Engine torque spec DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1430 of 2627

(10) Remove the thrust washers.

(11) Remove the rear oil seal retainer(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT REAR

OIL SEAL RETAINE - REMOVAL).

(12) Remove the crankshaft out of the block.

(13) Remove and discard the crankshaft rear oil

seal.

(14) Remove and discard the front crankshaft oil

seal.

INSTALLATION

(1) Select the proper main bearings(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) .

(2) Install main bearings in block and caps, and

lubricate bearings.

(3) Position the crankshaft into the cylinder block.

(4) Install the thrust washers.

NOTE: The main cap crossbolts are torqued after

final torque of the main cap bolts. Always use a

new washer/seal on crossbolts.

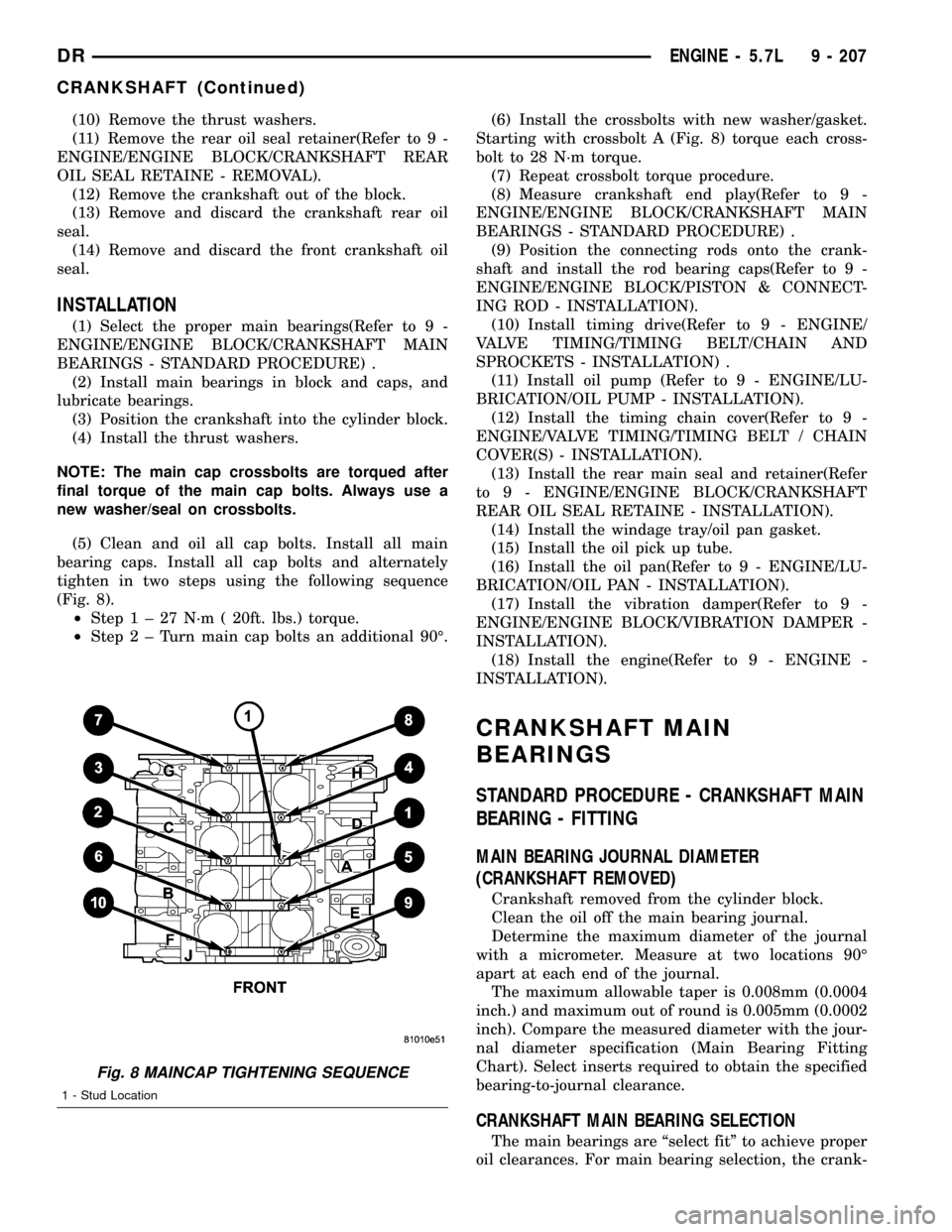

(5) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten in two steps using the following sequence

(Fig. 8).

²Step1±27N´m(20ft. lbs.) torque.

²Step2±Turnmain cap bolts an additional 90É.(6) Install the crossbolts with new washer/gasket.

Starting with crossbolt A (Fig. 8) torque each cross-

bolt to 28 N´m torque.

(7) Repeat crossbolt torque procedure.

(8) Measure crankshaft end play(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) .

(9) Position the connecting rods onto the crank-

shaft and install the rod bearing caps(Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - INSTALLATION).

(10) Install timing drive(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(11) Install oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(12) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(13) Install the rear main seal and retainer(Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

REAR OIL SEAL RETAINE - INSTALLATION).

(14) Install the windage tray/oil pan gasket.

(15) Install the oil pick up tube.

(16) Install the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(17) Install the vibration damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(18) Install the engine(Refer to 9 - ENGINE -

INSTALLATION).

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - CRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.0002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

Fig. 8 MAINCAP TIGHTENING SEQUENCE

1 - Stud Location

DRENGINE - 5.7L 9 - 207

CRANKSHAFT (Continued)

Page 1432 of 2627

CRANKSHAFT OIL SEAL -

REAR

DIAGNOSIS AND TESTING - REAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs, oil galley pipe plugs, oil filter runoff,

and main bearing cap to cylinder block mating sur-

faces. See Engine, for proper repair procedures of

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

REMOVAL

NOTE: This procedure can be performed in vehicle.

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506, remove the crankshaft

rear oil seal.

INSTALLATION

CAUTION: The rear seal must be installed dry for

proper operation. Do not lubricate the seal lip or

outer edge.

(1) Position the plastic seal guide onto the crank-

shaft rear face. Then position the crankshaft rear oil

seal onto the guide.

(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle, with a

hammer, tap the seal into place. Continue to tap on

the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) Install the transmission.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the transmission.

(3) Remove the drive plate / flywheel.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Remove the rear oil seal retainer mounting

bolts.

(6) Carefully remove the retainer from the engine

block.

DRENGINE - 5.7L 9 - 209

Page 1434 of 2627

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the air cleaner(Refer to 9 - ENGINE/

AIR INTAKE SYSTEM - REMOVAL).

(3) Remove intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(4) Remove cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(5) Remove rocker arm assembly and push rod-

s(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL). Identify

push rods to ensure installation in original location.

(6) Remove the cylinder head(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(7) Remove bolt from tappet guide holder.

(8) Remove tappet guide holder.

(9) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed and reused, identify

tappets to ensure installation in original location.

(10) Check camshaft lobes for abnormal wear.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets in their original positions.

(3)

Install tappet guide holder. Install the tappet

guide holder bolt and tighten to 12 N´m (106 in. lbs.)

torque.

(4) Install cylinder head(Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(5) Install pushrods and rocker arm assembly(Re-

fer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - INSTALLATION).

(6) Install cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(7)

Install intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLATION).

(8) Install the air cleaner(Refer to 9 - ENGINE/

AIR INTAKE SYSTEM - INSTALLATION).

(9) Connect the negative cable to the battery.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

(10) Road test vehicle and check for leaks.

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.The pistons are made of a high strength aluminum

alloy. Piston skirts are coated with a solid lubricant

(Molykote) to reduce friction and provide scuff resis-

tance. The piston top ring groove and land is anod-

ized. The connecting rods are made of forged

powdered metal, with a ªfractured capº design. A

pressed fit piston pin is used to attach the piston and

connecting rod.

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 11).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled. The

piston-rod assembly is specific for the left cylinder

bank ( odd numbered) and the right cylinder bank (

even numbered) and must not be interchanged.

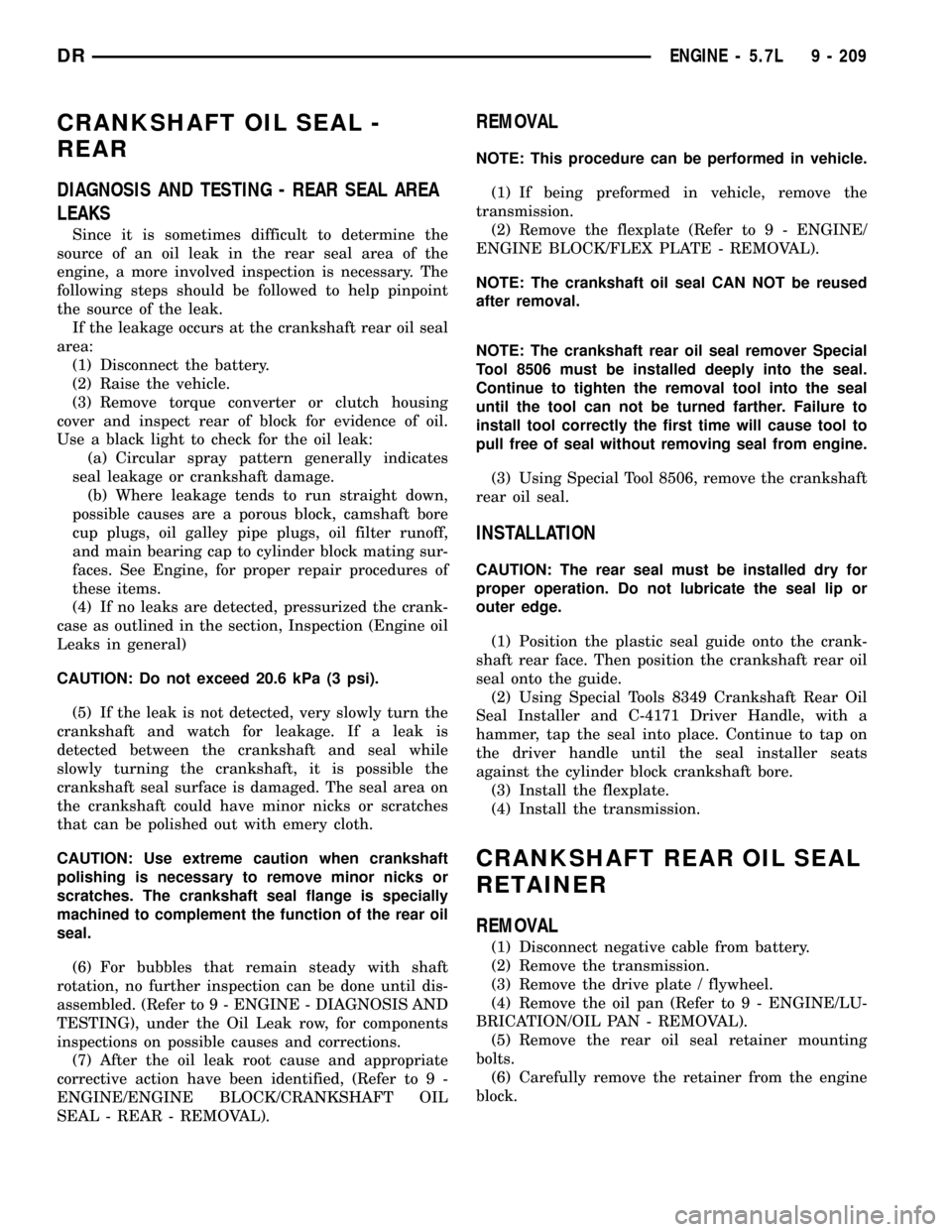

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 10). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

Fig. 10 MOLY COATED PISTON

1 - MOLY COATED

2 - MOLY COATED

DRENGINE - 5.7L 9 - 211

HYDRAULIC TAPPETS (Continued)

Page 1436 of 2627

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Before installing piston and connecting rod

assemblies into the bore, install the piston rings(Re-

fer to 9 - ENGINE/ENGINE BLOCK/PISTON RINGS

- STANDARD PROCEDURE).

(2) Immerse the piston head and rings in clean

engine oil. Position a ring compressor over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

(3) Position bearing onto connecting rod. Lubricate

bearing surface with clean engine oil.

(4) Install Special Tool 8507 Connecting Rod

Guides into connecting rod bolt threads.

(5) The pistons are marked on the piston pin bore

surface with an raised ªFº or arrow on top of piston

indicating installation position. This mark must be

pointing toward the front of engine on both cylinder

banks.

(6) Wipe cylinder bore clean and lubricate with

engine oil.

(7) Rotate crankshaft until connecting rod journal

is on the center of cylinder bore. Insert rod and pis-

ton into cylinder bore and carefully position connect-

ing rod guides over crankshaft journal.

(8) Tap piston down in cylinder bore using a ham-

mer handle. While at the same time, guide connect-

ing rod into position on rod journal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

(9) Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 21 N´m (15 ft. lbs.) plus a 90É turn.

(10) Install the following components:

²Cylinder head(s). (Refer to 9 - ENGINE/CYLIN-

DER HEAD - INSTALLATION).²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

²Install the intake manifold.

²Oil pan and gasket/windage tray. (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(11) Fill crankcase with proper engine oil to cor-

rect level.

(12) Connect negative cable to battery.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

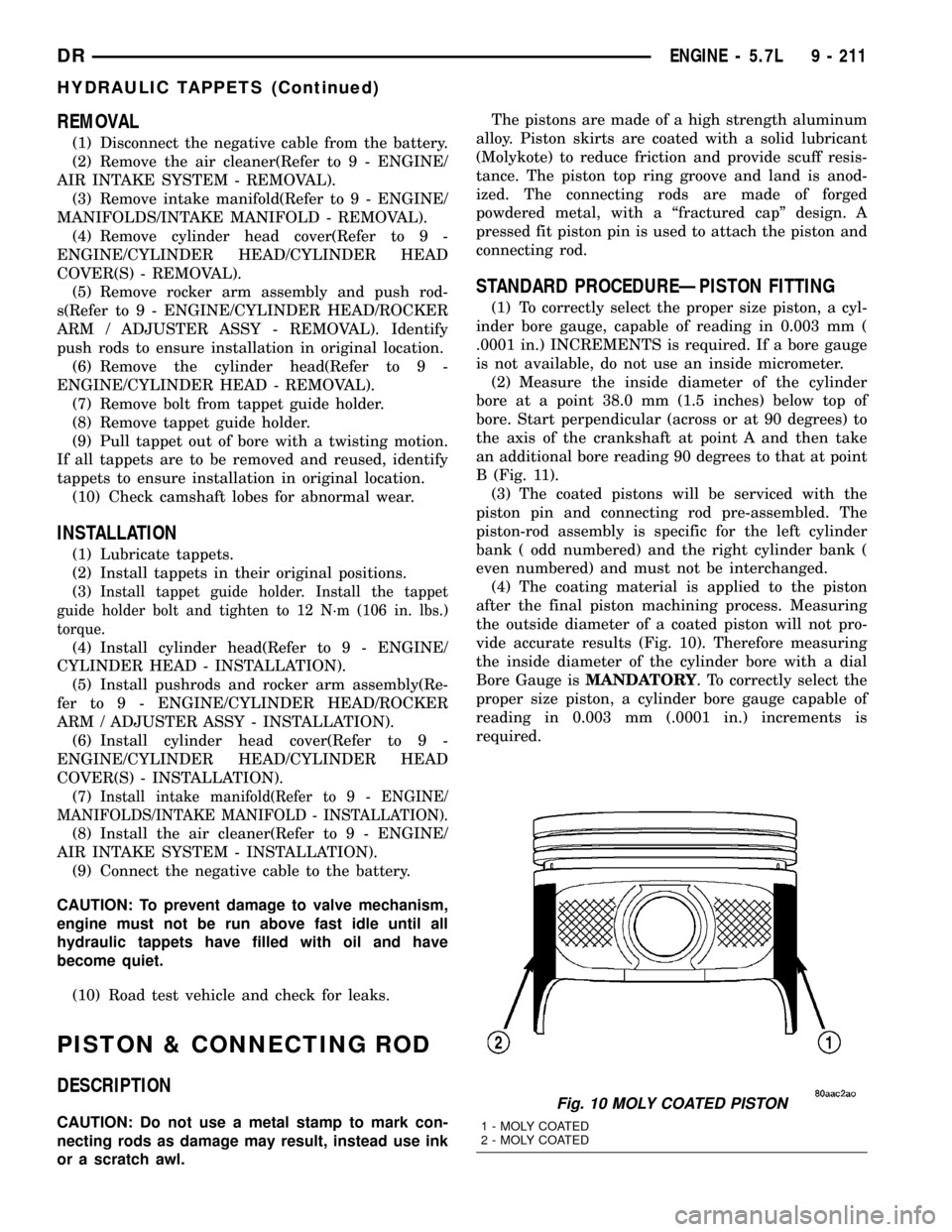

Before reinstalling used rings or installing new

rings, the ring clearances must be checked.

(1) Wipe the cylinder bore clean.

(2) Insert the ring in the cylinder bore.

NOTE: The ring gap measurement must be made

with the ring positioned at least 12mm (0.50 inch.)

from bottom of cylinder bore.

(3) Using a piston, to ensure that the ring is

squared in the cylinder bore, slide the ring downward

into the cylinder.

(4) Using a feeler gauge check the ring end gap

(Fig. 13). Replace any rings not within specification.

PISTON RING SIDE CLEARANCE

NOTE: Make sure the piston ring grooves are clean

and free of nicks and burrs.

Fig. 13 Ring

1 - FEELER GAUGE

DRENGINE - 5.7L 9 - 213

PISTON & CONNECTING ROD (Continued)

Page 1439 of 2627

(3) Using Special Tool 8512±A, press damper onto

crankshaft.

(4) Install then tighten crankshaft damper bolt to

176 N´m (129 ft. lbs.).

(5) Install fan blade assembly (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

INSTALLATION).

(6) Install radiator upper shroud and tighten fas-

teners to 11 N´m (95 in. lbs.).

(7) Install radiator upper hose.

(8) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(9) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(10) Connect negative cable to battery.

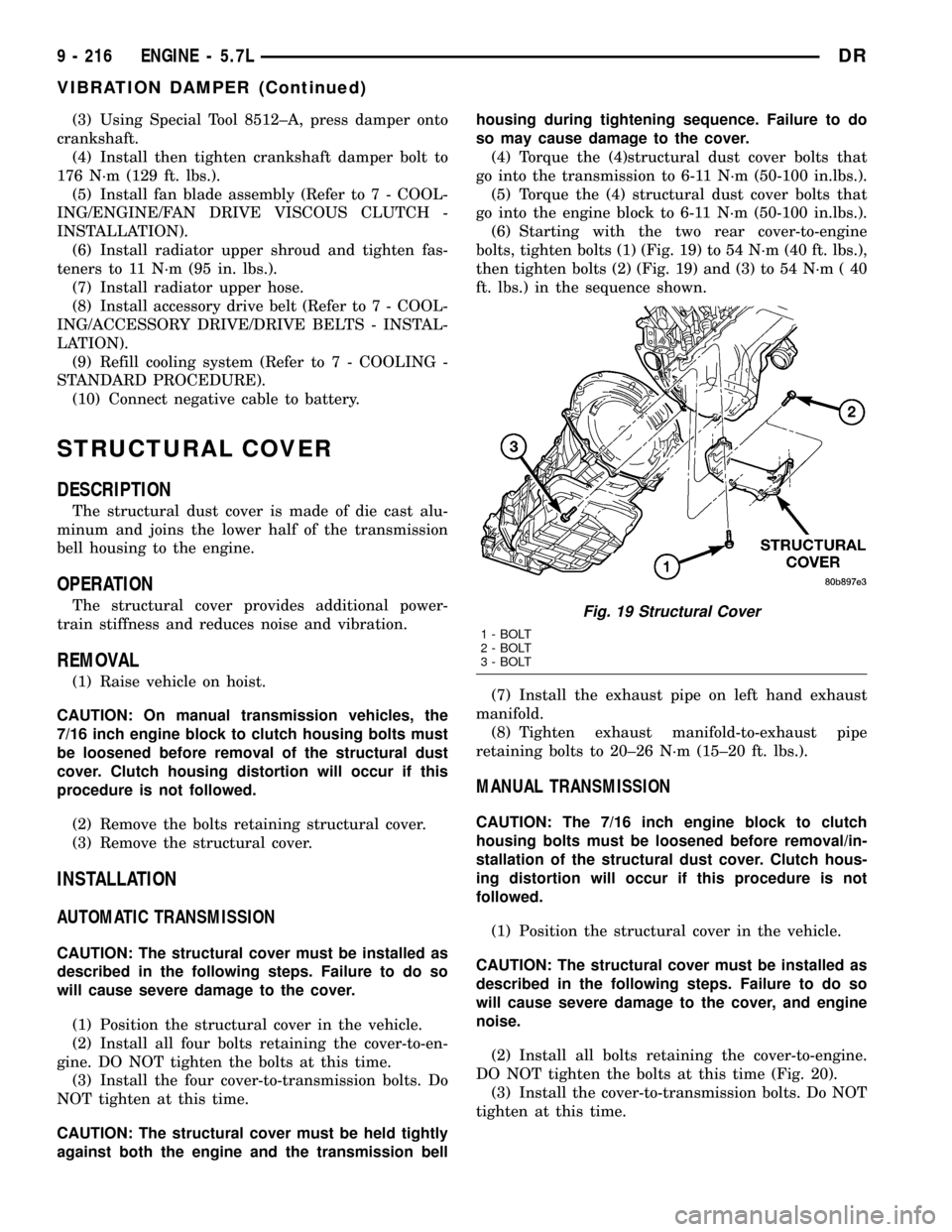

STRUCTURAL COVER

DESCRIPTION

The structural dust cover is made of die cast alu-

minum and joins the lower half of the transmission

bell housing to the engine.

OPERATION

The structural cover provides additional power-

train stiffness and reduces noise and vibration.

REMOVAL

(1) Raise vehicle on hoist.

CAUTION: On manual transmission vehicles, the

7/16 inch engine block to clutch housing bolts must

be loosened before removal of the structural dust

cover. Clutch housing distortion will occur if this

procedure is not followed.

(2) Remove the bolts retaining structural cover.

(3) Remove the structural cover.

INSTALLATION

AUTOMATIC TRANSMISSION

CAUTION: The structural cover must be installed as

described in the following steps. Failure to do so

will cause severe damage to the cover.

(1) Position the structural cover in the vehicle.

(2) Install all four bolts retaining the cover-to-en-

gine. DO NOT tighten the bolts at this time.

(3) Install the four cover-to-transmission bolts. Do

NOT tighten at this time.

CAUTION: The structural cover must be held tightly

against both the engine and the transmission bellhousing during tightening sequence. Failure to do

so may cause damage to the cover.

(4) Torque the (4)structural dust cover bolts that

go into the transmission to 6-11 N´m (50-100 in.lbs.).

(5) Torque the (4) structural dust cover bolts that

go into the engine block to 6-11 N´m (50-100 in.lbs.).

(6) Starting with the two rear cover-to-engine

bolts, tighten bolts (1) (Fig. 19) to 54 N´m (40 ft. lbs.),

then tighten bolts (2) (Fig. 19) and (3) to 54 N´m ( 40

ft. lbs.) in the sequence shown.

(7) Install the exhaust pipe on left hand exhaust

manifold.

(8) Tighten exhaust manifold-to-exhaust pipe

retaining bolts to 20±26 N´m (15±20 ft. lbs.).

MANUAL TRANSMISSION

CAUTION: The 7/16 inch engine block to clutch

housing bolts must be loosened before removal/in-

stallation of the structural dust cover. Clutch hous-

ing distortion will occur if this procedure is not

followed.

(1) Position the structural cover in the vehicle.

CAUTION: The structural cover must be installed as

described in the following steps. Failure to do so

will cause severe damage to the cover, and engine

noise.

(2) Install all bolts retaining the cover-to-engine.

DO NOT tighten the bolts at this time (Fig. 20).

(3) Install the cover-to-transmission bolts. Do NOT

tighten at this time.

Fig. 19 Structural Cover

1 - BOLT

2 - BOLT

3 - BOLT

9 - 216 ENGINE - 5.7LDR

VIBRATION DAMPER (Continued)

Page 1442 of 2627

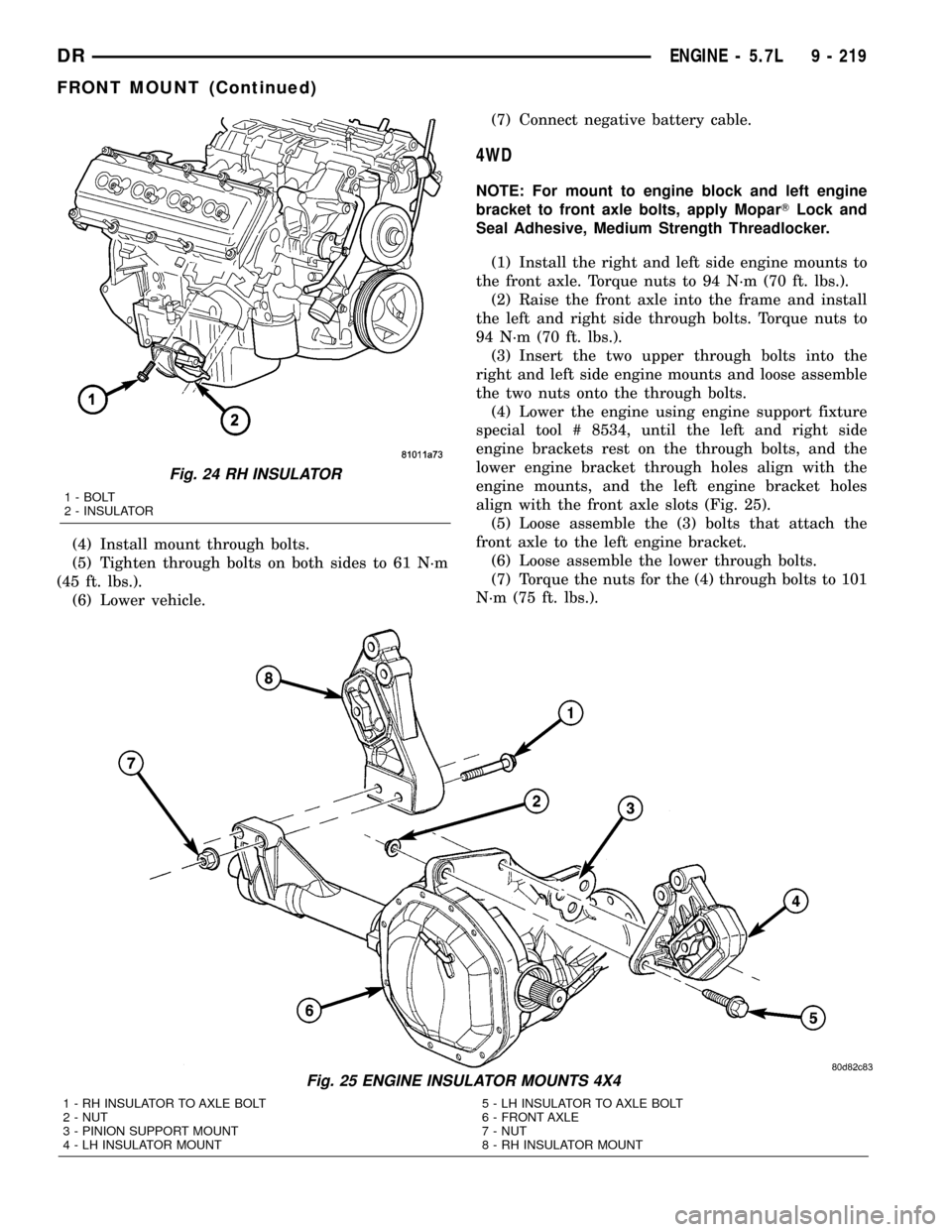

(4) Install mount through bolts.

(5) Tighten through bolts on both sides to 61 N´m

(45 ft. lbs.).

(6) Lower vehicle.(7) Connect negative battery cable.

4WD

NOTE: For mount to engine block and left engine

bracket to front axle bolts, apply MoparTLock and

Seal Adhesive, Medium Strength Threadlocker.

(1) Install the right and left side engine mounts to

the front axle. Torque nuts to 94 N´m (70 ft. lbs.).

(2) Raise the front axle into the frame and install

the left and right side through bolts. Torque nuts to

94 N´m (70 ft. lbs.).

(3) Insert the two upper through bolts into the

right and left side engine mounts and loose assemble

the two nuts onto the through bolts.

(4) Lower the engine using engine support fixture

special tool # 8534, until the left and right side

engine brackets rest on the through bolts, and the

lower engine bracket through holes align with the

engine mounts, and the left engine bracket holes

align with the front axle slots (Fig. 25).

(5) Loose assemble the (3) bolts that attach the

front axle to the left engine bracket.

(6) Loose assemble the lower through bolts.

(7) Torque the nuts for the (4) through bolts to 101

N´m (75 ft. lbs.).

Fig. 24 RH INSULATOR

1 - BOLT

2 - INSULATOR

Fig. 25 ENGINE INSULATOR MOUNTS 4X4

1 - RH INSULATOR TO AXLE BOLT

2 - NUT

3 - PINION SUPPORT MOUNT

4 - LH INSULATOR MOUNT5 - LH INSULATOR TO AXLE BOLT

6 - FRONT AXLE

7 - NUT

8 - RH INSULATOR MOUNT

DRENGINE - 5.7L 9 - 219

FRONT MOUNT (Continued)

Page 1443 of 2627

(8) Torque the (3) bolts that attach the front axle

to the left engine bracket to 101 N´m (75 ft. lbs.).

(9) Install the engine oil filter, if removed.

(10) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(11) Install the skid plate.

(12) Lower the vehicle.

(13) Reconnect the negative battery cable.

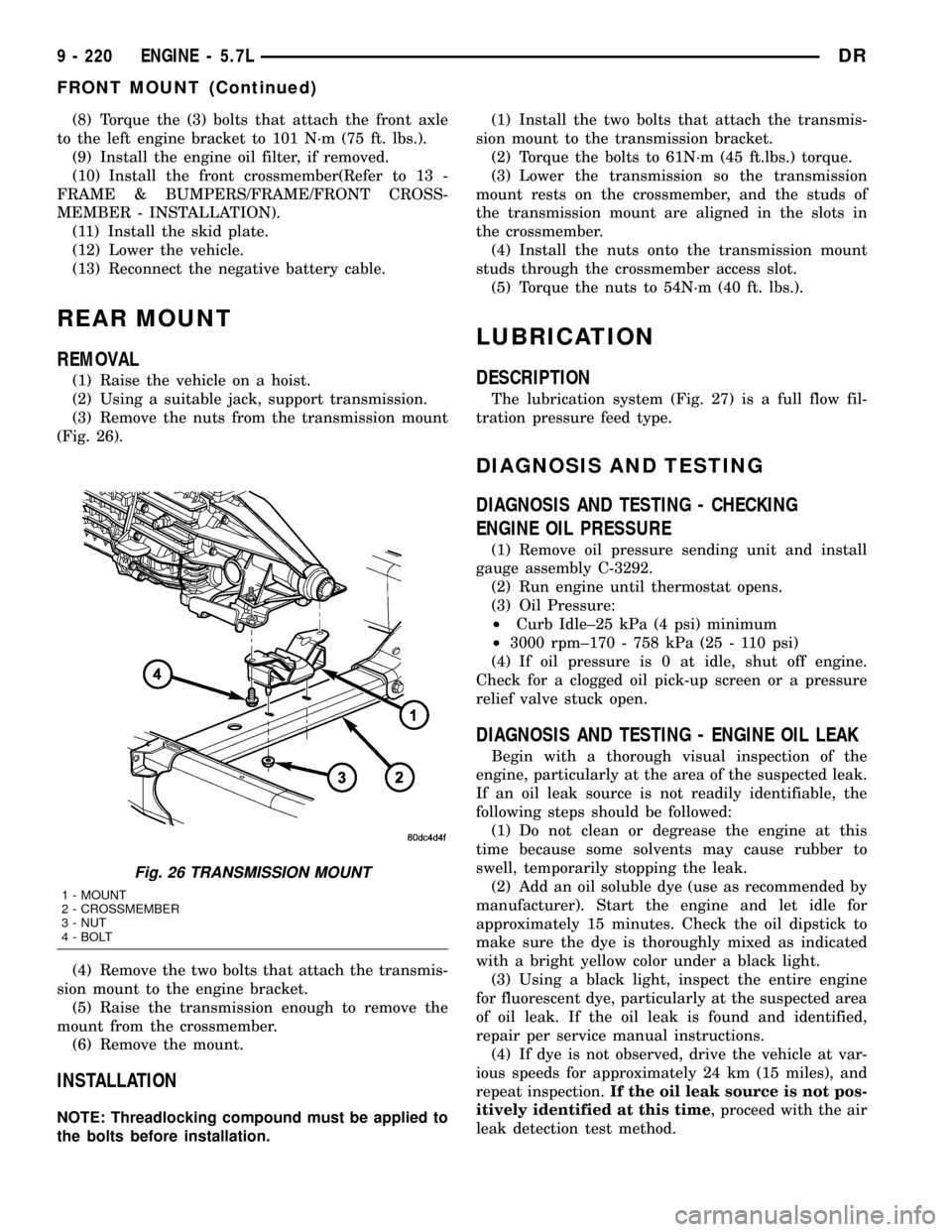

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Using a suitable jack, support transmission.

(3) Remove the nuts from the transmission mount

(Fig. 26).

(4) Remove the two bolts that attach the transmis-

sion mount to the engine bracket.

(5) Raise the transmission enough to remove the

mount from the crossmember.

(6) Remove the mount.

INSTALLATION

NOTE: Threadlocking compound must be applied to

the bolts before installation.(1) Install the two bolts that attach the transmis-

sion mount to the transmission bracket.

(2) Torque the bolts to 61N´m (45 ft.lbs.) torque.

(3) Lower the transmission so the transmission

mount rests on the crossmember, and the studs of

the transmission mount are aligned in the slots in

the crossmember.

(4) Install the nuts onto the transmission mount

studs through the crossmember access slot.

(5) Torque the nuts to 54N´m (40 ft. lbs.).

LUBRICATION

DESCRIPTION

The lubrication system (Fig. 27) is a full flow fil-

tration pressure feed type.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit and install

gauge assembly C-3292.

(2) Run engine until thermostat opens.

(3) Oil Pressure:

²Curb Idle±25 kPa (4 psi) minimum

²3000 rpm±170 - 758 kPa (25 - 110 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Fig. 26 TRANSMISSION MOUNT

1 - MOUNT

2 - CROSSMEMBER

3 - NUT

4 - BOLT

9 - 220 ENGINE - 5.7LDR

FRONT MOUNT (Continued)

Page 1445 of 2627

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 in the 5.7L engines.

These are specified with a dual SAE viscosity grade

which indicates the cold-to-hot temperature viscosity

range. Select an engine oil that is best suited to your

particular temperature range and variation.

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 28).

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the left

hand of the engine on the 5.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about ten

Fig. 28 API SYMBOL

9 - 222 ENGINE - 5.7LDR

LUBRICATION (Continued)

Page 1446 of 2627

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately five

minutes for oil to settle to bottom of crankcase,

remove engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules(Refer to LUBRI-

CATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION).

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase. Torque to 34

N´m ( 25 ft. lbs.).

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss.

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with fil-

ter.

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

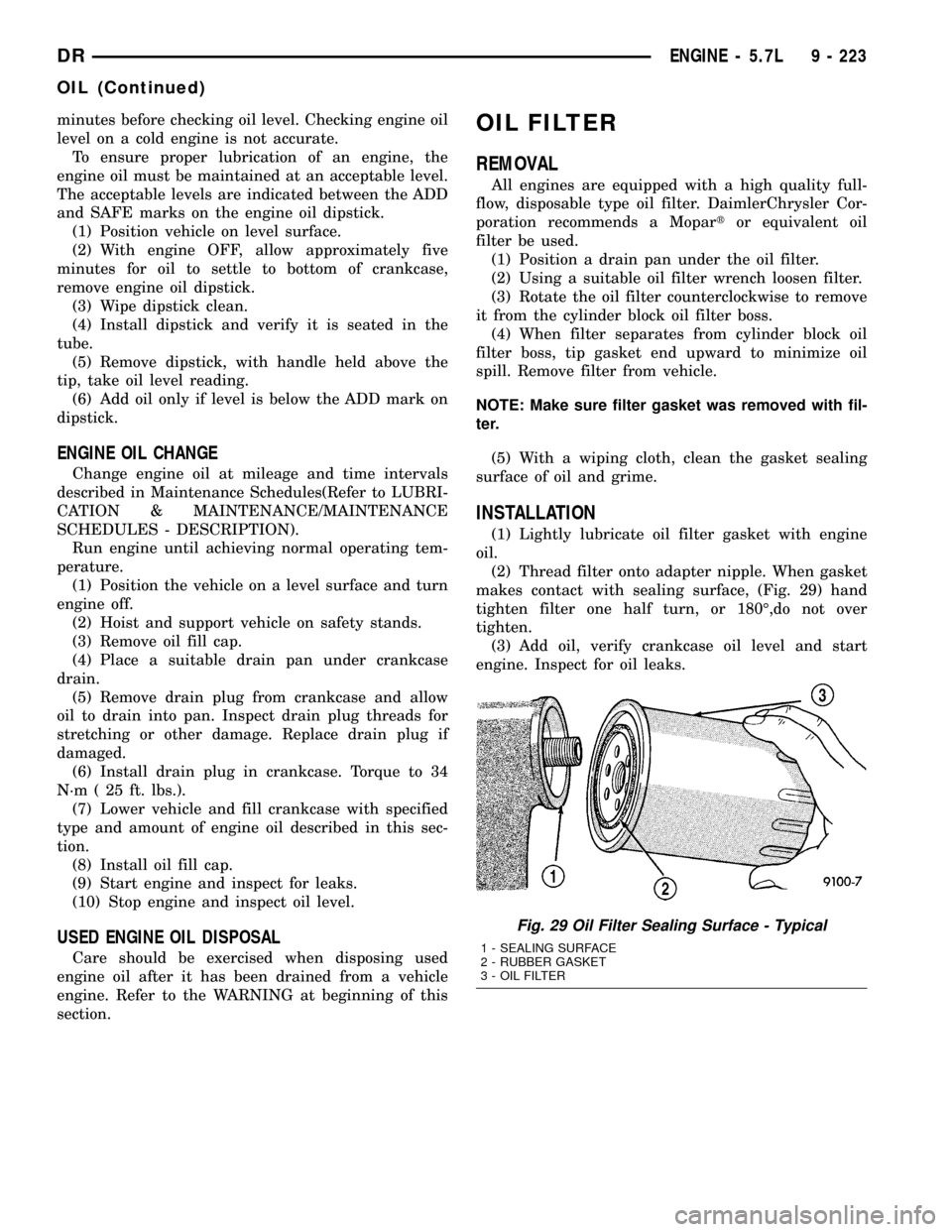

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 29) hand

tighten filter one half turn, or 180É,do not over

tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

Fig. 29 Oil Filter Sealing Surface - Typical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

DRENGINE - 5.7L 9 - 223

OIL (Continued)

Page 1447 of 2627

OIL PAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4) Remove the structural dust cover, if equipped.

(5) Drain engine oil.

(6) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for proper

clearance at fan shroud to fan and cowl to intake

manifold.

(7) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(8) Remove the oil pan mounting bolts and oil pan.

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(9) Unbolt oil pump pickup tube and remove tube.

(10) Inspect the integral windage tray and gasket

and replace as needed.

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

block and oil pan.

(2) Inspect the integral windage tray and gasket

and replace as needed.

(3) Reinstall the oil pump pickup tube with new

o-ring. Tighten tube to pump fasteners to 28 N´m

(250 in. lbs.).

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(4) Position the oil pan and install the mounting

bolts and studs.. Tighten the mounting bolts to 12

N´m (105 in.lbs.).

(5) Lower the engine into mounts using special

tool # 8534.

(6) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).(7) Remove special tool # 8534.

(8) Install structural dust cover, if equipped.

(9) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(10) Fill engine oil.

(11) Reconnect the negative battery cable.

(12) Start engine and check for leaks.

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube(Refer to 9

- ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(2) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Remove the four bolts, and the oil pump.

CLEANING

(1) Wash all parts in a suitable solvent.

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

these components are disassembled and or

removed from the pump the entire oil pump assem-

bly must be replaced.

(1) Remove the pump cover.

(2) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

(3) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 30). If the measurement is 0.235mm

(0.009 in.) or more the oil pump assembly must be

replaced.

(4) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 31). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

(5) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 32).

(6) Reinstall the pump cover. Torque fasteners to

15 N´m (132 in. lbs.).

9 - 224 ENGINE - 5.7LDR