning section of the manual

for recommended procedures.

(7) Remove the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - REMOVAL)

(8) Remove the air cleaner and support bracket, if

required. (Refer to 9 - ENGINE/AIR INTAKE SYS-

TEM/AIR CLEANER ELEMENT - REMOVAL)

(9) Remove the integrated power module. (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - REMOVAL)

(10) Remove the bolts and position aside the wire

harness and grounds, if required.

(11) Remove the upper radiator crossmember.

(Refer to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - REMOVAL)

(12) Remove the headlamp unit. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

(13) Remove the front cab mount to the Front End

Sheet Metal bracket (FESM) bolt.

Fig. 18 HYDROFORM FENDER RAILS

1 - HYDROFORM FENDER RAIL

2 - FRONT END SHEET METAL BRACKET

3 - UPPER RADIATOR CROSSMEMBER BOLTS (4)4 - UPPER RADIATOR CROSSMEMBER

5 - LOWER RADIATOR CROSSMEMBER BOLTS (8)

6 - LOWER RADIATOR CROSSMEMBER

DRFRAMES & BUMPERS 13 - 11

FRAME (Continued)

Page 1555 of 2627

(14) Remove the bolts attaching the lower radiator

crossmember to the hydroform fender rail. (Fig. 18)

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. The

inaccurate and high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.

(15) Using a reciprocating saw or equivalent, cut

the fender rail and shotgun at a straight and square

section of the hydroform and remove.

(16) Smooth and square the cut edges.

(17) Using the damaged structure as a reference

cut the service part at the same location as the first

cut. Smooth and square the cut edges.

NOTE: The repair structure should butt up to the

remaining structure and provide the same overall

vehicle geometry.

(18) Fabricate 51 mm (2.0 in.) long repair inserts

using scrap from the old structure or the replacement

part. It will be necessary to split the inserts on each

of their four sides to fit into the hydroform.

(19) Remove any paint or e-coat from the inserts

and also to the interior and exterior of the hydro-

forms.

(20) Cut plug weld holes as described below.

²On the upper rail, cut one 13 mm (0.5 in.) hole

on each side of the rail, 25 mm (1.0 in.) from the butt

joint of the tubes.

²On the lower rail, cut one 13 mm (0.5 in.) hole

on the top and bottom sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

²On the lower rail, cut two 13 mm (0.5 in.) holes

on the inner and outer sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(21) Install the insert 1º into the replacement part

and tack into place with a weld. (Refer to 13 -

FRAME & BUMPERS/FRAME - SPECIFICATIONS -

WELDING)

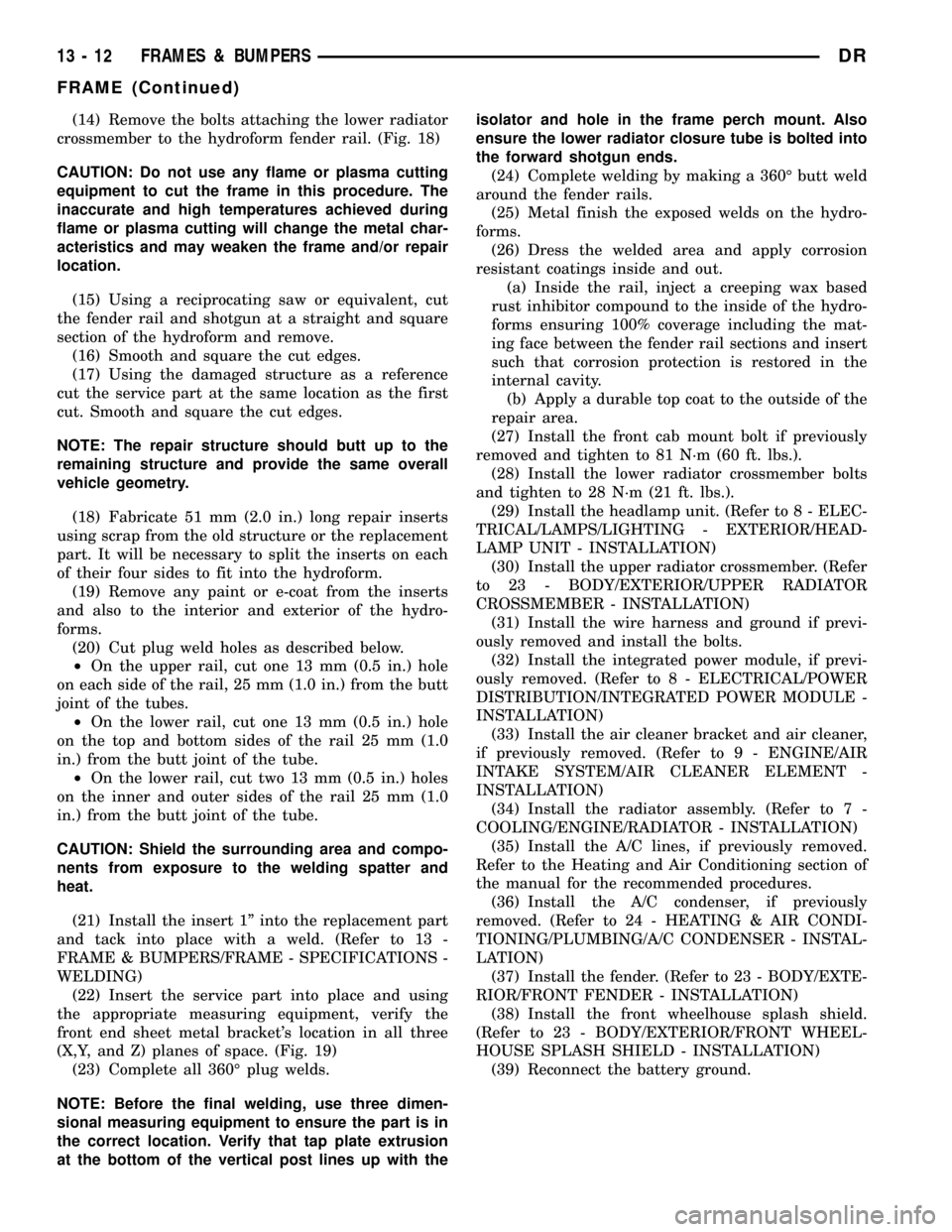

(22) Insert the service part into place and using

the appropriate measuring equipment, verify the

front end sheet metal bracket's location in all three

(X,Y, and Z) planes of space. (Fig. 19)

(23) Complete all 360É plug welds.

NOTE: Before the final welding, use three dimen-

sional measuring equipment to ensure the part is in

the correct location. Verify that tap plate extrusion

at the bottom of the vertical post lines up with theisolator and hole in the frame perch mount. Also

ensure the lower radiator closure tube is bolted into

the forward shotgun ends.

(24) Complete welding by making a 360É butt weld

around the fender rails.

(25) Metal finish the exposed welds on the hydro-

forms.

(26) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Inside the rail, inject a creeping wax based

rust inhibitor compound to the inside of the hydro-

forms ensuring 100% coverage including the mat-

ing face between the fender rail sections and insert

such that corrosion protection is restored in the

internal cavity.

(b) Apply a durable top coat to the outside of the

repair area.

(27) Install the front cab mount bolt if previously

removed and tighten to 81 N´m (60 ft. lbs.).

(28) Install the lower radiator crossmember bolts

and tighten to 28 N´m (21 ft. lbs.).

(29) Install the headlamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(30) Install the upper radiator crossmember. (Refer

to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - INSTALLATION)

(31) Install the wire harness and ground if previ-

ously removed and install the bolts.

(32) Install the integrated power module, if previ-

ously removed. (Refer to 8 - ELECTRICAL/POWER

DISTRIBUTION/INTEGRATED POWER MODULE -

INSTALLATION)

(33) Install the air cleaner bracket and air cleaner,

if previously removed. (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER ELEMENT -

INSTALLATION)

(34) Install the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION)

(35) Install the A/C lines, if previously removed.

Refer to the Heating and Air Conditioning section of

the manual for the recommended procedures.

(36) Install the A/C condenser, if previously

removed. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C CONDENSER - INSTAL-

LATION)

(37) Install the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - INSTALLATION)

(38) Install the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION)

(39) Reconnect the battery ground.

13 - 12 FRAMES & BUMPERSDR

FRAME (Continued)