Camshaft DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1429 of 2627

(15) Remove timing chain(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(16) Remove camshaft tensioner/thrust plate

assembly.

NOTE: Identify tappets to ensure installation in orig-

inal location.

(17) Remove the retainer assembly and tappets.

(18) Install a long bolt into front of camshaft to aid

in removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSPECTION

(1) The cam bearings are not serviceable. Do not

attempt to replace cam bearings for any reason.

INSTALLATION

INSTALLATION - CAMSHAFT CORE HOLE PLUG

CAUTION: The new core hole plug must be installed

to the proper depth or camshaft damage could

develope. The plug must be installed squarely in

the bore.

(1) Install a new core hole plug at the rear of cam-

shaft, using special tool # 9048. Clean plug and apply

mopartlock and seal adhesive to the edge of the

plug, before installing. The plug must be installed to

a depth of+/-0.25mm from the end of the machined

bevel, that is the end of the bevel that is closest to

the cam bearing.

INSTALLATION - CAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft

(2) Install camshaft Tensioner plate assembly.

Tighten bolts to 28 N´m (250 in. lbs.) torque.

(3) Install timing chain and sprockets(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION) .

(4) Measure camshaft end play(Refer to 9 -

ENGINE - SPECIFICATIONS). If not within limits

install a new thrust plate.

(5) Install the oil pump(Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(6) Install the oil pick up tube.

(7) Each tappet reused must be installed in the

same position from which it was removed.When

camshaft is replaced, all of the tappets must be

replaced.(8) Install the tappets and retainer assembly(Refer

to 9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - INSTALLATION).

(9) Install both left and right cylinder heads(Refer

to 9 - ENGINE/CYLINDER HEAD - INSTALLA-

TION) .

(10) Install pushrods

(11) Install rocker arms(Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

(12) Install timing case cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(13) Install the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(14) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(15) Install intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

(16) Install the A/C compressor, and set aside

(17) Install the generator.

(18) Install the accessory drive belt.

(19) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(20) Install the air cleaner assembly.

(21) Install the battery negative cable.

(22) Refill coolant.

(23) Refill engine oil.

(24) Start engine and check for leaks.

CRANKSHAFT

REMOVAL

(1) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(2) Remove the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the oil pump pickup.

(4) Remove the windage tray/oil pan gasket.

(5) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(6) Remove the oil pump(Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - REMOVAL).

(7) Remove the timing drive(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(8) Identify rod bearing caps before removal.

Remove rod bearing caps with bearings.

(9) Identify main bearing caps before removal.

Remove main bearing caps and bearings one at a

time.

9 - 206 ENGINE - 5.7LDR

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1432 of 2627

CRANKSHAFT OIL SEAL -

REAR

DIAGNOSIS AND TESTING - REAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs, oil galley pipe plugs, oil filter runoff,

and main bearing cap to cylinder block mating sur-

faces. See Engine, for proper repair procedures of

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

REMOVAL

NOTE: This procedure can be performed in vehicle.

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506, remove the crankshaft

rear oil seal.

INSTALLATION

CAUTION: The rear seal must be installed dry for

proper operation. Do not lubricate the seal lip or

outer edge.

(1) Position the plastic seal guide onto the crank-

shaft rear face. Then position the crankshaft rear oil

seal onto the guide.

(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle, with a

hammer, tap the seal into place. Continue to tap on

the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) Install the transmission.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the transmission.

(3) Remove the drive plate / flywheel.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Remove the rear oil seal retainer mounting

bolts.

(6) Carefully remove the retainer from the engine

block.

DRENGINE - 5.7L 9 - 209

Page 1434 of 2627

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the air cleaner(Refer to 9 - ENGINE/

AIR INTAKE SYSTEM - REMOVAL).

(3) Remove intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(4) Remove cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(5) Remove rocker arm assembly and push rod-

s(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL). Identify

push rods to ensure installation in original location.

(6) Remove the cylinder head(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(7) Remove bolt from tappet guide holder.

(8) Remove tappet guide holder.

(9) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed and reused, identify

tappets to ensure installation in original location.

(10) Check camshaft lobes for abnormal wear.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets in their original positions.

(3)

Install tappet guide holder. Install the tappet

guide holder bolt and tighten to 12 N´m (106 in. lbs.)

torque.

(4) Install cylinder head(Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(5) Install pushrods and rocker arm assembly(Re-

fer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - INSTALLATION).

(6) Install cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(7)

Install intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLATION).

(8) Install the air cleaner(Refer to 9 - ENGINE/

AIR INTAKE SYSTEM - INSTALLATION).

(9) Connect the negative cable to the battery.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

(10) Road test vehicle and check for leaks.

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

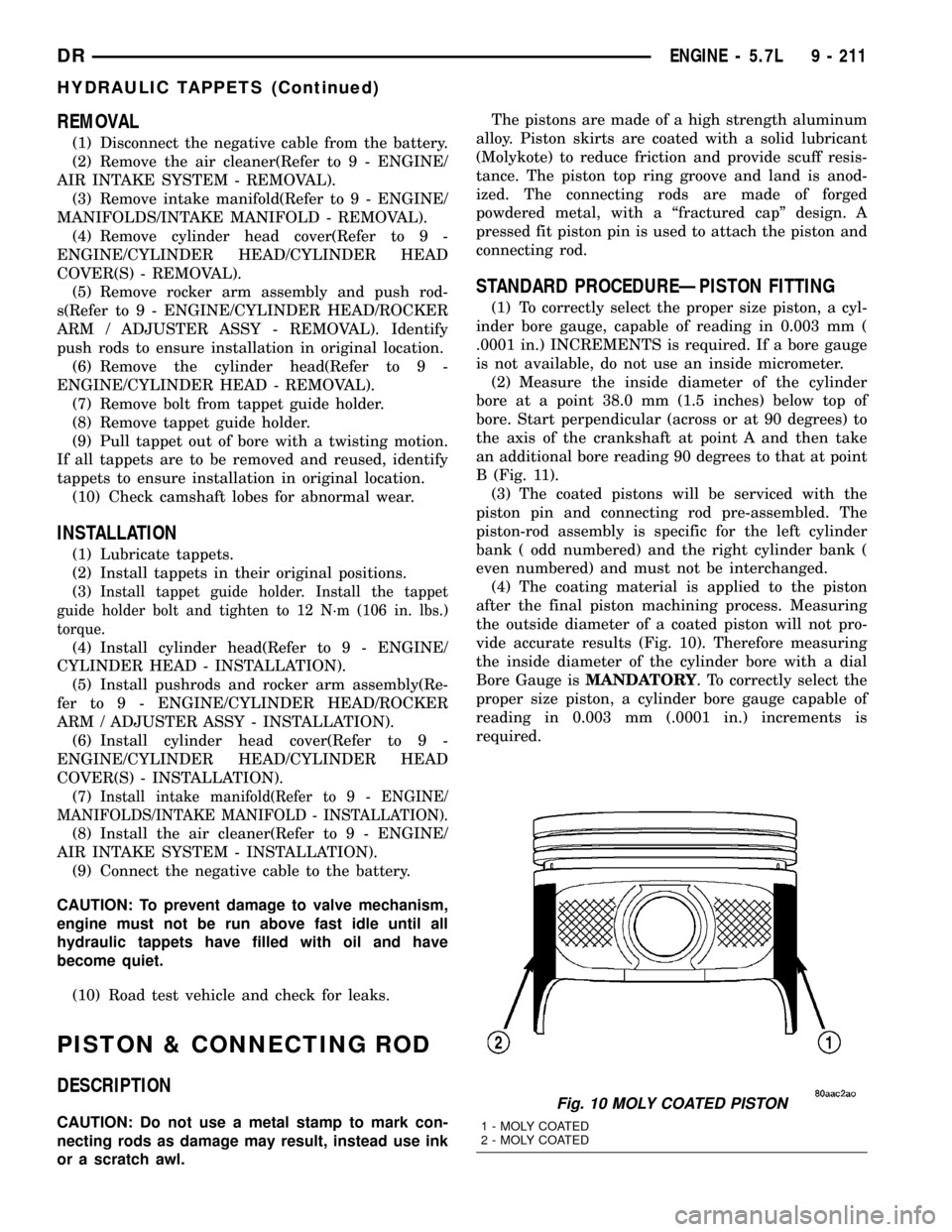

or a scratch awl.The pistons are made of a high strength aluminum

alloy. Piston skirts are coated with a solid lubricant

(Molykote) to reduce friction and provide scuff resis-

tance. The piston top ring groove and land is anod-

ized. The connecting rods are made of forged

powdered metal, with a ªfractured capº design. A

pressed fit piston pin is used to attach the piston and

connecting rod.

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 11).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled. The

piston-rod assembly is specific for the left cylinder

bank ( odd numbered) and the right cylinder bank (

even numbered) and must not be interchanged.

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 10). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

Fig. 10 MOLY COATED PISTON

1 - MOLY COATED

2 - MOLY COATED

DRENGINE - 5.7L 9 - 211

HYDRAULIC TAPPETS (Continued)

Page 1445 of 2627

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 in the 5.7L engines.

These are specified with a dual SAE viscosity grade

which indicates the cold-to-hot temperature viscosity

range. Select an engine oil that is best suited to your

particular temperature range and variation.

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 28).

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the left

hand of the engine on the 5.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about ten

Fig. 28 API SYMBOL

9 - 222 ENGINE - 5.7LDR

LUBRICATION (Continued)

Page 1451 of 2627

TIMING/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect battery negative cable.

(2) Drain cooling system.

(3) Remove Timing Chain Cover.

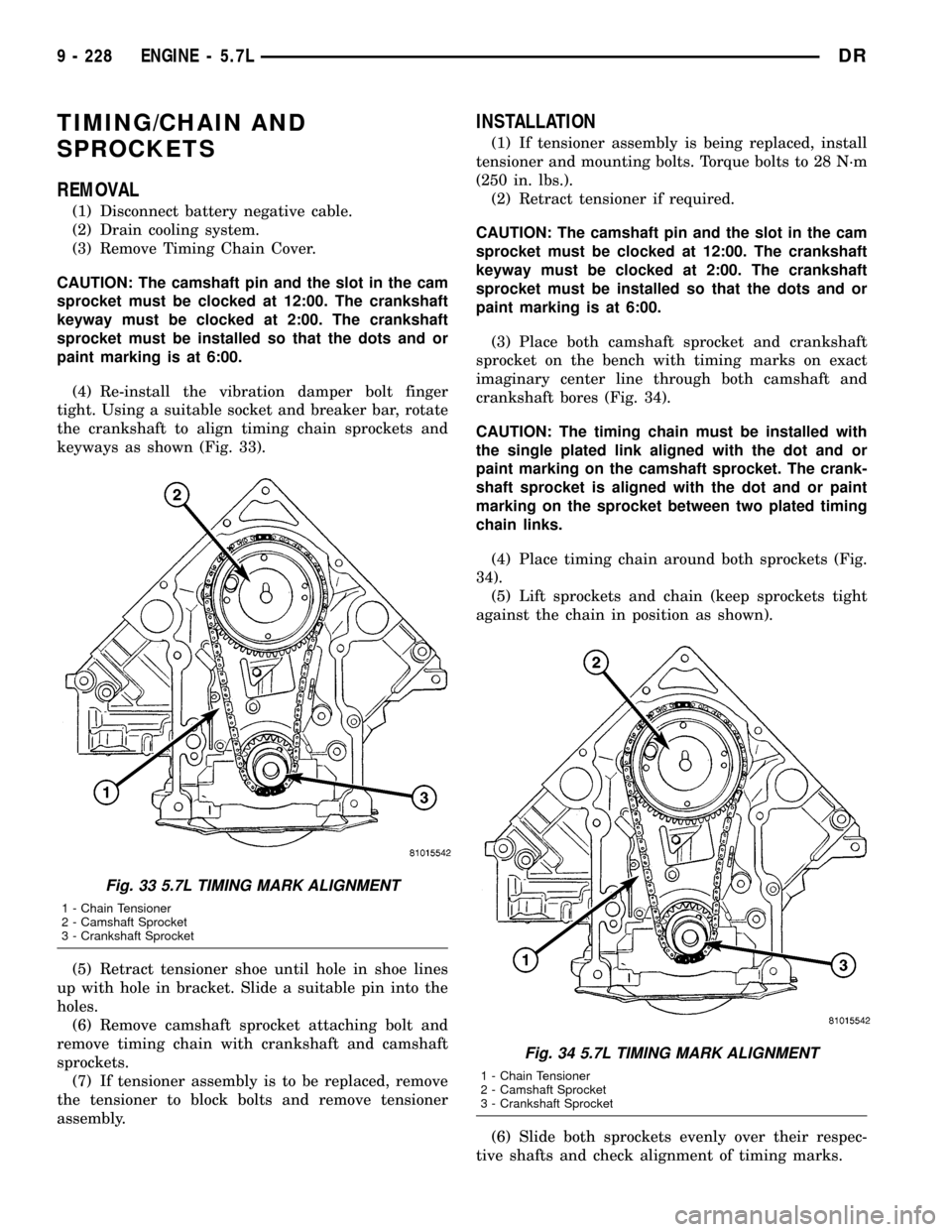

CAUTION: The camshaft pin and the slot in the cam

sprocket must be clocked at 12:00. The crankshaft

keyway must be clocked at 2:00. The crankshaft

sprocket must be installed so that the dots and or

paint marking is at 6:00.

(4) Re-install the vibration damper bolt finger

tight. Using a suitable socket and breaker bar, rotate

the crankshaft to align timing chain sprockets and

keyways as shown (Fig. 33).

(5) Retract tensioner shoe until hole in shoe lines

up with hole in bracket. Slide a suitable pin into the

holes.

(6) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

(7) If tensioner assembly is to be replaced, remove

the tensioner to block bolts and remove tensioner

assembly.

INSTALLATION

(1) If tensioner assembly is being replaced, install

tensioner and mounting bolts. Torque bolts to 28 N´m

(250 in. lbs.).

(2) Retract tensioner if required.

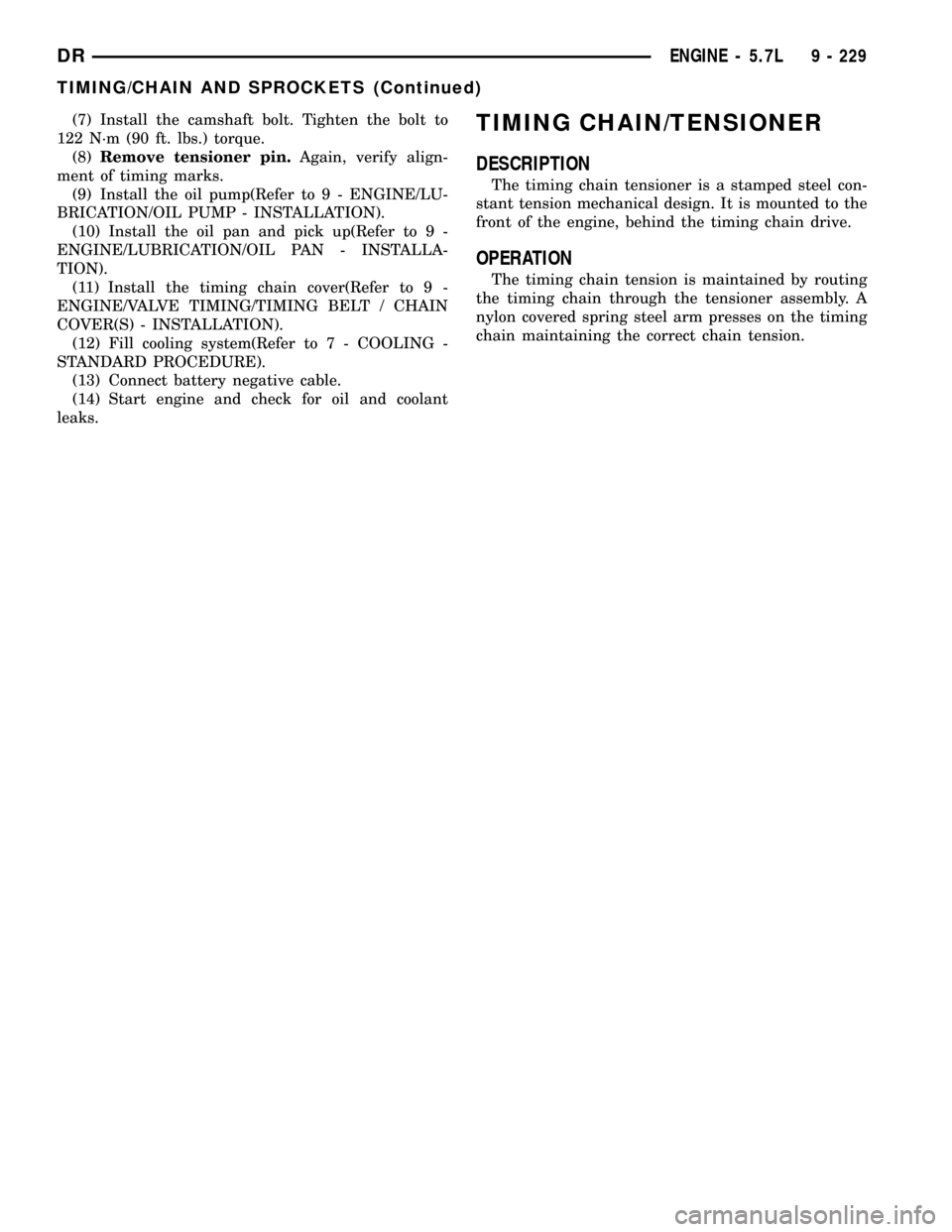

CAUTION: The camshaft pin and the slot in the cam

sprocket must be clocked at 12:00. The crankshaft

keyway must be clocked at 2:00. The crankshaft

sprocket must be installed so that the dots and or

paint marking is at 6:00.

(3) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores (Fig. 34).

CAUTION: The timing chain must be installed with

the single plated link aligned with the dot and or

paint marking on the camshaft sprocket. The crank-

shaft sprocket is aligned with the dot and or paint

marking on the sprocket between two plated timing

chain links.

(4) Place timing chain around both sprockets (Fig.

34).

(5) Lift sprockets and chain (keep sprockets tight

against the chain in position as shown).

(6) Slide both sprockets evenly over their respec-

tive shafts and check alignment of timing marks.

Fig. 33 5.7L TIMING MARK ALIGNMENT

1 - Chain Tensioner

2 - Camshaft Sprocket

3 - Crankshaft Sprocket

Fig. 34 5.7L TIMING MARK ALIGNMENT

1 - Chain Tensioner

2 - Camshaft Sprocket

3 - Crankshaft Sprocket

9 - 228 ENGINE - 5.7LDR

Page 1452 of 2627

(7) Install the camshaft bolt. Tighten the bolt to

122 N´m (90 ft. lbs.) torque.

(8)Remove tensioner pin.Again, verify align-

ment of timing marks.

(9) Install the oil pump(Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(10) Install the oil pan and pick up(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(11) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(12) Fill cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery negative cable.

(14) Start engine and check for oil and coolant

leaks.TIMING CHAIN/TENSIONER

DESCRIPTION

The timing chain tensioner is a stamped steel con-

stant tension mechanical design. It is mounted to the

front of the engine, behind the timing chain drive.

OPERATION

The timing chain tension is maintained by routing

the timing chain through the tensioner assembly. A

nylon covered spring steel arm presses on the timing

chain maintaining the correct chain tension.

DRENGINE - 5.7L 9 - 229

TIMING/CHAIN AND SPROCKETS (Continued)

Page 1453 of 2627

ENGINE 5.9L DIESEL

TABLE OF CONTENTS

page page

ENGINE 5.9L DIESEL

DESCRIPTION........................232

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE

DIAGNOSIS - MECHANICAL............233

DIAGNOSIS AND TESTINGÐSMOKE

DIAGNOSIS CHARTS.................236

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS.......239

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS........239

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS........240

STANDARD PROCEDUREÐHYDROSTATIC

LOCK..............................240

REMOVAL

REMOVAL - ENGINE..................241

REMOVALÐCRANKCASE BREATHER....242

INSTALLATION

INSTALLATION - ENGINE..............242

INSTALLATIONÐCRANKCASE BREATHER . 243

SPECIFICATIONS

SPECIFICATIONS - 5.9L DIESEL.........244

TORQUE...........................245

SPECIAL TOOLS

5.9L DIESEL ENGINE.................246

ENGINE DATA PLATE

DESCRIPTION........................248

AIR CLEANER ELEMENT

REMOVAL............................248

INSTALLATION........................249

CYLINDER HEAD

DESCRIPTION........................249

REMOVAL............................249

CLEANING

CLEANINGÐCYLINDER HEAD..........251

CLEANINGÐCROSSHEADS............251

CLEANINGÐPUSHRODS..............252

INSPECTION

INSPECTION - CYLINDER HEAD.........252

INSPECTIONÐCROSSHEADS..........252

INSPECTIONÐPUSHRODS.............253

INSTALLATION........................253

CYLINDER HEAD COVER(S)

REMOVAL

REMOVALÐCYLINDER HEAD COVER....255

REMOVALÐROCKER HOUSING.........255

CLEANING...........................255INSPECTION.........................255

INSTALLATION

INSTALLATIONÐCYLINDER HEAD COVER . 255

INSTALLATION - ROCKER HOUSING.....255

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION........................256

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVES,

GUIDES AND SPRINGS................256

STANDARD PROCEDURE - VALVE LASH

ADJUSTMENT AND VERIFICATION.......259

REMOVAL - VALVE SPRINGS AND SEALS . . . 260

INSTALLATION........................261

ROCKER ARM / ADJUSTER ASSY

DESCRIPTION........................261

REMOVAL............................261

CLEANING...........................262

INSPECTION.........................262

INSTALLATION........................263

ENGINE BLOCK

STANDARD PROCEDURE

STANDARD PROCEDURE - CYLINDER

BLOCK REFACING...................264

STANDARD PROCEDURE - CYLINDER

BORE - DE-GLAZE...................264

STANDARD PROCEDUREÐCYLINDER

BORE REPAIR.......................265

STANDARD PROCEDUREÐCAM BORE

REPAIR ............................267

INSPECTION.........................267

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

REMOVALÐCAMSHAFT BEARINGS......268

REMOVAL - CAMSHAFT...............268

INSPECTION.........................270

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS . . 271

INSTALLATION - CAMSHAFT............271

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE................272

CRANKSHAFT AND GEAR

DESCRIPTION........................273

REMOVAL - GEAR.....................273

INSTALLATION - GEAR..................273

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - MAIN BEARING

CLEARANCE........................274

9 - 230 ENGINE 5.9L DIESELDR

Page 1466 of 2627

(8) Replace injector o-ring and sealing washer on

injectors #5 and #6. Install injectors and torque using

the following steps:

²Step 1ÐInstall injector hold-down capscrews

and torque to 5 N´m (44 in. lbs.) torque.

²Step 2ÐLoosen injector hold-down capscrews.

²Step 3ÐInstall HPC connector tube and nut.

Torque nut to 15 N´m (11 ft. lbs.) torque.

²Step 4ÐTorque injector hold-down capscrews to

10 N´m (89 in. lbs.) torque.

²Step 5ÐTorque HPC connector tube nut to 50

N´m (37 ft. lbs.) torque.

(9) Install #5 and #6 high pressure fuel lines. Fol-

low correct torque sequence per section 14. Torque

fuel line fittings to 30 N-m (22 ft-lb). Torque brace

capscrew to 24 N-m (18 ft-lb).

(10) Install rear engine lift bracket. Torque to 77

N-m (57 ft-lb).

(11) Install push tubes, rocker arms, and pedestals

for cylinders #4, #5, and #6. Torque the mounting

bolts to 36 N-m (27 ft-lbs).

(12) Reset valve lash on cylinders #4, #5, and #6.

Torque adjusting nuts to 24 N-m (18 ft-lbs).

(13) Install cylinder head cover. Torque to 24 N-m

(18 ft-lbs).(Refer to 9 - ENGINE/CYLINDER HEAD -

INSTALLATION).

(14) Connect breather tube and lube oil drain tube

to breather housing cover. Install breather housing.

Torque capscrews to 24 N-m (18 ft-lbs)

(15) Connect fuel supply and return hoses.

(16) Connect ECM ground to hydroform screw.

Connect ECM power connector.

(17) Install the APPS cable(s) to the APPS. Install

the throttle linkage cover.

(18) Install the power steering pump.

(19) Install the damper and speed indicator ring.

Torque to 40 N-m (30 ft-lb) plus 60 degrees.

(20) Connect the engine block heater connection.

(21) Connect the A/C compressor and pressure sen-

sor connectors

(22) Install the charge air cooler and a/c condenser

(if equipped). Install and tighten the charge air

cooler mounting bolts to 2 N-m (17 in-lbs).

(23) Connect the charge air cooler piping. Torque

all clamps to 8 N-m (72 in-lbs).

(24) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(25) Install the radiator upper support panel.

(26) Install radiator.

(27) Connect the transmission quick-connect oil

cooler lines.(28) Raise vehicle.

(29) Connect a/c compressor suction/discharge hose

(if equipped).

(30) Install the radiator lower hose and clamps.

(31) Install the battery negative cables to the

engine block on the driver and passenger side.

(32) Install the transmission adapter with a new

camshaft rectangular ring seal. Torque to 77 N-m (57

ft-lb).

(33) Install the flywheel/flexplate. Torque to 137

N-m (101 ft-lb).

(34) Install the starter motor. Torque to 43 N-m

(32 ft-lb). (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(35) Connect engine to vehicle harness connectors.

(36) Install transmission and transfer case (if

equipped).

(37) Connect the exhaust pipe to the turbocharger

elbow.

(38) Connect the transmission auxiliary oil cooler

lines (if equipped).

(39) Lower the vehicle.

(40) Connect the heater core supply and return

hoses.

(41) Install the cooling fan and upper fan shroud

at the same time. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION).

(42) Install the coolant recovery bottle.

(43) Install the windshield washer bottle.

(44) Install the upper radiator hose and clamps.

(45) Raise vehicle.

(46) Connect electronically controlled fan drive

wire harness. Install lower radiator fan shroud.

(47) Change oil filter and install new engine oil.

(48) Fill the cooling system with coolant. (Refer to

7 - COOLING - STANDARD PROCEDURE).

(49) Connect grid heater harness at grid heater

relays.

(50) Connect electrical connections to rear of alter-

nator.

(51) Start the engine and inspect for engine oil,

coolant, and fuel leaks.

INSTALLATIONÐCRANKCASE BREATHER

(1) Install a new o-ring onto the breather element.

(2) Lubricate o-ring and install into cylinder head

cover. Torque capscrews to 10 N´m (89 in. lbs.).

(3) Connect breather tube and lube oil drain tube.

(4) Install breather cover (Fig. 4). Torque to 24

N´m (18 ft. lbs.)

(5) Install oil fill cap.

DRENGINE 5.9L DIESEL 9 - 243

ENGINE 5.9L DIESEL (Continued)

Page 1467 of 2627

SPECIFICATIONS

SPECIFICATIONS - 5.9L DIESEL

GENERAL DESCRIPTION

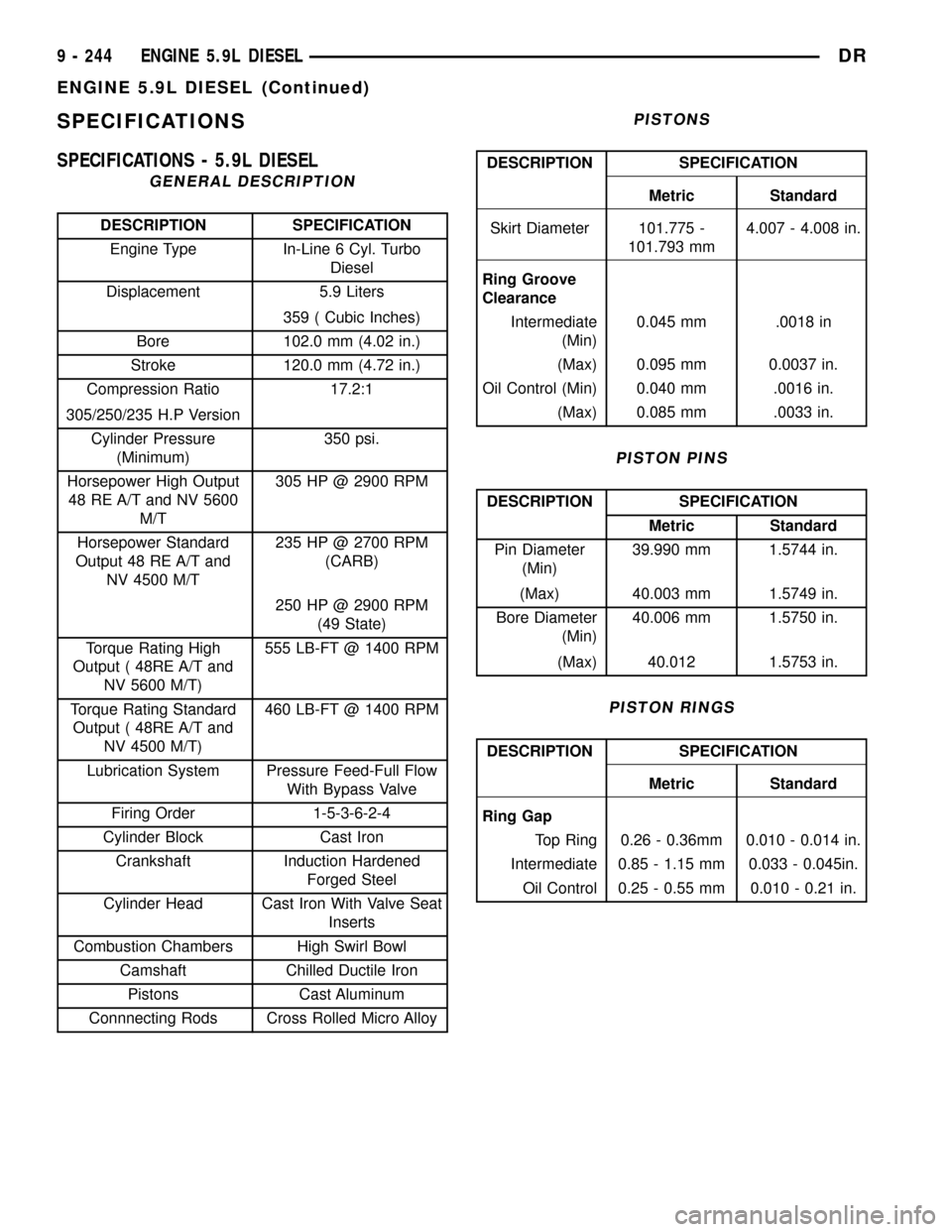

DESCRIPTION SPECIFICATION

Engine Type In-Line 6 Cyl. Turbo

Diesel

Displacement 5.9 Liters

359 ( Cubic Inches)

Bore 102.0 mm (4.02 in.)

Stroke 120.0 mm (4.72 in.)

Compression Ratio 17.2:1

305/250/235 H.P Version

Cylinder Pressure

(Minimum)350 psi.

Horsepower High Output

48 RE A/T and NV 5600

M/T305 HP @ 2900 RPM

Horsepower Standard

Output 48 RE A/T and

NV 4500 M/T235 HP @ 2700 RPM

(CARB)

250 HP @ 2900 RPM

(49 State)

Torque Rating High

Output ( 48RE A/T and

NV 5600 M/T)555 LB-FT @ 1400 RPM

Torque Rating Standard

Output ( 48RE A/T and

NV 4500 M/T)460 LB-FT @ 1400 RPM

Lubrication System Pressure Feed-Full Flow

With Bypass Valve

Firing Order 1-5-3-6-2-4

Cylinder Block Cast Iron

Crankshaft Induction Hardened

Forged Steel

Cylinder Head Cast Iron With Valve Seat

Inserts

Combustion Chambers High Swirl Bowl

Camshaft Chilled Ductile Iron

Pistons Cast Aluminum

Connnecting Rods Cross Rolled Micro Alloy

PISTONS

DESCRIPTION SPECIFICATION

Metric Standard

Skirt Diameter 101.775 -

101.793 mm4.007 - 4.008 in.

Ring Groove

Clearance

Intermediate

(Min)0.045 mm .0018 in

(Max) 0.095 mm 0.0037 in.

Oil Control (Min) 0.040 mm .0016 in.

(Max) 0.085 mm .0033 in.

PISTON PINS

DESCRIPTION SPECIFICATION

Metric Standard

Pin Diameter

(Min)39.990 mm 1.5744 in.

(Max) 40.003 mm 1.5749 in.

Bore Diameter

(Min)40.006 mm 1.5750 in.

(Max) 40.012 1.5753 in.

PISTON RINGS

DESCRIPTION SPECIFICATION

Metric Standard

Ring Gap

Top Ring 0.26 - 0.36mm 0.010 - 0.014 in.

Intermediate 0.85 - 1.15 mm 0.033 - 0.045in.

Oil Control 0.25 - 0.55 mm 0.010 - 0.21 in.

9 - 244 ENGINE 5.9L DIESELDR

ENGINE 5.9L DIESEL (Continued)

Page 1490 of 2627

After removing the boring bar, use a honing stone

to chamfer the corner of the repair sleeve(s).

SLEEVE MACHINING DIMENSIONS CHART

ITEM MEASUREMENT

SLEEVE PROTRUSION MIN. - FLUSH WITH

BLOCK

MAX. - 0.050 mm

(0.0019 in.)

SLEEVE DIAMETER 101.956 mm (4.014 in.)

SLEEVE CHAMFER APPROX. 1.25 mm

(0.049 in.) by 15É

A correctly honed surface will have a crosshatch

appearance with the lines at 15É to 25É angles with

the top of the cylinder block. For the rough hone, use

80 grit honing stones. To finish hone, use 280 grit

honing stones.

Finished bore inside dimension is 102.020 0.020

mm (4.0165 0.0008 inch).

A maximum of 1.2 micrometer (48 microinch) sur-

face finish must be obtained.

After finish honing is complete, immediately clean

the cylinder bores with a strong solution of laundry

detergent and hot water.

After rinsing, blow the block dry with compressed

air.

Wipe the bore with a white, lint-free, lightly oiled

cloth. Make sure there is no grit residue present.

Apply a rust-preventing compound if the block will

not be used immediately.

A standard diameter piston and a piston ring set

must be used with a sleeved cylinder bore.

STANDARD PROCEDUREÐCAM BORE REPAIR

For standard bushings, not oversized, maximum

front and rear cam bushing bore diameter is 59.248

mm. (2.3326 in.). DO NOT bore the intermediate cam

bore to the front cam bore oversize dimensions. Max-

imum front and rear camshaft bushing installed

diameter is 54.147 mm. (2.1318 in.). Minimum

installed diameter is 54.083 mm. (2.1293 in.). Maxi-

mum intermediate camshaft bore diameter is 54.164

mm. (2.1324 in.).

A surface finish of 2.3 micrometers (92 microinch)

must be maintained. Not more than 20% of an area

of any one bore may be 3.2 micrometers (126 micro-

inch).

Camshaft bores can be repaired individually. It is

not necessary to repair undamaged cam bores in

order to repair individually damaged cam bores. The

standard front bushing cannot be used to repair

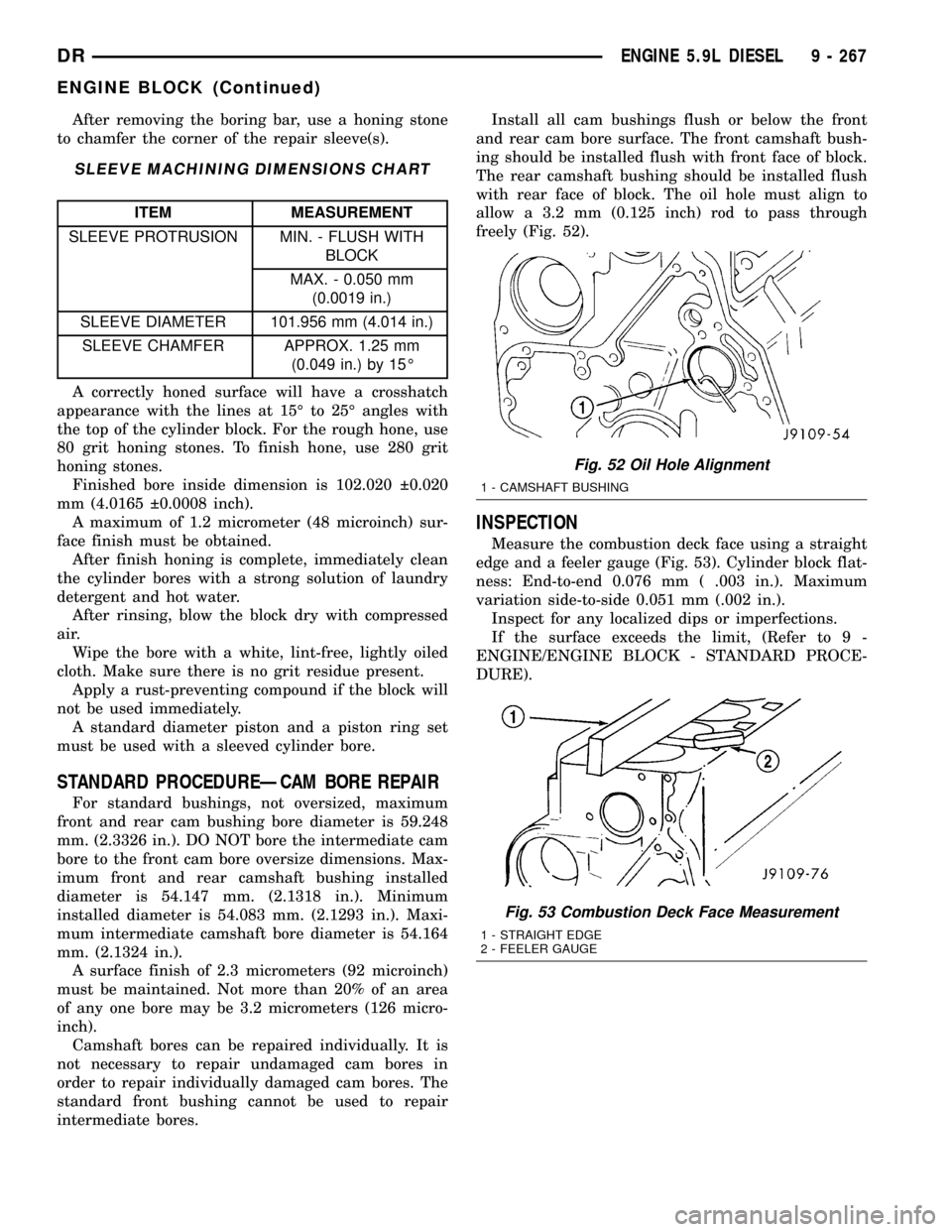

intermediate bores.Install all cam bushings flush or below the front

and rear cam bore surface. The front camshaft bush-

ing should be installed flush with front face of block.

The rear camshaft bushing should be installed flush

with rear face of block. The oil hole must align to

allow a 3.2 mm (0.125 inch) rod to pass through

freely (Fig. 52).

INSPECTION

Measure the combustion deck face using a straight

edge and a feeler gauge (Fig. 53). Cylinder block flat-

ness: End-to-end 0.076 mm ( .003 in.). Maximum

variation side-to-side 0.051 mm (.002 in.).

Inspect for any localized dips or imperfections.

If the surface exceeds the limit, (Refer to 9 -

ENGINE/ENGINE BLOCK - STANDARD PROCE-

DURE).

Fig. 52 Oil Hole Alignment

1 - CAMSHAFT BUSHING

Fig. 53 Combustion Deck Face Measurement

1 - STRAIGHT EDGE

2 - FEELER GAUGE

DRENGINE 5.9L DIESEL 9 - 267

ENGINE BLOCK (Continued)